Dynamic configuration method for energy-consumption-oriented discrete manufacturing system resources

A manufacturing system and dynamic configuration technology, applied in the direction of manufacturing computing systems, resources, instruments, etc., can solve the problem of high energy consumption in the production and processing process, without considering the cost of energy consumption of manufacturing equipment resources and processing tasks, and has not been significantly improved, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

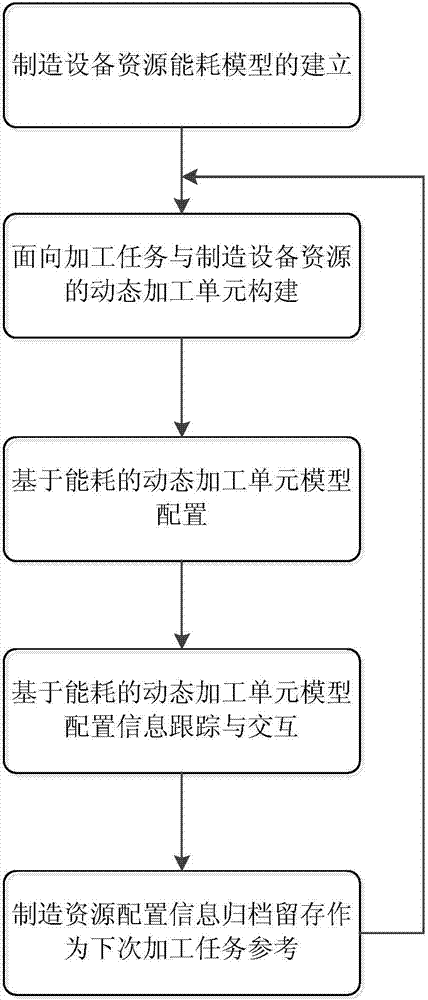

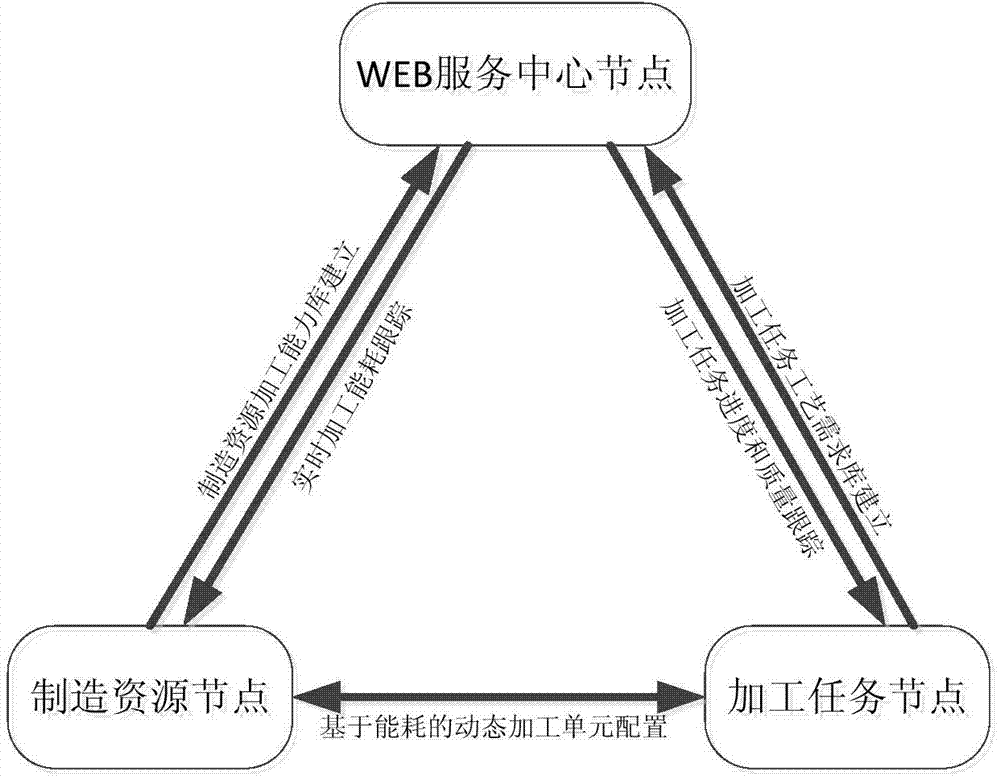

[0038] Such as figure 1 As shown, the implementation process of the present invention includes: establishment of a processing task energy consumption model, dynamic processing unit construction for processing tasks and manufacturing equipment resources, dynamic processing unit model configuration based on energy consumption, and dynamic processing unit configuration information tracking based on energy consumption Classified archives for interacting with configuration schemes.

[0039] 1. Establishment of energy consumption model for processing tasks.

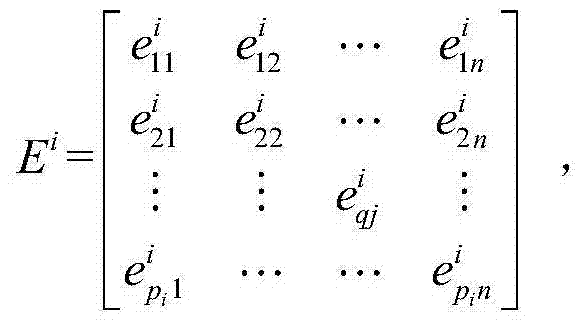

[0040] Assuming that there are m types of tasks that need to be processed, their process sets are respectively The processing time set of the processing task procedure is The required completion time set of processing tasks is L M ={L 1 , L 2 ,... L i ,... L m}, where p i Indicates the number of processes of the i-th task; at the same time, there are N sets of manufacturing equipment resources, expressed as N={s 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com