Patents

Literature

79results about How to "Improve production management efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Remote automatic monitoring system for aquaculture and monitoring method thereof

InactiveCN101995875AReduce labor intensityReduce labor costsTotal factory controlProgramme total factory controlMonitoring systemWater quality

The invention provides a remote automatic monitoring system for aquaculture and a monitoring method thereof. The system is implemented by combining the conventional electronic products such as a water quality parameter sensor, an environmental parameter sensor, an aquaculture execution device and the like and a communication network; centralized setting and monitoring management are performed by adopting a monitoring device; a controller independently analyzes the monitoring data of the sensors according to the setting and controls the operating process of an executor according to the analysis result so as to improve the production management efficiency of the aquaculture and adapt the requirement of modern integrated management; the working personnel can monitor the actual condition of an aquaculture unit without going to the aquaculture site, and the system automatically gives an alarm in emergency, so the system is favorable for improving the management efficiency, saving the management cost and reducing the risk of the aquaculture; and the management of the aquaculture unit can be quantitatively set through the monitoring device so that the management is more digitalized and standardized, the system is favorable for unifying the management standards, and technical guarantee is provided for large-scale development of the aquaculture.

Owner:CHONGQING ACADEMY OF SCI & TECH

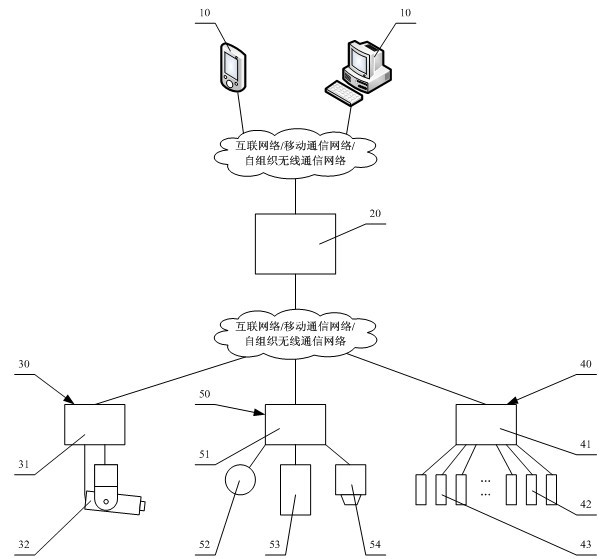

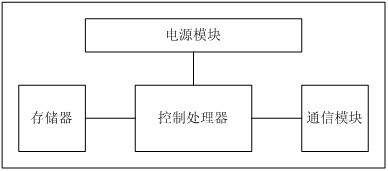

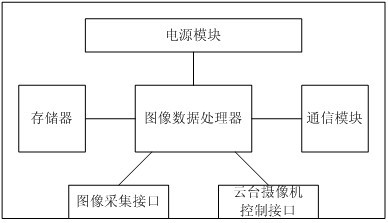

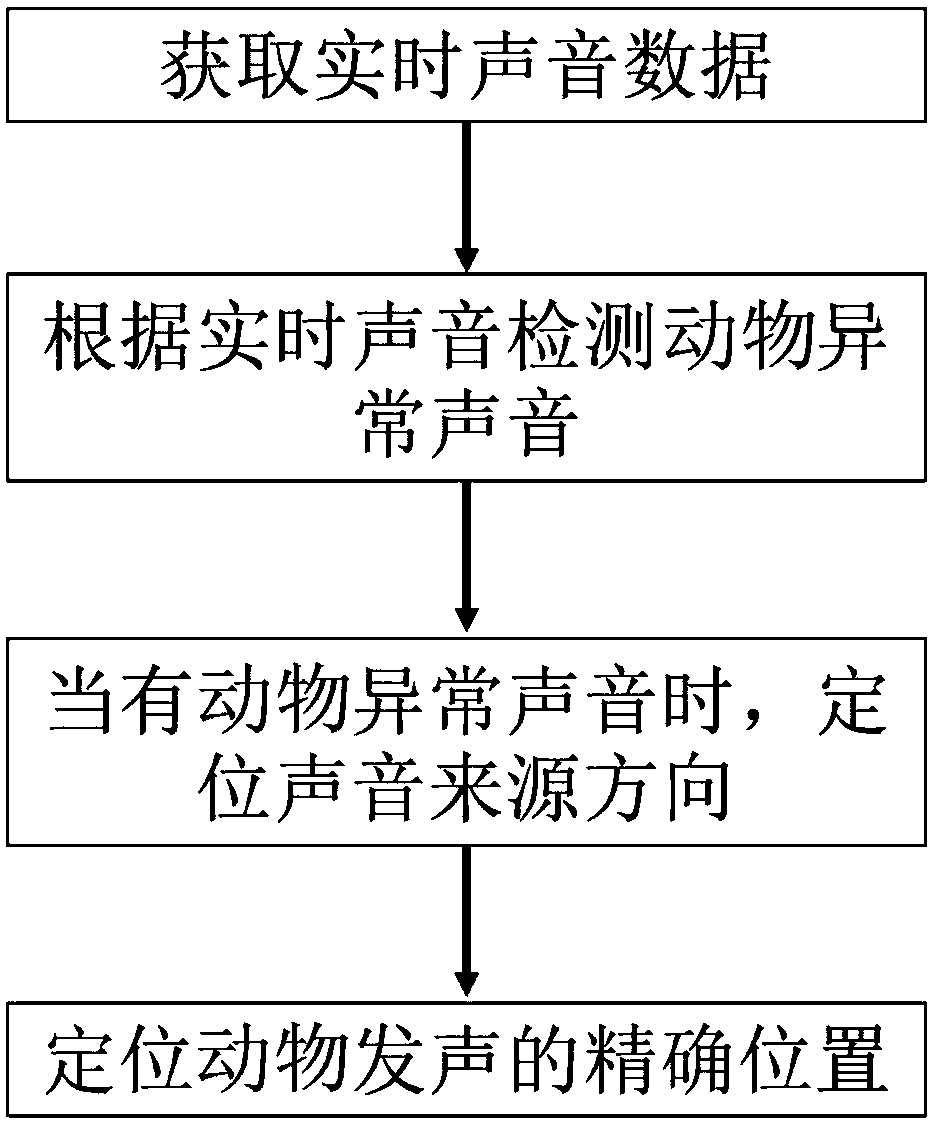

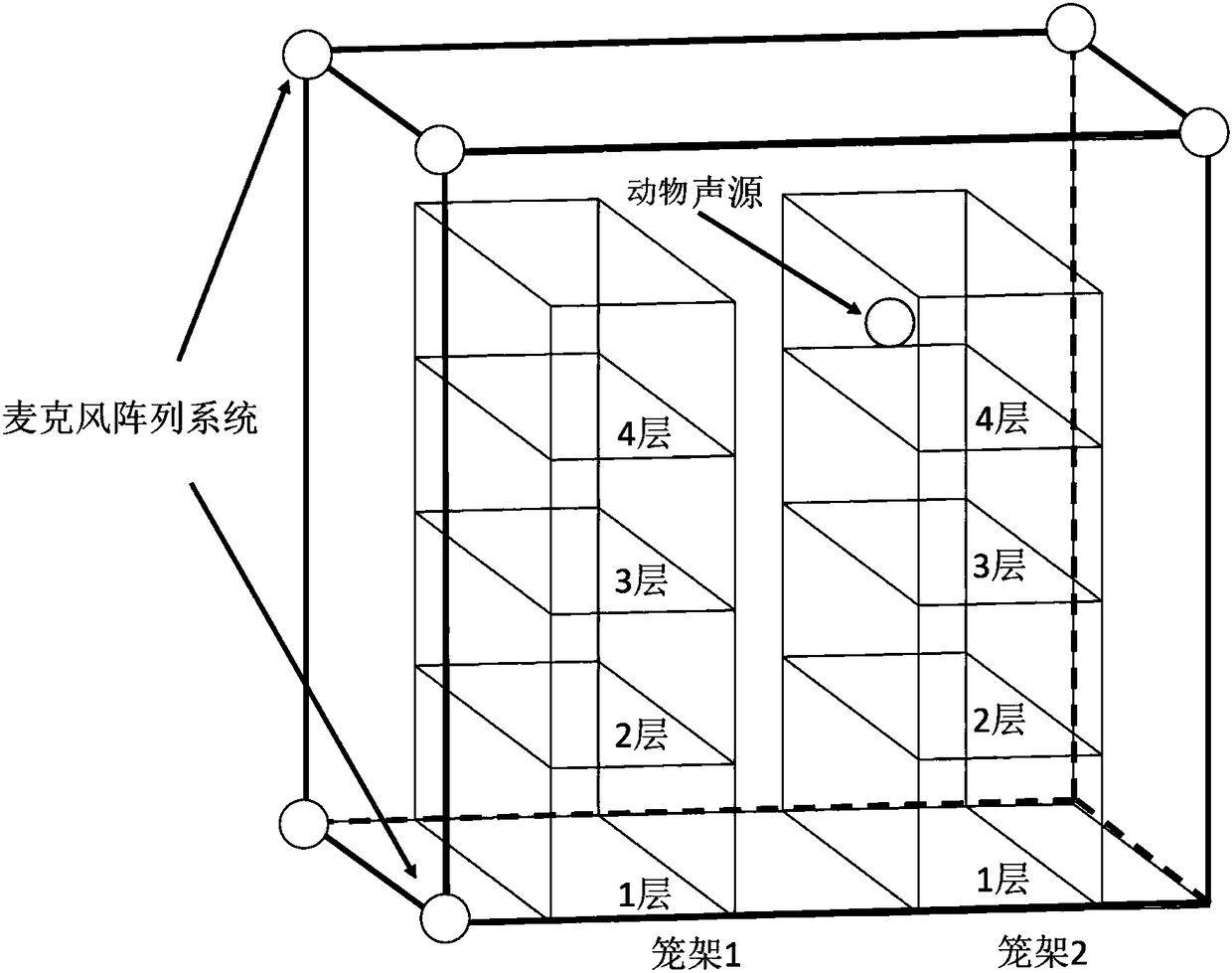

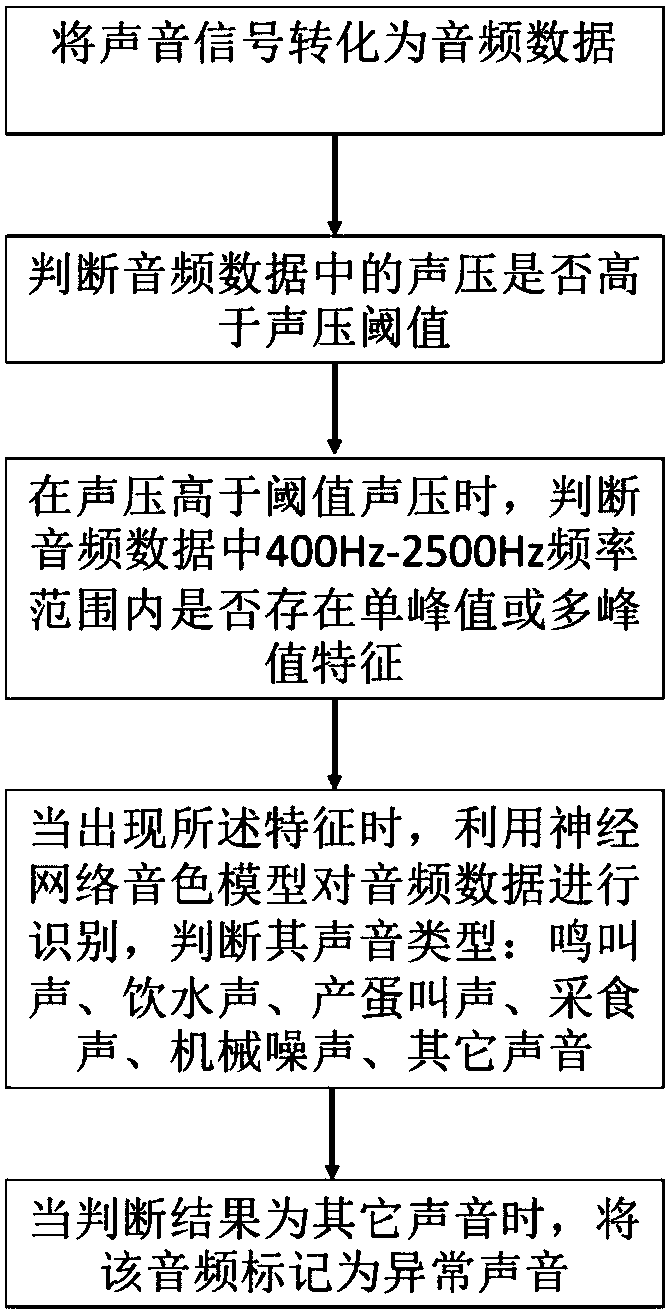

Method and system used for real time positioning and identification of abnormal sound in animal breeding shed

InactiveCN108198562AStress-free automated monitoringFast automated monitoring meansSpeech analysisPosition fixationManagement efficiencyMaterial resources

The invention relates to a method and system used for real time positioning and identification of abnormal sound in animal breeding shed. The method includes acquiring real time sound data; detectingwhether animal abnormal sound is in presence according to the acquired real time sound data; when animal abnormal sound is detected, positioning the direction which the abnormal sound comes from; positioning the accurate position of a sounding animal in the direction which the abnormal sound comes from; marking the animal abnormal sound and the sounding position and storing in a history audio fileform. According to the invention, the non-intrusion, continuous and real time sound system is adopted for monitoring the abnormal sounding condition of animals at night, accurate identification of abnormal sounding of animals at night by breeding staff is assisted, and animal sound type identification accuracy and positioning precision are improved. 24-hour continuous monitoring of the animal breeding shed is realized, so that the system saves man power and material resource and improves breeding management efficiency substantially.

Owner:CHINA AGRI UNIV

Automatic monitoring method for aquaculture

InactiveCN104570994AReduce labor intensityReduce labor costsTotal factory controlProgramme total factory controlWater qualityUnexpected events

The invention discloses an automatic monitoring method for aquaculture. According to the automatic monitoring method, a water quality parameter sensor, an environment parameter sensor and aquaculture execution equipment together with a communication network are adopted for realizing automatic monitoring on aquaculture, monitoring equipment is adopted for centralized arrangement and monitoring management, a controller is adopted to analyze monitoring data of an independently arranged sensor and control the operation process of an executor according to analysis result, the production and management efficiency of aquaculture is improved, and the modern integrated management requirements are met; operators can monitor the practical situation of aquaculture units without going to a culture place in person, the system can make an alarm automatically when emergent accidents happen, the management efficiency can be improved, the management cost is reduced, and the aquaculture risk is reduced; by adopting a big data technique, big data of monitoring information are stored in different classifications in a cloud data center, the management information of users can be analyzed, a most beneficial culture management mode can be summarized and fed back to the users in time, and thus the culture benefits of the users are increased.

Owner:JIANGMEN HONGKE ELECTRONICS TECH CO LTD

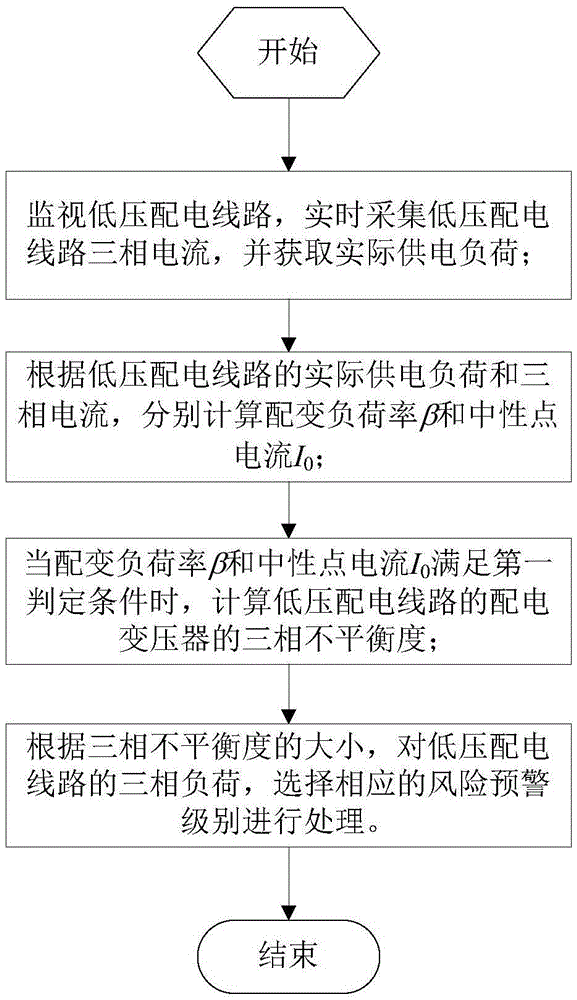

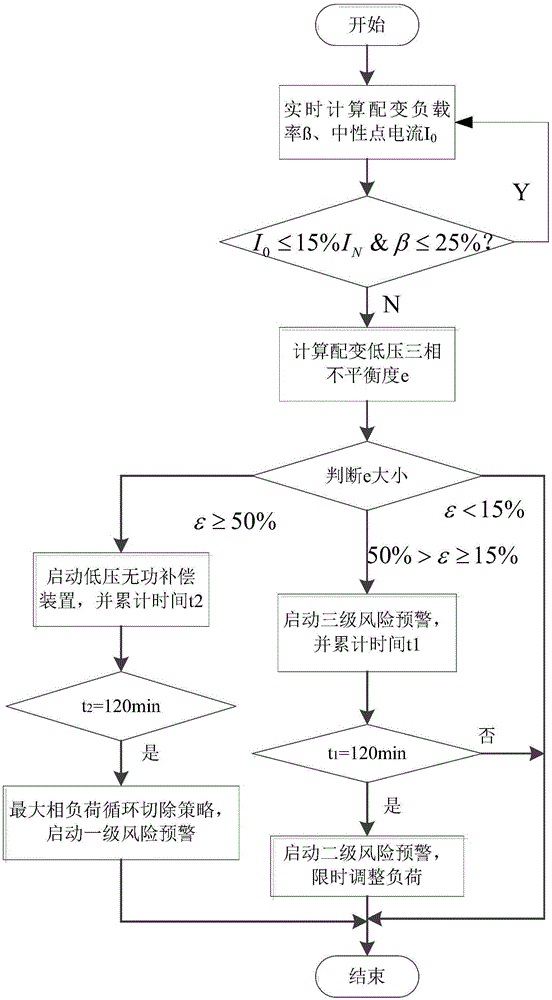

Low-voltage distribution line distribution transformer three-phase unbalance protection method and device

ActiveCN105591396AReduce agingExtended service lifePower network operation systems integrationContigency dealing ac circuit arrangementsDistribution transformerLow voltage

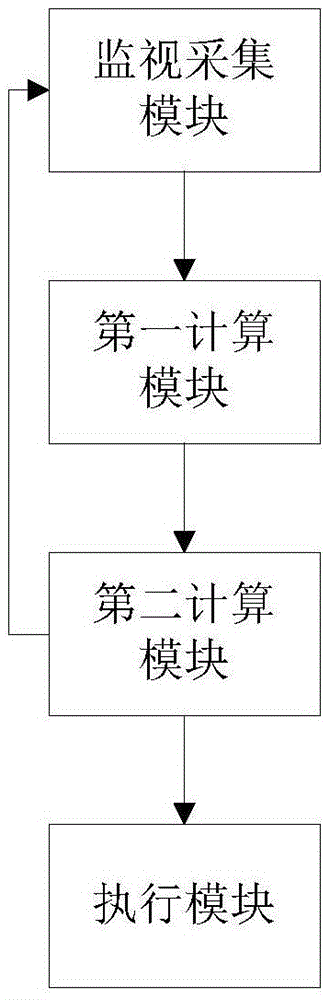

The invention discloses a low-voltage distribution line distribution transformer three-phase unbalance protection method and device. The method comprises following steps: monitoring a low-voltage distribution line, acquiring three-phase current of the low-voltage distribution line in real time, and obtaining actual power supply load; calculating distribution transformer load rate [beta] and neutral point current I0 on the basis of the actual power supply load and the three-phase current of the low-voltage distribution line; when the distribution transformer load rate [beta] and the neutral point current I0 satisfying a first judging condition, calculating three-phase unbalancedness of the low-voltage distribution line distribution transformer; selecting corresponding risk pre-warning levels for processing the low-voltage distribution line three-phase load on the basis of the three-phase unbalancedness. The device comprises a monitoring acquiring module, a first calculation module, a second calculation module, and an execution module. By means of the method and device, the unbalancedness of three-phase current can be greatly reduced.

Owner:STATE GRID CORP OF CHINA +2

Production data processing method and data acquisition device

InactiveCN101546390ALow costImprove production management efficiencyCo-operative working arrangementsSpecial data processing applicationsProduction lineEmployee number

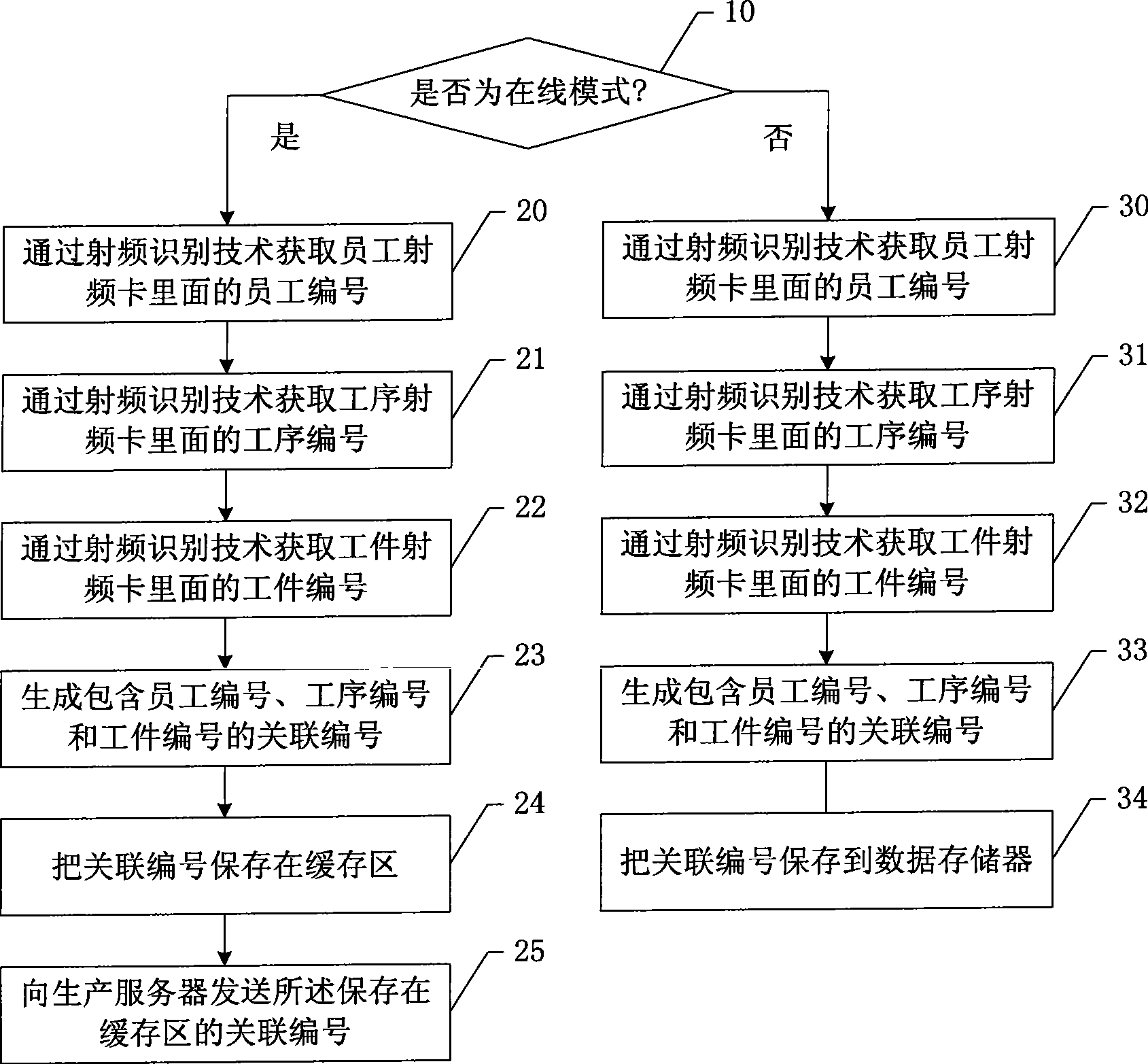

The invention relates to data processing technology, in particular to a production data processing method applying radio frequency identification technology and a data acquisition device. The production data processing method comprises: step A, judging whether production data are in an on-line mode, if so, continuing step B, otherwise, continuing step C; step B, acquiring employee numbers, process numbers and workpiece numbers through the radio frequency identification technology respectively, generating associated numbers comprising the employee numbers, the process numbers and the workpiece numbers, and sending the associated numbers to a production server; and step C, acquiring employee numbers, process numbers and workpiece numbers through the radio frequency identification technology respectively, generating associated numbers comprising the employee numbers, the process numbers and the workpiece numbers, and storing the associated numbers in a data memory. The invention adopts a technical proposal that the data acquisition device acquires data and the production server automatically counts the workpiece number of employees, so the cost for counting workpieces on a production line is lowered, and the production and management efficiency is improved.

Owner:广东凌康科技有限公司

Intelligent motor system

InactiveCN106849517ARealize acquisitionRealize accumulationElectric motor controlStructural associationQuality of serviceLife time

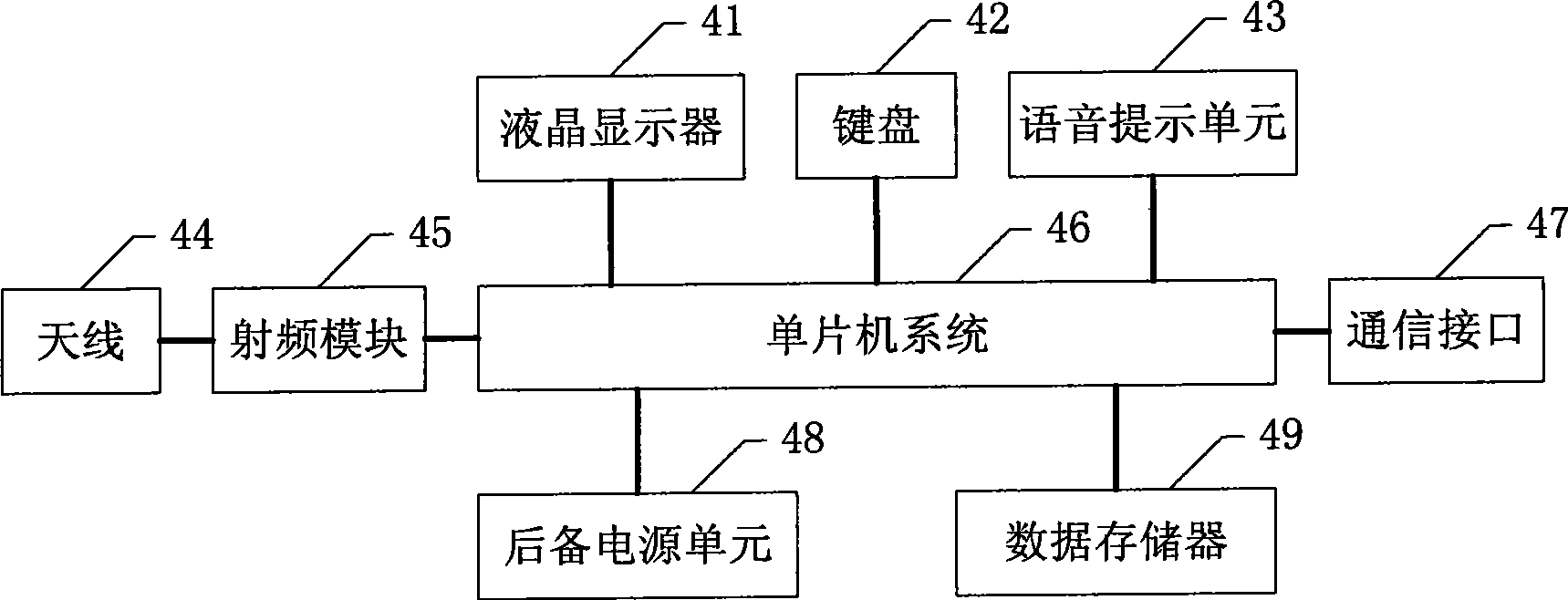

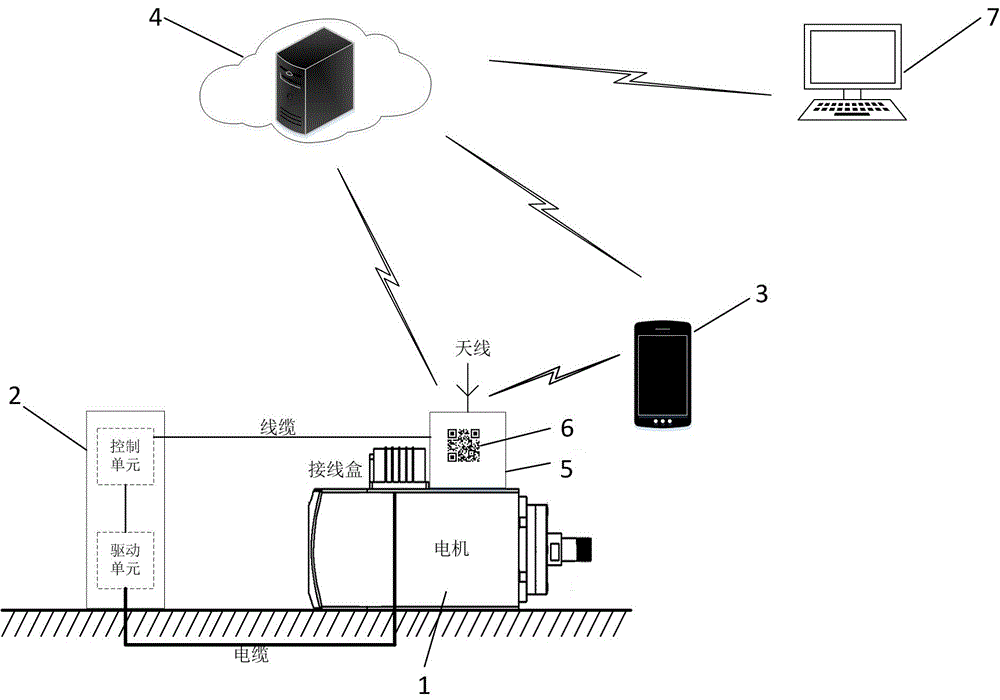

The invention provides an intelligent motor system and belongs to the field of intelligent electrical engineering. The system includes an integrated intelligent on-line monitoring device, a driving control device, a portable device and a cloud server. The integrated intelligent on-line monitoring device and a motor are integrated into a whole so as to achieve long-term, continuous and real-time big data monitoring and accumulation and the use of almost all relevant data of factory data, historical data and real-time operation data. On this basis, motor intelligent fault diagnosis and state early warning are conducted, and operating personnel are timely informed by the portable device to achieve intelligent operation management and maintenance; the driving control device directly conducts intelligent operation control over the motor, and a manufacturer finds and analyzes product defects and effectively improve the after-sale service quality; the use of a two-dimensional code achieves tracking of all data during the whole service life time of the motor. The system has the advantages of being high in intelligence degree, simple in structure, low in cost, high in practicability, convenient to use and the like.

Owner:HARBIN UNIV OF SCI & TECH +1

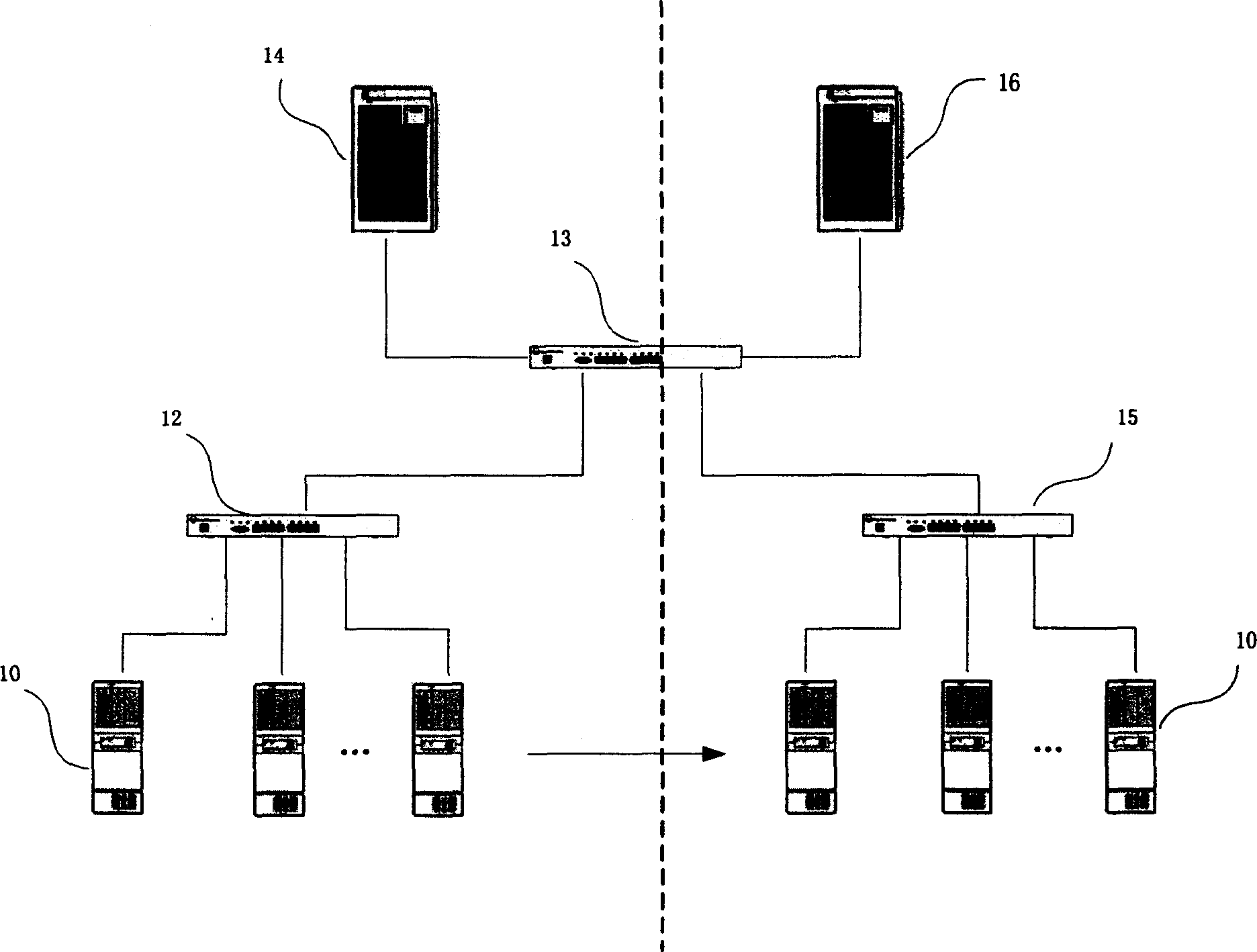

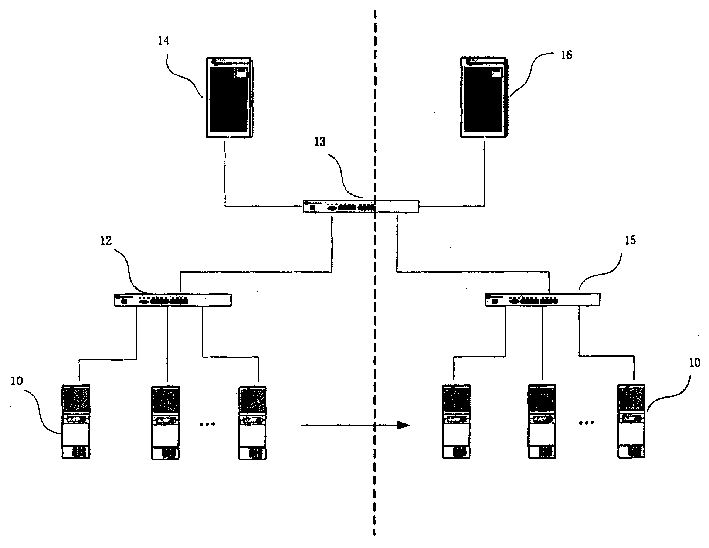

Refresh method of network computer BIOS

InactiveCN1598783AImplement auto-refreshImprove production/management efficiencyHardware monitoringClient-sideNetwork Computer

The invention relates to an approach of refreshing BIOS of network computer. It includes server setting operation and BIOS refresh flow. Server setting operation is to set files in server BIOS refresh system to corresponding files in default value of BIOS that is waiting for refresh. So BIOS refresh system can automatically run at start. BIOS refresh flow is to start network computer and connect with server, download BIOS refresh system to client from server, start and execute BIOS refresh system. So BIOS can be refreshed automatically. Adopting the invention, some network computers whose BIOSes are waiting for refresh can connect with server at the same time and theirs BIOSes can be refreshed in batch.

Owner:LENOVO (BEIJING) CO LTD

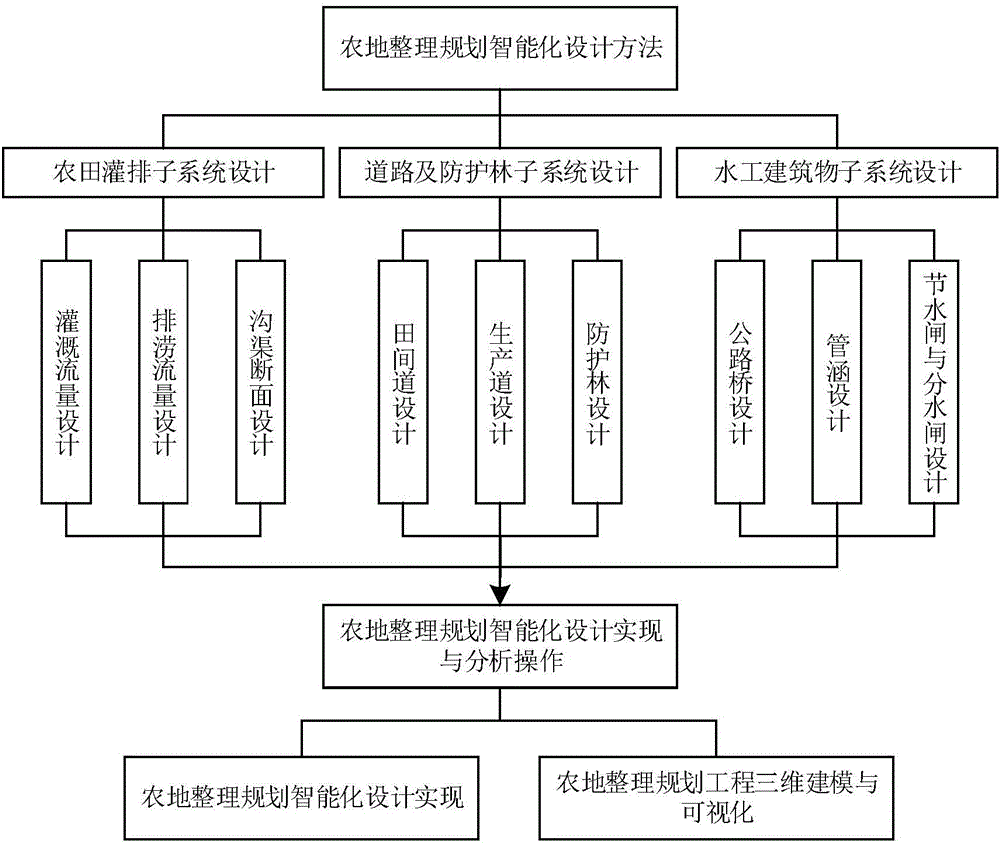

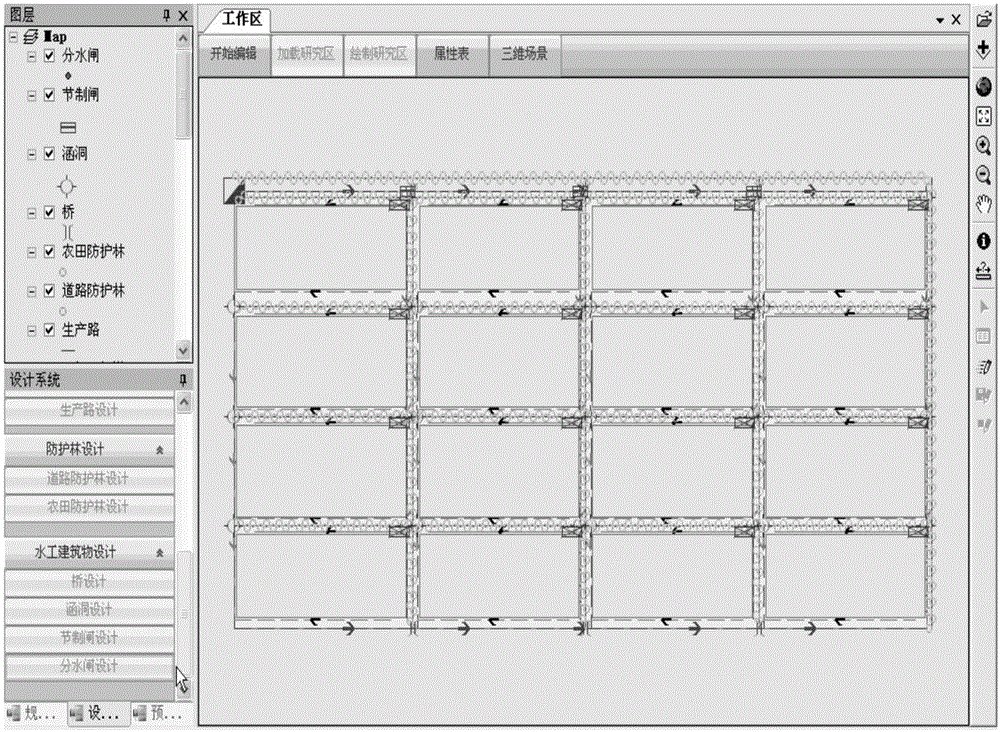

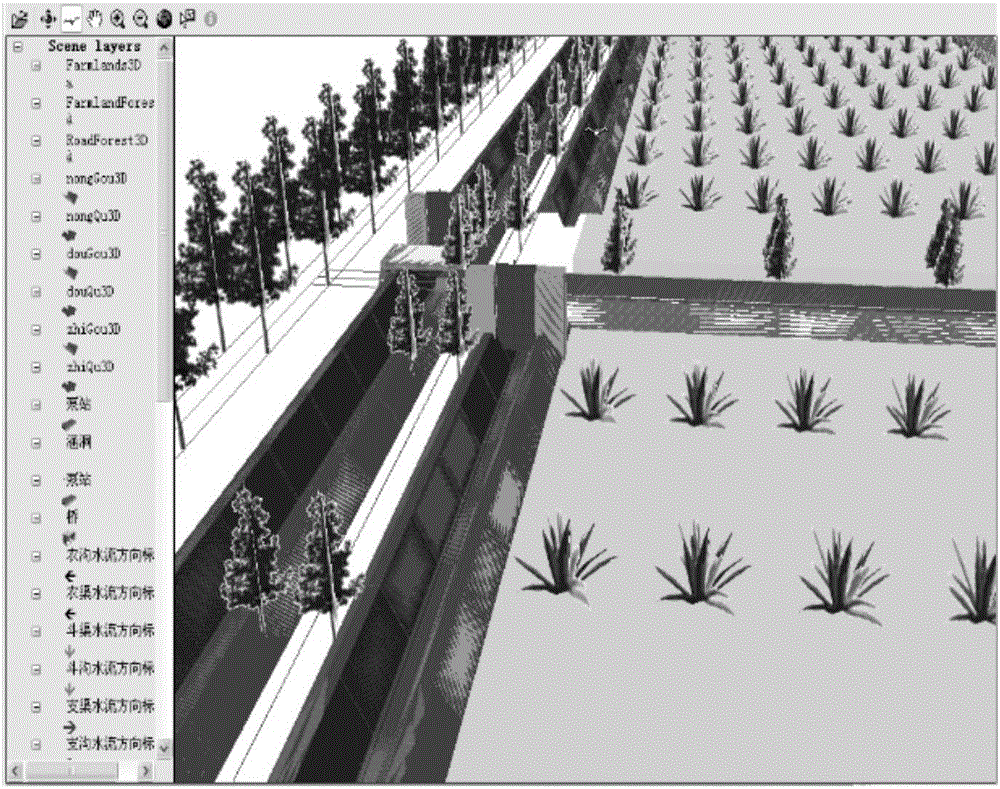

Farmland consolidation plan intelligent design method supported by GeoDesign

ActiveCN105825003AIncrease profitImprove production management efficiencyGeometric CADSpecial data processing applicationsIntelligent designInformatization

The invention provides a farmland consolidation plan intelligent design method supported by GeoDesign. GIS, data mining, knowledge discovery and other technologies are comprehensively applied based on a geographic design idea, to carry out geography abstraction and extraction and representation of relevant knowledge rules on farmland consolidation engineering, thus completing parameterization setting of a farmland irrigation subsystem, a hydraulic construction subsystem and a road and protection forest subsystem in a farmland consolidation plan; furthermore, a uniform organization and management method for geographic object space relation, orientation information, attribute information, design parameter and knowledge rules of the farmland consolidation engineering is explored, so that intelligent design of a farmland consolidation plan is realized; on the basis of the intelligent design, GIS space inquiry, space analysis and three-dimensional modeling technologies are comprehensively used, so that three-dimensional modeling, three-dimensional visual analysis and other operations of the farmland consolidation planning engineering are realized. According to the method, the efficiency of the farmland consolidation planning and design can be effectively improved, and a technical support and a decision basis can be provided for efficient utilization of farmland resources, farmland informatization management and precise agriculture.

Owner:江苏金沙地理信息股份有限公司

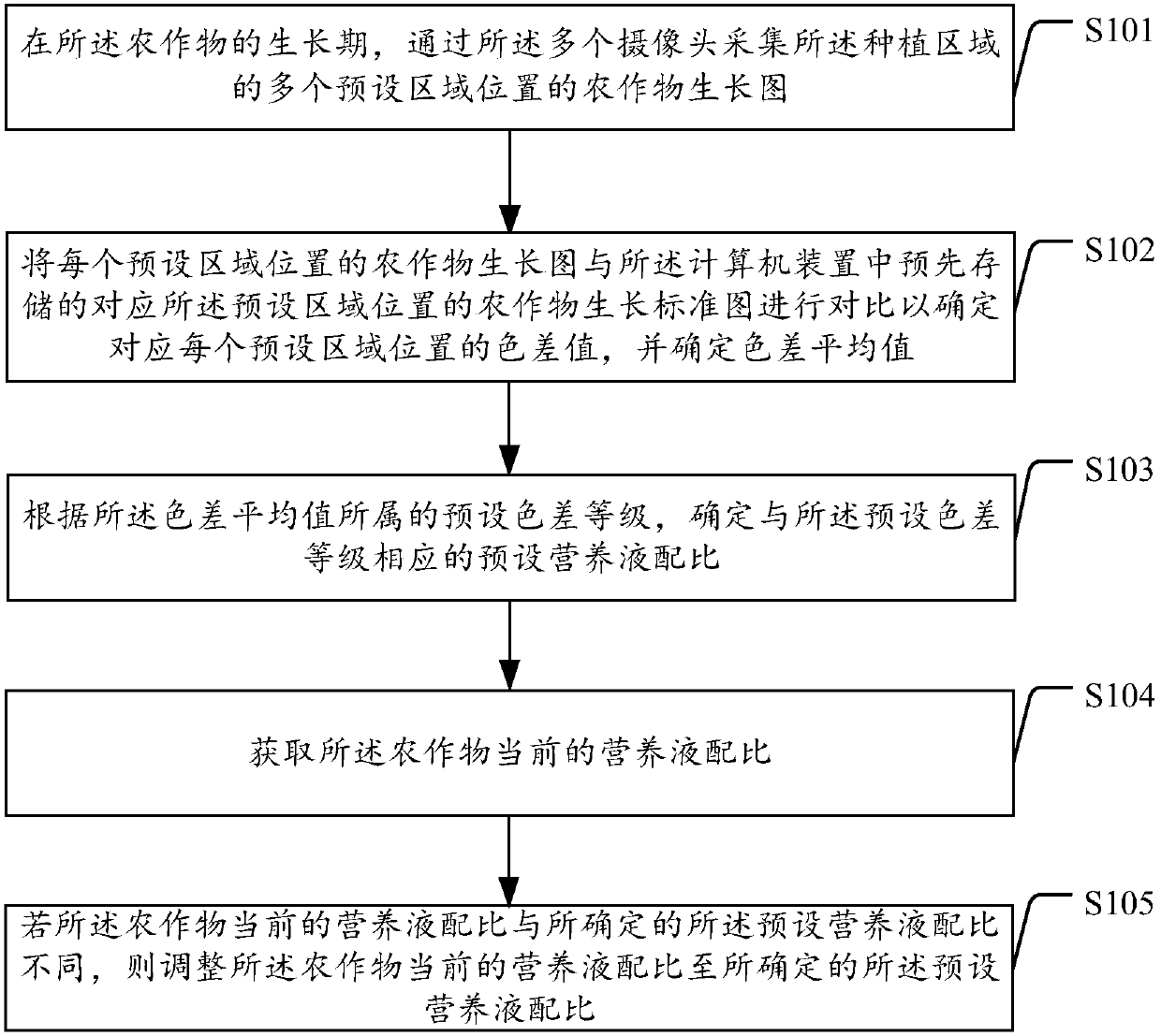

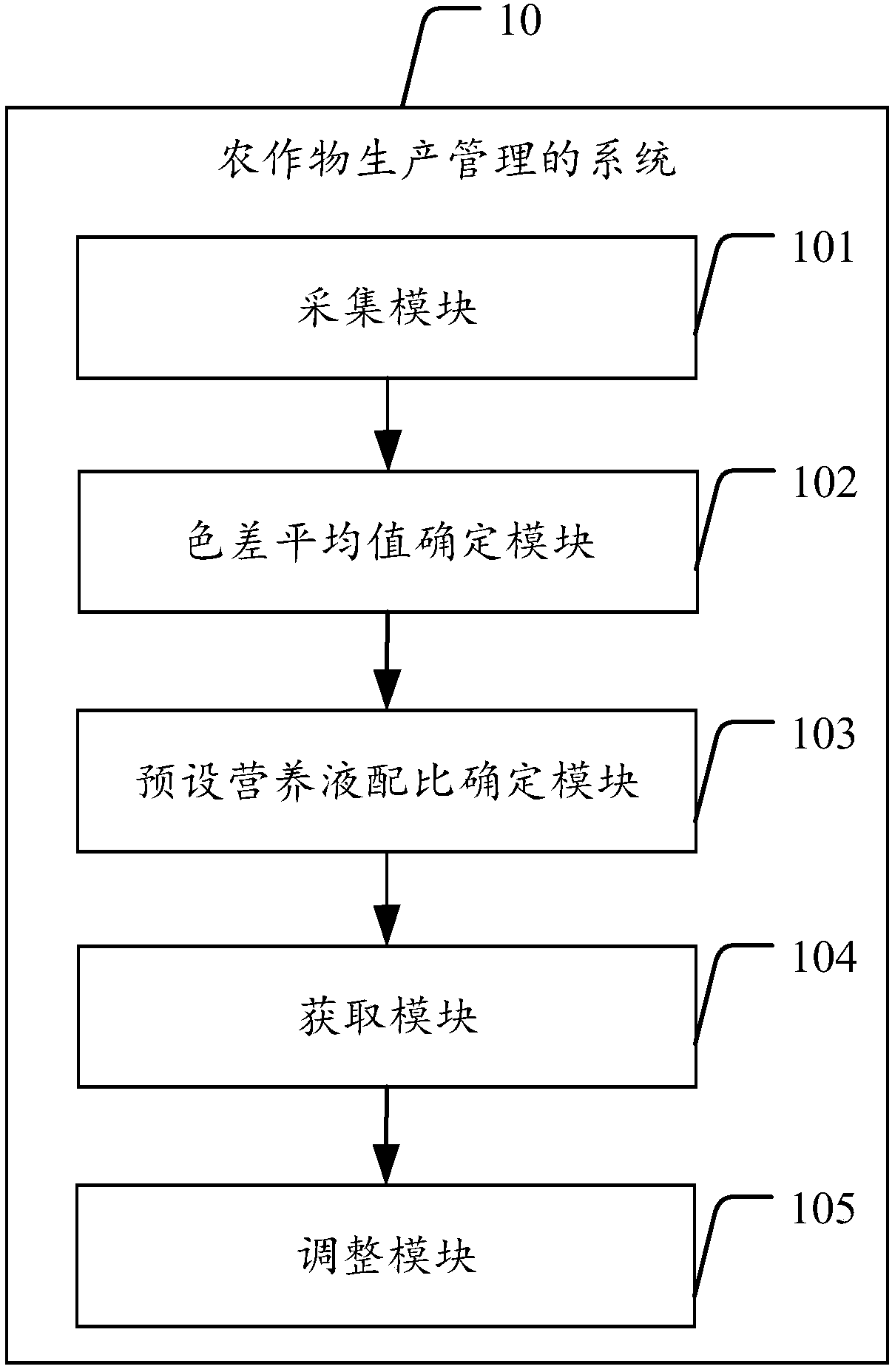

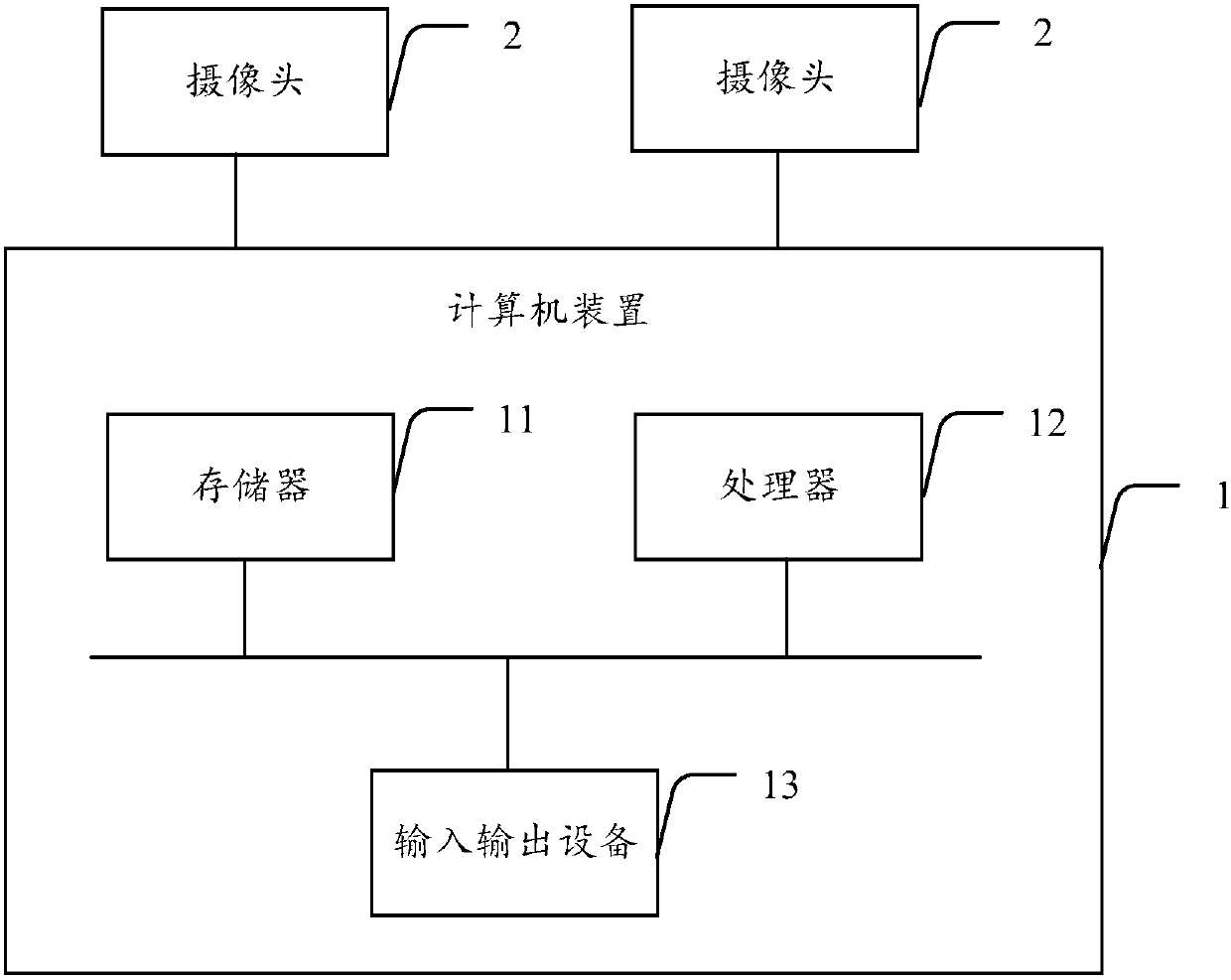

Crop production management method and system, computer device and storage medium

InactiveCN107844771AImprove production management efficiencyLow costCharacter and pattern recognitionResourcesNutrient solutionStandard map

The invention discloses a crop production management method and system, a computer device and a storage medium. In the invention, crop growth maps of a plurality of preset region positions of a planting region are collected through a plurality of cameras during the growing period of crops, each crop growth map is compared with a crop growth standard map of the corresponding preset region positionpre-stored in a computer device to determine a color difference value of each preset region position, the average color difference is determined, according to the preset color difference level to which the color difference average value belongs, a preset nutrient solution ratio corresponding to the preset color difference level is determined, a current nutrient solution ratio of the crops is obtained, and if the current nutrient solution ratio differs from the preset nutrient solution ratio, the current nutrient solution ratio of the crop is adjusted to be the determined preset nutrient solution ratio. According to the invention, the nutrient solution ratio of the crop can be adjusted through image comparison, the efficiency of crop production management is increased, and the cost of cropproduction management is reduced.

Owner:SHENZHEN SPRINGWOODS HLDG CO LTD

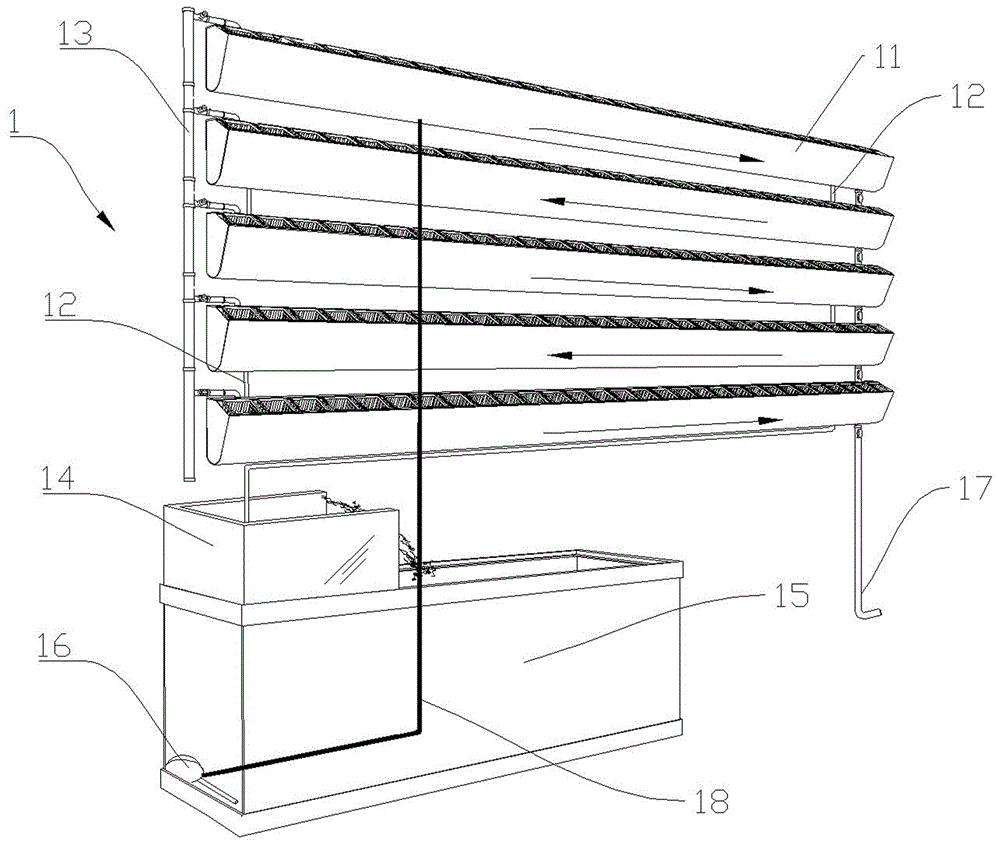

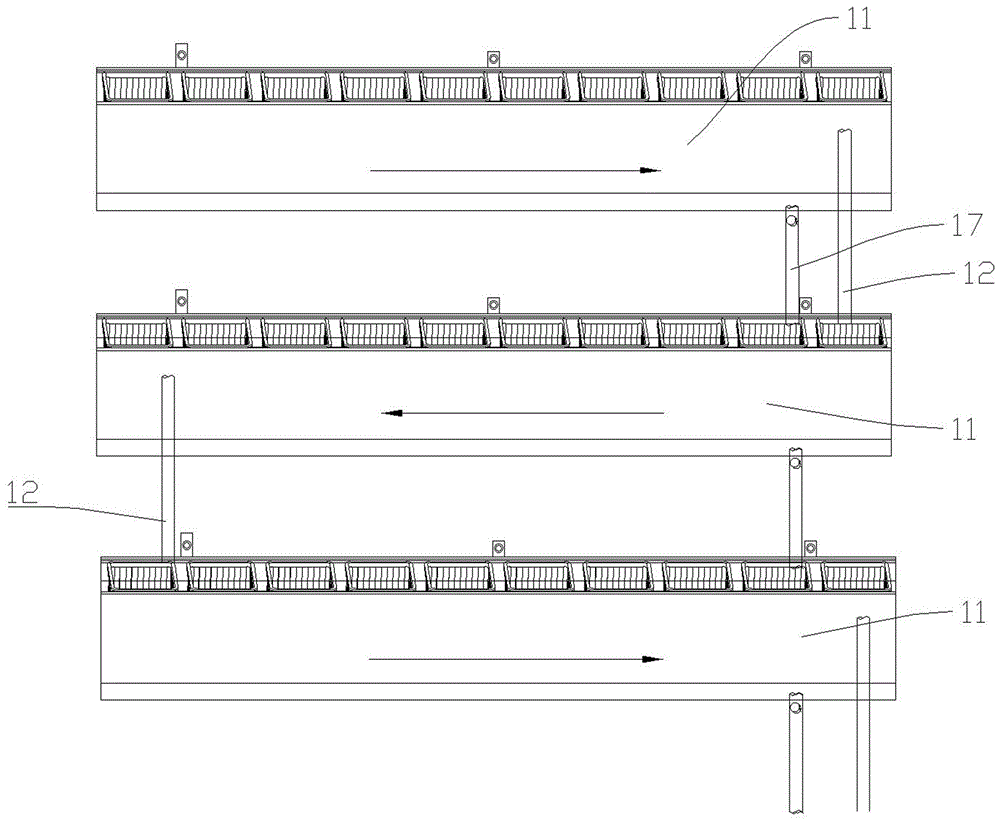

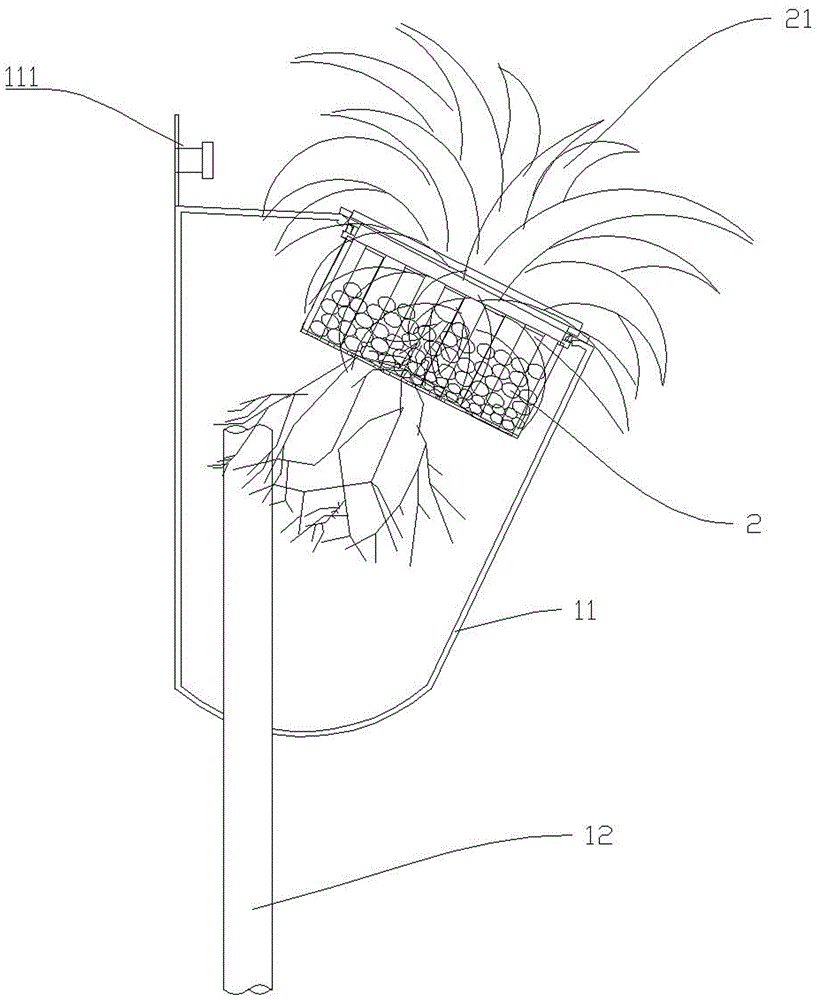

Hydroponic plant wall planting method and device

ActiveCN105684868AEasy to manageElegant managementPisciculture and aquariaAgriculture gas emission reductionLife qualityAir cleaning

The invention discloses a hydroponic plant wall planting method and device. The method comprises the following steps that formed hydroponic plants are adopted for planting; formed plant planting baskets are adopted for planting hydroponic plants; water of a circulating system is absorbed thoroughly through a hydroponic plant wall device with water tanks and a circulating water draining system for plant culture to form a hydroponic plant wall. Plants of different varieties can be combined and planted on the water tanks by adopting the formed plant planting baskets, a water pump pumps water in a fish tank or a fish pond to the top of the plant wall, the water of each-level water tank reaches the overflow opening and then naturally flows down to the next level, and water of the lowest-level water tank reaches the overflow opening position and then flows back to the fish tank or the fish pond to form water circulation. Air purification, clean planting and ecological environmental protection can be achieved, the life quality can be improved, modular production can be achieved, operation is convenient, maintenance is easy, and the practicability is high.

Owner:GUANGZHOU JINGRUN GARDEN GREENING CO LTD

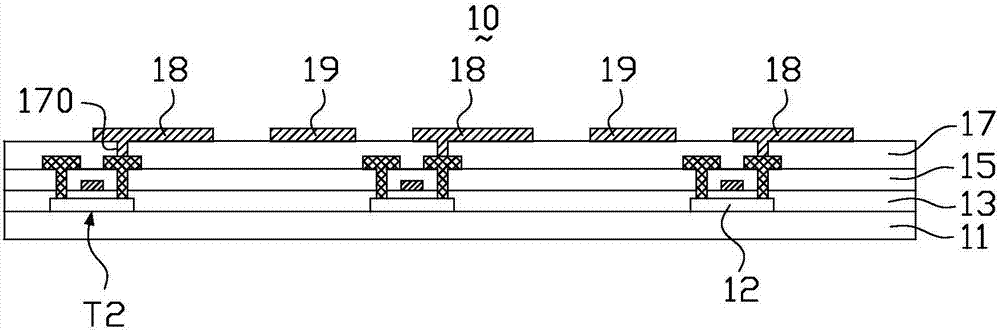

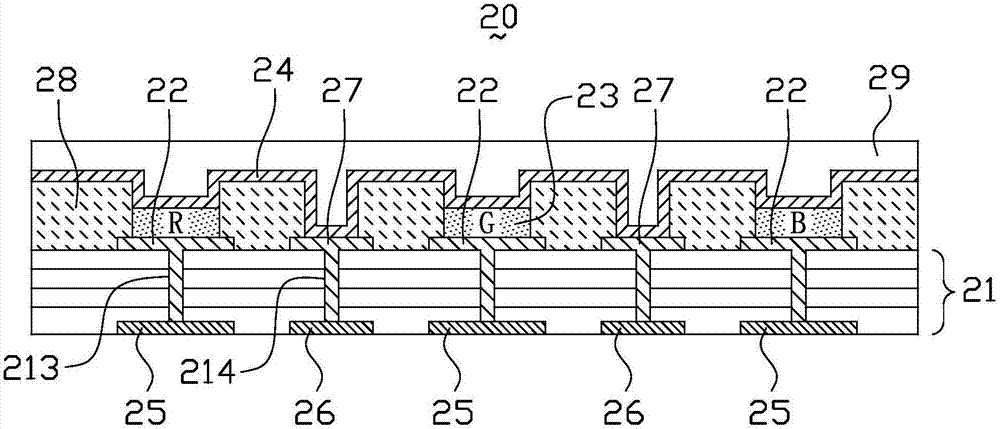

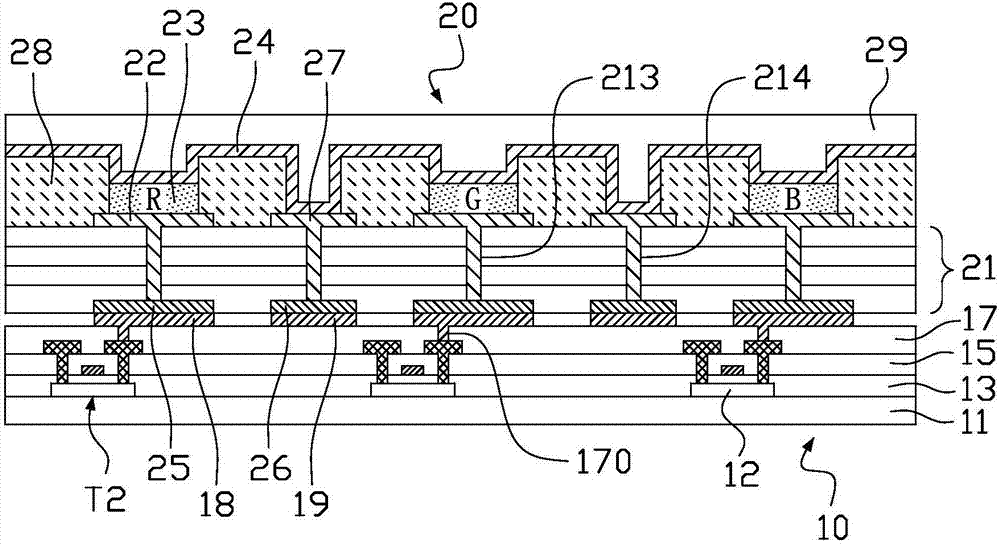

Organic light-emitting diode display device and manufacturing method thereof

ActiveCN107887403AImprove production management efficiencyImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingTransistor arrayDisplay device

The invention provides an organic light-emitting diode display device and a manufacturing method thereof. The organic light-emitting diode display device is composed of an array element substrate andan organic light-emitting diode substrate that are oppositely bonded together. The array element substrate consists of a first substrate, a thin-film transistor array element arranged on the first substrate, and a first bonding electrode and a second bonding electrode, wherein the first bonding electrode and the second bonding electrode are arranged on the thin-film transistor array element. The organic light-emitting diode substrate includes a second substrate, a third bonding electrode arranged on a first surface of the second substrate, and an organic light-emitting diode arranged on an opposite second surface of the second substrate. On the basis of opposite bonding of the array element substrate and the organic light-emitting diode substrate, an LTPS preparation process and an OLED preparation process are carried out separately; and because the prepared flexible OLED substrate can be cut into any shape, one-time production of various products under a certain PPI is realized and thus utilization of multiple sets of evaporation masks is not needed, so that the cost is lowered and the production efficiency and the yield are improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

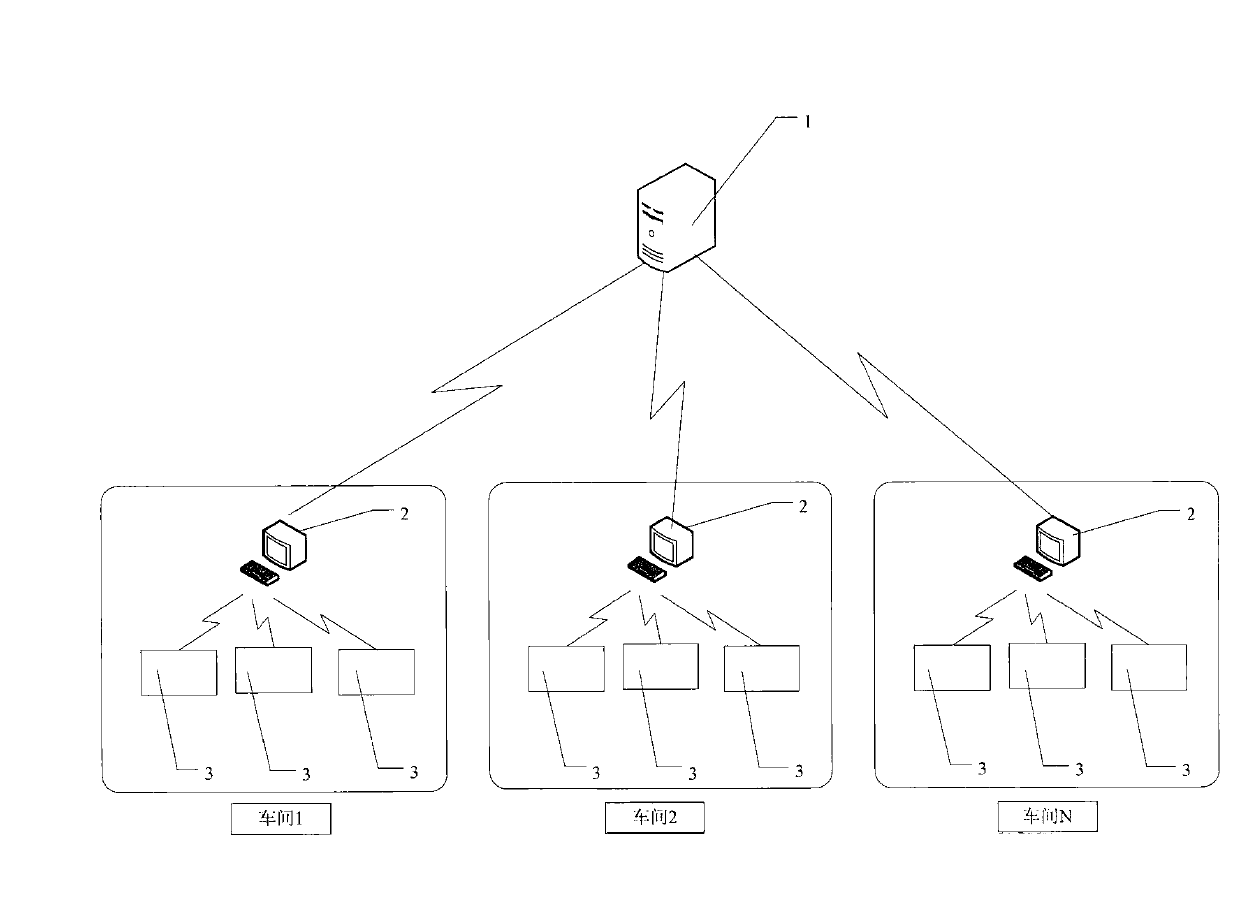

Production monitoring system of manufacturing plant of printed circuit board (PCB) or liquid crystal display (LCD) or solar cell

InactiveCN103135527AReal-time understanding of production statusKnow the actual production quantity in real timeTotal factory controlProgramme total factory controlAnalysis dataStatistical analysis

The invention relates to a production monitoring system of a manufacturing plant of a printed circuit board (PCB), a liquid crystal display (LCD) or a solar cell. The production monitoring system of the manufacturing plant of the PCB, the LCD or the solar cell is characterized by comprising a monitoring center and at least one data collection transmission device, wherein the monitoring center is arranged at a remote end. Each workshop of the PCB, the LCD or the solar cell manufacturing plant is provided with one data collection transmission device, or at least two workshops sharing one data collection transmission device. The data collection transmission device is connected with a data interface device, and production equipment in the workshop is connected with one data interface device. By means of the production monitoring system, an administer of the manufacturing plant of the PCB, the LCD or the solar cell can visit the monitoring center any time anywhere through a terminal (for example, a mobile intelligent terminal) and know the state of a production line, the actual production amount and statistic analysis data in real time. The production monitoring system of the manufacturing plant of the PCB, the LCD or the solar cell has the advantages of being free from space and time intervals, completely intelligent, free from need of manual intervention, and capable of improving efficiencies of production and management and reducing labor cost.

Owner:上海飞为智能系统股份有限公司

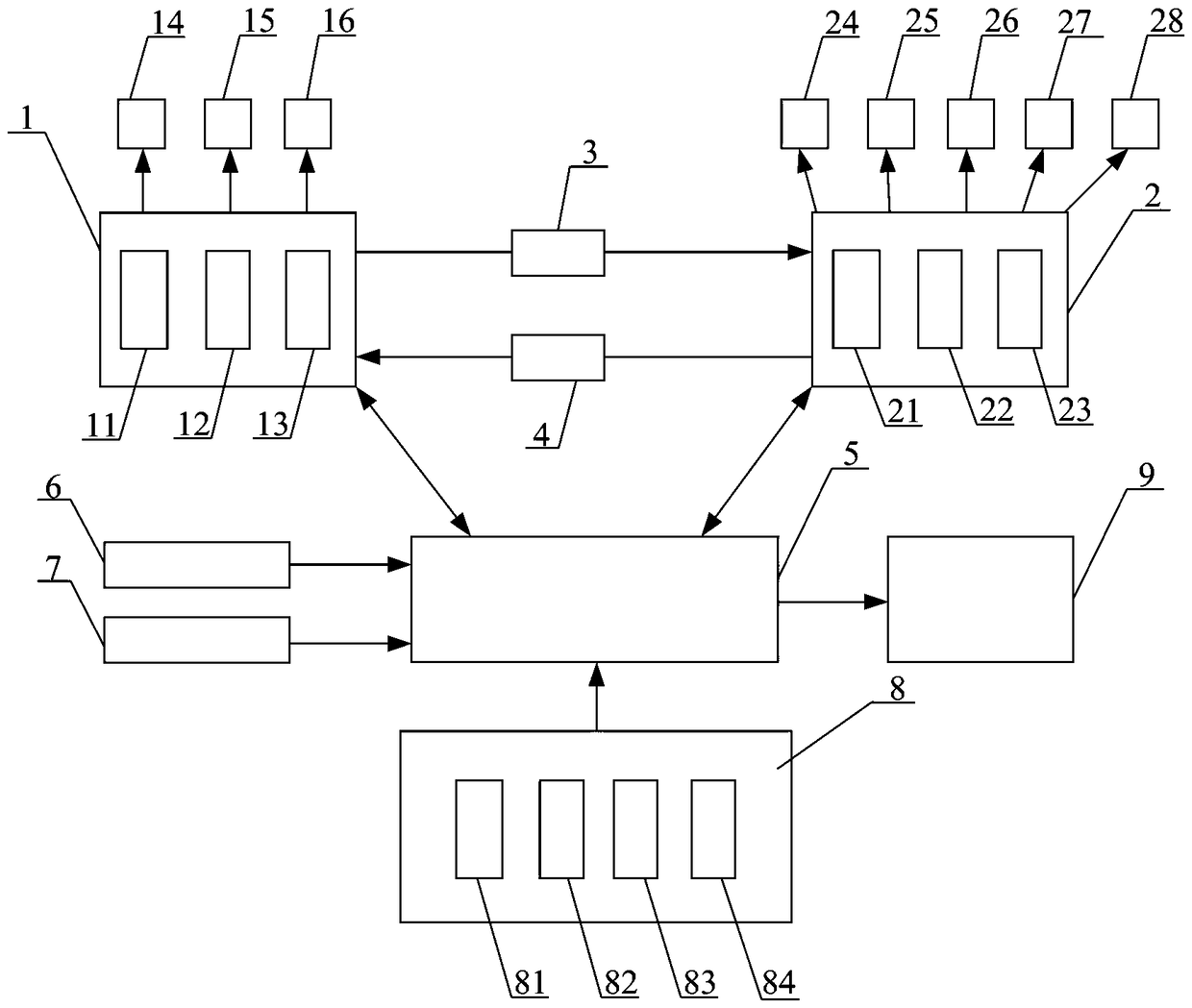

Workshop information physical monitoring and management platform system

InactiveCN108205735ATo ensure the target requirements of transparent green managementImprove production management efficiencyResourcesManufacturing computing systemsManagement efficiencyPhysical system

The invention discloses a workshop information physical monitoring and management platform system. The workshop information physical monitoring and management platform system is characterized by consisting of a reality physical system, a virtual information system, an information feedback module, an information control module, a monitoring and management platform, a design change module, a manufacturing change module, a data / information module and a digital model which are connected by an Ethernet, wherein the monitoring and management platform is based on an information sensing layer of Internet of Things, and utilizes a virtual reality technique to establish a three-dimensional visualizing digital model for workshop and production line objects to monitor and manage. Compared with the prior art, the workshop information physical monitoring and management platform system has the advantages that the digital model is implemented in the whole design, manufacturing and management process,the reality physical system and the virtual information system are highly integrated, and the data value of the digital model can be mined by modules; the production quality is improved, the construction cycle is shortened, the production cost is reduced, the workshop production management efficiency is improved, and the design construction mode is gradually upgraded to an innovative service modeof ''design+construction+operation''.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

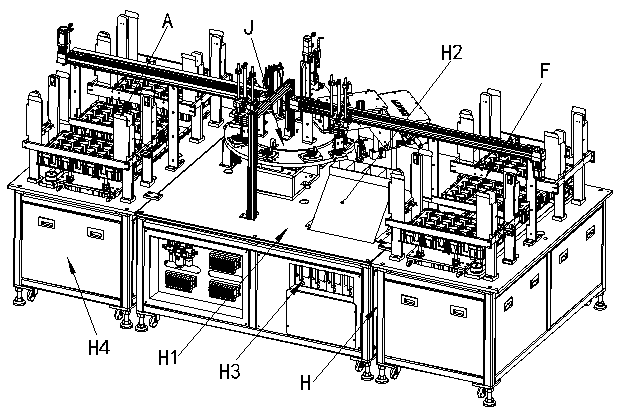

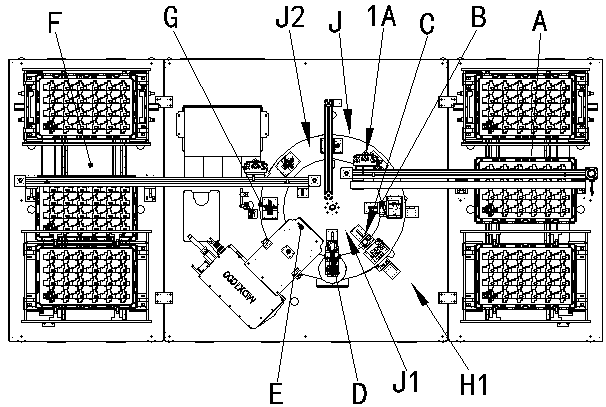

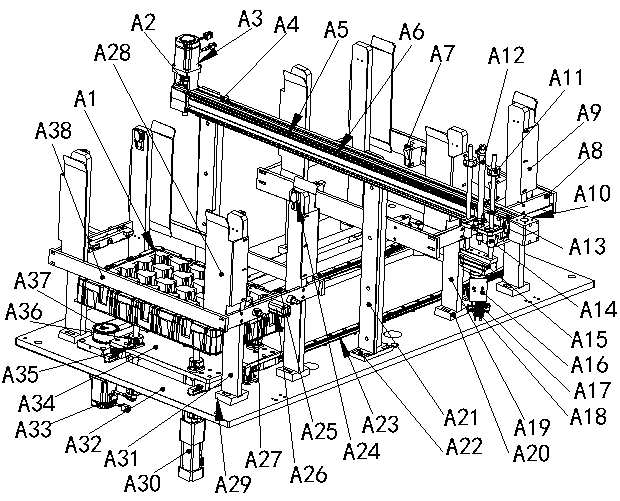

Automobile connector PIN needle detecting machine and detecting method thereof

PendingCN108387825AFast trackImprove detection efficiencyTesting dielectric strengthCo-operative working arrangementsEngineeringConnector Pin

The invention discloses an automobile connector PIN needle detecting machine and a detecting method thereof. A feeding station, an electrical characteristic detecting station, a high and low needle detecting station, an image detecting station, a laser marking station, a code scanning station and a material discharging station are respectively located on corresponding detection or operation stations on an externally-rotary index dial; a feeding jaw of the feeding station is oppositely matched with a loading station on the index dial, and the electrical characteristic detecting station includesan electrical characteristic upper detecting component and an electrical characteristic lower detecting component; the high and low needle detecting station comprises a high and low needle upper detecting component and a high and low needle lower detecting component; the image detecting station comprises an image detecting upper component and an image detecting lower component; the laser markingstation is arranged above the index dial; the code scanning station is located above the index dial, and the discharge jaw of the material discharging station is oppositely matched with a discharge station on the index dial. Automatic feeding and discharging detection is achieved, the detection efficiency and accuracy are improved, the manual operation intensity is lowered, the detection quality is improved, and the quality pass rate is increased.

Owner:HANGZHOU TAISHANG MACHINERY CO LTD

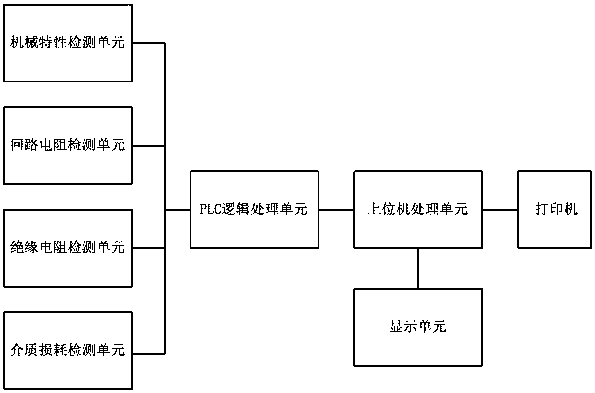

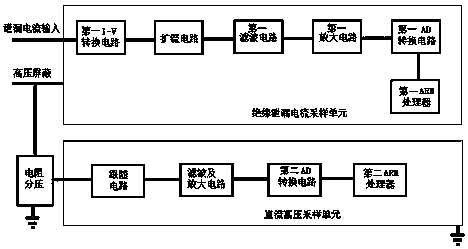

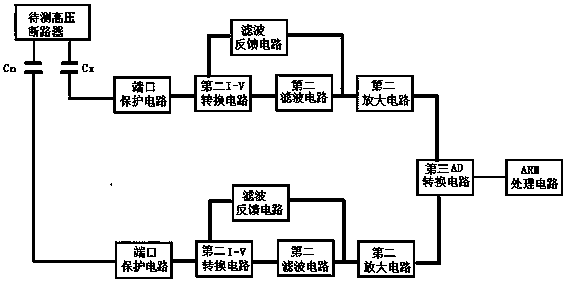

Automatic high-voltage circuit breaker detection system

InactiveCN108037449AImprove production management efficiencySave manpower and material resourcesCircuit interrupters testingInsulation resistancePower equipment

The invention discloses an automatic high-voltage circuit breaker detection system and relates to the technical field of detection for power equipment in a power system. The automatic high-voltage circuit breaker detection system comprises a circuit breaker pre-testing item detection unit, a PLC (Programmable Logic Controller) logic processing unit and an upper computer processing unit which are connected in sequence. Property indexes such as the mechanical property, the loop resistance, the insulation resistance and the medium consumption of a circuit breaker are respectively detected by a mechanical property detection unit, a loop resistance detection unit, an insulation resistance detection unit and a medium consumption detection unit of the circuit breaker pre-testing item detection unit, all detection data are uniformly converted and classified through the PLC logic processing unit and are further processed and analyzed by the upper computer processing unit, then detection resultsand primary diagnosis conclusions can be made, the defect that a plurality of detectors need to be carried over for multiple detection items is avoided, a high-voltage circuit breaker can be detectedrelatively intelligently and integrally, the production and management efficiency is greatly improved, the labor and the materials are saved, and the working intensity is alleviated.

Owner:GUANGXI POWER GRID ELECTRIC POWER RES INST

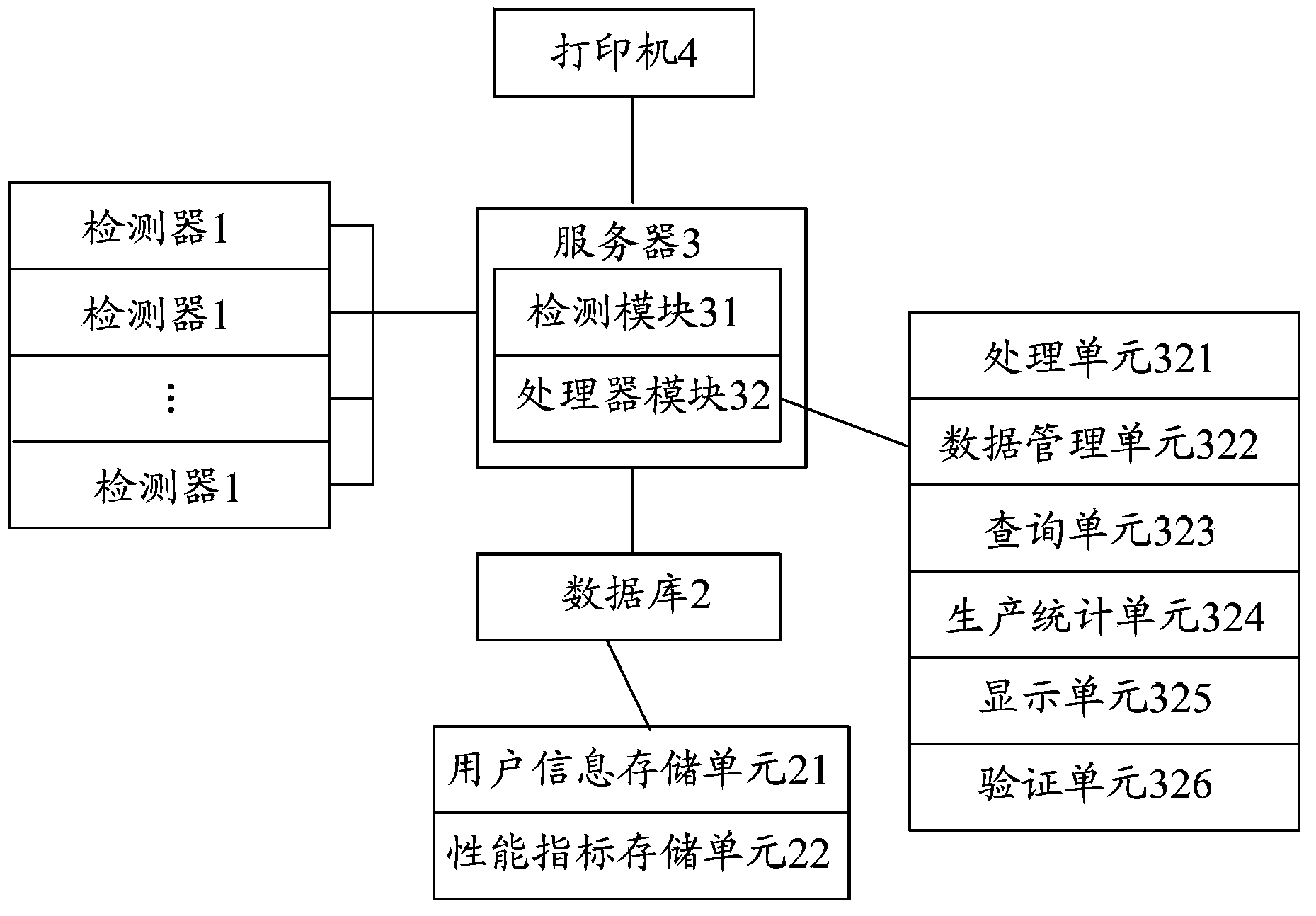

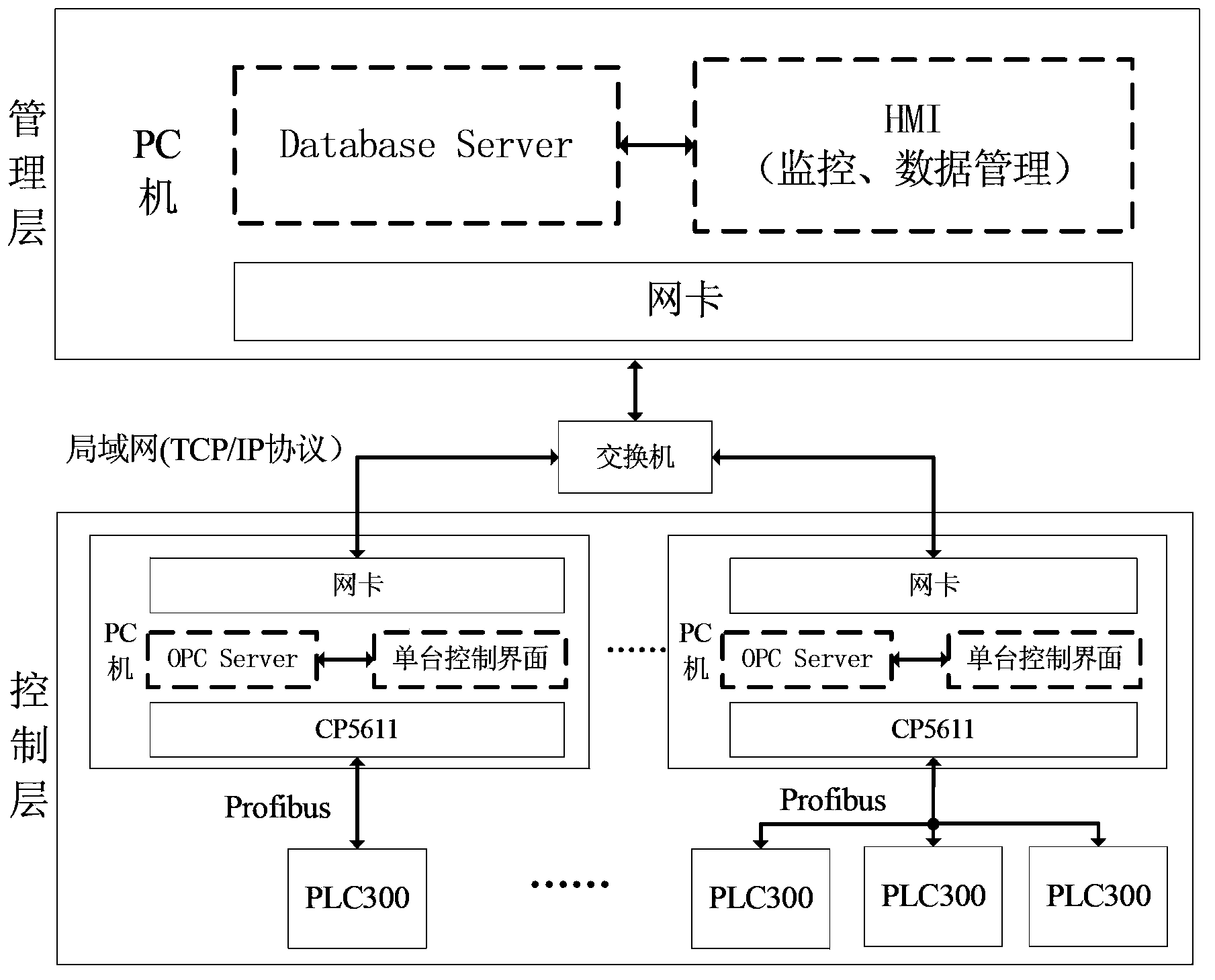

Breaker detecting and assembly line production management system

InactiveCN103513178AReduce wasteImprove processing precisionTotal factory controlCircuit interrupters testingUser inputAssembly line

The invention discloses a breaker detecting and assembly line production management system. The breaker detecting and assembly line production management system comprises a plurality of detectors, a database and a server, and the detectors are respectively used for detecting all performance indexes of the breaker, and the database is used for storing user register information, product information and detecting information and a detecting result of corresponding products. The server is used for collecting data detected by the detectors, processing the collected data, working out a detecting result and sending the detecting result and the received data to the database to be stored. Operations of inquiring and generating a report form are carried out according to user input, and an inquiry result and a generated report form are displayed. According to the breaker detecting and assembly line production management system, product detecting information is automatically collected and processed, storage is automatically managed, the breaker detecting and assembly line production management system has the advantages of being high in processing precision and efficiency, and saving in labor power and resource, the inquiring process is convenient, and production cost is reduced.

Owner:SHANGHAI UNIV OF ENG SCI

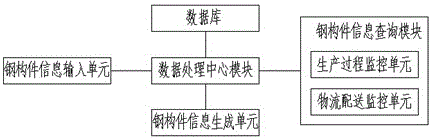

Steel structure production distribution system based on BIM and two-dimensional codes

InactiveCN106296014AEasy to processImprove production management efficiencyForecastingDesign optimisation/simulationFully developedManagement unit

The present invention relates to a steel structure production distribution system based on BIM and two-dimensional codes. The system comprises a steel structure information input unit, a data processing center module, a database configured to store steel member production and distribution data, a steel member information query module and a steel member information generation unit for generating two-dimensional codes. The steel structure information input unit, the database, the steel member information query module and the steel member information generation unit are connected with the data processing center, and the data processing center module includes a production task unit, a raw material management unit, a production processing unit, a quality detection unit, an inbound and outbound unit and a logistics distribution unit. Through adoption of the BIM technology and the two-dimensional code technology, the automatic production distribution system is established so as to solve the problem that the steel structure production distribution process is low in efficiency and fully develop the production capacity of a device.

Owner:SHANGHAI BAOYE GRP CORP

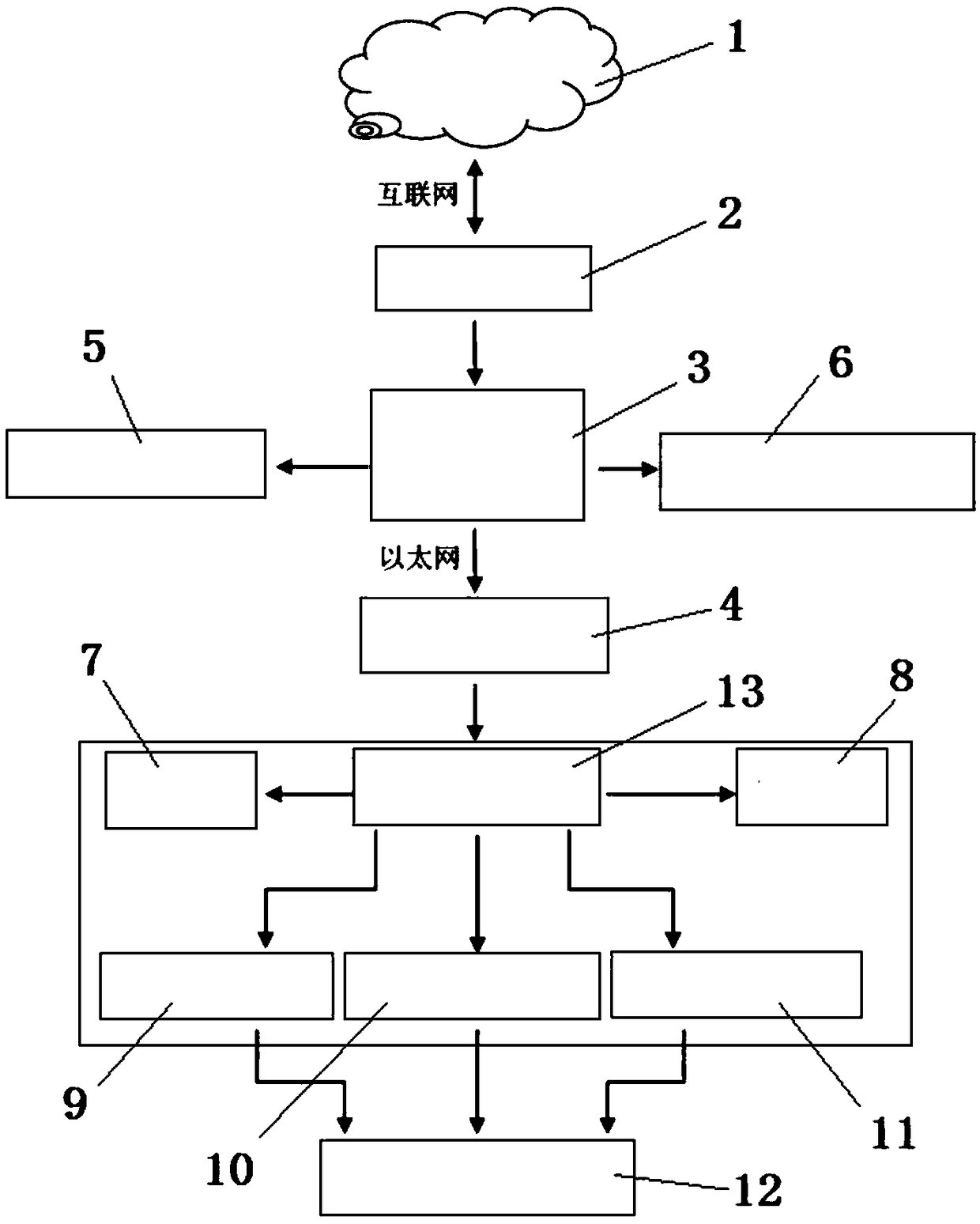

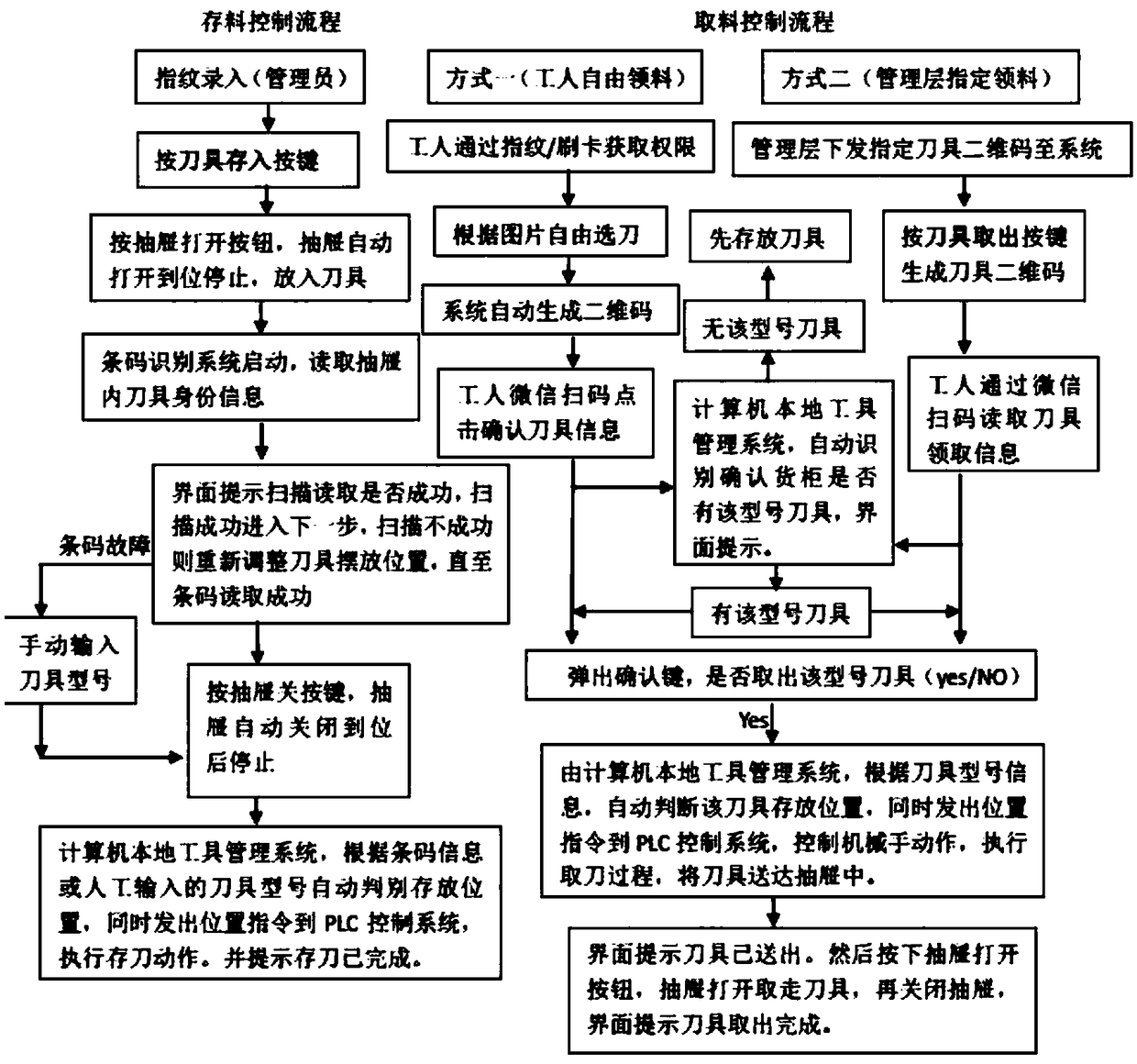

Control system and method of intelligent cloud cutter management system

PendingCN108132653AImprove quality and efficiencyImprove management efficiencyTotal factory controlProgramme total factory controlControl systemThe Internet

The invention discloses a control system and method of an intelligent cloud cutter management system. The control system comprises a cloud server, a cutter storage cabinet, a local cutter management system and a PLC control system, the cutter storage cabinet is provided with the local cutter management system and the PLC control system, the cloud server is in communication connection with the local cutter management system via the Internet, the local cutter management system is in communication connection with the PLC control system via Ethernet, and the PLC control system comprises an industrial control computer, a sensor and first, second and third servo control systems. Via the control system and method, cutters can be stored and taken normally in a 24-hour unmanned condition in a factory storehouse, the cutter can be taken when necessary and is returned timely after use, the production and management efficiency is improved, and the storage management staff, stock and production cost are reduced.

Owner:XINAN TOOLS GUIZHOU PROV

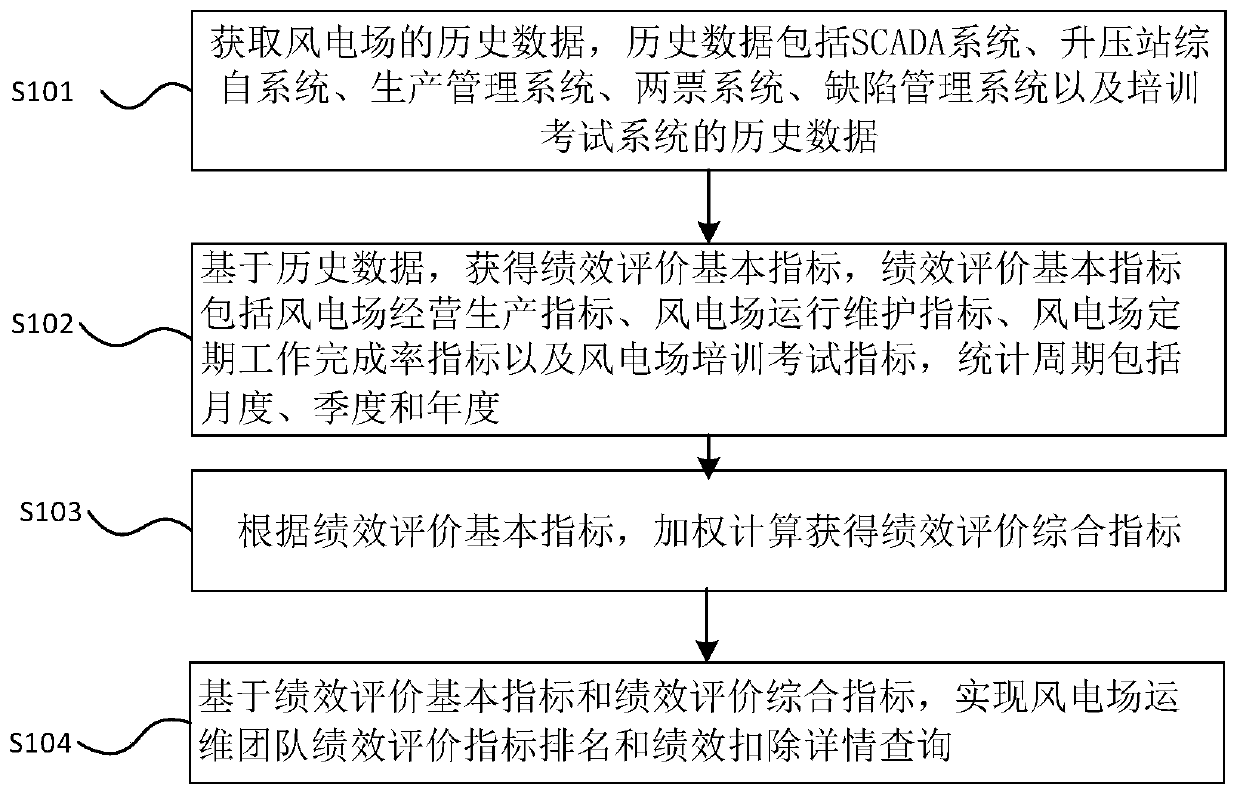

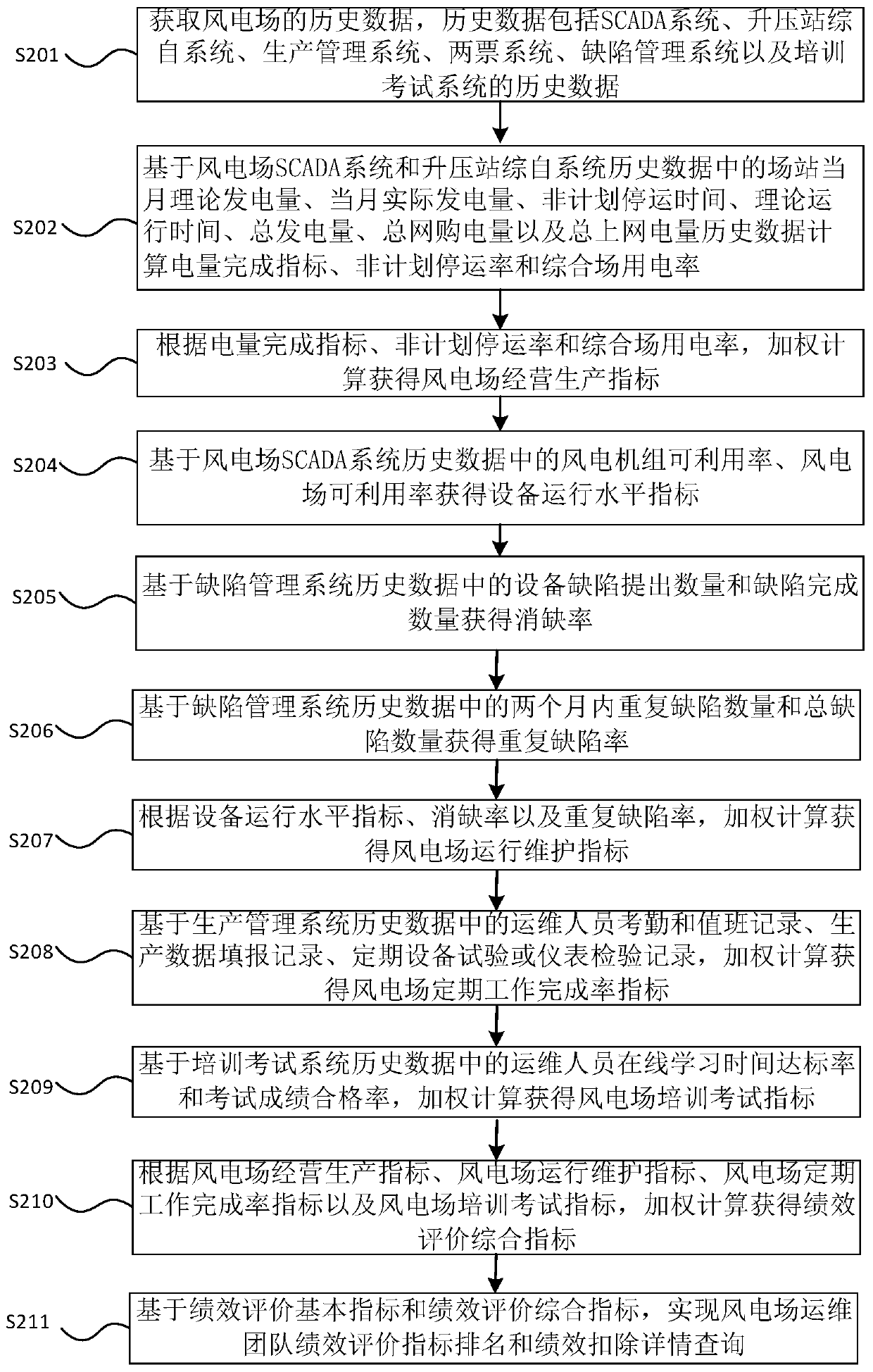

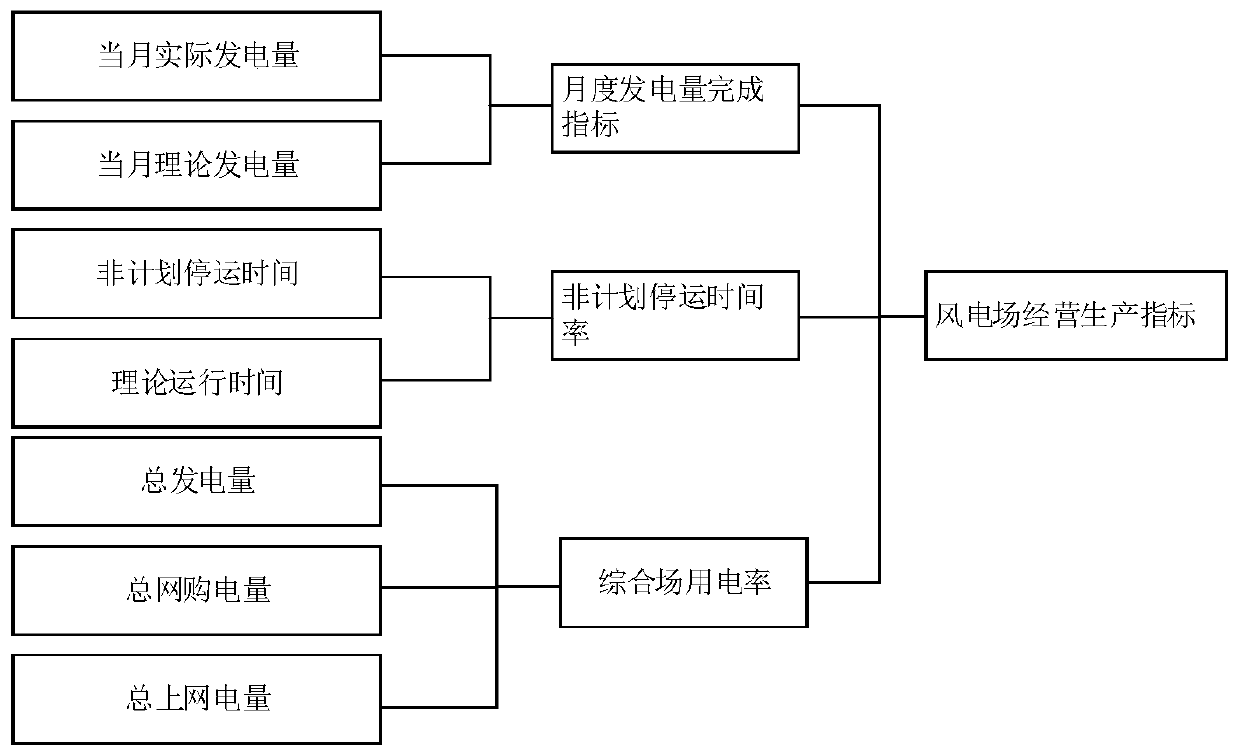

Wind power plant operation and maintenance performance evaluation management method and system

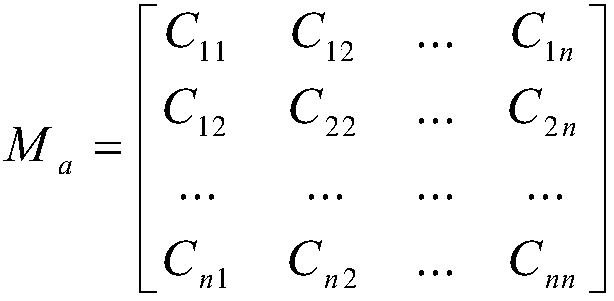

PendingCN110458392ARealize centralized managementEfficient integrationResourcesPeaking power plantRanking

The invention discloses a wind power plant operation and maintenance performance evaluation management method and system. The method comprises the steps of obtaining historical data of a wind power plant; based on the historical data, obtaining basic indicators of performance evaluation, wherein performance evaluation basic indexes comprise a wind power plant operation and production index, a windpower plant operation and maintenance index, a wind power plant periodic work completion rate index and a wind power plant training examination index. According to the performance evaluation based basic indexes, weighted calculation is carried out to obtain a performance evaluation comprehensive index and a performance evaluation basic index and a performance evaluation comprehensive index to achieve wind power plant operation and maintenance team performance evaluation index ranking and performance deduction detail query. The technical problem that traditional wind power plant production andoperation performance management is incomplete is solved, centralized management and performance benchmarking of wind power plant operation and maintenance personnel are achieved, wind power plant production and management data are effectively fused, production management efficiency is improved, and an effective excitation mechanism is formed.

Owner:HUNAN DATANG XIANYI TECH CO LTD +1

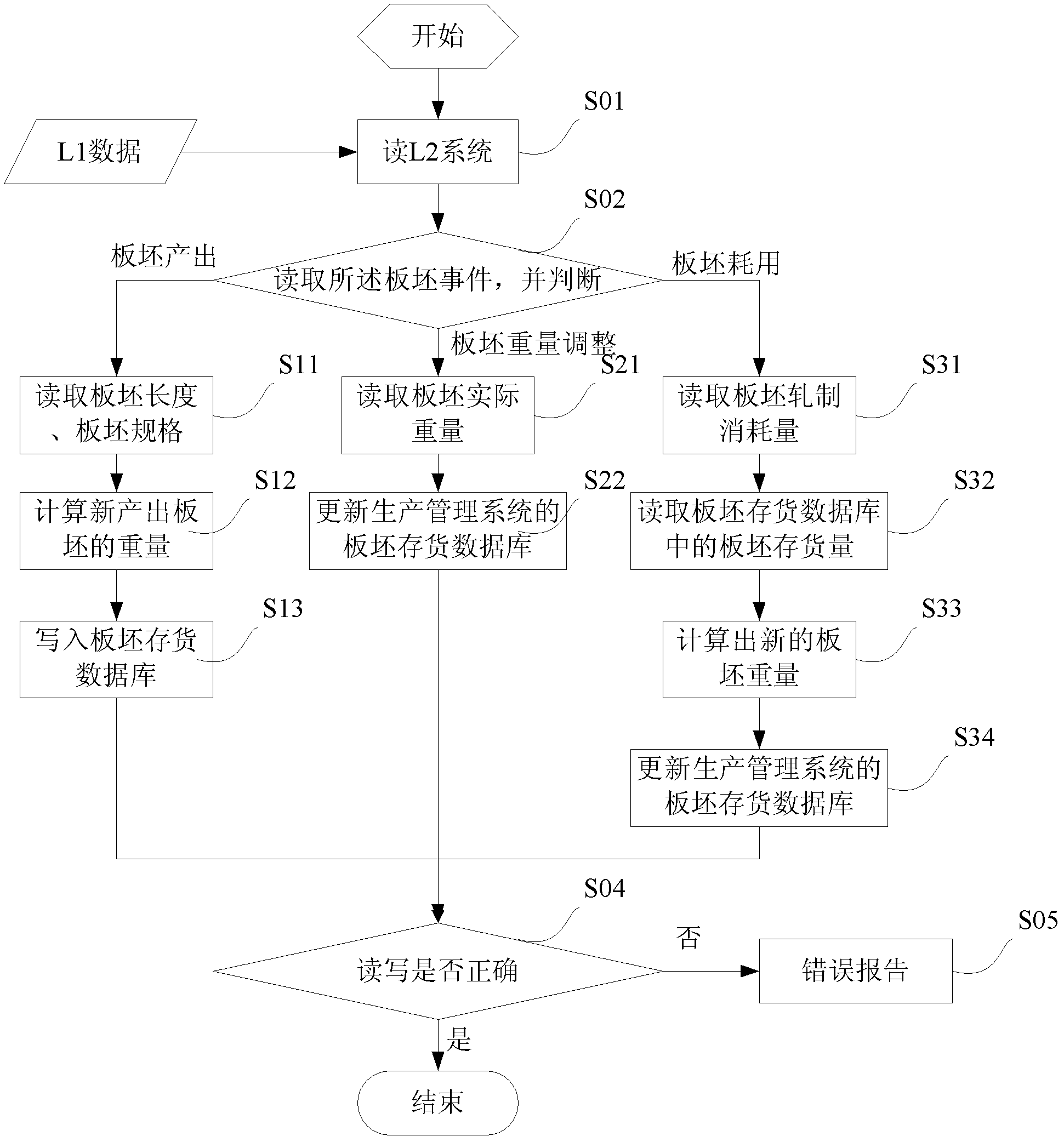

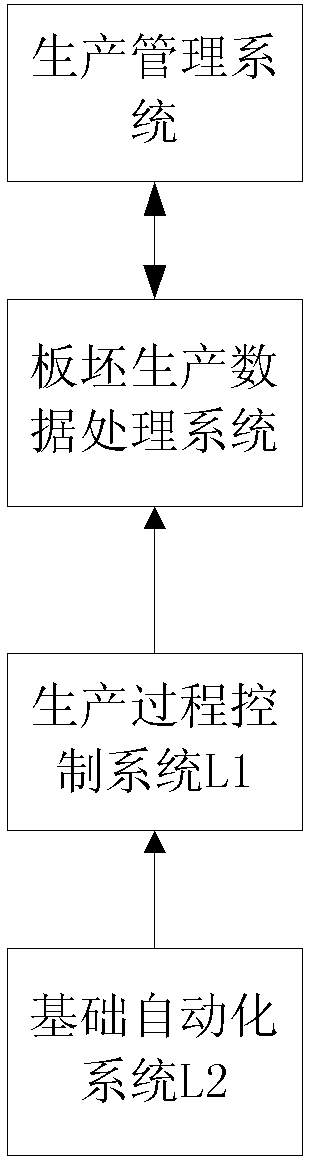

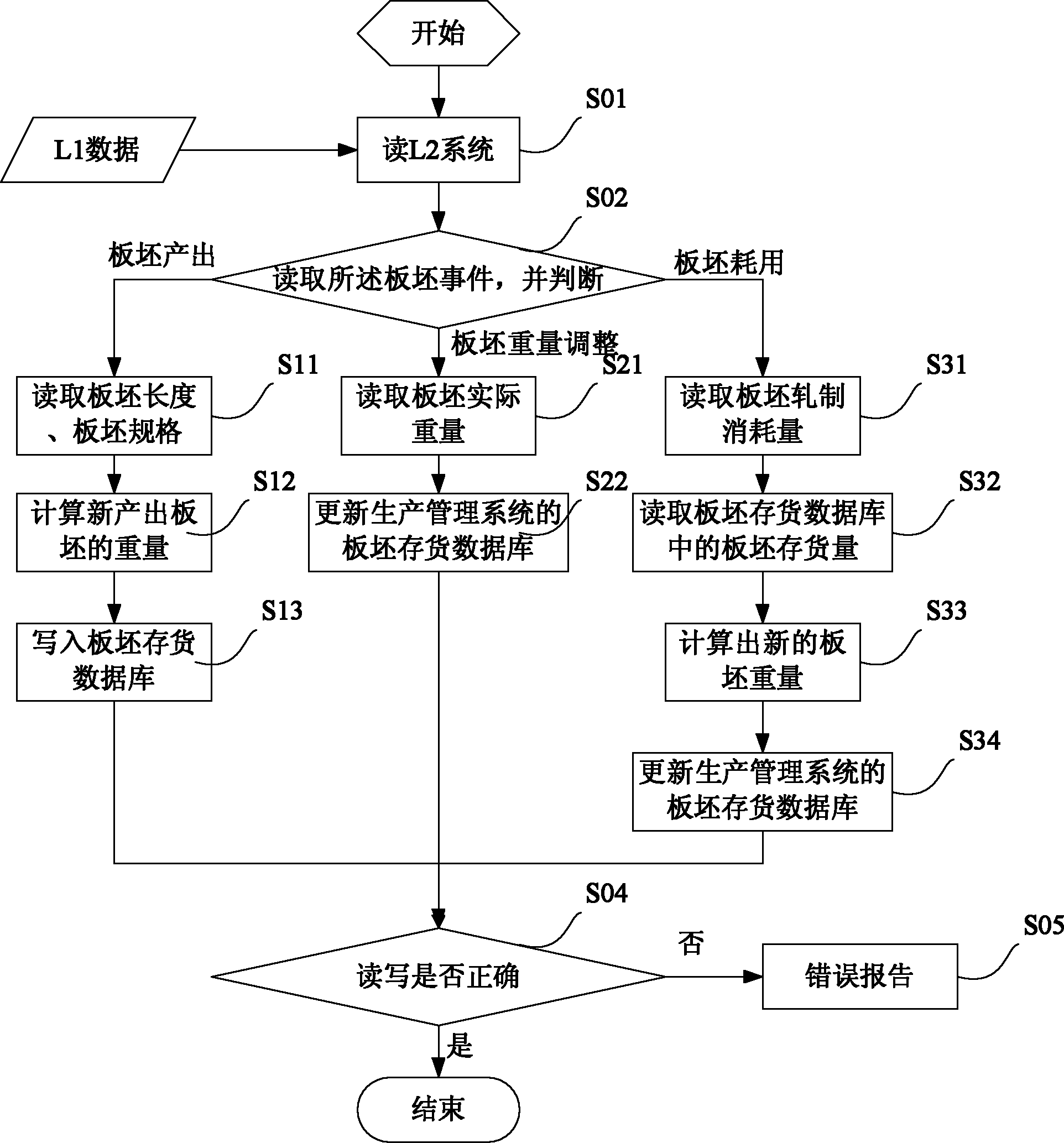

Slab production data processing method

InactiveCN102495900AConsistency is easyImprove production management efficiencyLogisticsSpecial data processing applicationsControl systemManagement efficiency

The invention discloses a slab production data processing method for realizing synchronous matching consistency of slab material flow and information flow. The method comprises the following steps of: acquiring slab information of a steel-making production process control system in real time, if the process is a slab production process, reading slab specification data, calculating weight of the produced slabs, and writing the weight data into a slab stock database of a production management system; if the process is a slab weight regulation process, reading the actual weight of the slabs, and updating the slab stock database with the read actual weight of the slabs; if the process is a slab consumption process, reading slab rolling consumption, and calculating new slab weight so as to update the slab stock database with the new slab weight. The method has the advantages of being easy to realize and convenient to maintain, and can be dynamically regulated. With the method, the consistency of the slab material flow information and the information is implemented, requirements of process flows are completely satisfied, management efficiency of slab production is improved, labor cost is reduced, and cost reduction and benefit increase are realized.

Owner:武钢集团有限公司

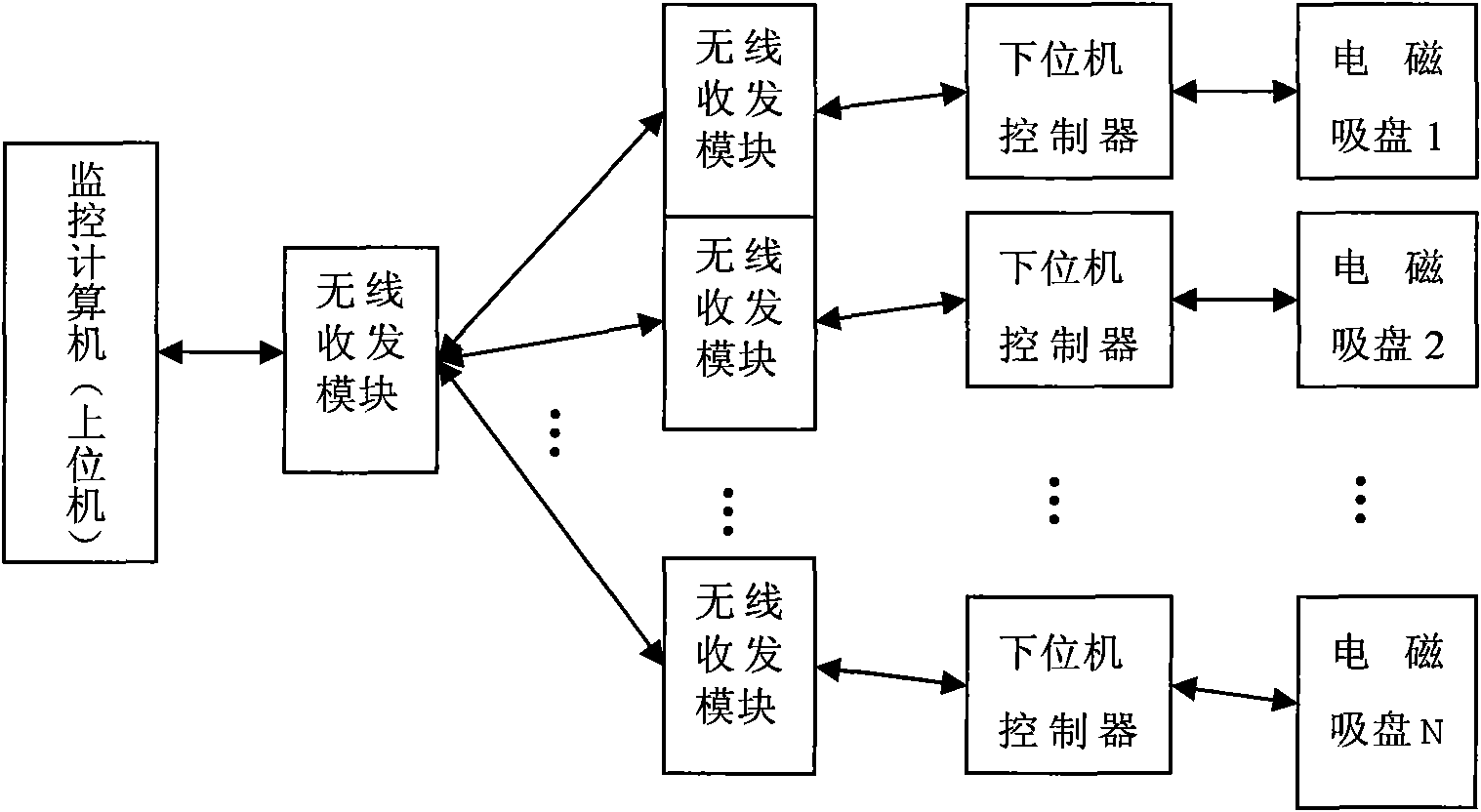

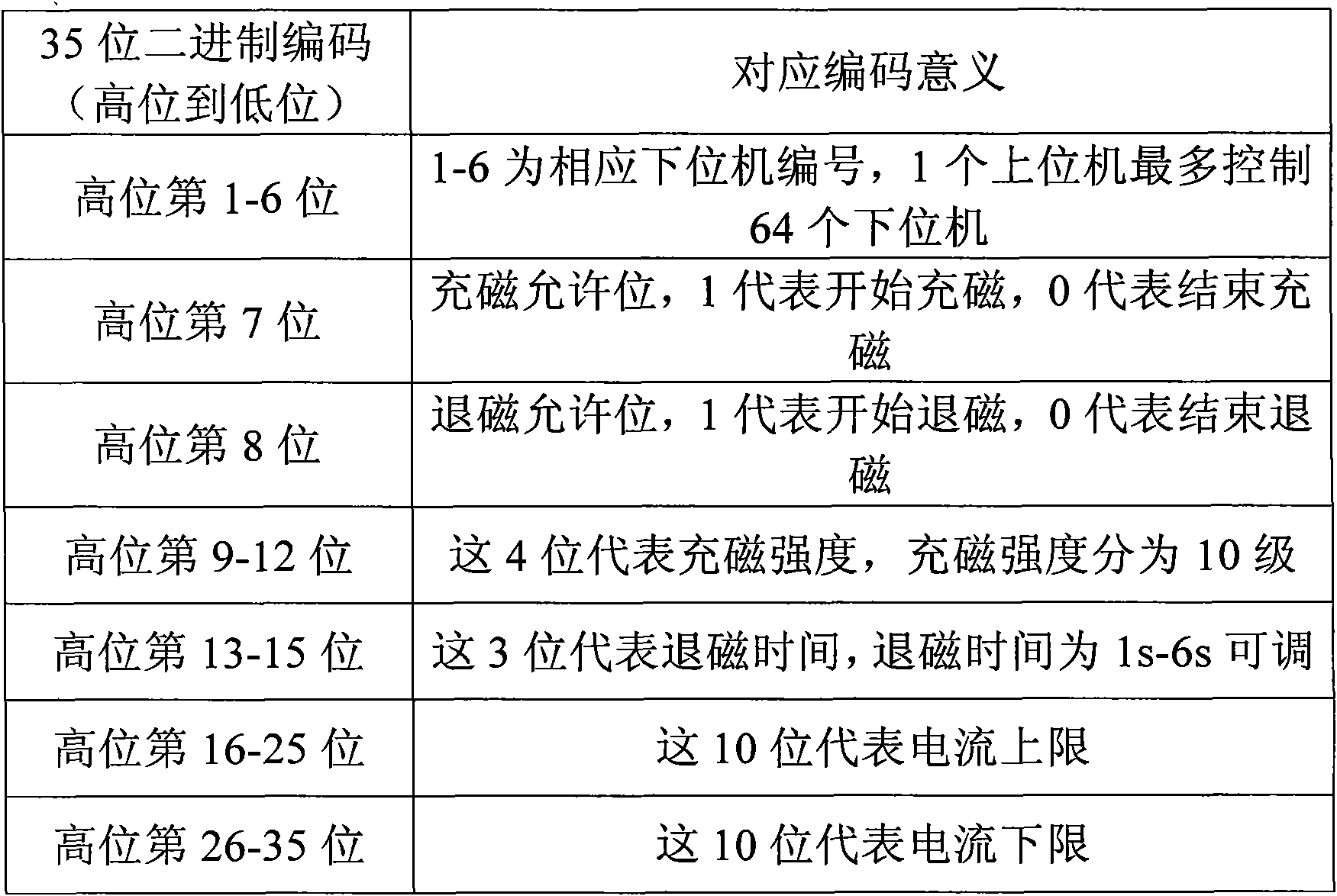

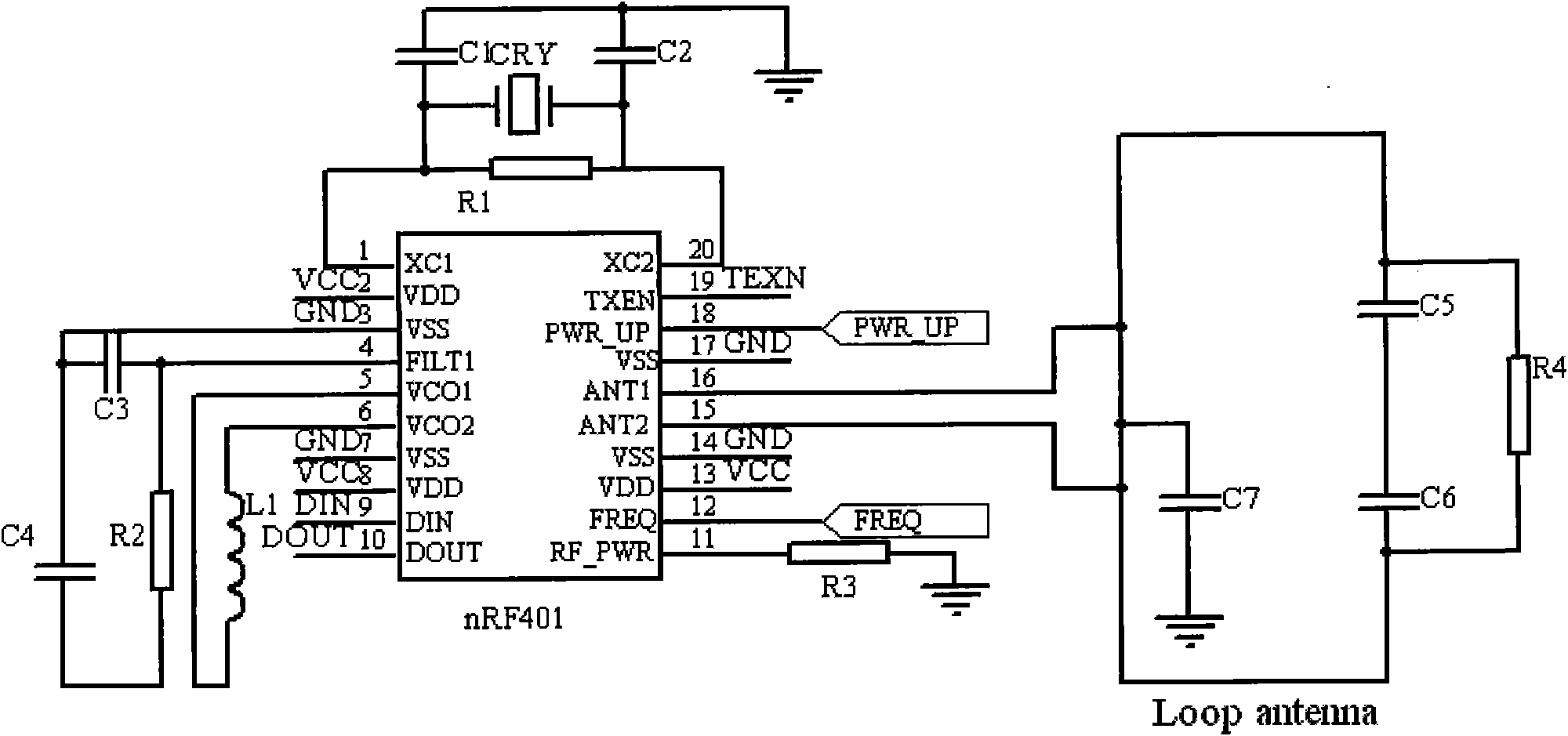

Embedded wireless intelligent electromagnetic chuck magnetizing and demagnetizing control system

InactiveCN101968647AReal-time detection and control of working statusImprove production management efficiencyTotal factory controlProgramme total factory controlEmbedded systemManagement system

The invention relates to an embedded wireless intelligent electromagnetic chuck magnetizing and demagnetizing control system which is an automatic management system of an electromagnetic chuck controller. The system comprises an upper computer and a lower computer, wherein the upper computer is a monitoring computer, the lower computer comprises an ARM (Advanced RISC Machine) controller connected with an electromagnetic chuck, and the monitoring computer and the ARM controller are both connected with a wireless transceiver module; the upper computer is used for setting the parameters of the electromagnetic chuck connected with the lower computer and simultaneously processing data fed back by the lower computer; and the lower computer is used for analyzing information received by the upper computer and comparing the information with codes of the lower computer per se, controlling the working of a magnetizing and demagnetizing circuit according to the received information if matching succeeds, and discarding the information and receiving the next piece of information again if the matching does not succeed. The system can be used for detecting and controlling the working states of multiple electromagnetic chucks in a workshop in real time and is simple and feasible to operate, the intelligence degree of a factory is increased so that production efficiency is obviously improved, and the system is applicable to the requirement of modern production.

Owner:JIANGNAN UNIV

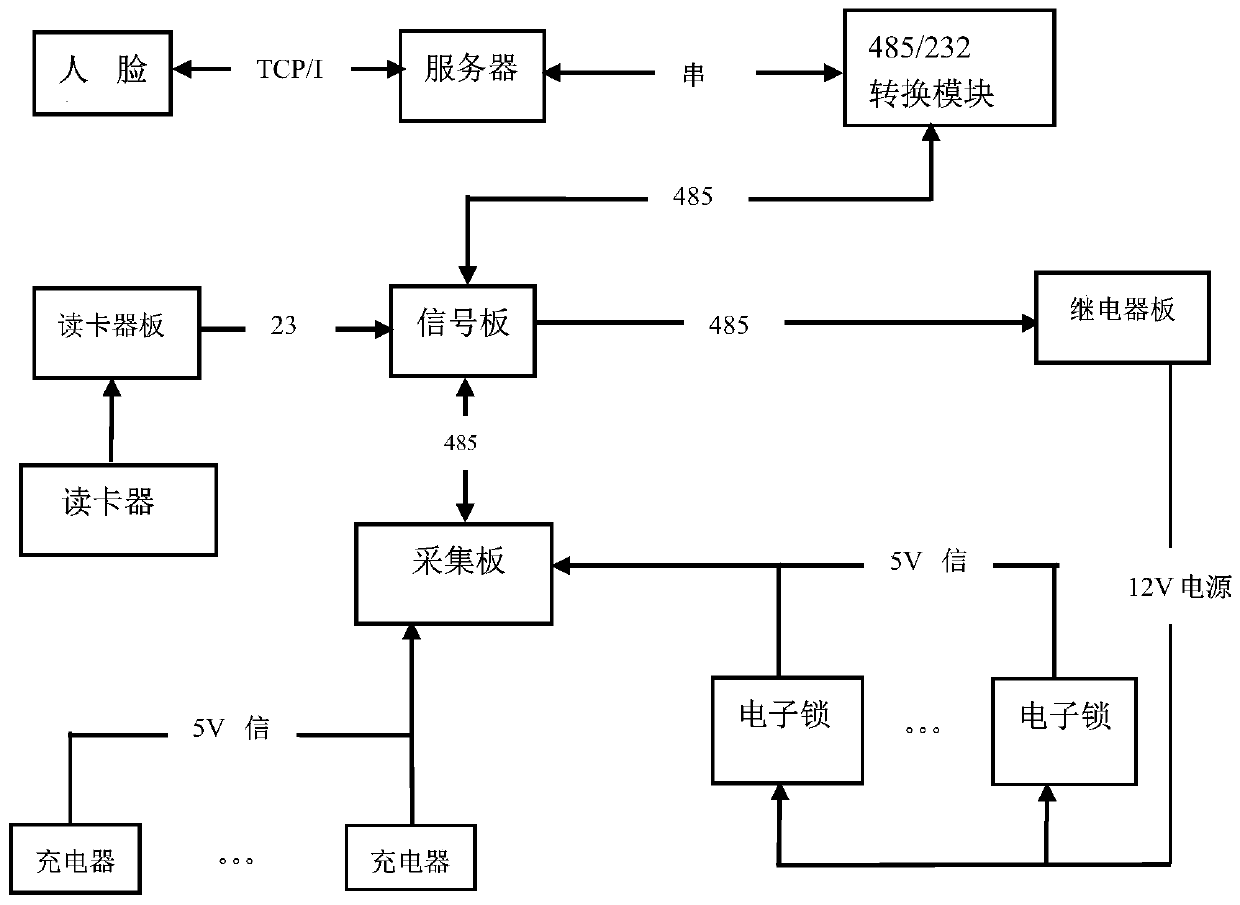

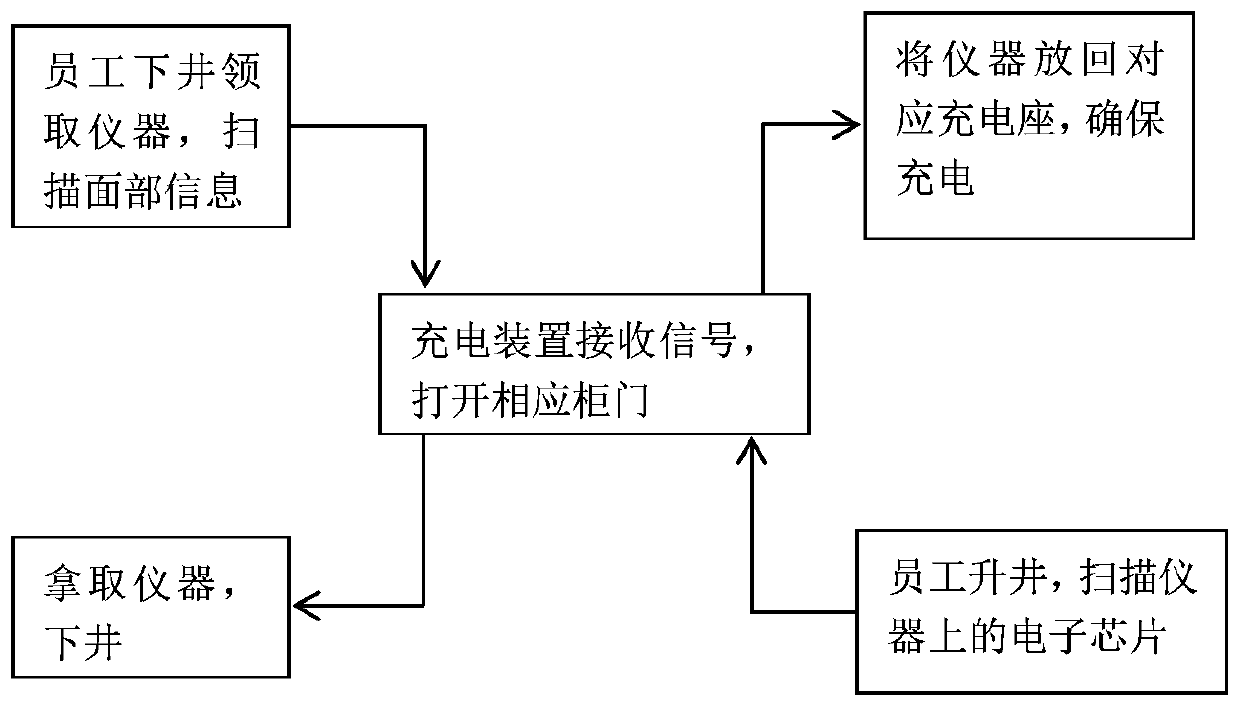

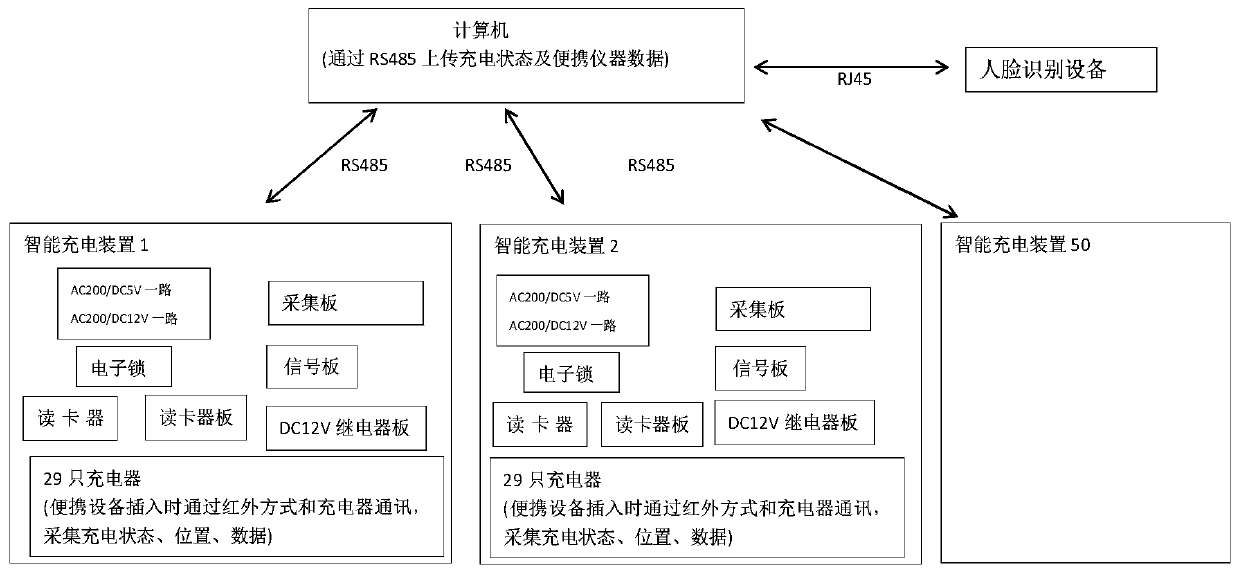

Intelligent portable instrument management system, apparatus and method

PendingCN110660175AAchieve distributionAchieve recyclingChecking time patrolsBatteries circuit arrangementsCollection analysisProcess engineering

The present invention discloses an intelligent portable instrument management system, apparatus and method, and relates to the technical field of mining equipment management systems. According to theintelligent portable instrument management system provided by the present invention, a face recognition function, an electronic tag recognition function, and a portable device charging function are integrated, detection and uploading of data collected by a portable instrument, and batteries and other instrument states can be realized, collection and analysis of methane, carbon monoxide and other gases at corresponding locations in coal mines can be realized, unmanned distribution of portable instruments for operators, personnel attendance, and personnel trajectory tracking downhole can be realized, and a fixed-point punch-in function can be supported.

Owner:YANGZHONG SOUTH MINE ELECTRICAL

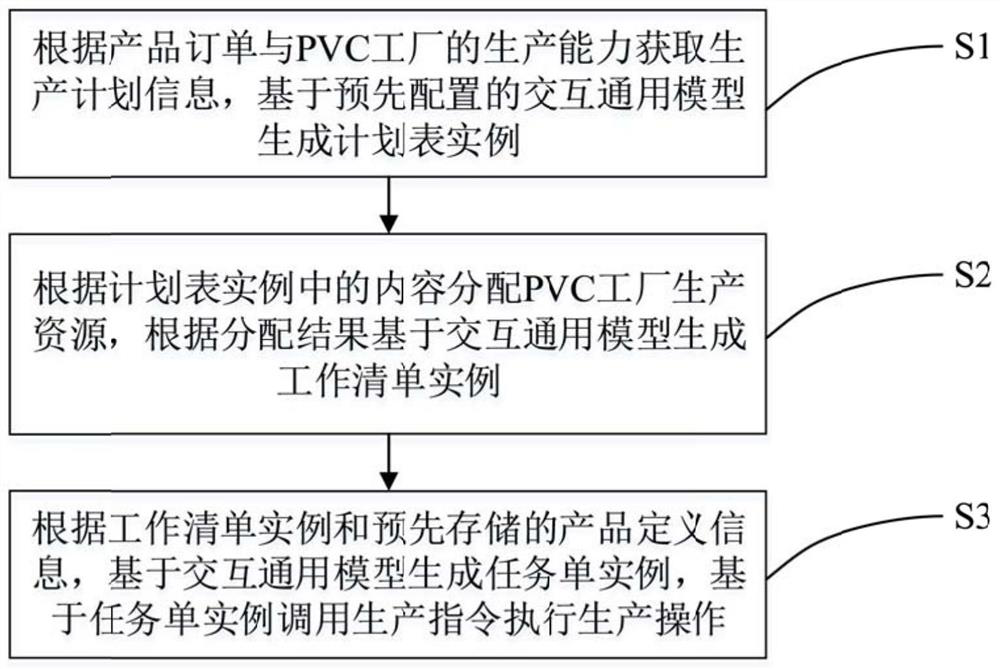

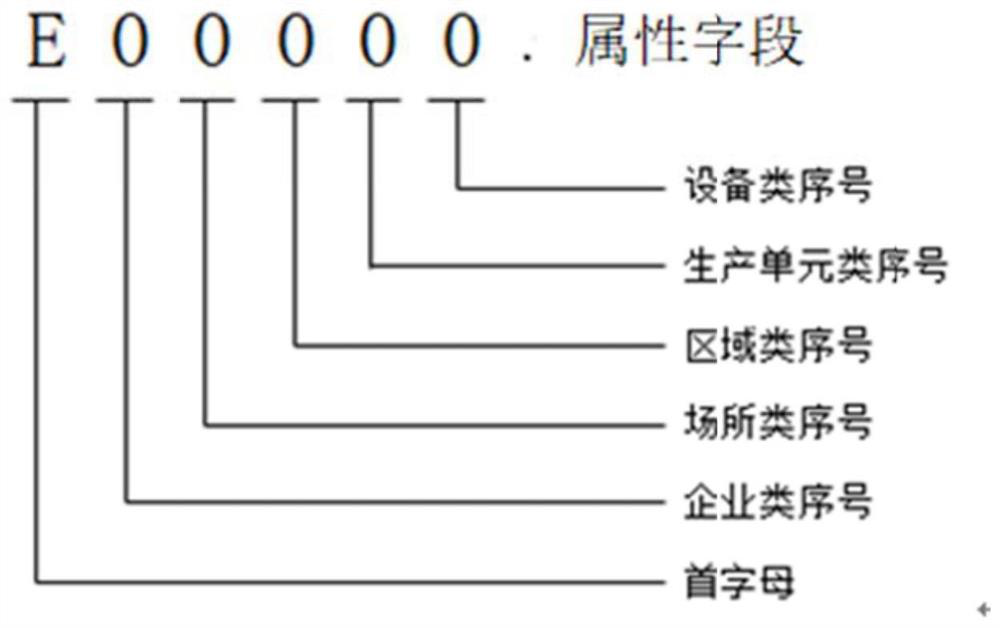

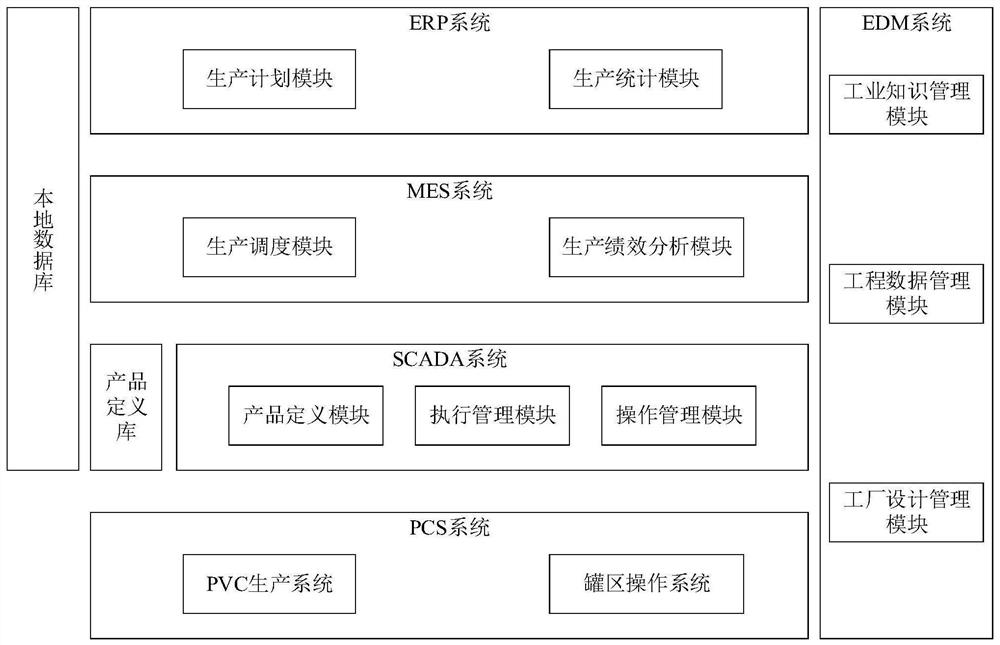

Interaction method and device for PVC factory integrated management system

PendingCN111967706AImprove compatibilityRealize integrated managementDigital data information retrievalOffice automationComputer compatibilityManagement efficiency

The invention provides an interaction method for PVC factory integrated management system, and the method comprises the steps: obtaining production plan information according to a product order and the production capacity of the PVC factory, and generating a plan table instance based on a pre-configured interaction universal model; allocating PVC factory production resources according to the content in the schedule instance, and generating a work list instance based on an interactive general model according to an allocation result; and generating a task list instance based on the interactive universal model according to the work list instance and pre-stored product definition information, and calling a production instruction to execute production operation based on the task list instance.According to the invention, the production schedule and the work list are respectively generated through the pre-configured interactive universal model, and the interactive model has universality, sothat the models and data definitions among different systems are unified, the data compatibility is improved, the integrated management of order management and production control in the PVC factory isrealized, and the production management efficiency is improved.

Owner:ZHEJIANG SUPCON TECH +1

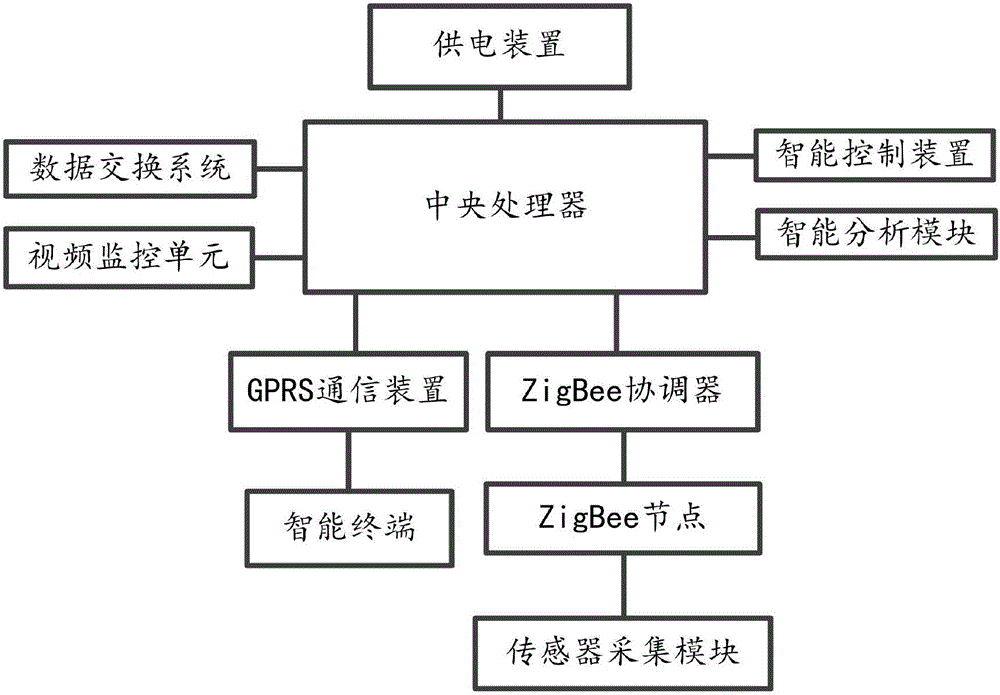

Agricultural informatization management system based on Internet of Things

InactiveCN106774558AReal-time acquisitionReal time monitoringSimultaneous control of multiple variablesVideo monitoringInformatization

The invention discloses an agricultural informatization management system based on an Internet of Things. The agricultural informatization management system comprises a central processing unit, a power supply unit, a ZigBee coordinator, a plurality of ZigBee nodes, a sensor acquisition module, a video monitoring unit, a GPRS (General Packet Radio Service) communication device, an intelligent terminal, an intelligent control device, a data exchange system and an intelligent analysis module, wherein the central processing unit is electrically connected with the video monitoring unit, the GPRS communication device, the ZigBee coordinator, the intelligent control device, the data exchange system and the intelligent analysis module; the intelligent terminal is electrically connected with the central processing unit through the GPRS communication device; the ZigBee coordinator and the plurality of ZigBee nodes form a ZigBee network; the sensor acquisition module consists of the plurality of ZigBee nodes. The system disclosed by the invention is capable of realizing scientific, efficient and high-utilization-rate sustainable development and realizing functions of real-time data acquisition, monitoring, automatic control, alarm and the like.

Owner:GUANGZHOU KAIYAO ASSET MANAGEMENT CO LTD

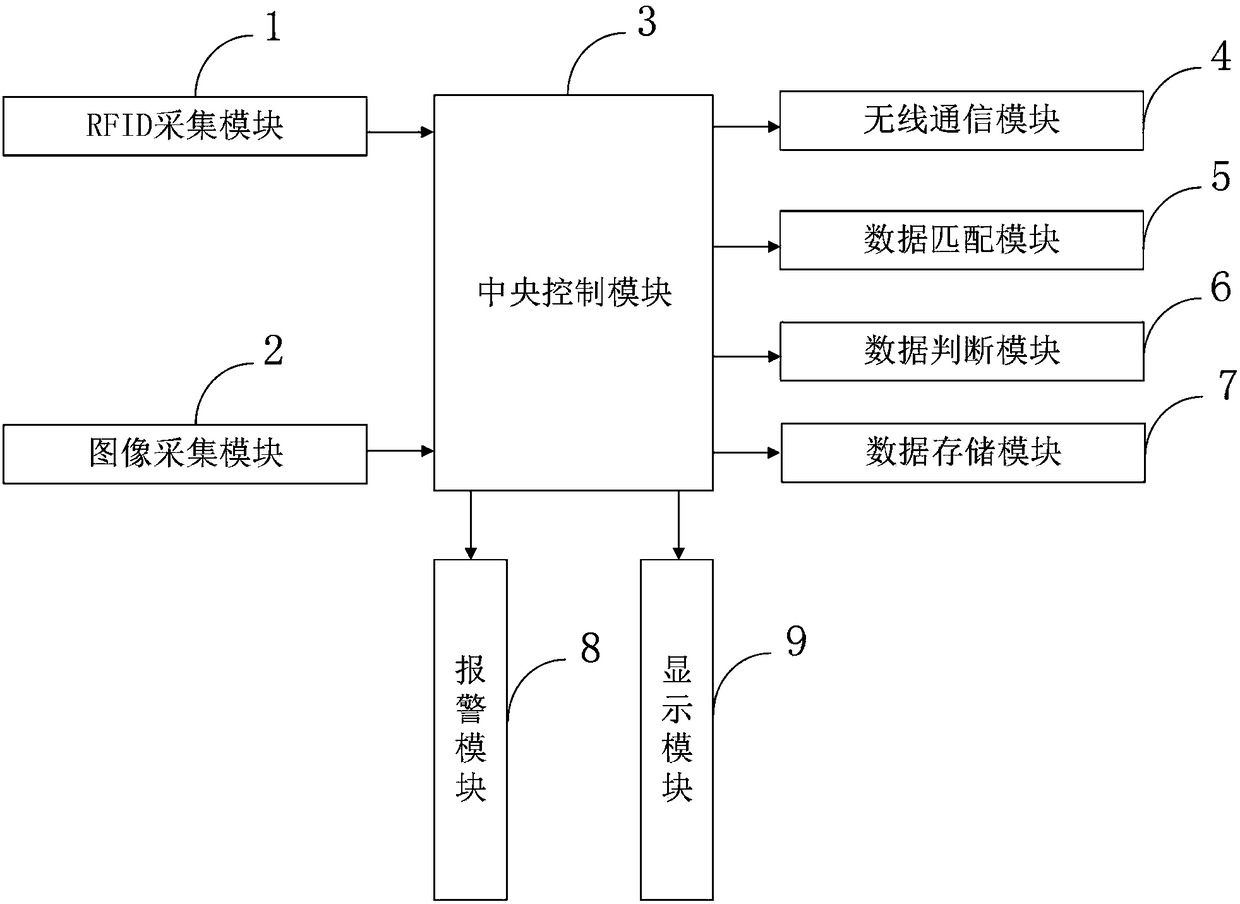

Production process information collection system for machine manufacturing workshop based on RFID

InactiveCN108268018AGuarantee authenticityReduce the burden onTotal factory controlProgramme total factory controlData matchingCollection system

The invention belongs to the technical field of machine manufacturing, and discloses a production process information collection system for a machine manufacturing workshop based on RFID. The system comprises an RFID collecting module, an image collecting module, a central control module, a wireless communication module, a data matching module, a data judging module, a data storage module, an alarm module, and a display module. Through the RFID collecting module and the data judging module, the system does not need to carry out the manual statistical operation of the produced workpieces, number and time, thereby greatly reducing the monitoring burden of a workshop group. Meanwhile, the image collection module collects an image comprising the workpiece state information of the machine manufacturing workshop and the state information of equipment, does not need manual statistics and table filling, guarantees the authenticity of data, greatly reduces the cost, and improves the productionmanagement efficiency.

Owner:WUHAN POLYTECHNIC UNIVERSITY

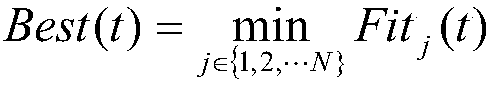

Automatic monitoring soilless culture device

InactiveCN103503758AReduce difficultyEasy to controlAgriculture gas emission reductionCultivating equipmentsSolenoid valveCulture environment

The invention discloses an automatic monitoring soilless culture device which comprises a trough body, a U-shaped drain pipe, a liquid level meter, a liquid inlet pipe, a solenoid valve, a PLC device and an alerter connected with the PLC device. The water inlet end of the U-shaped drain pipe is arranged on the bottom inside the trough body, the water outlet end of the U-shaped drain pipe is arranged outside the trough body, the height of the water outlet with the solenoid valve is smaller than that of the water inlet end, the liquid level meter is arranged in the trough body and is connected with the signal input end of the PLC device, and the liquid inlet pipe is arranged on the trough body and is communicated with the inner portion of the trough body. The automatic monitoring soilless culture device achieves automatic monitoring and alarm on culture media and culture environments of a soilless culture system. The automatic monitoring soilless culture device achieves the automatic monitoring and alarm on the content of culture solutions in a culture process, reduces difficulty of soilless culture, and improves culture efficiency.

Owner:单成伟

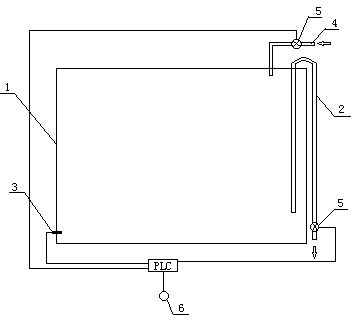

Forest tree planting scheme based on Internet of Things

InactiveCN103947504AImprove production management efficiencyImprove sales efficiencyMeasurement devicesForestryThe InternetManagement efficiency

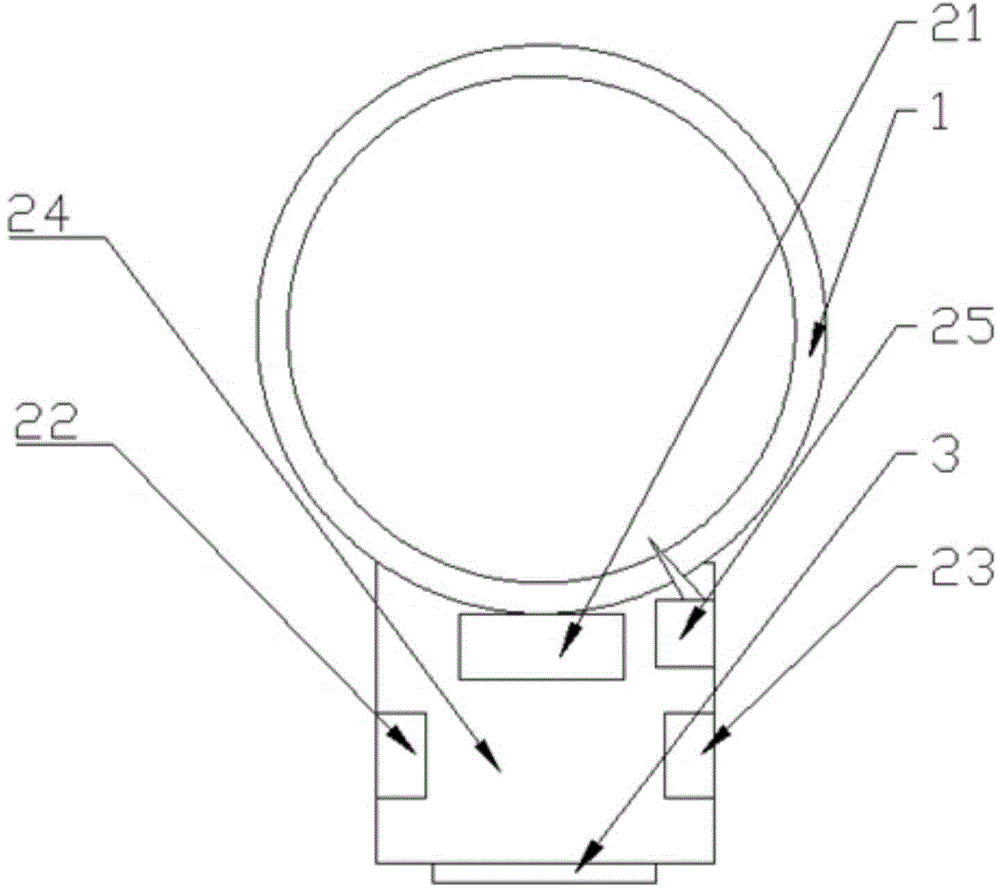

The invention provides a forest tree planting scheme based on an Internet of Things. Devices for the forest tree planting scheme based on the Internet of Things comprise a fixing ring, a recorder and a code bar, wherein the fixing ring is sheathed on a tree, the recorder is fixedly arranged on the fixing ring and the code bar is attached onto the recorder. The forest tree planting scheme based on the Internet of Things has the characteristics that the specific growth situation of each tree can be known, the production management efficiency is improved, the information of each tree can be disclosed through a network and the selling efficiency is improved.

Owner:天津华瑞聚源金属制品有限公司

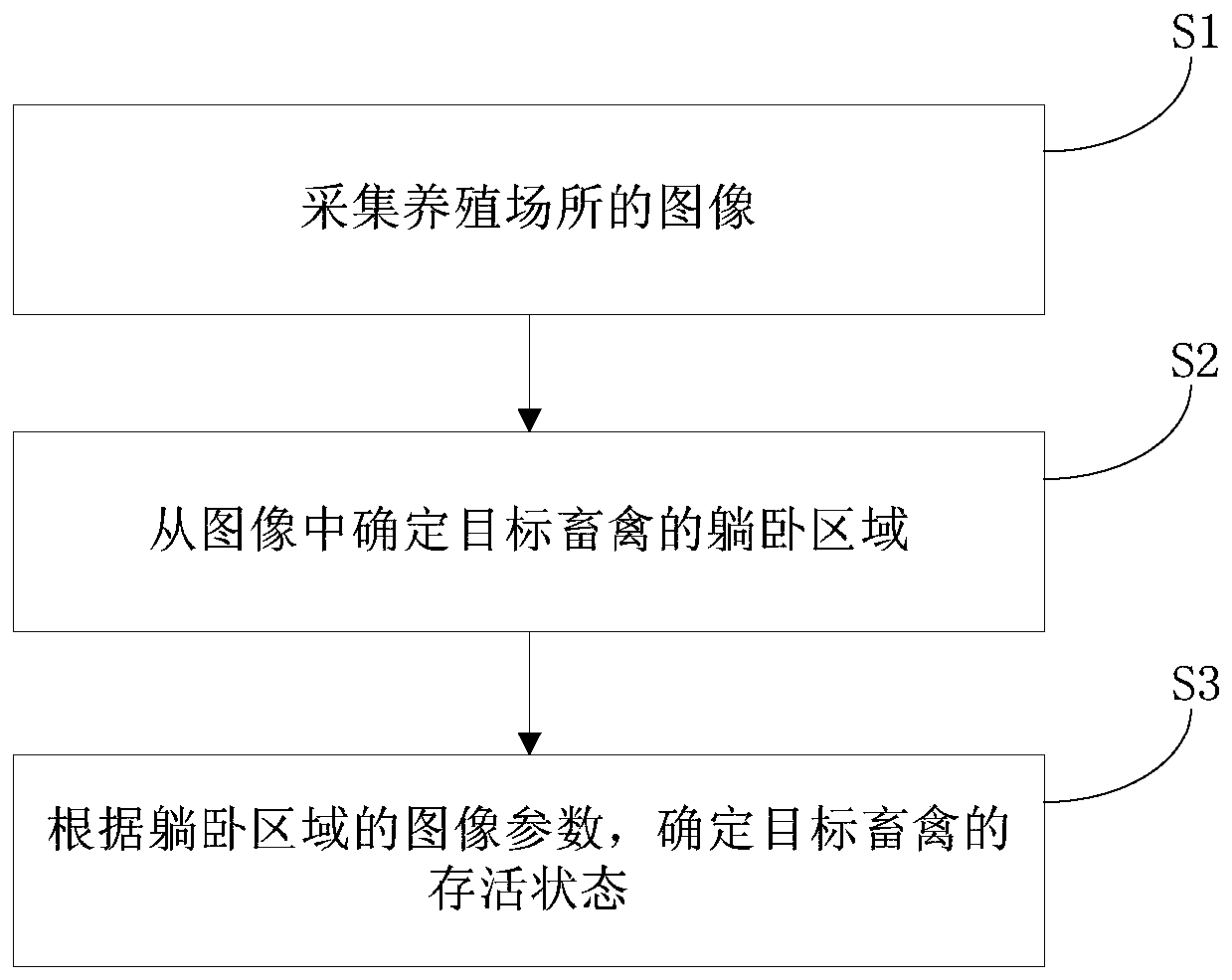

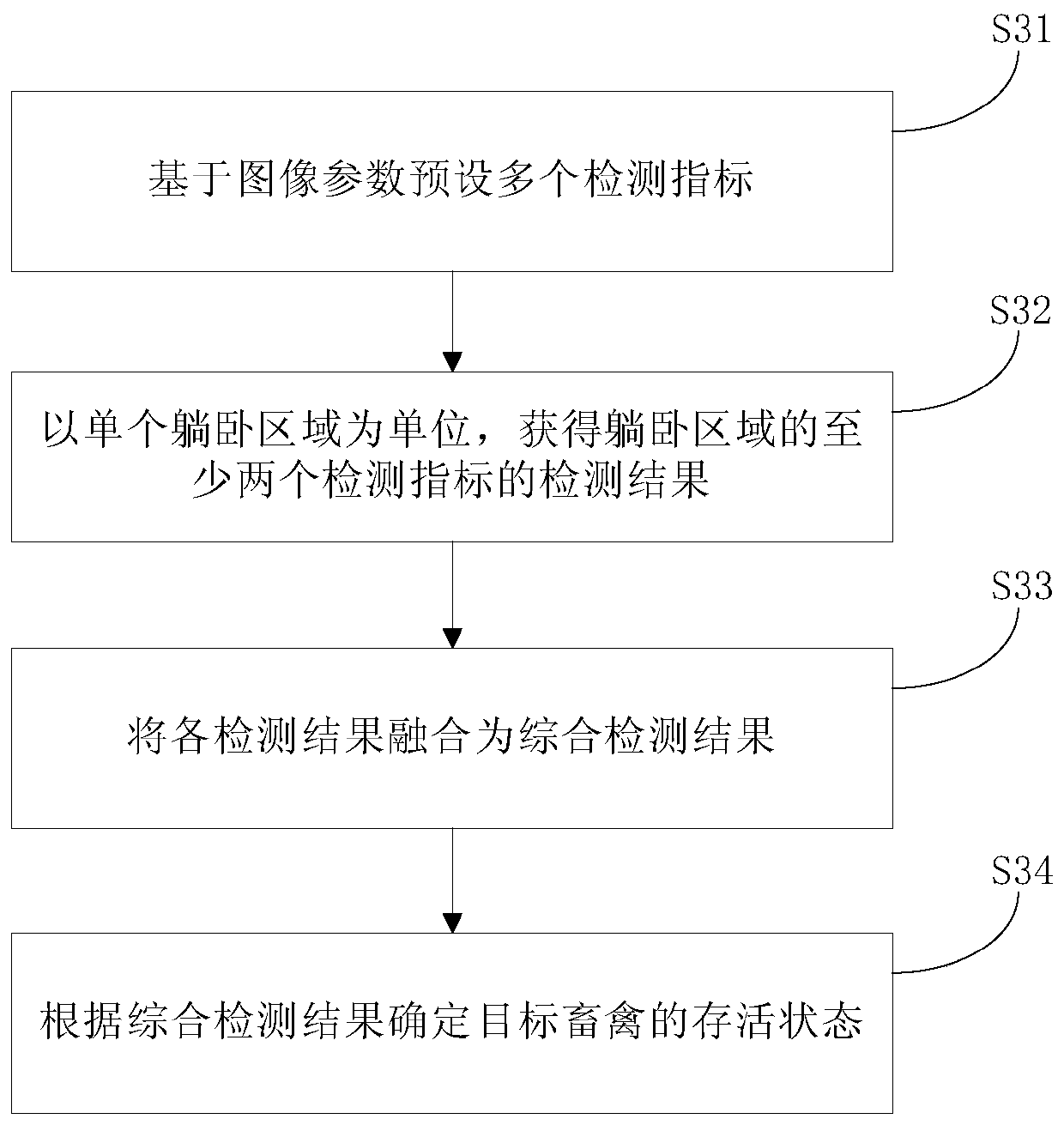

Livestock and poultry survival detection method, device, equipment and computer program product

PendingCN110287902AReduce manpower consumptionImprove efficiencyCharacter and pattern recognitionSensing radiation from moving bodiesManagement efficiencyLivestock

The invention discloses a livestock and poultry survival detection method, device and equipment and a computer program product. The method comprises the steps of collecting an image of a breeding site; determining a lying area of the target livestock and poultry from the image; and determining the survival state of the target livestock and poultry according to the image parameters of the lying area. According to the invention, the image processing technology and the data analysis technology are combined; the livestock and poultry survival state can be analyzed and managed, compared with a traditional manual inspection method, the labor consumption is greatly reduced, the production management efficiency is improved, dead livestock and poultry in group breeding can be timely and accurately detected, detection and intelligent breeding of sick and weak livestock and poultry are facilitated, and economic loss caused by disease transmission is prevented.

Owner:洛阳语音云创新研究院

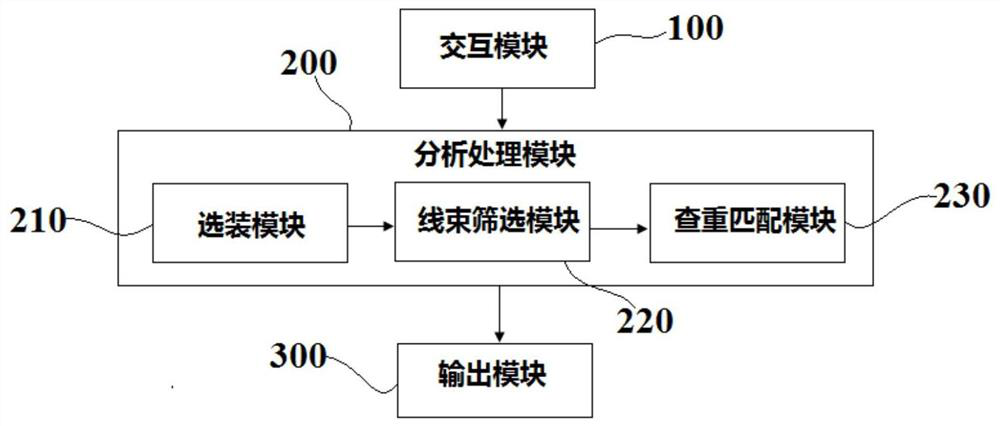

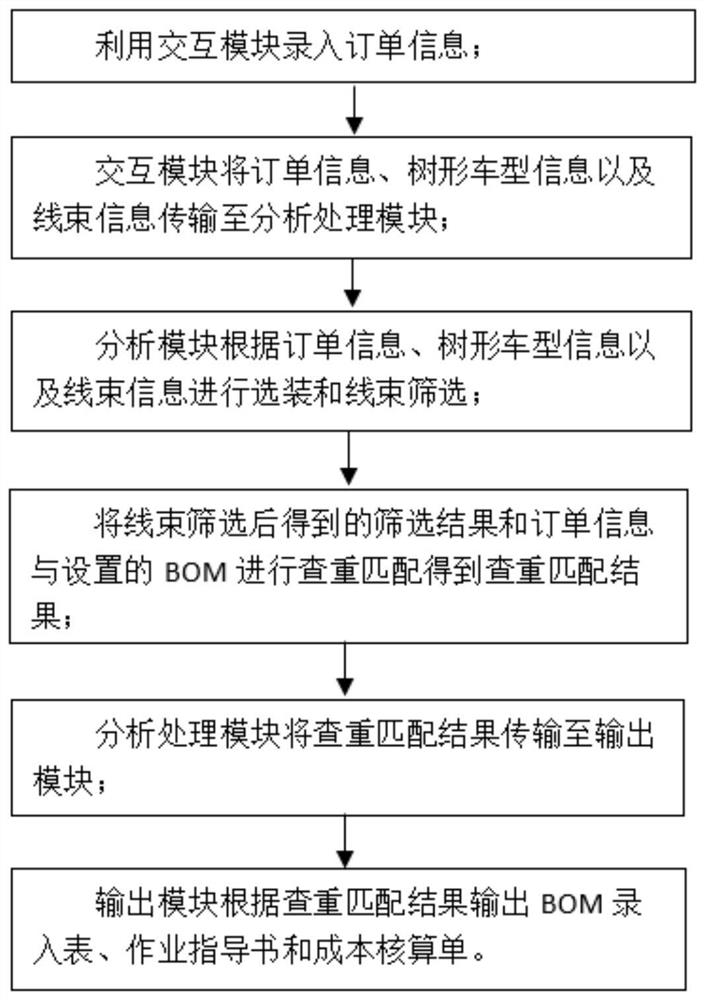

Intelligent optional system and method for automobile parts

PendingCN112132699ARealize automatic selectionImprove selection efficiencyCharacter and pattern recognitionOther databases indexingComputer scienceScreening Result

The invention discloses an intelligent optional system and method for automobile parts, and belongs to the technical field of automobile manufacturing. The system comprises an interaction module, an analysis processing module and an output module, wherein the interaction module and the output module are respectively connected with the analysis processing module. The method comprises the steps thatorder information is input through an interaction module; the analysis module performs selection and harness screening according to the order information, the tree-shaped vehicle model information and the harness information, and performs duplicate checking matching on a screening result and the order information obtained after harness screening and a set BOM; and the analysis processing module transmits the duplicate checking matching result to the output module, and the output module outputs a BOM entry table, an operation instruction book and a cost accounting list according to the duplicate checking matching result. The defects that in the prior art, the efficiency of manually selecting and installing the automobile parts is low, and data missing is likely to be caused are overcome, automatic selecting and installing can be achieved, and therefore the production efficiency is improved, the selecting and installing process can be tracked and traced, and the problem of data missingis avoided.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

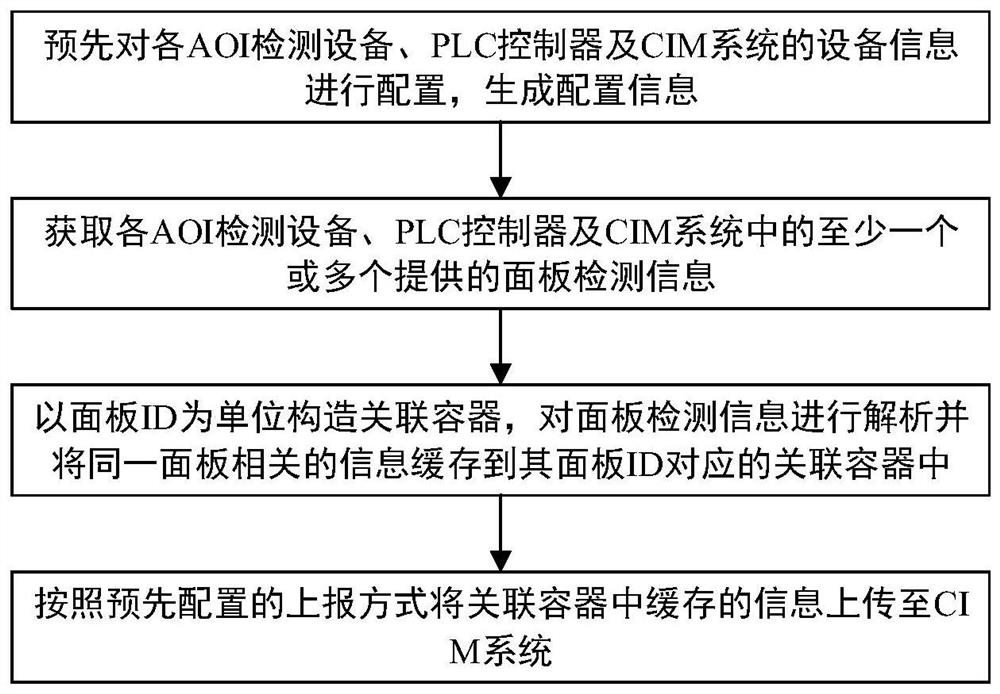

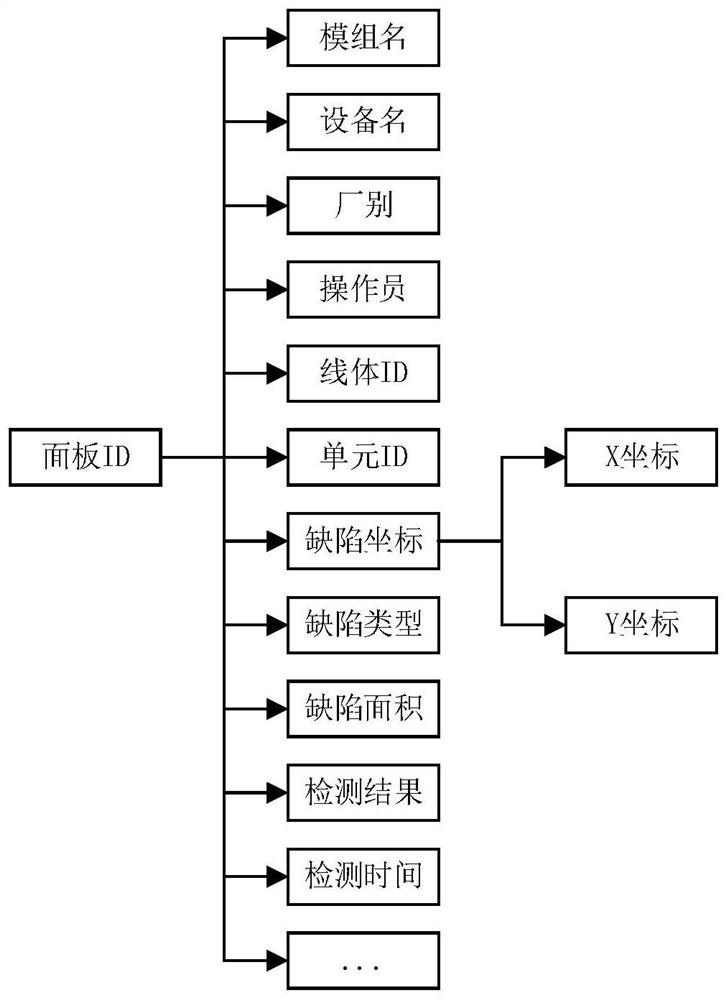

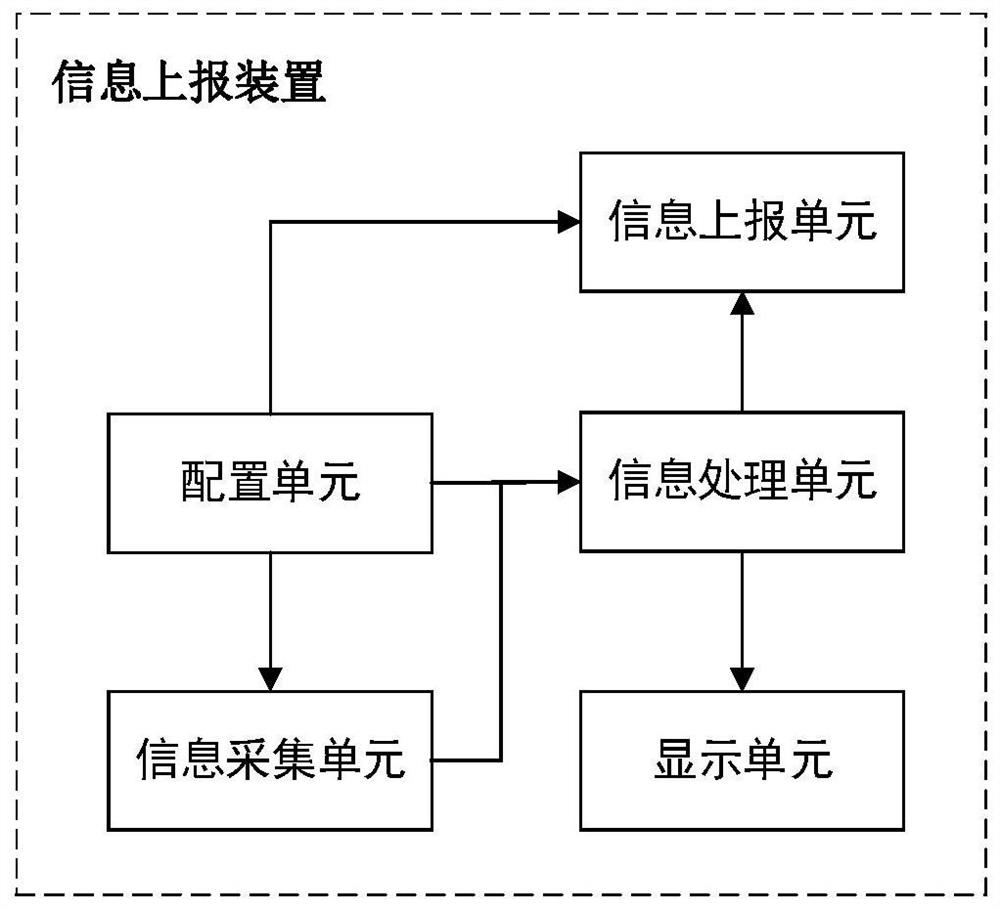

Information reporting method, device, equipment and production control system

InactiveCN111624970AQuick searchImprove efficiencyData processing applicationsRelational databasesControl systemEngineering

The invention discloses an information reporting method, device and equipment and a production control system, and relates to the technical field of display panel detection. The information reportingmethod comprises the following steps: acquiring panel detection information provided by at least one or more of each detection device, a PLC controller and a CIM system; constructing an associated container by taking the panel ID as a unit, analyzing the panel detection information, and caching the information related to the same panel into the associated container corresponding to the panel ID; uploading the information cached in the associated container to a CIM system according to a pre-configured reporting mode. According to the invention, the scattered detection information of each panelat different detection sites is integrated and associated, so that a user can quickly find out defect reasons and perform production management on an assembly line.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com