Feature-based numerical-control method for processing and manufacturing complicated parts

A technology of complex parts and parts, which is applied in the field of feature-based CNC machining and manufacturing of complex parts, can solve problems such as loose manufacturing systems and difficult digital integrated manufacturing, so as to improve production efficiency, reduce dependence on experience, and facilitate automation and intelligence sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

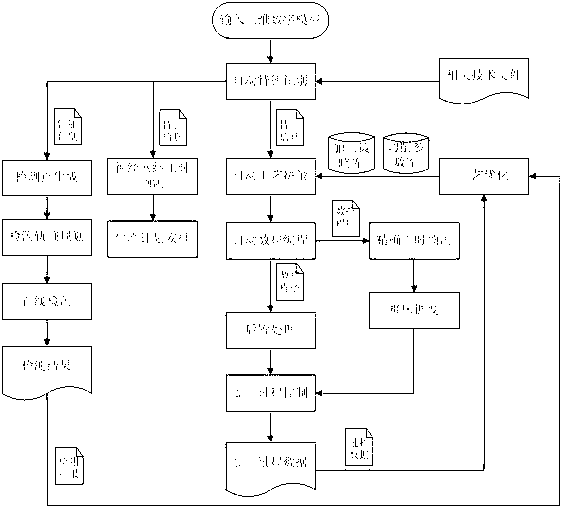

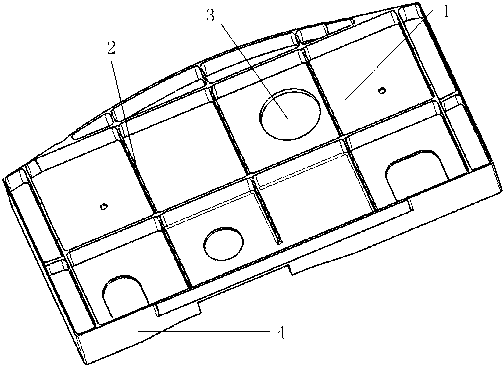

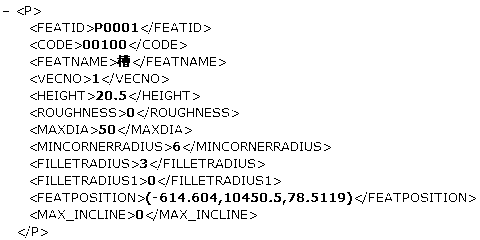

[0057] A feature-based NC machining and manufacturing method for complex parts, expressing the geometry and process information of parts in the entire manufacturing process based on features, using features as the carrier of manufacturing knowledge and experience to achieve effective integration of information, in order to achieve effective integration of information in the entire manufacturing process Maintain the validity of features and the consistency of feature evolution, and use object-oriented and ontology-based methods to represent features:

[0058] (1) Define the ontology of features and the classes of features in each application domain;

[0059] (2) Feature recognition is performed based on the method of holographic attribute surface and edge graph, and the geometric information and process information of the part are extracted from the 3D d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com