Automatic polishing method and device for finish-milling hook face

An automatic polishing and curved surface technology, applied in the field of aero-engines, can solve the problems of the existence of polishing blind spots and the high cost of automatic polishing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

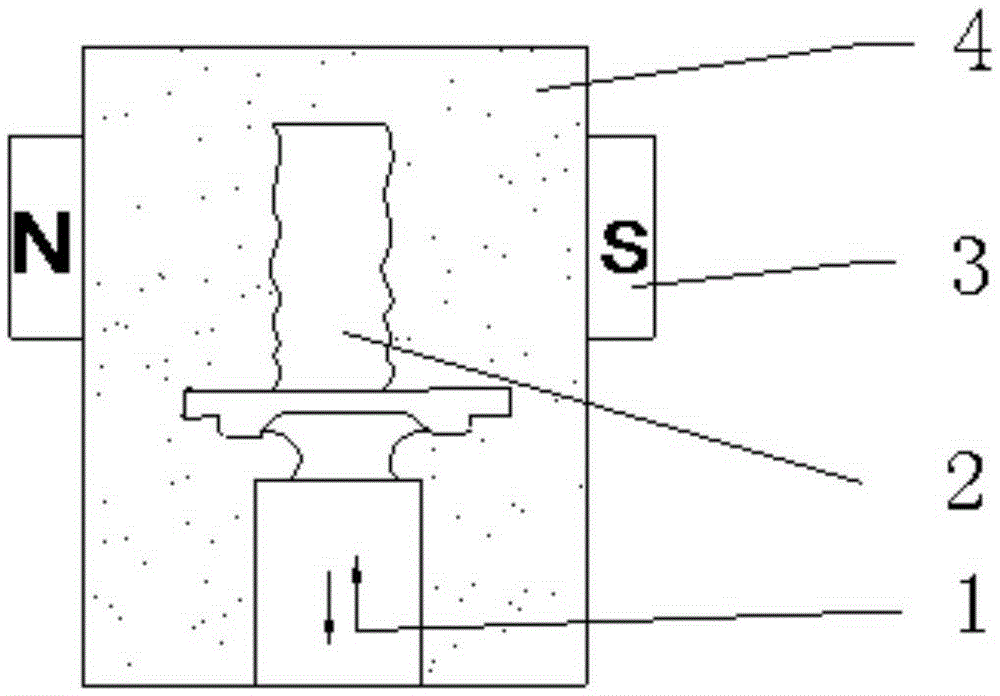

[0009] The structure of the polishing device of the present invention is as figure 1 As shown, it includes a vibrator 1, a blade 2 is set on the vibrator 1, and a magnetic field generator 3 is set on both sides of the blade 2. The vibration direction of the blade 2 is perpendicular to the direction of the magnetic force line. When the magnetic abrasive grain 4 is not applied with a magnetic field, its polishing process The effect is the same as that of ordinary vibrating finishing; under the condition of applying a magnetic field, the magnetic abrasive particles 4 can be condensed into a whole, and the magnetic abrasive particles 4 can fit well with the corrugated shape produced by the milling tool marks on the surface of the blade, which can be very complete Copy the waviness of the surface of the blade, so that an integral polishing medium can be formed around the curved surface of the blade. When the blade reciprocates up and down under the action of the vibration source, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com