Workshop material distribution device and method

A technology for conveying devices and materials, applied in logistics, instruments, manufacturing computing systems, etc., can solve problems such as poor configuration, poor ductility of distribution models, and poor ductility, and achieve the effect of simplifying complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0061] In order to achieve the purpose of the present invention, in some embodiments of the workshop material distribution device and method,

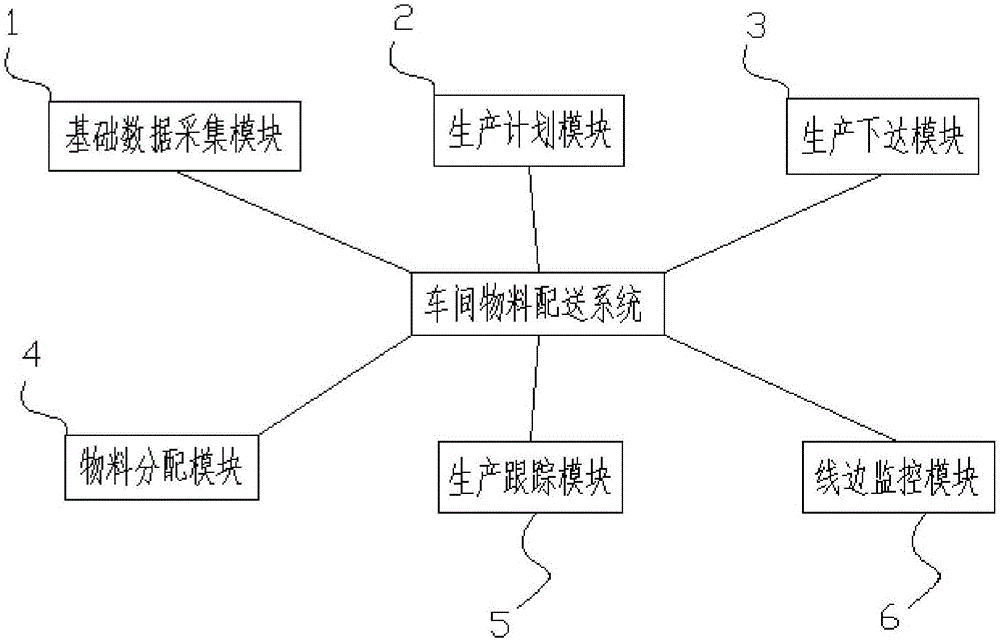

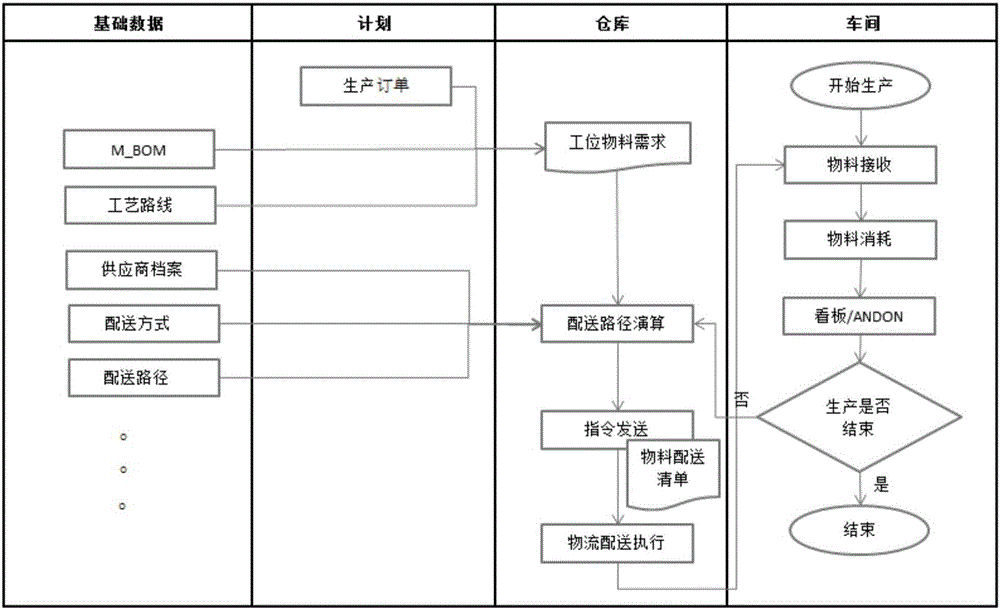

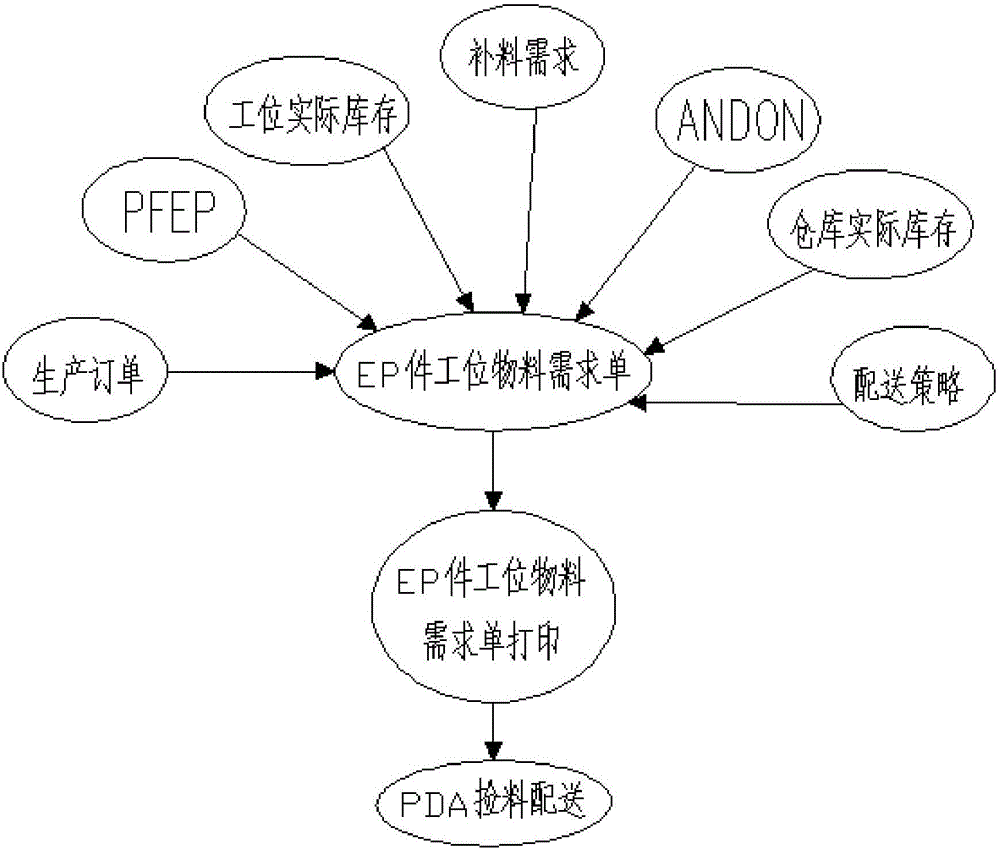

[0062] like figure 1 As shown, the workshop material distribution device includes: a basic data collection module 1 , a production planning module 2 , a production ordering module 3 , a material distribution module 4 , a production tracking module 5 and a line edge monitoring module 6 .

[0063] The basic data acquisition module 1 is used to collect and save each group of basic data in the process of material production and distribution; the production planning module 2 is used to generate production orders; the production release module 3 is used to 2 The generated production order distributes the material plan to each station to form a corresponding station material plan, and notifies and sends it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com