Slab production data processing method

A technology of data processing and production management system, which is applied in the field of slab production data processing to achieve the effects of easy maintenance, improved management efficiency and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

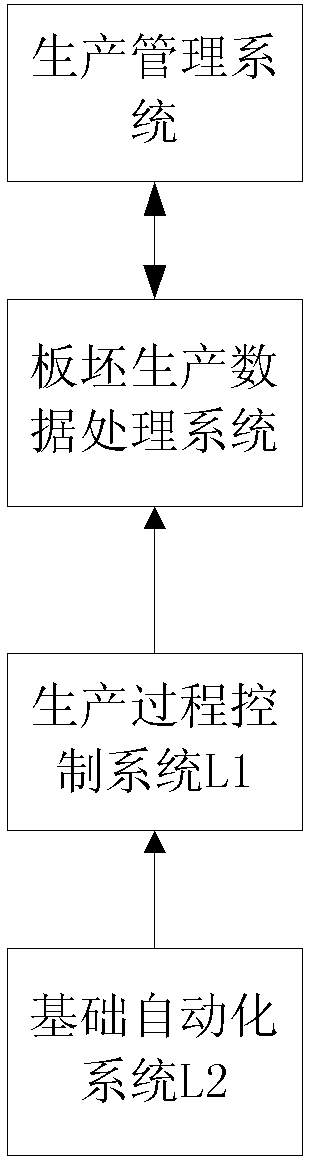

[0016] Such as figure 2 The structure diagram of the production data processing system on which the present invention depends is shown. During the production process, the steelmaking basic automation system L1 system feeds back the slab information in the production process to the steelmaking L2 system in real time, and the steelmaking production process control system L2 system collects Summarize the slab production tracking information and feed it back to the slab production data processing system. The slab production data processing system is connected to the production management system, and completes the writing and updating of the slab inventory database in the production management system to maintain the slab inventory database. The billet information is consistent with the actual production. The above-mentioned systems are connected through an industrial network or a TCP / IP protocol network.

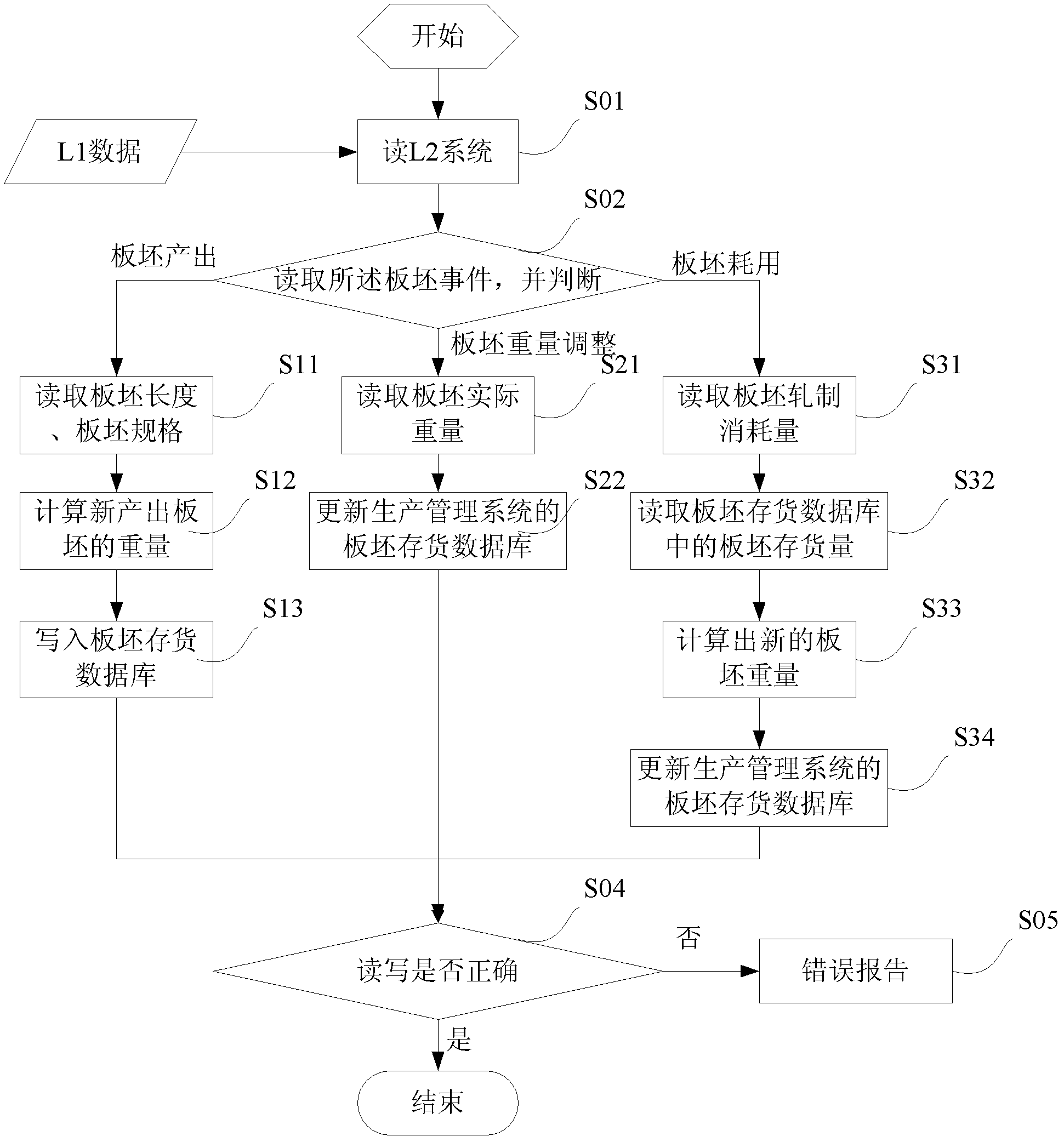

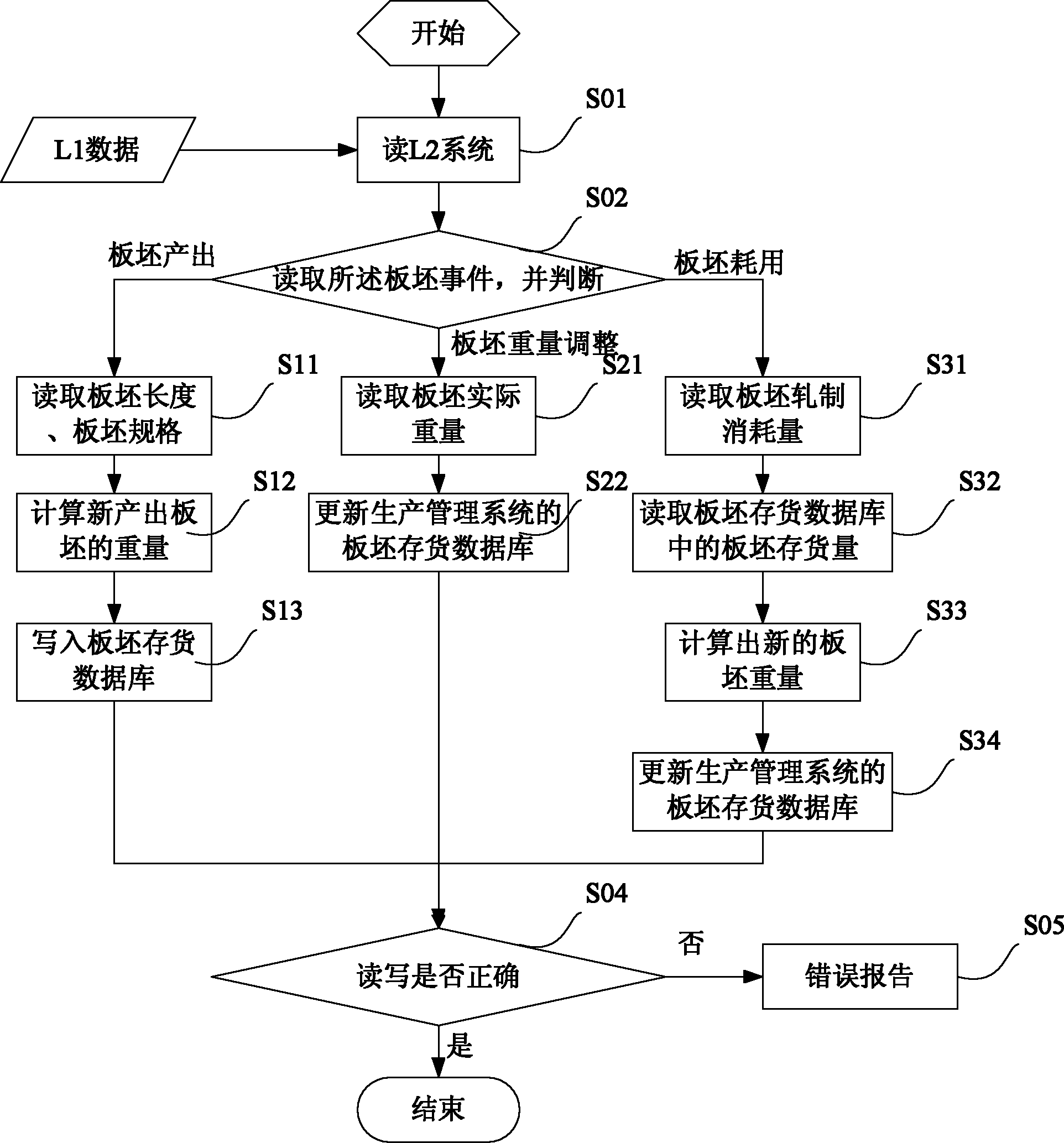

[0017] Such as figure 1 As shown, a certain slab production data processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com