Rough machining method of helical surface of hourglass worm

A toroidal worm and helical surface technology, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of high rigidity requirements of machine tools, and the homogenization effect is not as good as the envelope method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

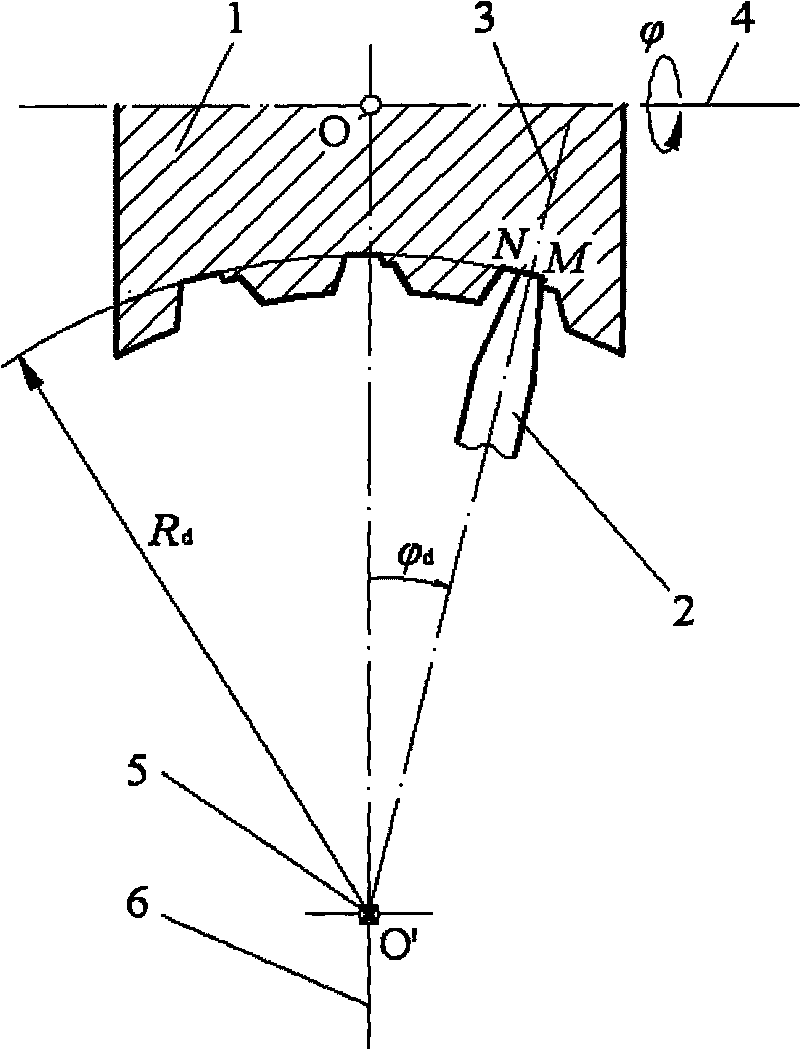

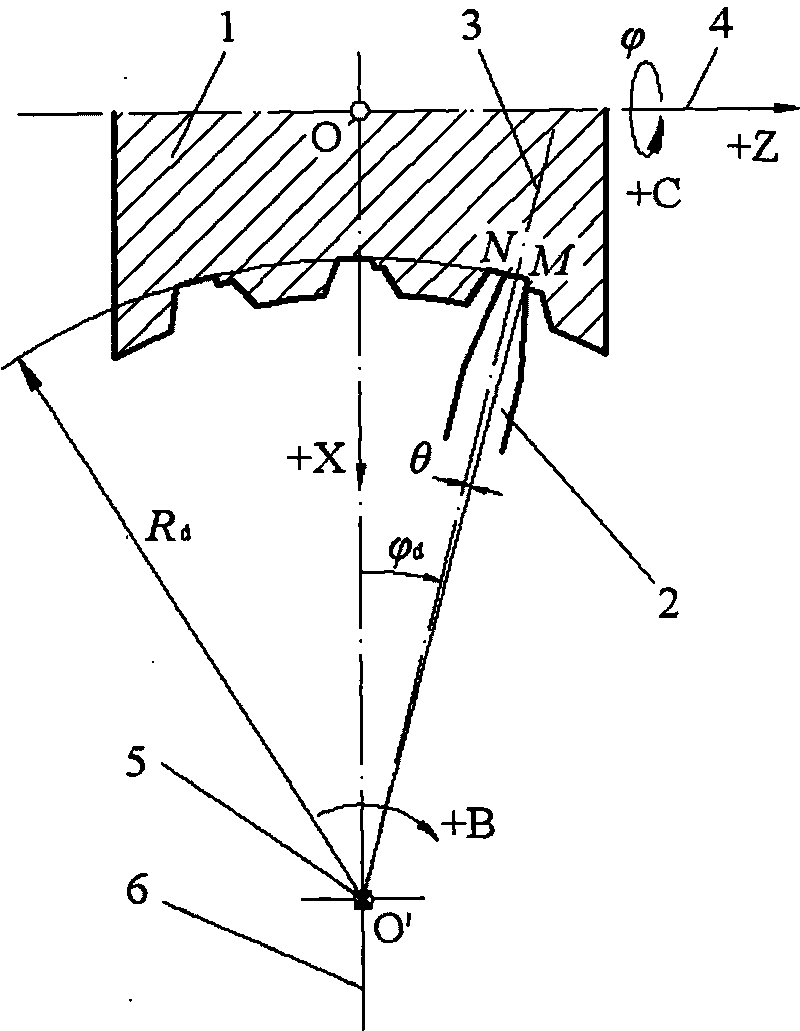

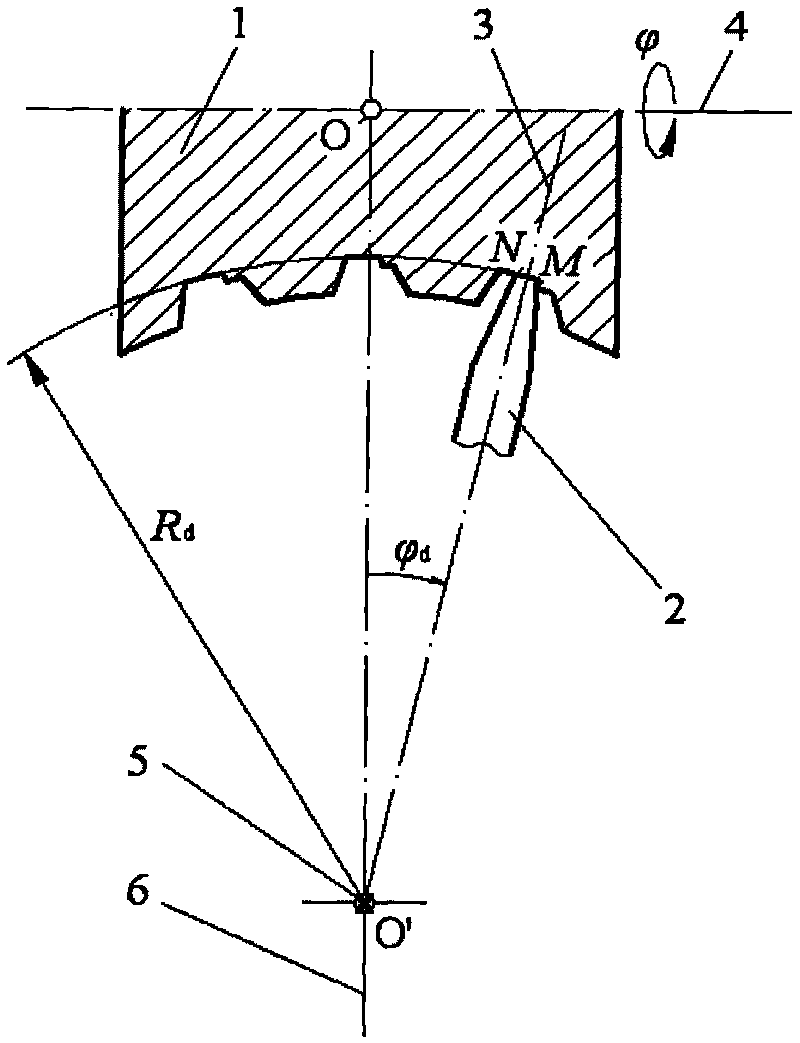

[0010] Embodiments of the present invention will be described below according to the accompanying drawings. Taking the non-modified planar enveloping toroidal worm pair as an example, the relevant parameters are: center distance a=250mm, right-handed worm head number z 1 =1, the number of worm gear teeth z 2 =40, Diameter of worm pitch circle d 1 =82mm, worm gear indexing circle diameter d 2 =418mm, modulus of worm wheel end face m t =10.45mm, diameter of worm root circle d f1 =63.20mm, diameter of worm addendum circle d a1 =96.64mm, worm root arc radius R f1 =218.40mm, worm addendum arc radius R a1 =201.68mm, main base circle diameter d b =158mm, worm working length L w = 130mm.

[0011] figure 2 The CNC machine tool in has a three-axis linkage C-axis, X-axis and B-axis, and a fixed Z-axis. The common vertical line of the C-axis and the B-axis is a fixed public vertical line 6, and the public vertical line 6 and the C-axis and the B-axis The intersection points of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com