UWB-based discrete manufacturing plant material delivery cart control system

A discrete manufacturing workshop and control system technology, applied in the field of logistics, can solve problems such as complex distribution wiring and poor distribution flexibility, and achieve the effects of flexible configuration, improved flexibility, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] Such as Figure 1-6 shown.

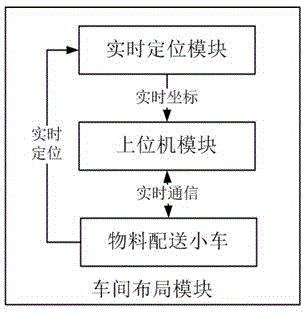

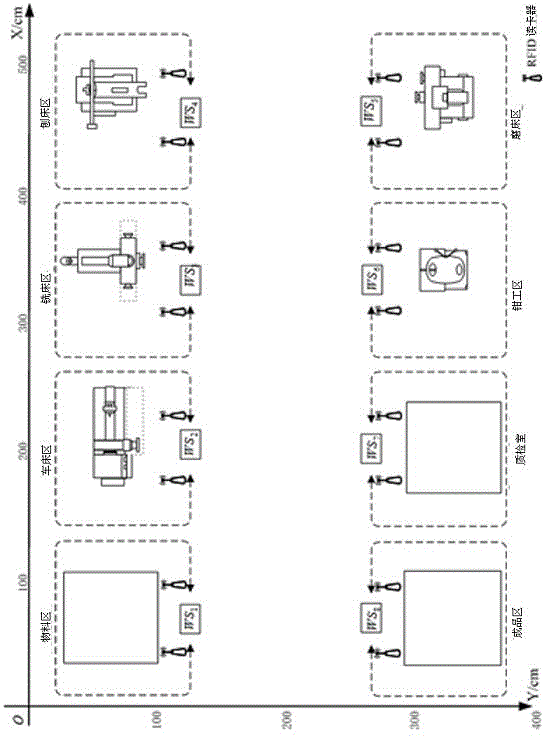

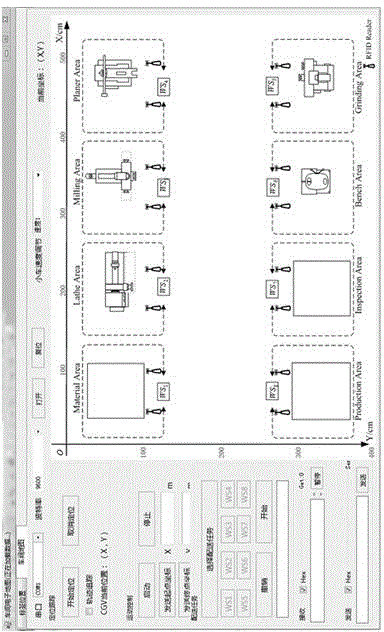

[0034] A UWB-based discrete manufacturing workshop material delivery car control system, which includes a workshop layout module, a host computer module, a material delivery car and a real-time positioning module, such as figure 1 shown. The workshop layout module consists of 8 basic functional areas, such as figure 2As shown, they are material area, lathe area, milling machine area, planer area, grinder area, fitter area, quality inspection room and finished product area. The coordinates of feature points in each basic functional area are calibrated by a unified coordinate system. An RFID reader is placed in the area to detect whether there is material delivery in the area and the type of material to be delivered; the upper computer module includes a communication module, a speed control module, a motion control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com