Three-dimensional topography mark comparison measuring instrument

A technology of three-dimensional shape and measuring instrument, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problem of low adjustment accuracy, and achieve the effects of adjustable resolution, variable field of view, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

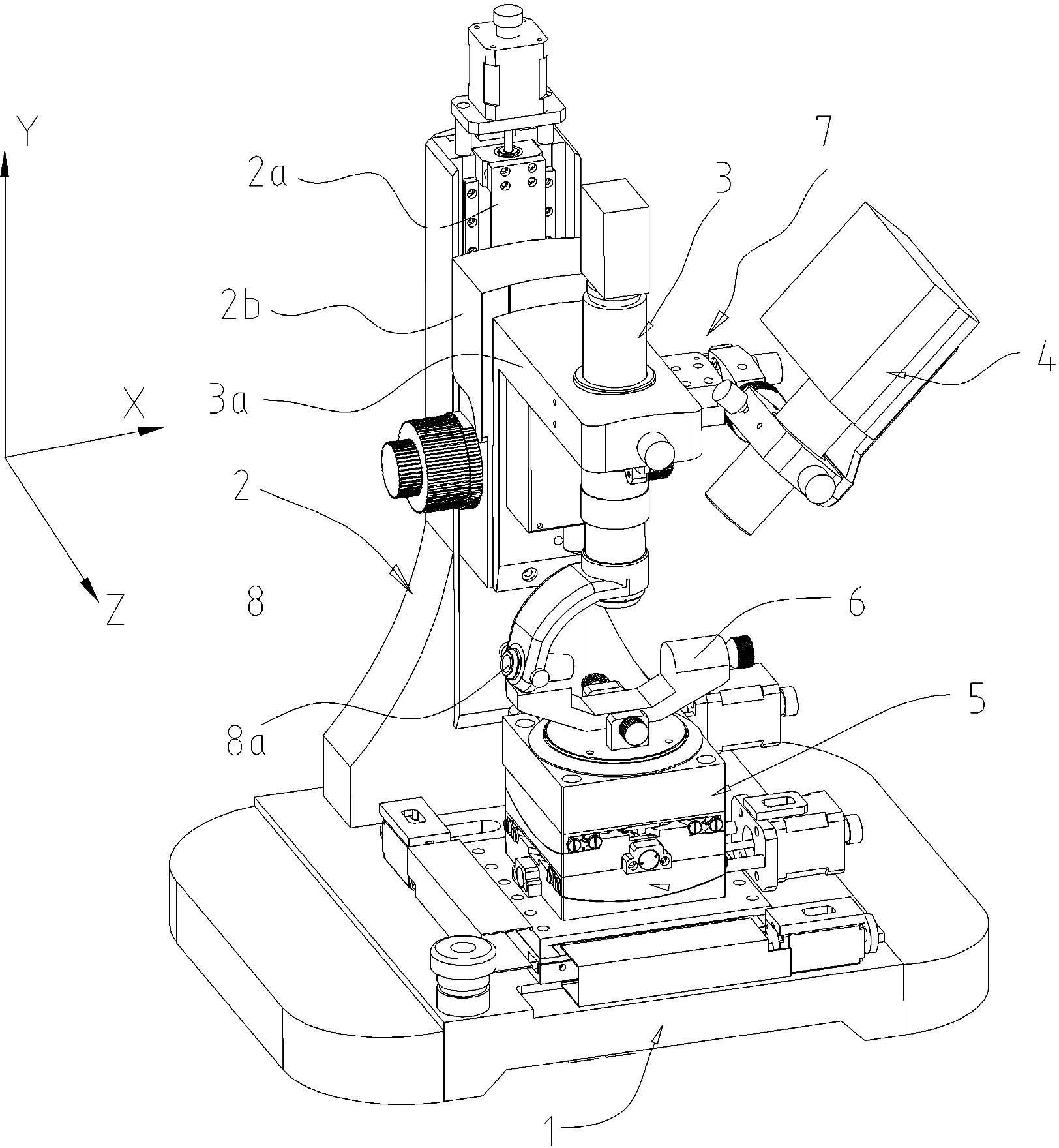

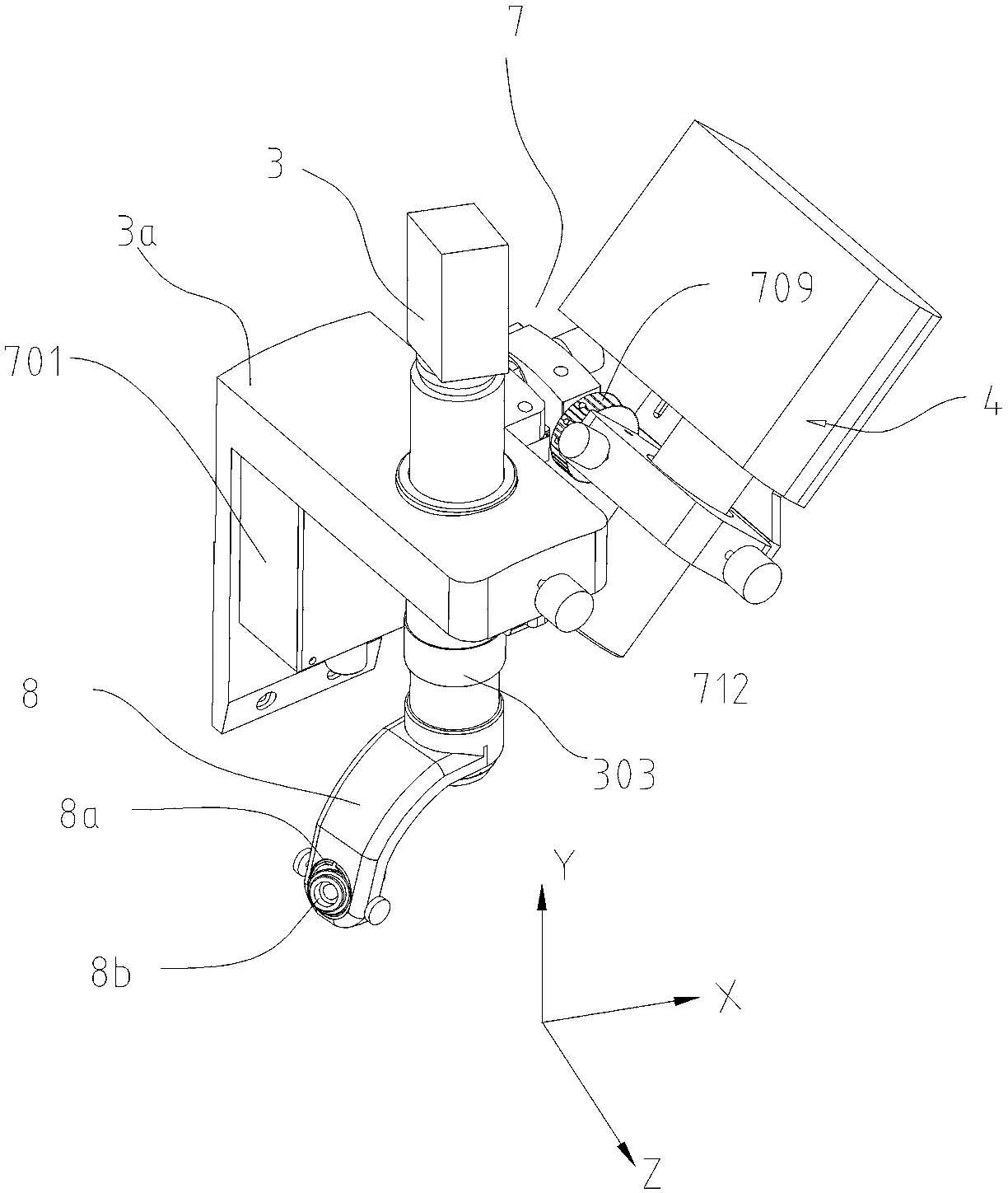

[0031] like figure 1 , is a kind of three-dimensional shape trace contrast measuring instrument provided by the present invention, comprises base 1, column 2, microscopic camera 3, projector 4, cloud platform 5, and the above-mentioned five parts are described in detail below respectively:

[0032] a. The base 1 has a clear structure and no further explanation is needed;

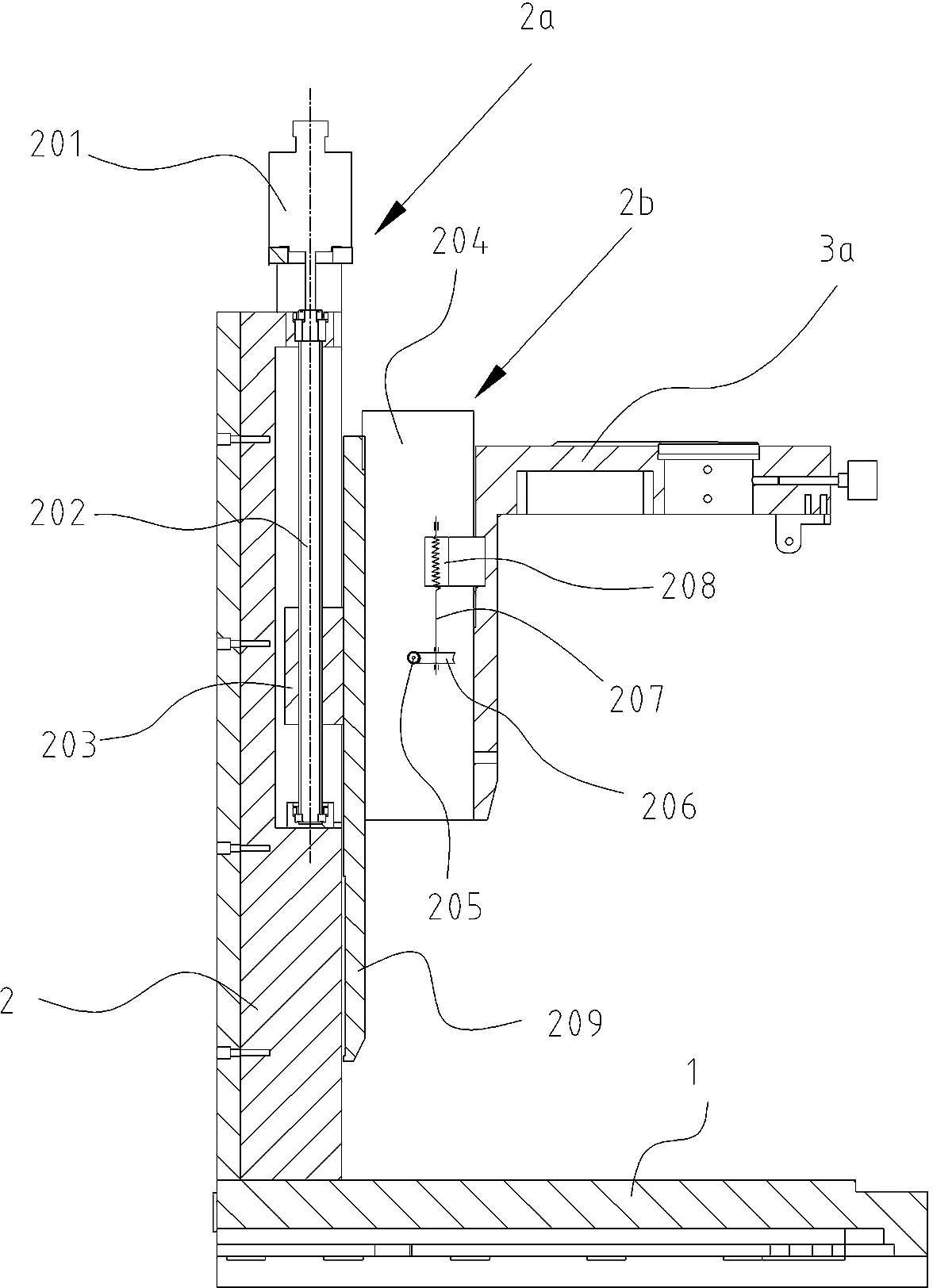

[0033] b. The column 2 is arranged on the rear side of the upper plane of the base. The column is provided with a quick lifting device 2a, and the quick lifting device 2a is connected with a fine-tuning lifting device 2b.

[0034] see figure 2 , the fast lifting device 2a includes: a stepping screw 202 arranged in the inner cavity of the column 2, the upper end of the stepping screw 202 is connected with a stepping motor 201 arranged above the column, and the stepping screw 202 is connected to the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com