Intelligent welding device for steel-plastic composite pipe

A steel-plastic composite pipe, intelligent technology, applied in the direction of tubular items, other household appliances, household appliances, etc., can solve the problems of low work efficiency and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is further described in detail through specific implementation methods:

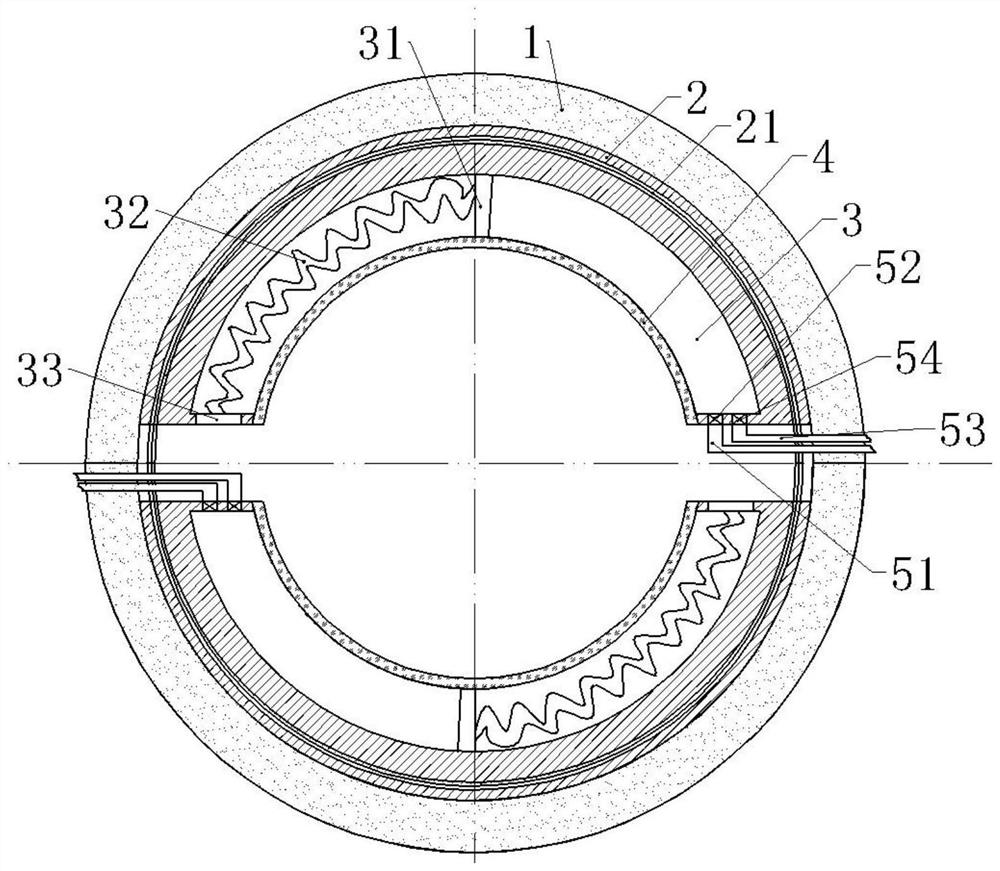

[0030] The reference signs in the drawings of the description include: jacket 1, electromagnetic heating part 2, coil 21, semi-circular cylindrical cavity 3, slide plate 31, telescopic part 32, through hole 33, conductor plate 4, water inlet pipe 51, single To the water inlet valve 52, the water outlet pipe 53, and the one-way water outlet valve 54.

[0031] The embodiment is basically as attached figure 1 Shown:

[0032] An intelligent welding device for steel-plastic composite pipes includes a main machine and a fixture. The main machine is provided with a display screen which is a touch screen, and the display screen is provided with start and stop buttons. The display screen is set, which is convenient for observing the working parameters in the welding process and convenient for operation. Both the fixture and the welding host are equipped with electrical wire interfaces, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com