Hydrostatic guide rail based on precision improvement and temperature maintaining system

A hydrostatic guideway, precision technology, applied in the direction of maintenance and safety accessories, large fixed members, metal processing machinery parts, etc., can solve the problems of dynamic error, reduce the processing accuracy of parts, vibration of tool parts, etc., to reduce manufacturing requirements, Strong throttling effect and open installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

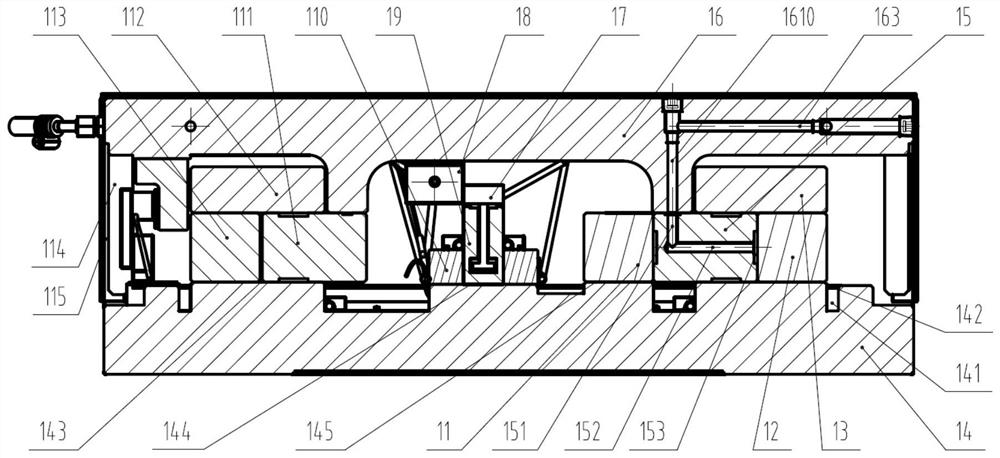

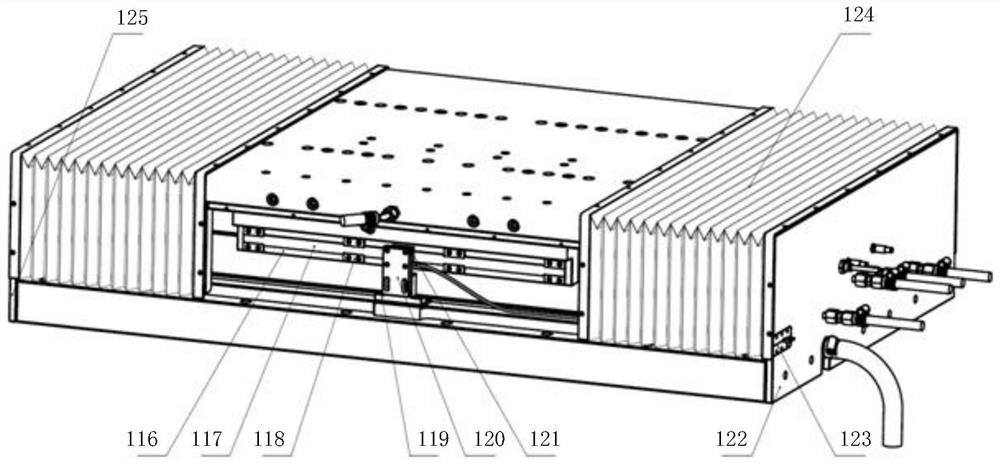

[0057] Such as Figure 1-Figure 8 As shown, the hydrostatic guideway based on improved precision includes a support assembly, a drive assembly, a position measurement assembly, a cooling assembly and a protection assembly, and the support assembly includes a fixed part and a sliding part;

[0058] The fixed part includes a middle side guide rail bar 11, a main side guide rail bar 12, a main upper guide rail bar 13, a guide rail base 14, an auxiliary upper guide rail bar 112 and an auxiliary side guide rail bar 113, and the upper end surface of the guide rail base 14 is provided with a base set Oil tank 141, the first boss 142 of the base, the second boss 143 of the base and the fourth boss 145 of the base are arranged in the oil collecting tank 141 of the base, the main side guide rail bar 12, the auxiliary side guide rail bar 113 and the middle side guide rail The bars 11 are respectively fixed on the upper end surfaces of the first boss 142 of the base, the second boss 143 o...

Embodiment 2

[0084] This embodiment is based on Embodiment 1, the heights of the first boss 142 of the base and the second boss 143 of the base are the same, the heights of the main slider 15 and the auxiliary slider 111 are the same, and the main side rail bar 12 and the auxiliary side The heights of the guide rail bars 113 are the same; the first horizontal step oil hole 163 of the workbench, the second level step oil hole 164 of the workbench, the third level step oil hole 165 of the workbench, and the fourth level step oil flow hole of the workbench The same throttle is installed at the steps of the hole 166, the fifth horizontal step oil hole 168 of the workbench and the sixth level step oil hole 169 of the workbench, the first vertical step oil hole 1610 of the workbench, the workbench The second vertical step oil hole 1611, the third vertical step oil hole 1612 of the workbench, the fourth vertical step oil hole 1613 of the workbench, the fifth vertical step oil hole 1614 of the work...

Embodiment 3

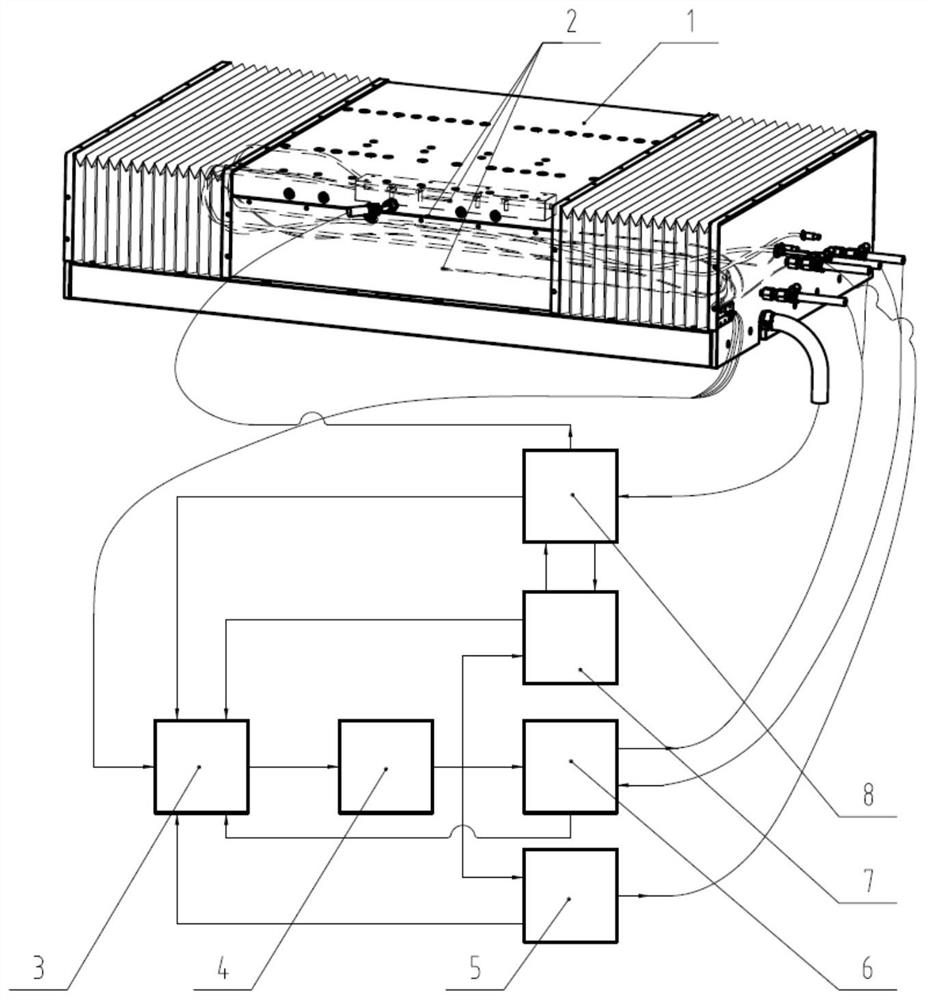

[0086] The hydrostatic guide rail temperature maintenance system based on improved precision includes the hydrostatic guide rail 1 described in Embodiment 1 or Embodiment 2, and also includes a temperature sensor 2, a data collector 3, a controller 4, a cooling fan 5, a first Oil cooler 6, second oil cooler 7 and lubricating oil supply device 8;

[0087] There are multiple temperature sensors 2, which are respectively installed in the inner area of the hydrostatic guide rail 1, the air outlet of the cooling fan 5, the oil outlet of the first oil cooler 6, the oil outlet of the second oil cooler 7 and The oil outlet of the lubricating oil supply device 8;

[0088] The input end of the data collector 3 is connected to the temperature sensor 2, and the output end is connected to the input end of the controller 4; the output end of the controller 4 is connected to the air cooler 5, the first oil cooler 6 and the second oil cooler 7 connected to the control input;

[0089] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com