High intensity and high-toughness hot-rolled steel sheet and method for producing the same

A technology for a hot-rolled steel sheet and a production method, applied in the field of metallurgy, can solve the problems of high cost and high price, and achieve the effects of reducing alloy cost, reducing rolling force and rolling energy consumption, and preventing grain growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0032] Table 1 provides 8 examples of the chemical composition of the high-strength high-toughness weldable hot-rolled steel sheet of the present invention

[0033] Table 1 Chemical composition of high-strength and high-toughness weldable hot-rolled steel sheets (wt%)

[0034] Preface

[0035] Table 2 shows the main controlled cooling process rolling process parameters of the 8 steel plates with different components listed in Table 1.

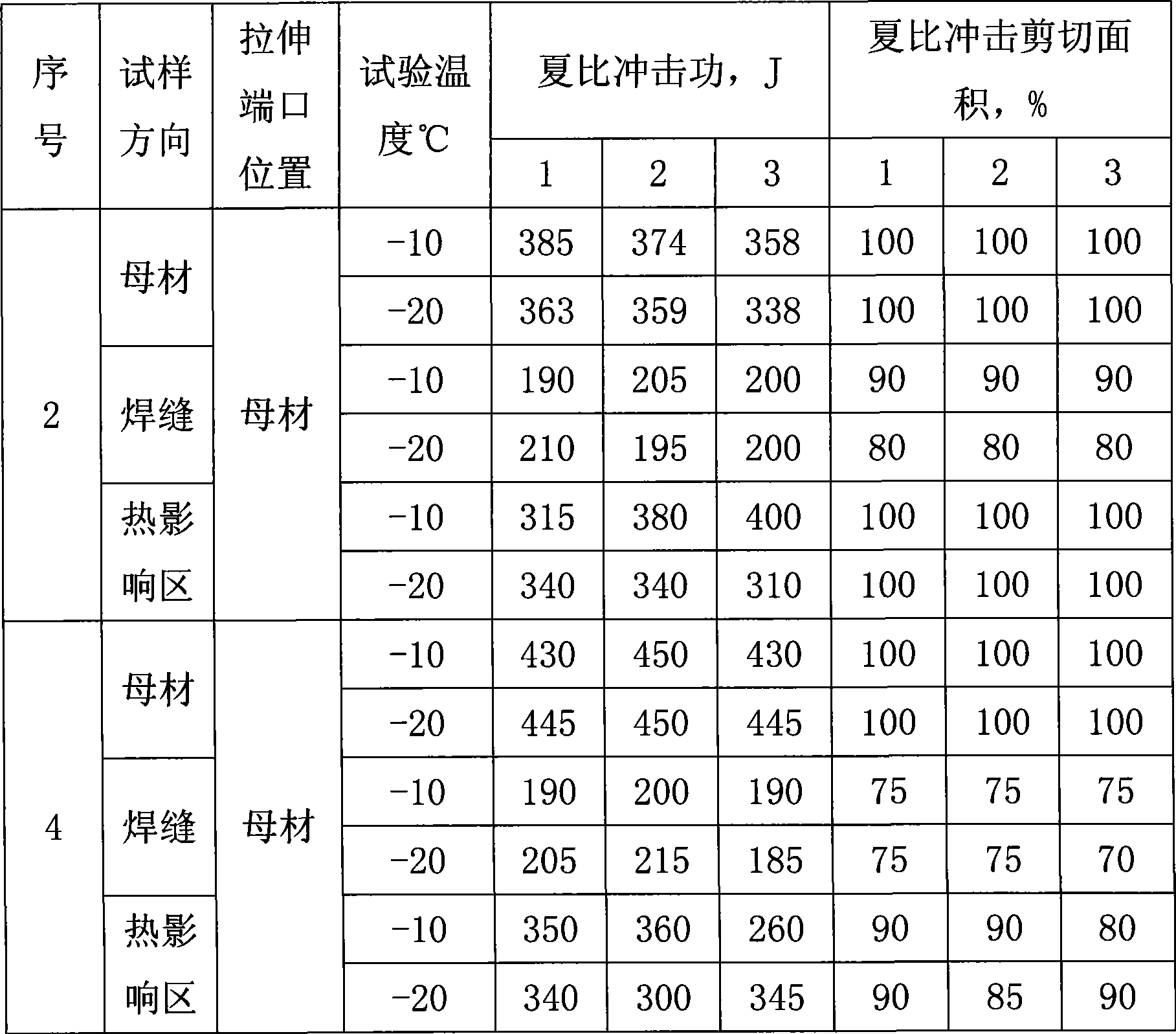

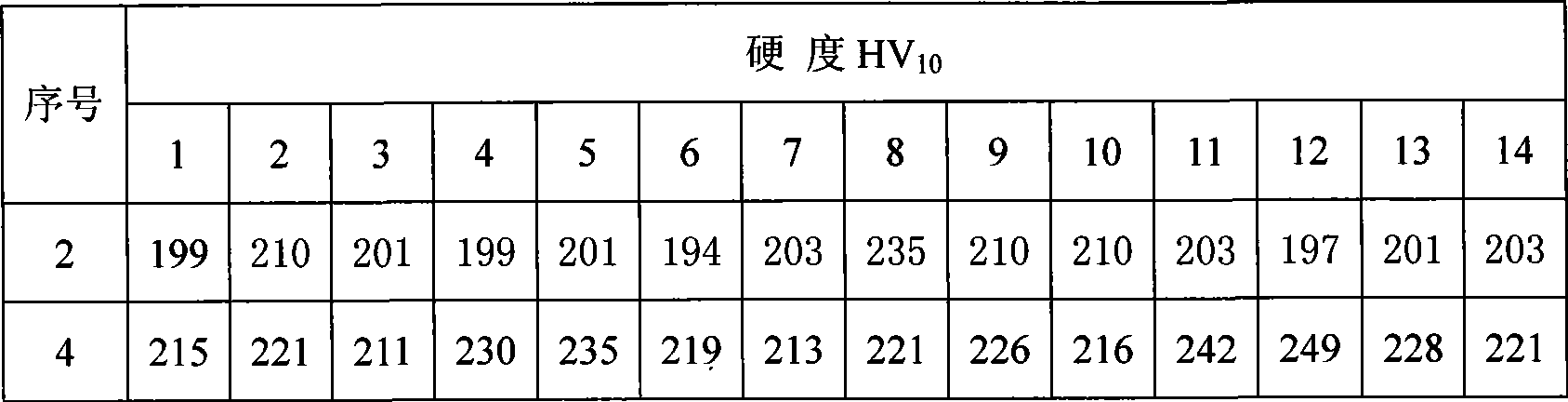

[0036]

[0037] In the above-mentioned embodiment, the welding process of this hot-rolled steel plate adopts 4-wire submerged arc welding, the current is 450-1000A, the voltage is between 20-30, the heat input is 45KJ / cm, and the moving speed of the welding wire is 1.7m / min. filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com