Discrete manufacturing machinery product quality tracing method based on outlier detection

A technology for outlier detection and mechanical products, applied in the direction of manufacturing computing systems, resources, instruments, etc., can solve the problem that the quality traceability method cannot be analyzed accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the purpose of the present invention, technical solutions and advantages clearer, the present invention will be described in further detail below in conjunction with accompanying drawing:

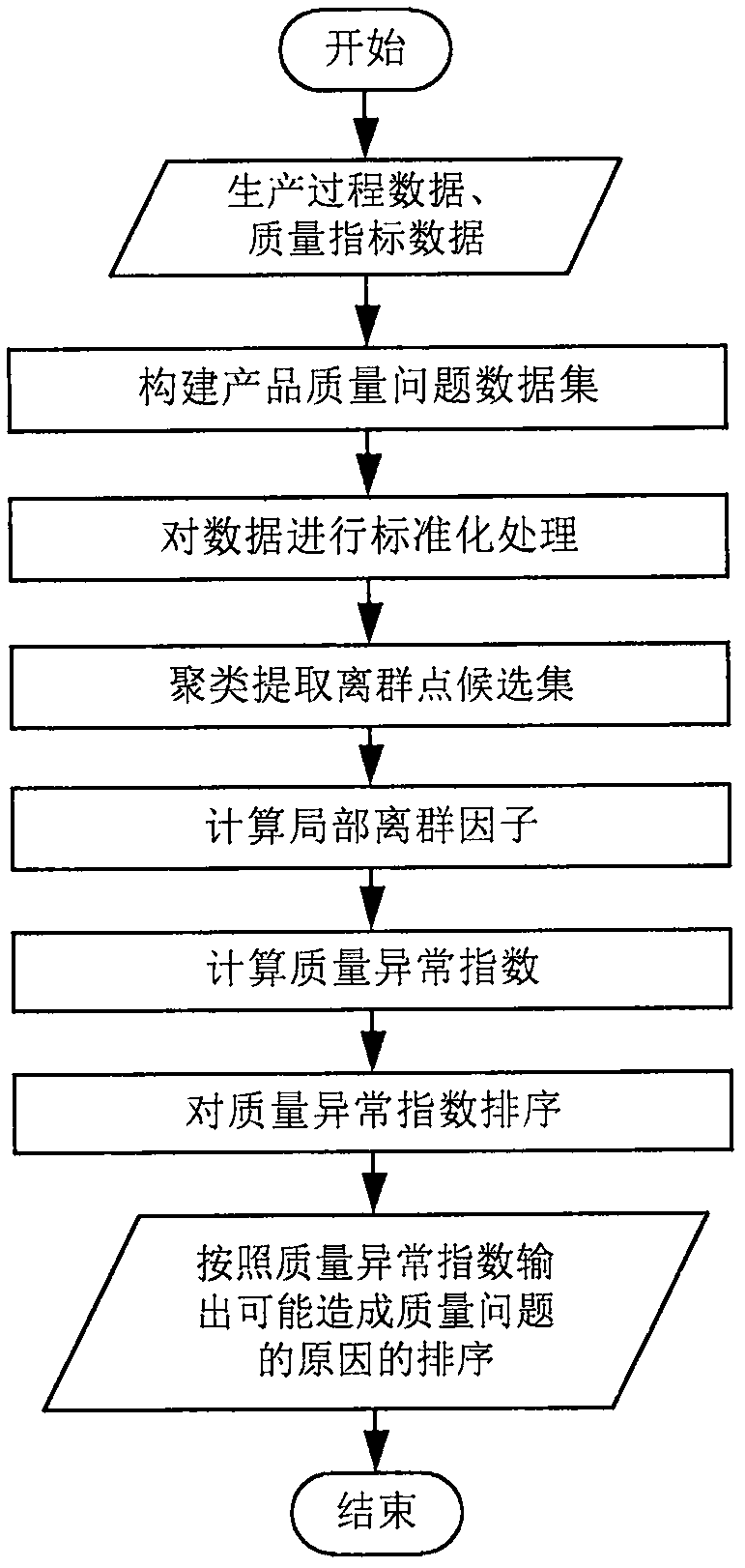

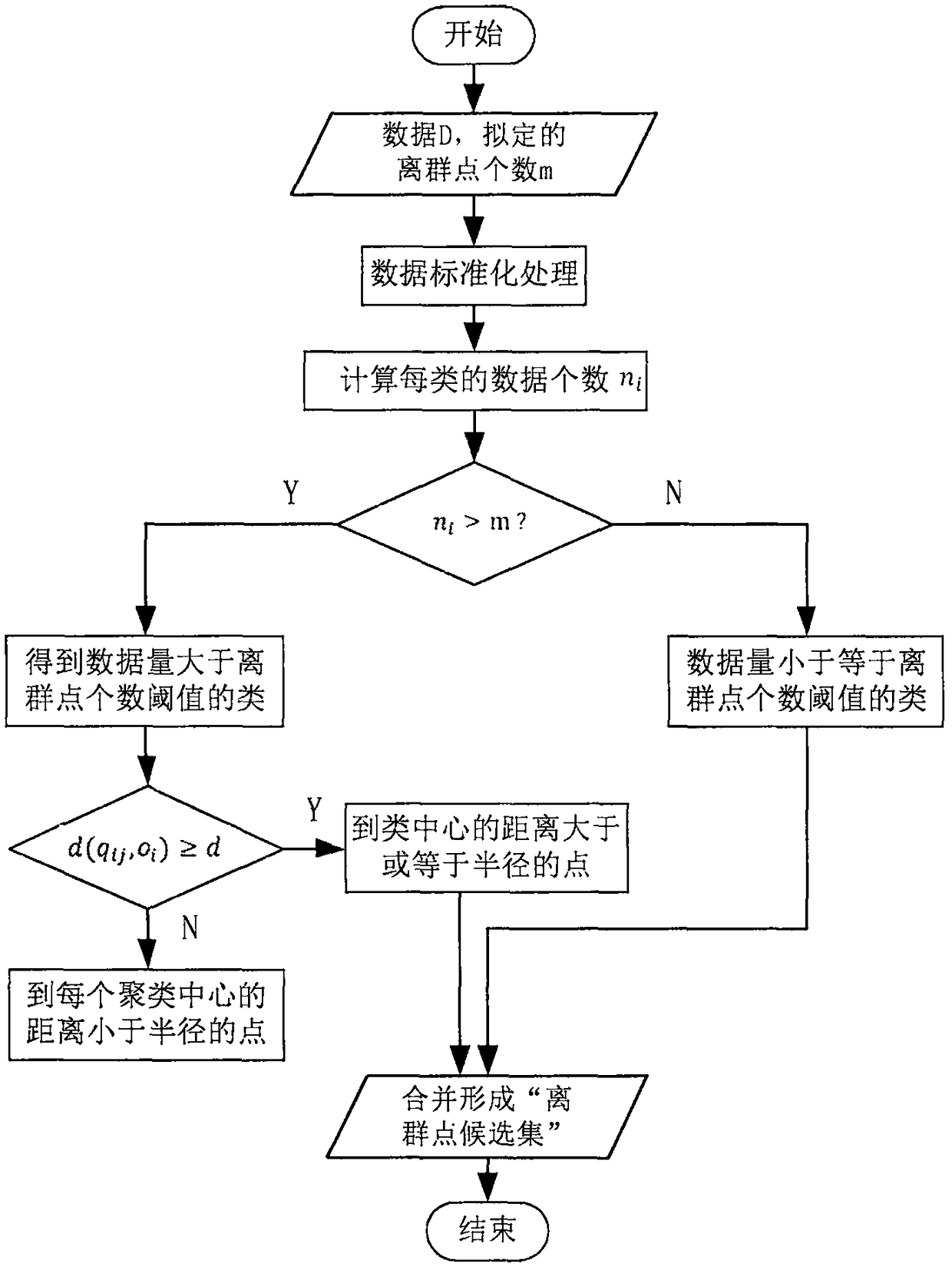

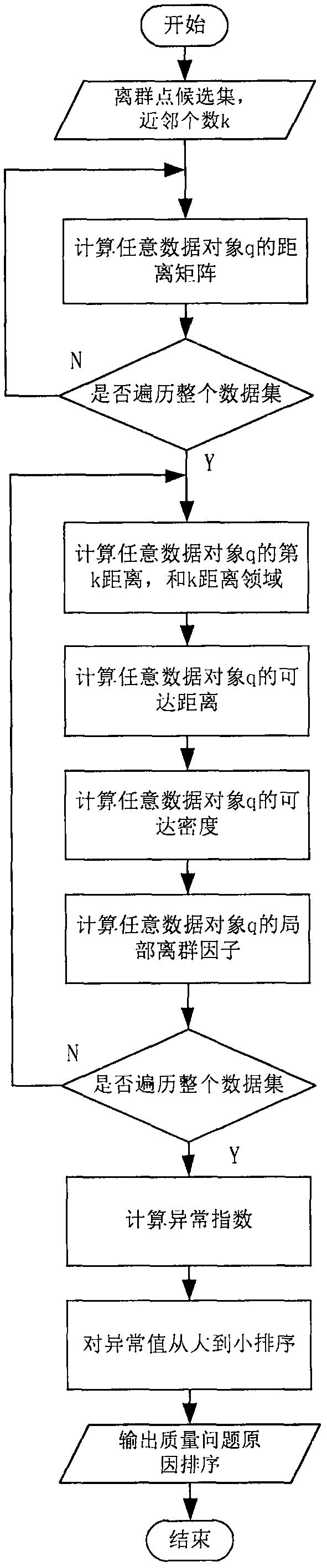

[0053] The present invention proposes a quality traceability method for discrete manufacturing machinery products based on outlier point detection, such as figure 1 As shown, the method includes the following steps:

[0054] 1. Construct a data set of discrete manufacturing product quality problems: divide m potential causes of product quality problems according to human, machine, material, law, environment, etc. n types of quality index data of products produced under the following conditions; a m*n quality problem traceability data set is constructed by using n types of product quality index data under potential m types of reasons. The product quality index includes two categories, one type It is an index that reflects the internal quality of the product, mainly t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com