Numerical control spherical lathe

A spherical lathe and spindle technology, applied in the field of machine tools, can solve the problems of unstable sphericity, high equipment cost, and only semi-finishing, etc., to reduce the process and turnover storage, improve the quantity and quality, and reduce the replacement time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

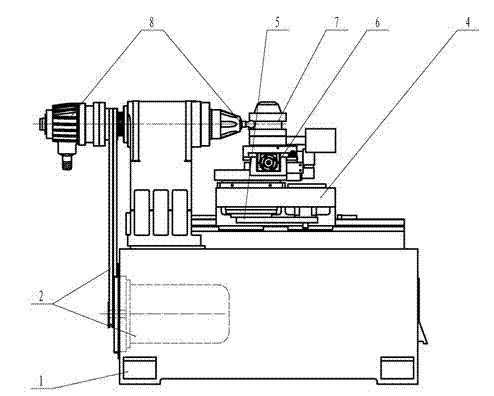

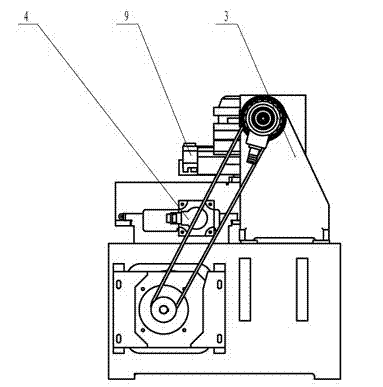

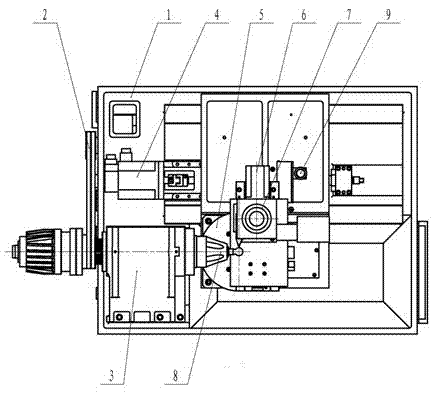

[0048] The present invention will be further described below in conjunction with two embodiments. in Figure 1-Figure 5 is a schematic diagram of embodiment 1, Figure 6-10 It is the schematic diagram of embodiment 2.

[0049] As shown in the figure, the CNC spherical lathe of the present invention has a main structure including a base 1, a servo motor 2 is arranged in the base 1, a main shaft assembly 3 is arranged on the base 1, and the main shaft assembly 3 communicates with the servo motor through a reduction transmission device. 2 connection, a workpiece clamping unit 8 is installed at the front end of the main shaft assembly 3; it is characterized in that a Z-axis center positioning unit 4 is provided on the base 1, a Y-axis rotation unit 5 is installed on it, and a Y-axis rotation unit 5 is installed on the Y-axis rotation unit 5. The X-axis radius feed unit 6 is equipped with a tool rest and a conversion unit 7 on the upper part of the X-axis radius feed unit 6 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com