Surface treatment method of 3C product aluminum alloy outer parts and application

A surface treatment, aluminum alloy technology, applied in the direction of surface reaction electrolytic coating, anodizing, electrolytic coating, etc., can solve the problems of poor permeability of oxide film, difficult to obtain color, low gloss and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

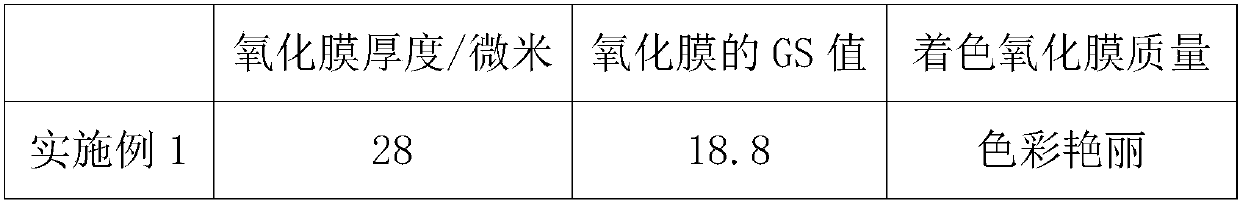

Embodiment 1

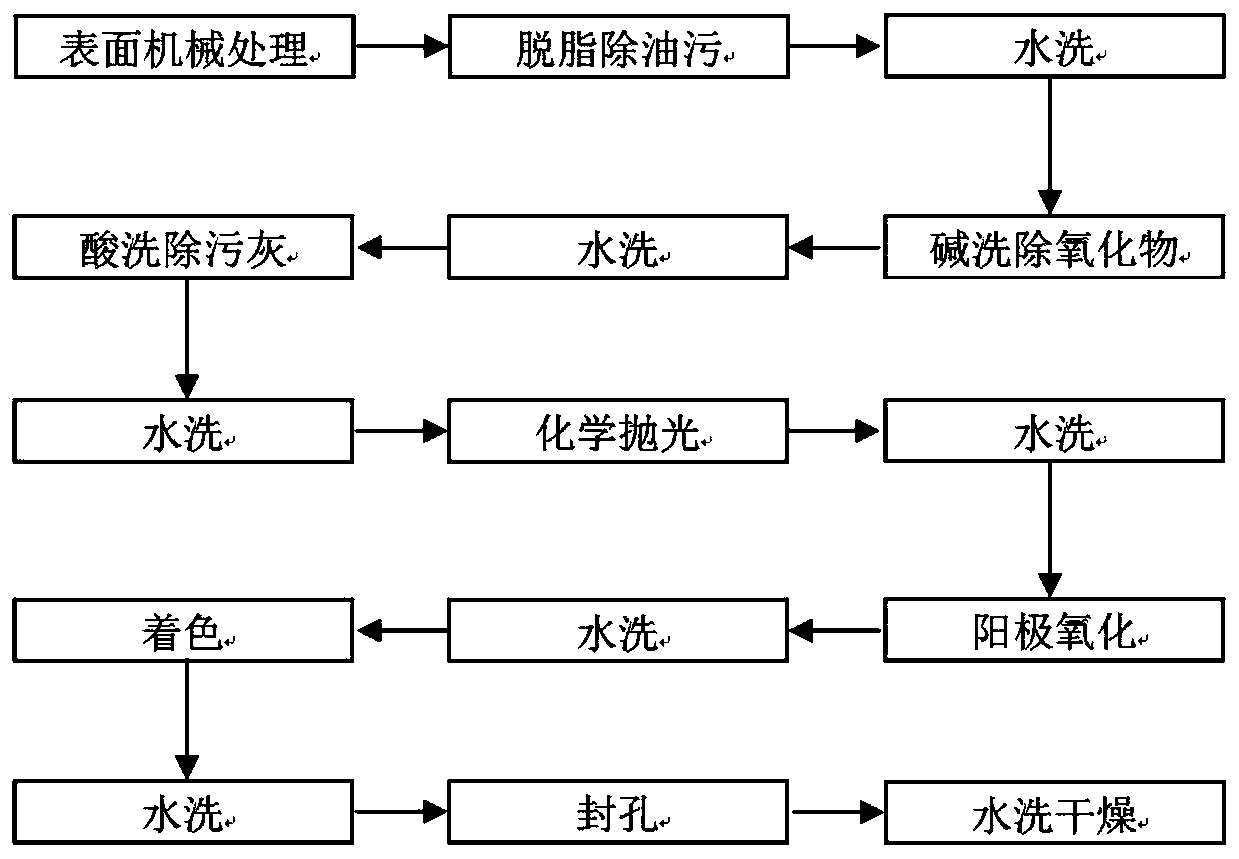

[0050] A method for surface treatment of an aluminum alloy backplane for a smart phone, the process flow of which is as follows figure 1 shown, including the following steps:

[0051] (1) Mechanically polish the surface of the aluminum alloy backplane of the smartphone to remove the processing knife marks, burrs, scratches, etc. on the surface to obtain a smooth surface;

[0052] (2) Put the aluminum alloy backplane of the smart phone into a degreasing solution at 85° C. for 8 minutes to remove the oil on the surface. The degreasing solution is a mixed aqueous solution of sodium carbonate, sodium phosphate and sodium citrate, and the concentration of sodium carbonate is 70g / L, sodium phosphate concentration is 35g / L, sodium citrate concentration is 12g / L;

[0053] (3) Put the cleaned aluminum alloy back panel of the smart phone into an alkaline washing solution at 30°C for alkaline cleaning for 2.5 minutes to remove the natural oxide film on the surface. The alkaline solution...

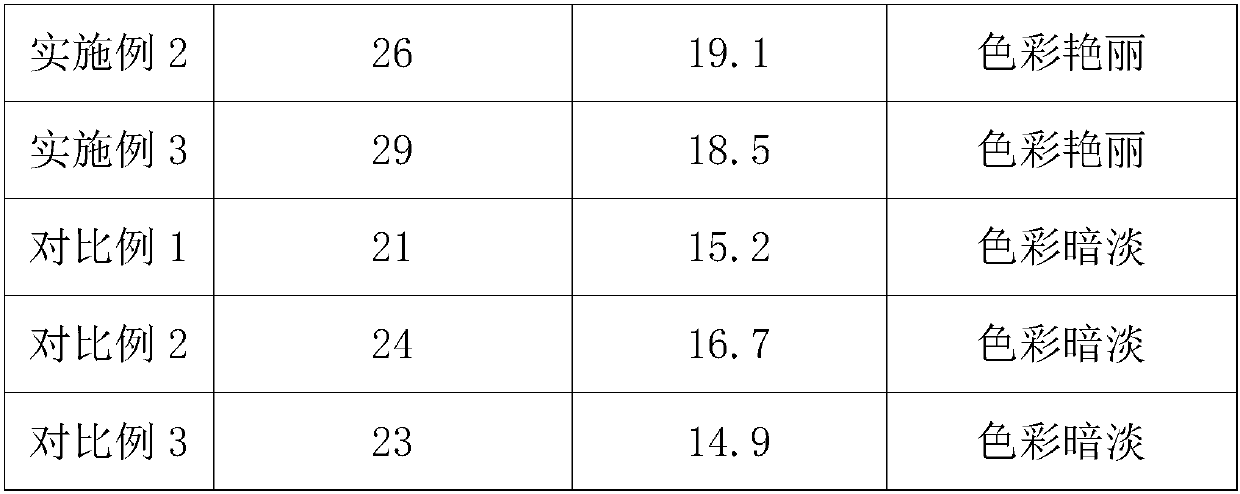

Embodiment 2

[0060] A method for surface treatment of an aluminum alloy backplane for a smart phone, comprising the steps of:

[0061] (1) Mechanically polish the surface of the aluminum alloy backplane of the smartphone to remove the processing knife marks, burrs, scratches, etc. on the surface to obtain a smooth surface;

[0062] (2) Put the aluminum alloy backplane of the smart phone into the degreasing solution at 80°C for 8 minutes to remove the oil on the surface. The degreasing solution is a mixed aqueous solution of sodium carbonate, sodium phosphate and sodium citrate, and the concentration of sodium carbonate is 80g / L, the concentration of sodium phosphate is 30g / L, and the concentration of sodium citrate is 15g / L;

[0063] (3) Put the cleaned aluminum alloy backplane of the smart phone into an alkaline solution at 30°C for alkaline cleaning for 2 minutes to remove the natural oxide film on the surface. The alkaline solution is a mixed aqueous solution of sodium hydroxide and sodiu...

Embodiment 3

[0070] A method for surface treatment of an aluminum alloy backplane for a smart phone, comprising the steps of:

[0071] (1) Mechanically polish the surface of the aluminum alloy backplane of the smartphone to remove the processing knife marks, burrs, scratches, etc. on the surface to obtain a smooth surface;

[0072] (2) Put the aluminum alloy backplane of the smartphone into a degreasing solution at 90°C for 7 minutes to remove the oil on the surface. The degreasing solution is a mixed aqueous solution of sodium carbonate, sodium phosphate and sodium citrate, and the concentration of sodium carbonate is 60g / L, the concentration of sodium phosphate is 40g / L, and the concentration of sodium citrate is 10g / L;

[0073] (3) Put the cleaned aluminum alloy backplane of the smart phone into an alkaline solution at 25°C for alkaline cleaning for 2 minutes to remove the natural oxide film on the surface. The alkaline solution is a mixed aqueous solution of sodium hydroxide and sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com