Production process information collection system for machine manufacturing workshop based on RFID

A production process and information collection technology, which is applied in general control systems, control/regulation systems, program control, etc., can solve the problems of assembly sequence combination explosion, data reliability decline, and infeasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0112] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0113] It takes a lot of time to collect accurate actual production information for existing machinery manufacturing and processing. In particular, traditional processing equipment generally does not have data acquisition devices, which restricts the improvement of production management level of similar enterprises and leads to low production efficiency; at the same time If the production status information cannot be collected accurately and effectively, the closed-loop control of the entire production process cannot be realized, which affects the improvement of production efficiency and restricts the management level of the enterprise.

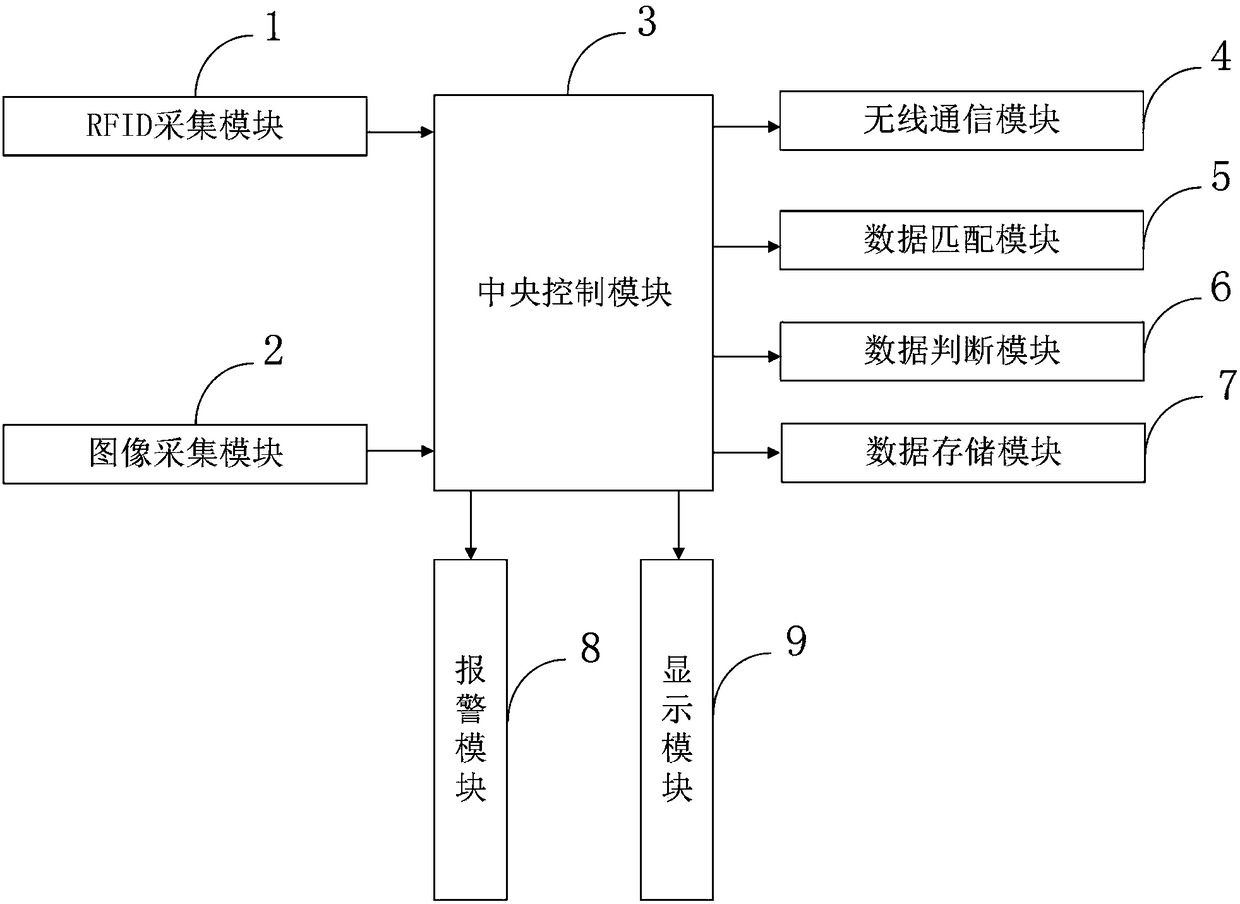

[0114] like figure 1 As shown, the RFID-based machine manufacturing workshop production process information collection sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com