A virtual debugging system based on an OPC UA industrial communication protocol

A technology for industrial communication and debugging systems, applied in transmission systems, digital transmission systems, manufacturing tools, etc., can solve problems such as inability to connect various types of equipment, and achieve the effects of improving portability, reducing costs, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

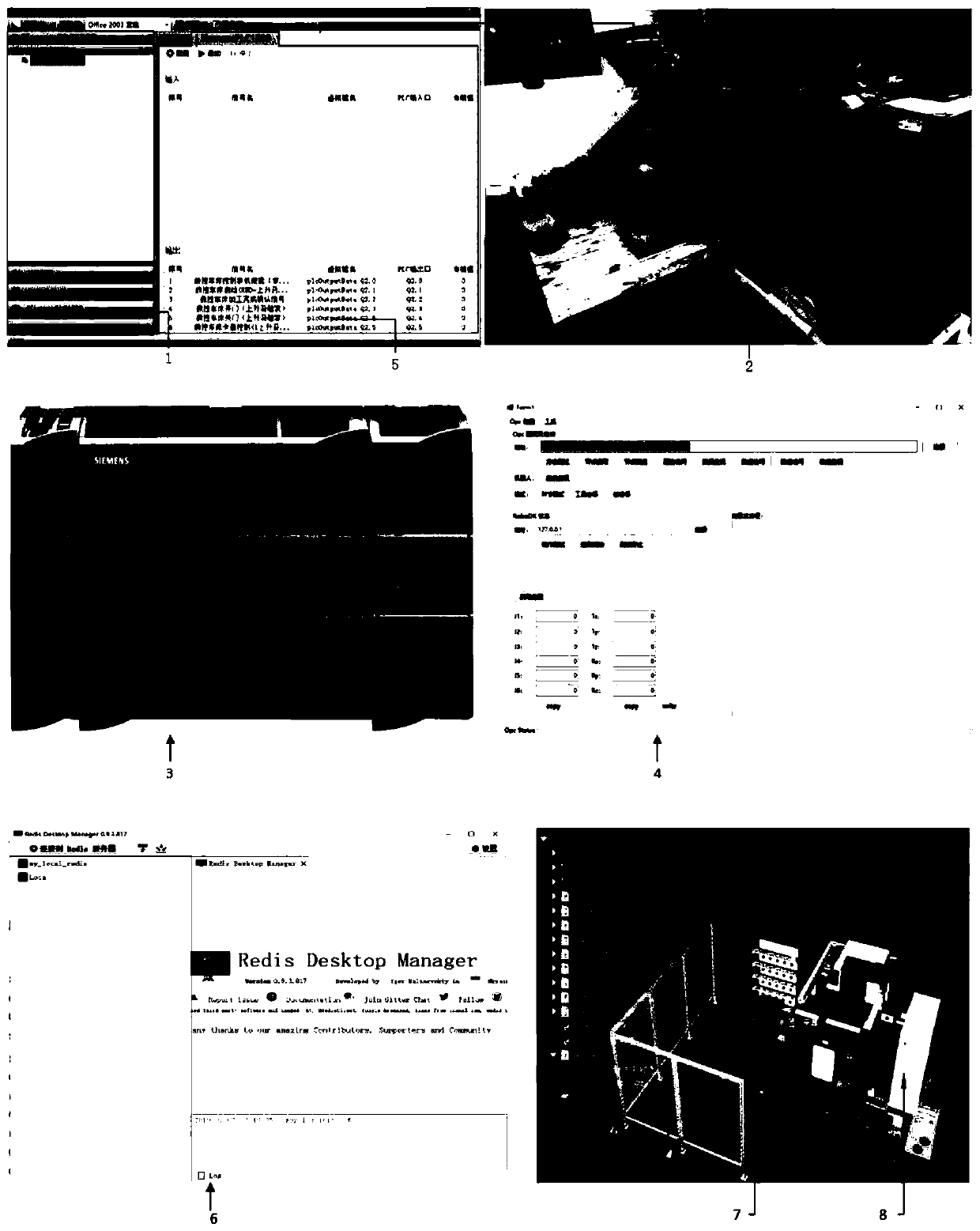

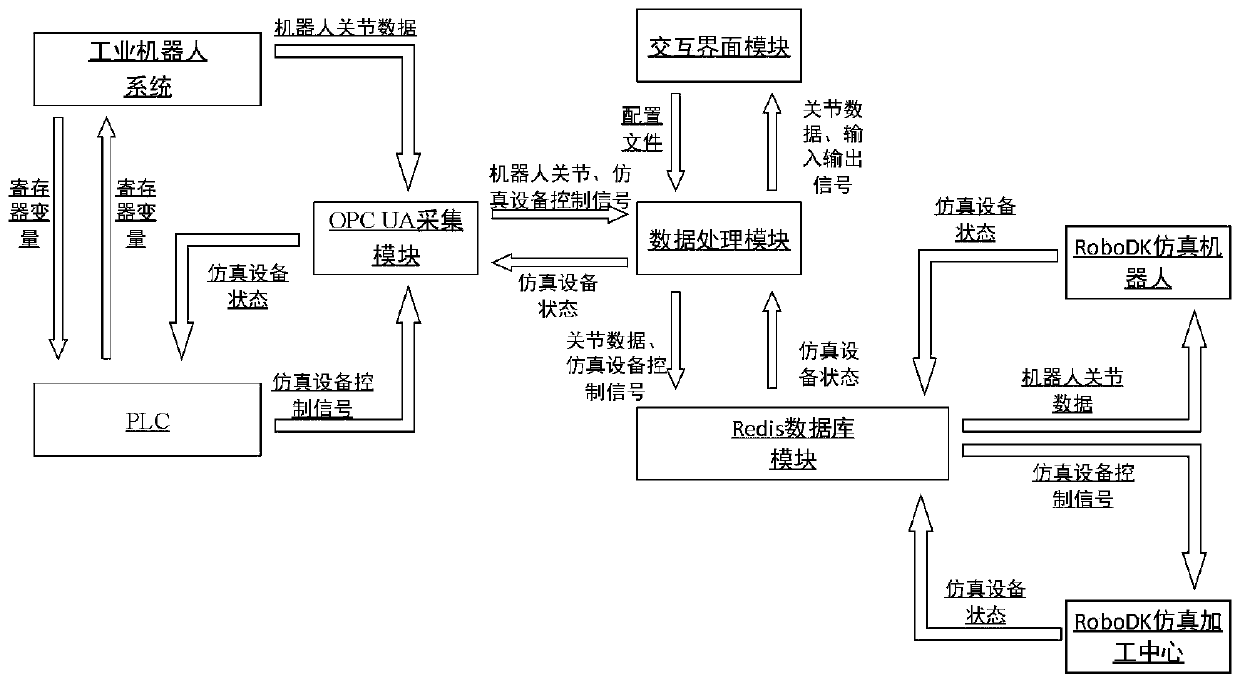

[0028] combine figure 1 with figure 2 , the specific implementation of the patent of the present invention is as follows:

[0029] Interactive interface module: first connect the interactive interface module to the switch through Ethernet, ensure that the PC, industrial robot and PLC are in the same network segment, configure the signal to be collected on the interactive interface module, and open the system management operation of the interactive interface module Interface, start the plug-in of Siemens PLC and robot system; click the configuration button in the interactive interface module of Siemens PLC, configure the IP address of the target PLC to be connected, right-click in the input and output table and select "Add", and fill in the virtual key name of the database , the address of the signal, the remark of the signal name and the current value. After confirming that it is correct, an input or output signal will be added to the table. At this time, the signal created ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com