Information management system for on-line production of printing machine and method thereof

A production information and management system technology, which is applied in the printing machine online production information management system, the online control and real-time data collection field of the printing machine online production information management system, can solve the problem of low operation and management efficiency, and the production management department cannot timely Effectively grasp and fail to meet the problems of printing equipment productivity, efficiency, quality and equipment monitoring, so as to improve the level of management and monitoring, realize seamless integration, improve the efficiency of use and the benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

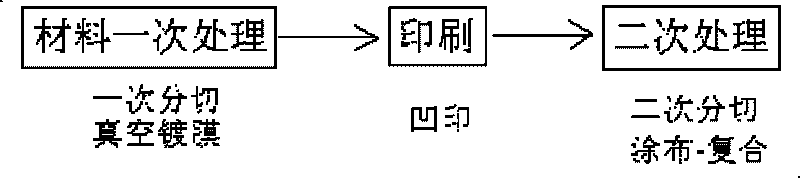

[0038] like figure 1 , is a schematic diagram of the process flow of the existing gravure printing machine production line, and the process flow is:

[0039] 1), the material is processed once, and the cutting and vacuum coating (aluminum plating) are completed once;

[0040] 2), gravure printing;

[0041] 3) Secondary treatment, complete coating and compounding, and secondary slitting.

[0042] In the production process of the prior art, information is transmitted and communicated through manual summons between each link in the above-mentioned production process, and the efficiency of operation and management is very low, which cannot meet the production rate and efficiency of the printing equipment of the production enterprise. , quality and equipment monitoring requirements.

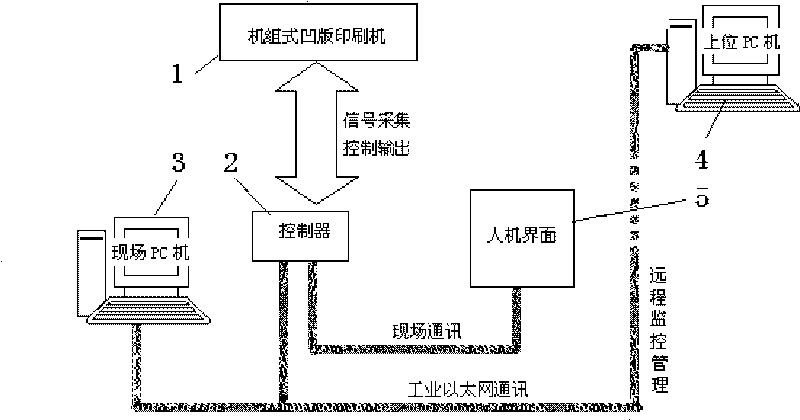

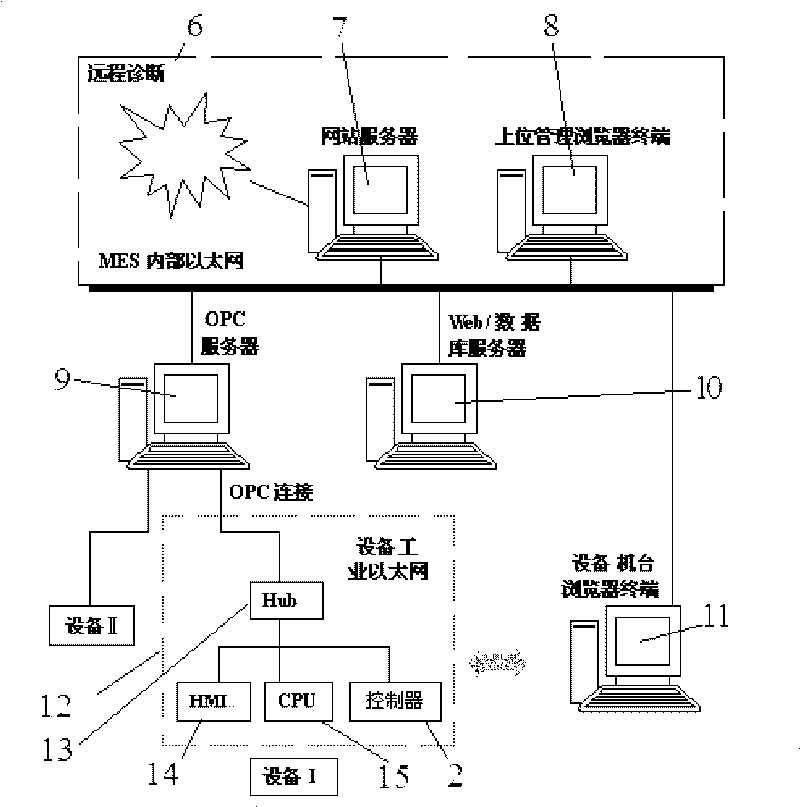

[0043] 1. The printing machine online production informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com