Workpiece feeding device and method

A technology for retrieving devices and workpieces, applied in conveyor control devices, metal processing, manufacturing tools, etc., can solve problems such as unrecognizable workpiece status, achieve the effects of reducing manual workload, ensuring continuity, and facilitating management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

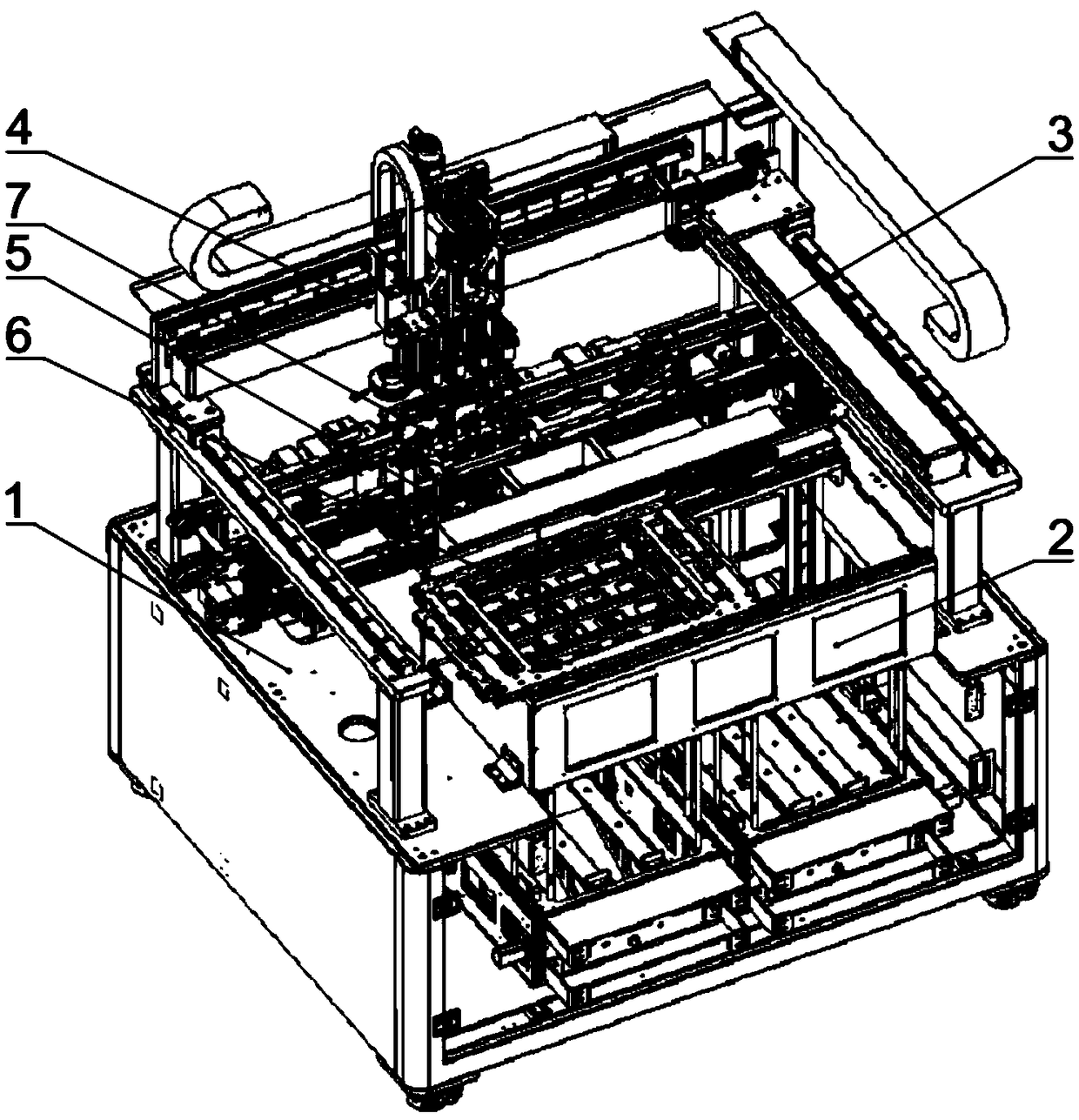

[0077] This embodiment provides a workpiece feeding device, the structure of which is as follows: figure 1 and Figure 12 As shown, it includes a workbench 1, a feeding mechanism 2, a transmission line mechanism 3, a workpiece handling mechanism 4 and a screening mechanism 5. The feeding mechanism 2 is provided with a feeding location 6 , and the transmission line mechanism 3 is provided with an installation location 7 . The workpiece transport mechanism 4 clamps the workpiece 8 from the feeding position 6 , and after being detected and screened by the screening mechanism 5 , moves and installs the qualified workpiece 8 to the target carrier 33 at the installation position 7 .

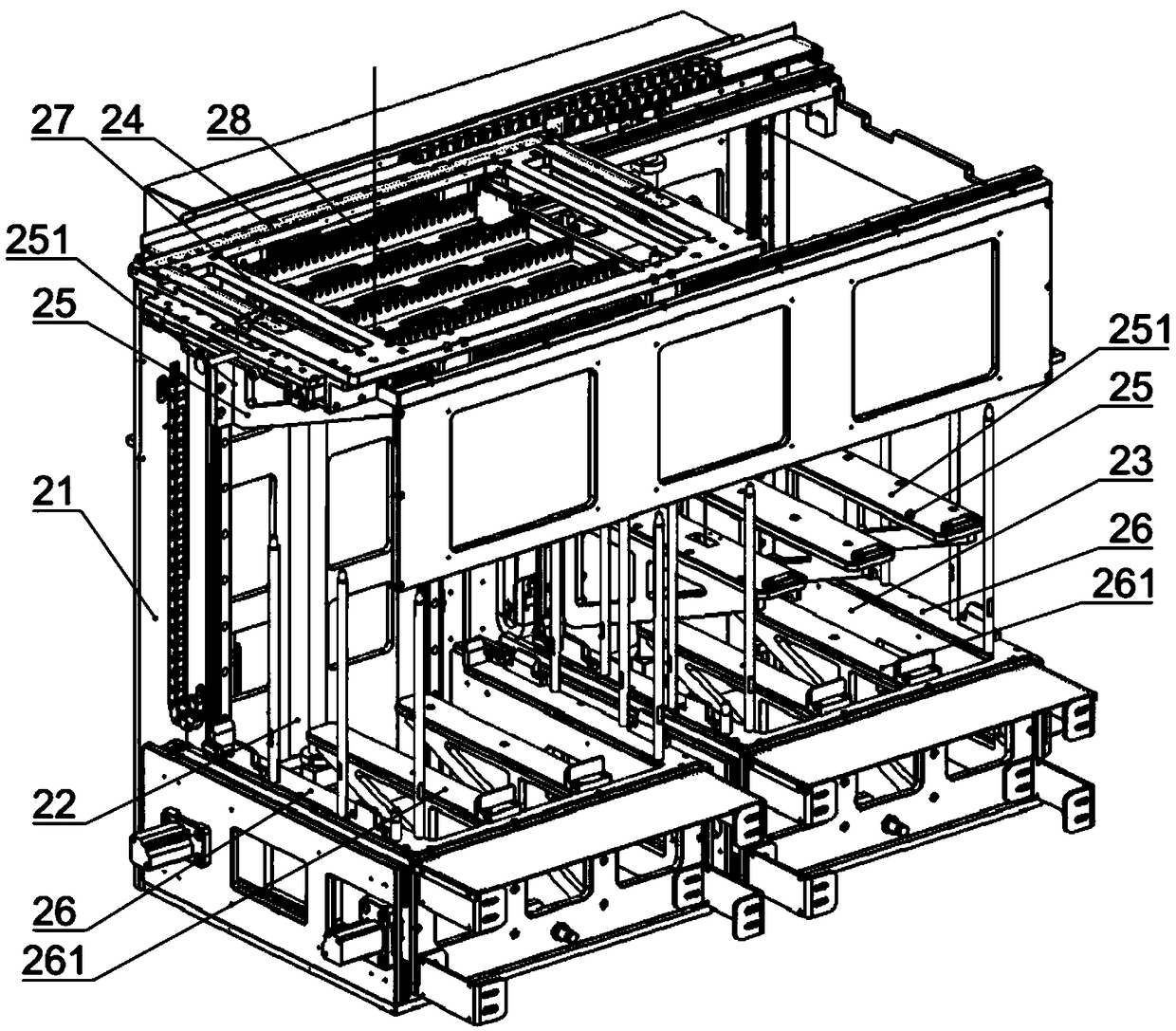

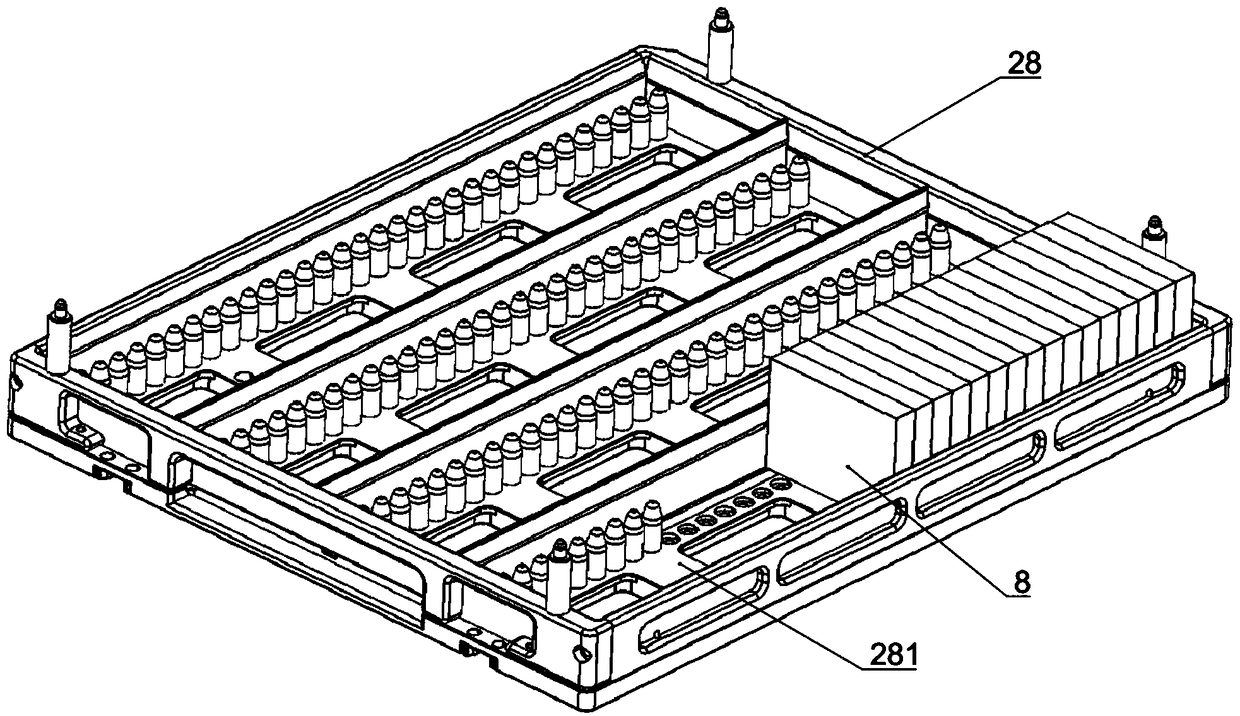

[0078] Such as figure 1 and figure 2 As shown, the feeding mechanism 2 in this embodiment adopts a clip-type feeding method for feeding, and it has a feeding area 22 for carrying the tray 28 and a return area 23 for recovering the tray 28 . Both the feeding area 22 and the returning area 23 are pr...

Embodiment 2

[0109] This implementation provides a workpiece feeding method, using the workpiece feeding device in Embodiment 1 to perform the following steps:

[0110] The detection mechanism on the reclaiming device detects the material tray at the feeding position, and takes pictures of the workpiece through the upper camera to obtain the position of the workpiece in the material tray;

[0111] The clamping unit determines the clamping position according to the detection result;

[0112] The moving device drives the reclaimer to move above the screening mechanism. The shape detection unit detects the shape of the workpiece. The reclaimer adjusts the clamping state of the workpiece according to the detection results. If the workpiece is qualified, it will maintain the clamping state. If the workpiece is unqualified, it will Release the grip on the workpiece and throw the workpiece into the waste box;

[0113] The detection mechanism on the reclaimer detects the carrier on the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com