Production line production process data docking and simulation model rapid modeling method and system in cloud manufacturing mode

A simulation model and production system technology, applied in manufacturing computing systems, database indexing, data processing applications, etc., can solve the problems of not supporting the rapid generation of basic models of production lines, not supporting cloud manufacturing models, etc., to reduce workload and improve Effects of Simulation Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below through specific embodiments and accompanying drawings.

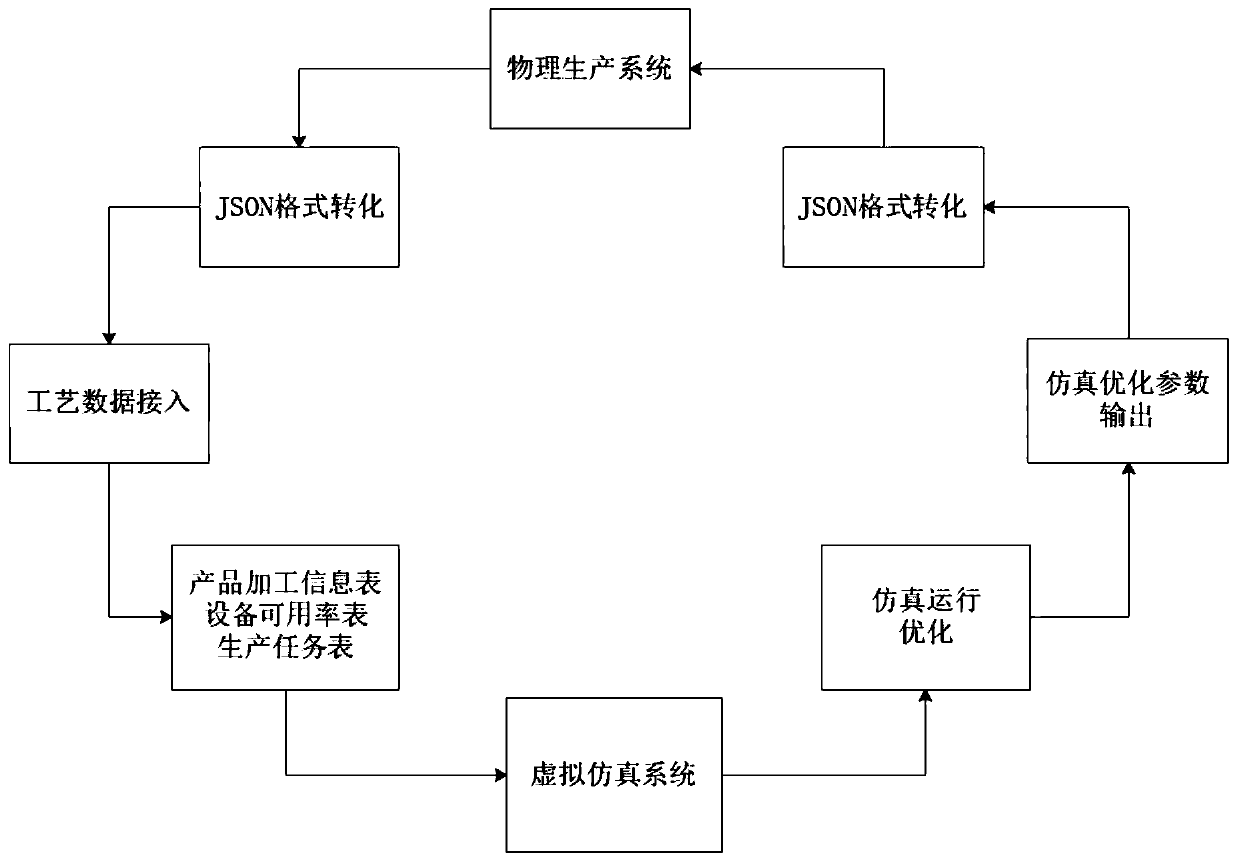

[0047] Main contents of the present invention include:

[0048] 1) Establish a processing technology data storage table with product type as the dimension in the discrete manufacturing production line simulation modeling tool;

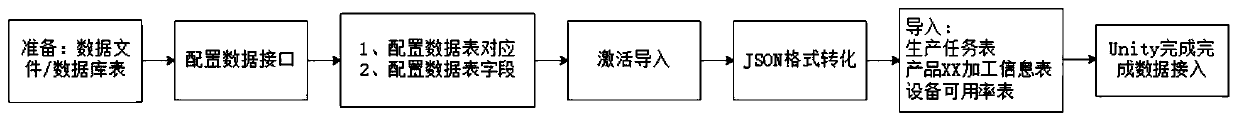

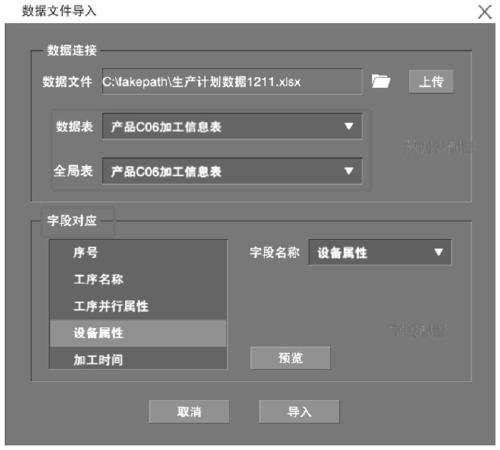

[0049] 2) The production line production process data docking interface and data field relationship are established to complete the data docking;

[0050] 3) Use the one-key rapid generation simulation model tool in the simulation modeling tool of the discrete manufacturing production line, generate the simulation model with the process flow relationship and simulation parameters in the product processing process data, and complete the construction of the simulation scene:

[0051] 4) When the simulation model is generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com