Automobile connector PIN needle detecting machine and detecting method thereof

A technology of testing machines and connectors, which is applied in the direction of measuring electricity, measuring devices, welding equipment, etc., and can solve problems such as unstable product testing quality, low testing accuracy, and slow measuring speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

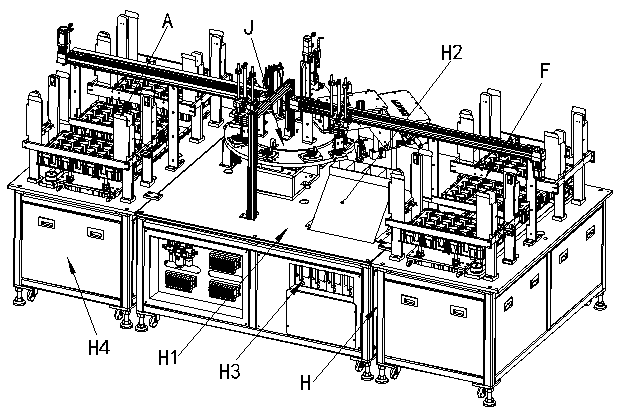

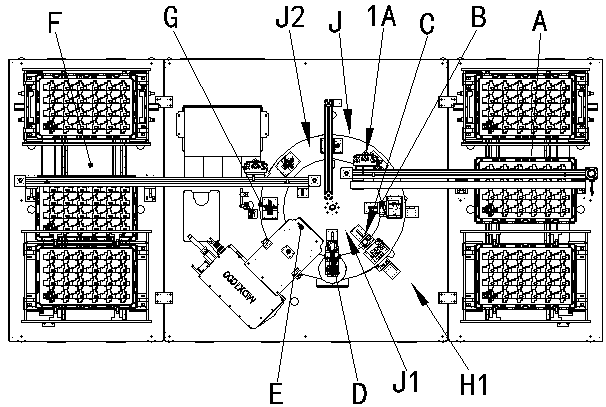

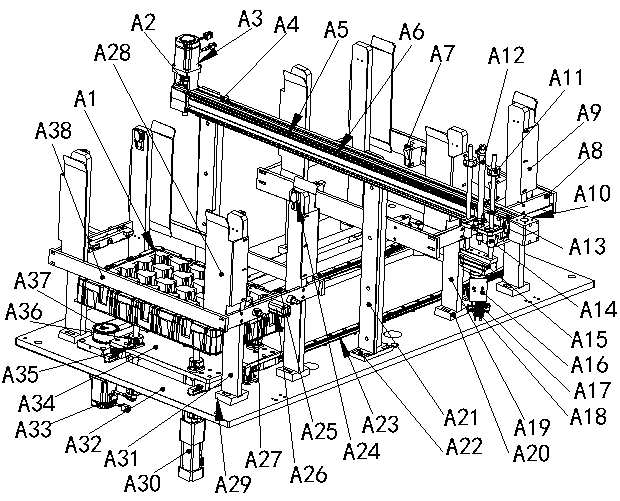

[0035] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 In the shown embodiment, a kind of automobile connector PIN needle detection machine, comprises detection frame H, also includes the feeding station A that is located on the detection frame H, indexing turntable J, electrical characteristic detection station B, High and low needle detection station C, image detection station D, laser marking station E, code scanning station G and output station F, feeding station A, electrical characteristic detection station B, high and low needle detection station C, Image detection station D, laser marking station E, code scanning station G and discharge station F are respectively set on the indexing turntable J at the corresponding loading station, electrical inspection station, high and low needle inspection station, At the image detection station, laser marking station, code scanning station and discharge station; the in...

Embodiment

[0044] A kind of detection method of automobile connector PIN needle detection machine, comprises the following steps

[0045] a. Power-on steps for normal power-on self-test operation;

[0046] b. the material to be inspected is placed in the material tray in the feeding station described in embodiment 1, the material tray is transported to the feeding conveyor arm assembly through the material tray conveying bottom rail assembly, and the feeding clamp in the feeding conveyor arm assembly The claw gripper picks up the material and transports it to the indexing turntable, and the material on the indexing turntable is sequentially fed into the feeding step;

[0047] c. The electrical characteristic detection steps of the electrical characteristic detection station of the electrical characteristic detection station described in embodiment 1 are used on the electrical detection station of the indexing turntable for the material to be inspected;

[0048] d. The high and low needl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com