Breaker detecting and assembly line production management system

A production management system and assembly line technology, applied in circuit breaker testing, comprehensive factory control, comprehensive factory control, etc., can solve the problems of waste of resources and space query, waste of storage space, easy to generate errors, etc., to improve production management The effect of efficiency, saving resources and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

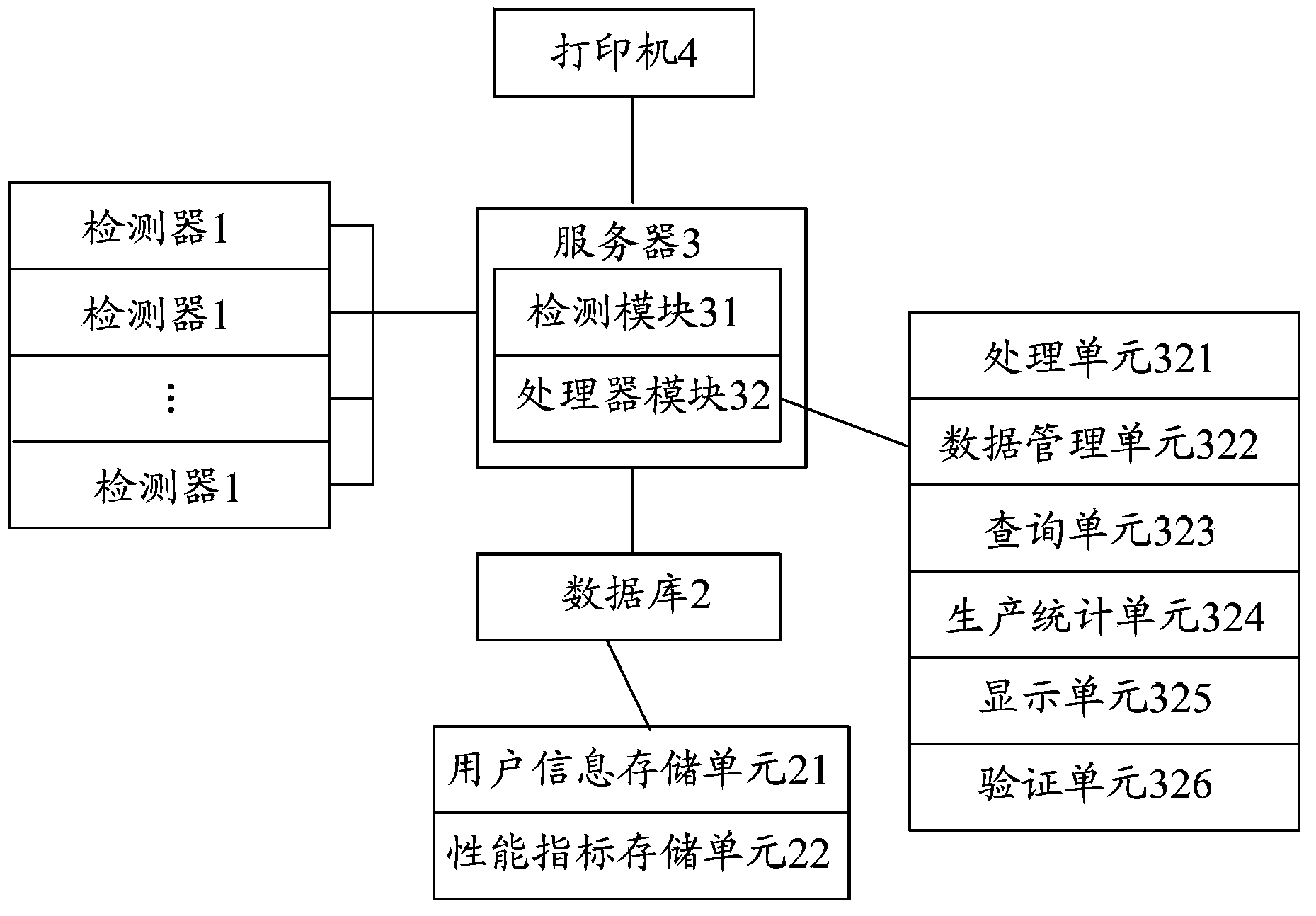

[0021] see figure 1 As shown: the circuit breaker detection and assembly line production management system provided by the present invention includes: several detectors 1, database 2, server 3 and printer 4, wherein:

[0022] Each detector 1 is used to detect various performance indicators of the circuit breaker, specifically including: run-in tester, open range overtravel detector, final pressure trip force circuit resistance detector, instantaneous setting detector, equivalent overload Long-time delay detector, reliability detector and withstand voltage detector.

[0023] Database 2 further includes:

[0024] User information storage unit 21: used to store user registration information, that is, user name and corresponding password;

[0025] Performance index storage unit 22: used to store product information and corresponding product testing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com