Large-sized discrete manufacturing workshop holographic map based on RFID and UWB and realization method

A discrete manufacturing workshop and manufacturing workshop technology, applied in workshop visualization system, large-scale discrete manufacturing workshop location service system and holographic environment map and implementation field, can solve the problem of weak workshop location service capability, difficulty in obtaining location and production data, and visualization of manufacturing site. problems such as low level, to achieve high application value, improve the level of visualization and information management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] Such as Figure 1-4 shown.

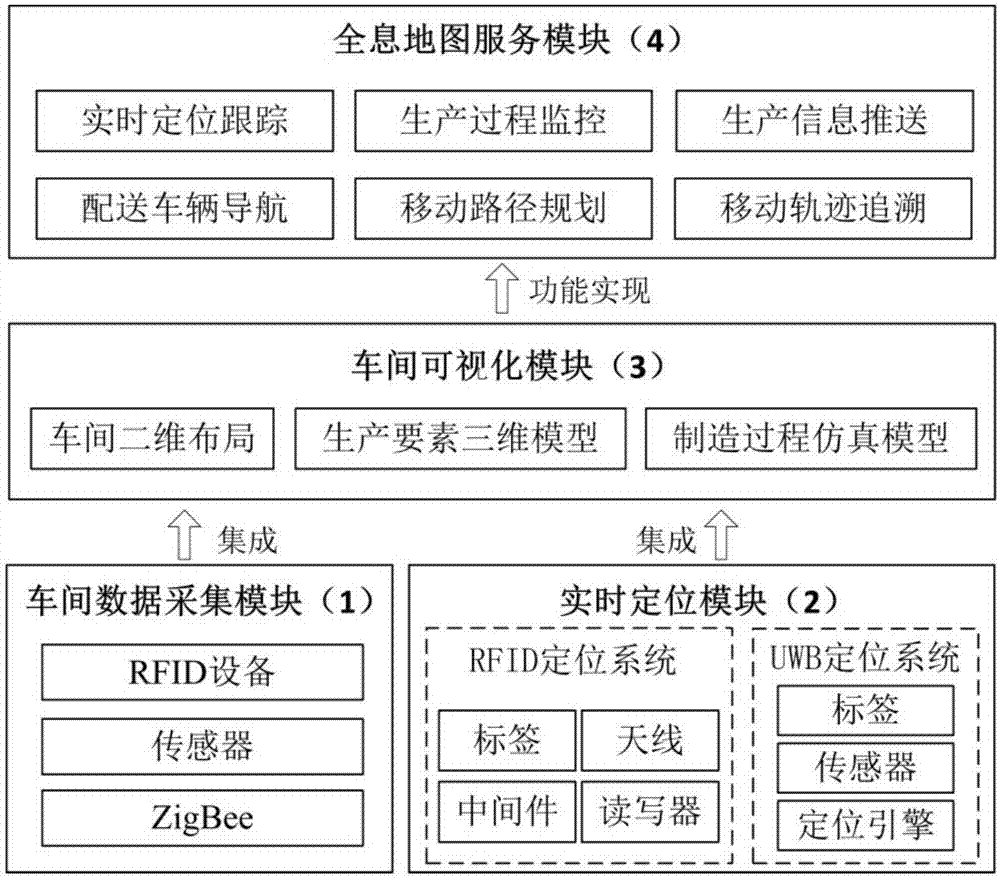

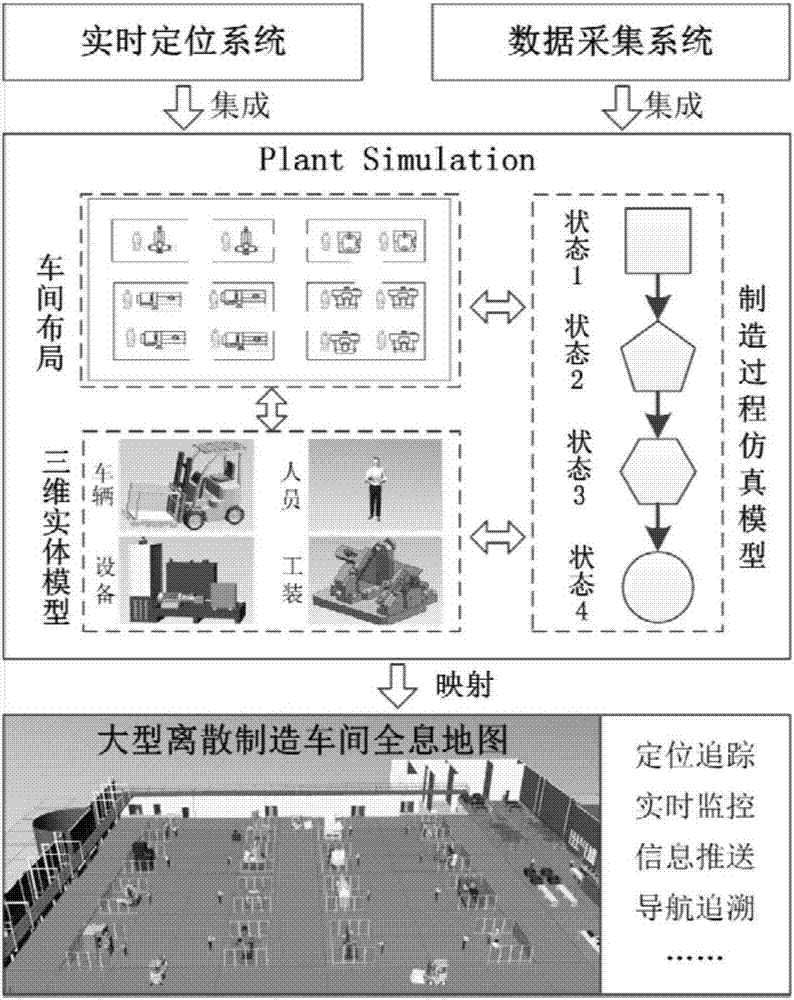

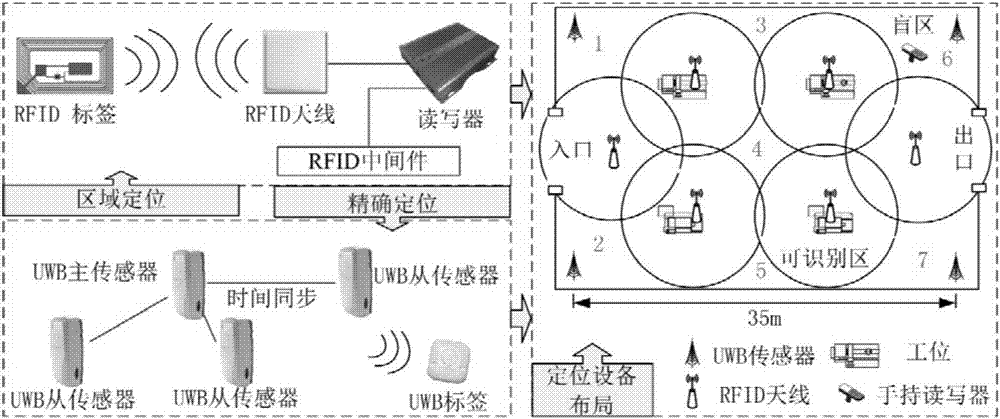

[0034] A holographic map of a large-scale discrete manufacturing workshop based on RFID and UWB, the overall structural framework is as follows figure 1As shown, it includes: workshop data acquisition module 1, real-time positioning module 2, workshop visualization module 3 and holographic map service module 4. The workshop data acquisition module 1 provides real-time production factor attributes, production status, manufacturing process, workshop logistics, workshop environment and other data for the workshop holographic map by the RFID data acquisition system and sensors. Identify the electronic tag information on the object, so as to collect the relevant data of the production factors bound to the tag. Various sensors deployed in the equipment or workshop are used for real-time perception of equipment operation d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com