Information reporting method, device, equipment and production control system

A technology for information reporting and production control, applied in general control systems, control/regulation systems, manufacturing computing systems, etc., can solve the problem of inability to quickly obtain panel full-process inspection data when needed, inability to quickly trace inspection records, and unrecorded panels. Detect information and other problems to facilitate the tracing of the cause of the problem, improve the efficiency and automation level, and facilitate the search for the cause.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

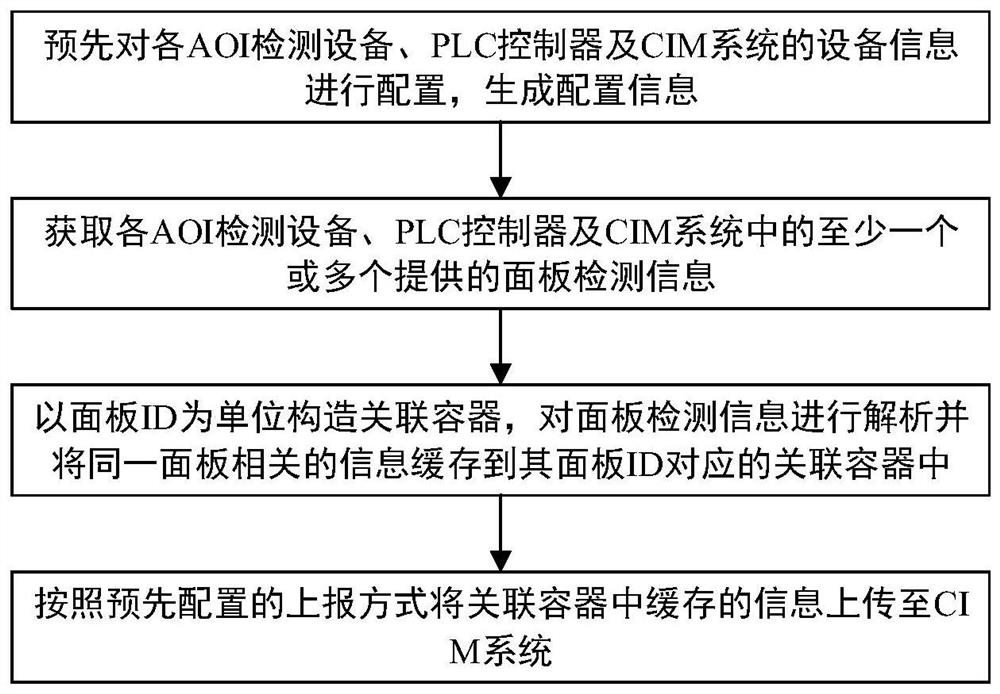

[0042] figure 1 is a flow chart of an information reporting method provided in this embodiment, see figure 1 As shown, the method mainly includes the following steps:

[0043] S1: Configure the equipment information of each AOI testing equipment, PLC controller and CIM system in advance, and generate configuration information;

[0044] For each AOI detection equipment and PLC controller, the configuration information includes but not limited to the IP address, port number and shared directory of the equipment; the shared directory is used to store the panel detection information generated by the AOI detection equipment; for the CIM system, the configuration The information includes but is not limited to the reporting method required by the CIM system, the IP address, port, device ID, and line ID of the CIM system.

[0045]In this embodiment, the AOI detection equipment is taken as an example for illustration, but it is not limited to the AOI detection equipment, and can also...

Embodiment 2

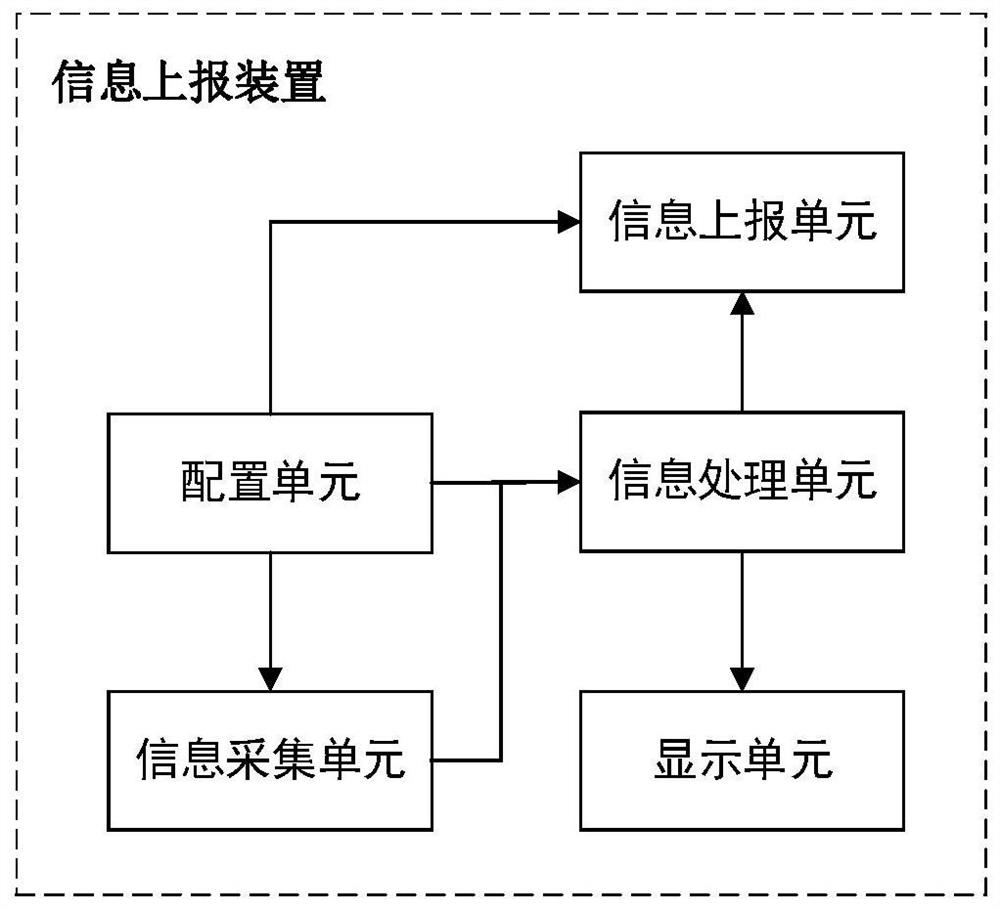

[0064] This embodiment provides an information reporting device, which is used to implement the information reporting method given in the embodiment; the device can be realized by software and / or hardware, and can be integrated on the information reporting device; image 3 It is a logical block diagram of the information reporting device provided by this embodiment, see image 3 , the device includes a configuration unit, an information collection unit, an information processing unit, and an information reporting unit;

[0065] The configuration unit is used to generate the configuration information of each AOI detection equipment, PLC controller and CIM system that communicate and interact with the information reporting device; in this embodiment, the configuration unit includes a first configuration module and a second configuration module; wherein,

[0066] The first configuration module is used to configure the equipment information of the AOI detection equipment that comm...

Embodiment 3

[0085] This embodiment also provides an information reporting device, which includes at least one processor and at least one memory, wherein a computer program is stored in the memory, and when the computer program is executed by the processor, the processor executes the process described in Embodiment 1. For the steps of the information reporting method, refer to Embodiment 1 for specific steps, and do not repeat them here; in this embodiment, the types of processors and memories are not specifically limited, for example: the processor can be a microprocessor, a digital information processor, an on-chip Programmable logic system, etc.; memory can be volatile memory, non-volatile memory or their combination, etc.

[0086] The information reporting device can also communicate with one or more external devices (such as a keyboard, a pointing terminal, a display, etc.), and can also communicate with one or more terminals that allow the user to interact with the information reporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com