Base-material-free adhesive tape processing technology avoiding tool marks on ultralight base films

A processing technology and adhesive tape technology, applied in the field of adhesive products processing technology, can solve the problems of cut marks left on the release film, affecting product quality, excessive half-cut, etc., to achieve simple product processing technology, avoid difficult control of depth, and ensure The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

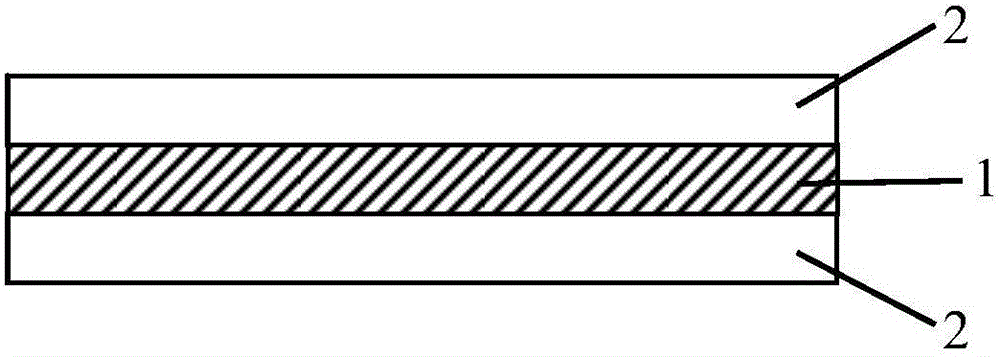

[0019] (1) if figure 1 As shown, the surface of the non-substrate adhesive tape 1 is compounded with the first release film 2;

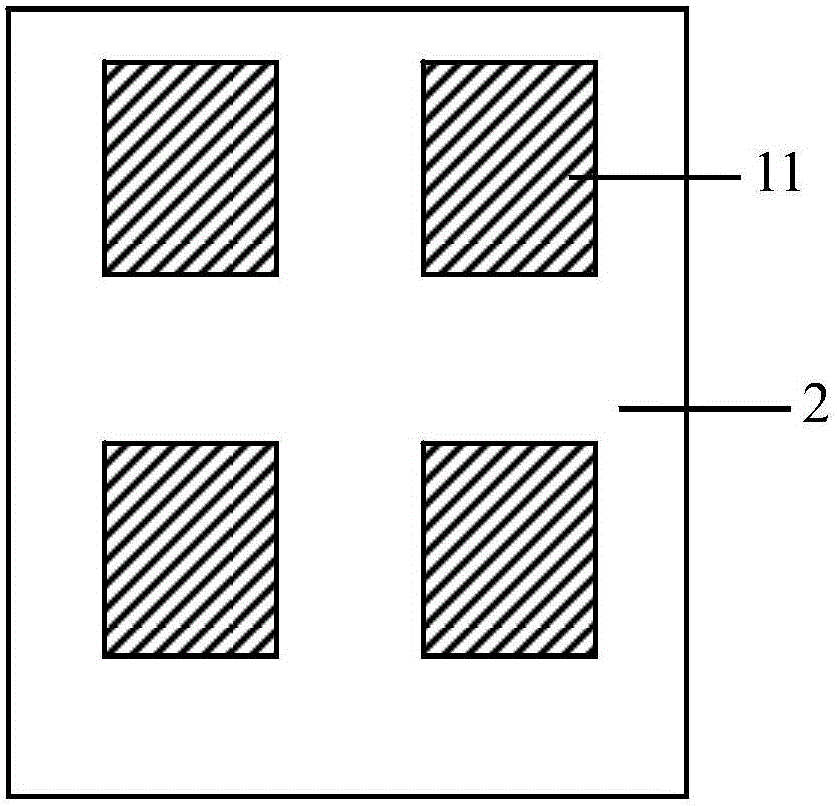

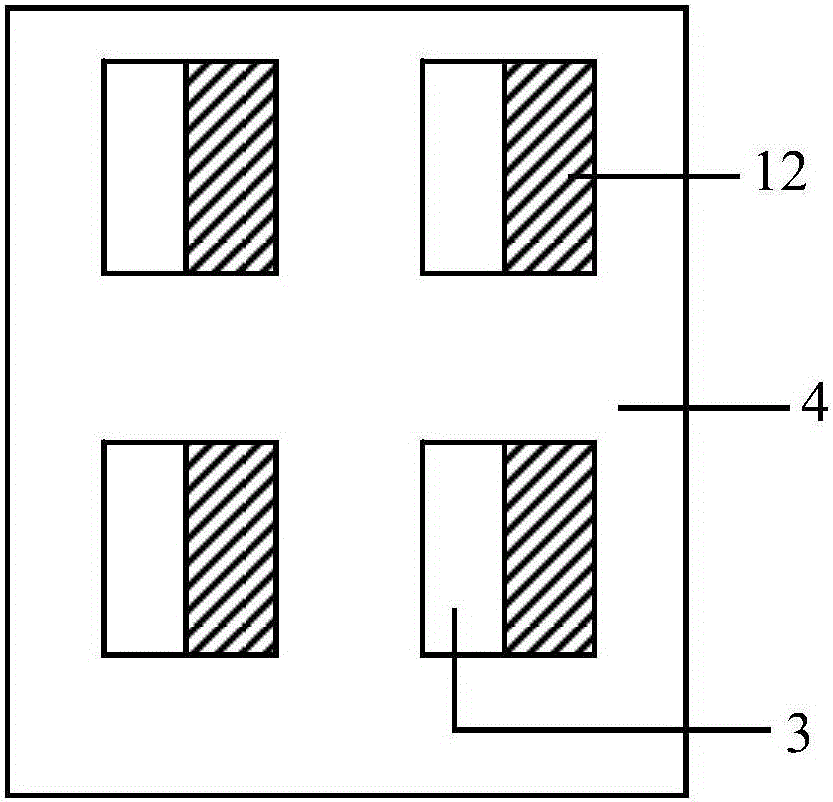

[0020] (2) Forming without base material tape, using a tape die-cutting molding tool to punch out the shape of the base material tape, and get rid of tape waste and the first release film 2 respectively;

[0021] The specific operation of this step is: fix the base-less tape forming tool on the die-cutting machine, set the punching step according to the product and operation requirements, and send the material that has completed step (1) into the designated position of the die-cutting machine, without base material. The tape die-cutting tool punches out the overall shape of the tape to obtain the molded non-substrate tape 11. After the die-cutting is completed, the tape die-cutting tool rises and separates, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com