Superhard functional ceramic machining parameter obtaining method, machining method and application

A technology of ceramic processing and acquisition method, which is applied in the field of acquisition of processing parameters of superhard functional ceramics, and can solve problems such as cutting tool marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The method for obtaining processing parameters of superhard functional ceramics comprises the following steps:

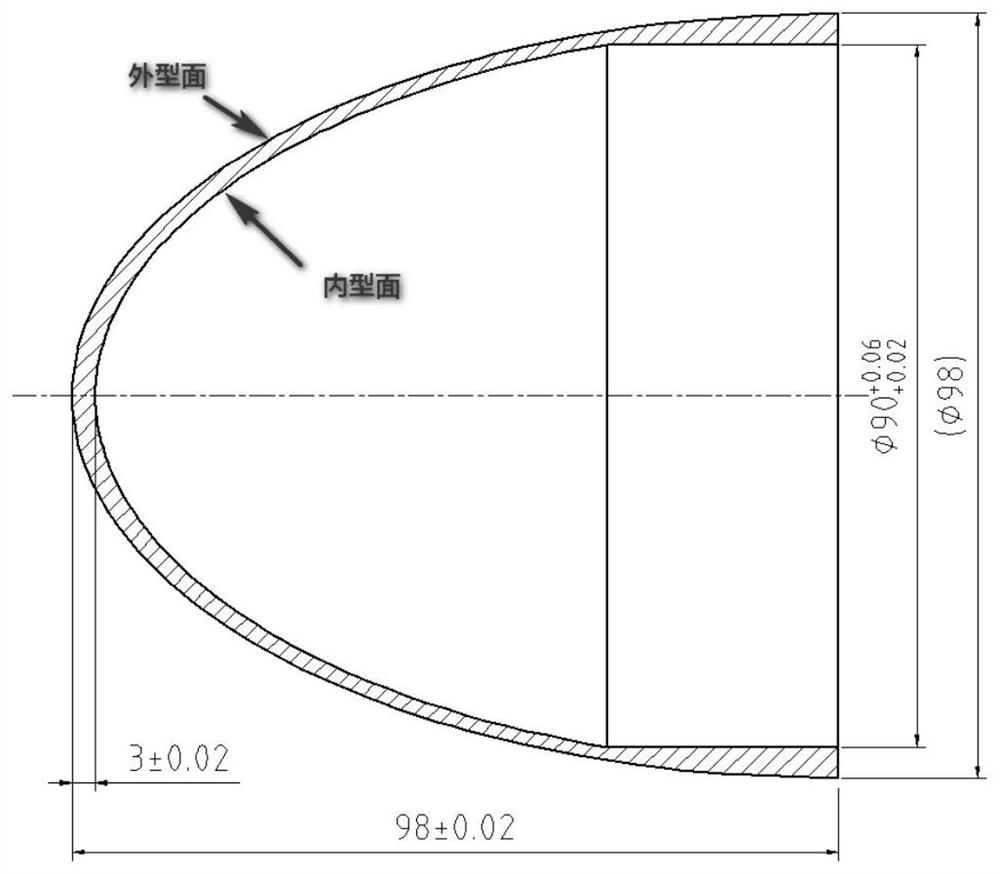

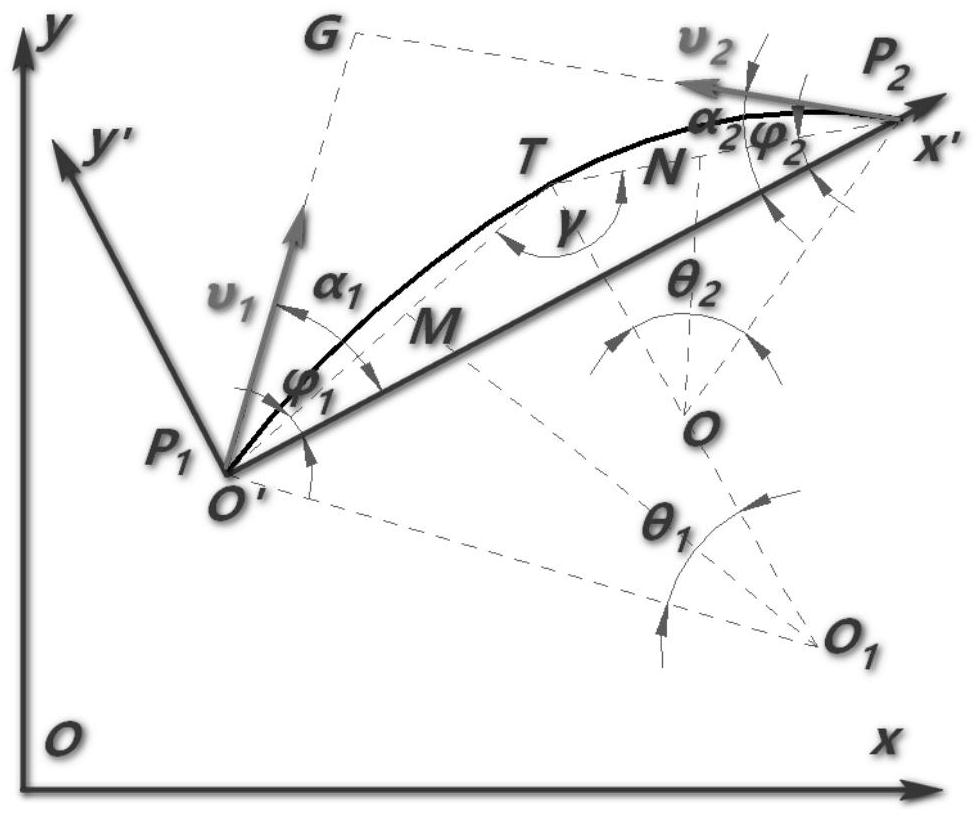

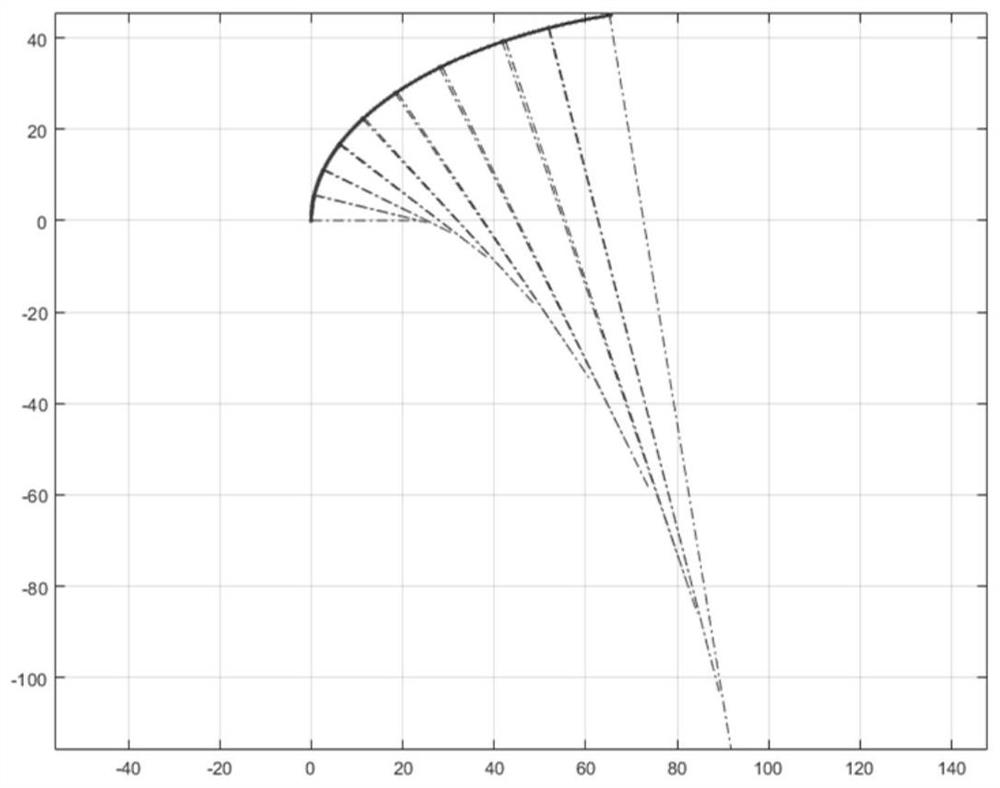

[0069] S1. Using segmented arc fitting, combined with double-arc approximation technology, the arc spline curve of the inner surface of superhard functional ceramics to be processed is obtained; the inner surface curve is generally an aspherical curve, such as figure 1 As shown, the arc spline fitting effect of the inner surface and the enlarged picture are as follows image 3 with Figure 4 shown;

[0070] Among them, the aspheric parameter equation is as follows:

[0071]

[0072] In the formula, R is the radius of the base circle, K is the conical parameter, A, B, C and D are the coefficients of the fourth order, the sixth order, the eighth order and the tenth order respectively;

[0073] The specific process of obtaining the arc spline curve is as follows:

[0074] Obtain the aspherical surface parameter equation and the coordinate information of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com