A kind of application method of clamping component for prefabrication of reinforcement cage of building foundation

A technology of clamping components and application method, applied in the field of construction, can solve the problems of uneven distribution of transverse ribs, detachment of transverse ribs, and unsatisfactory welding effect of transverse ribs, and achieves the advantages of ensuring strength, uniform distribution, and improving the scope of application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

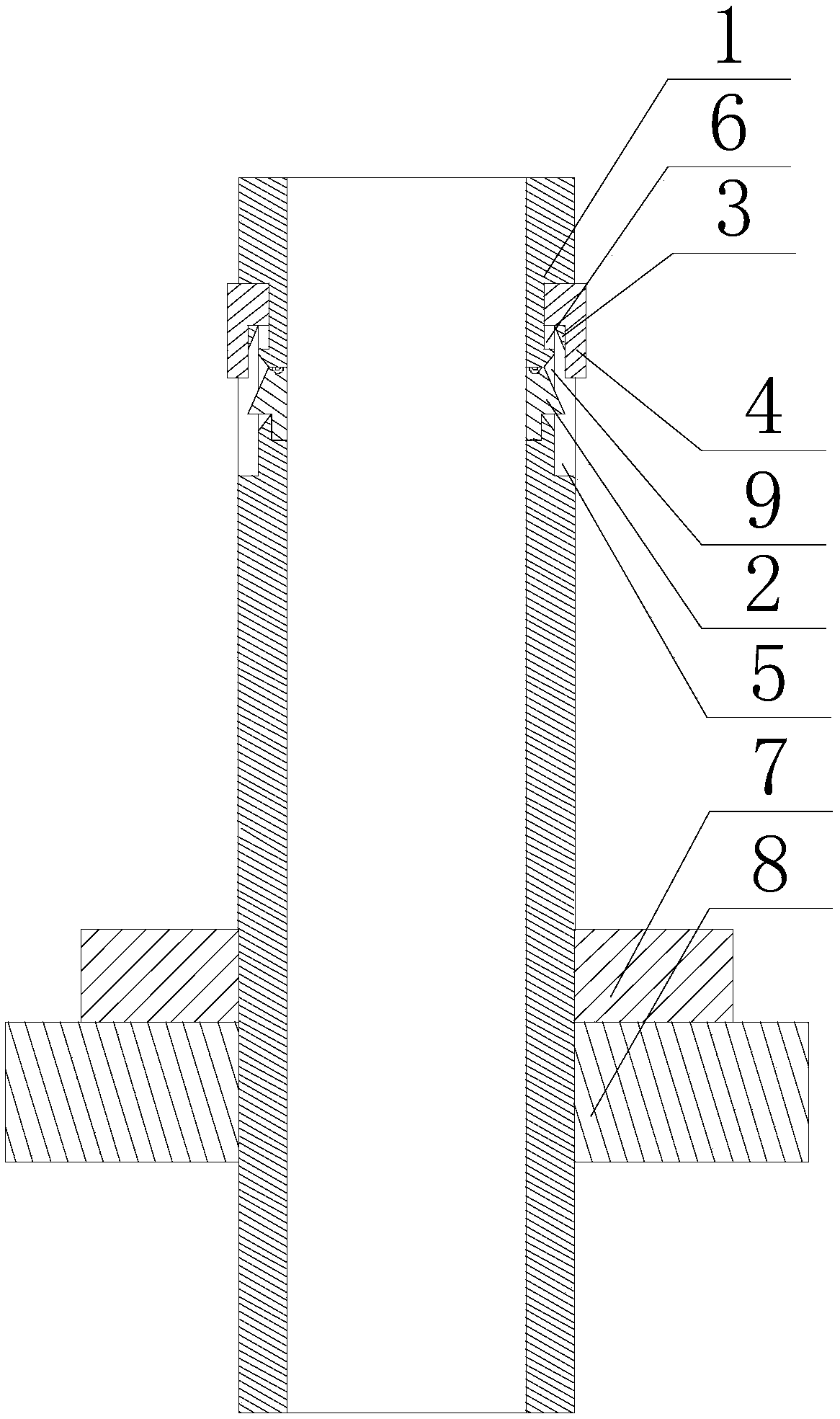

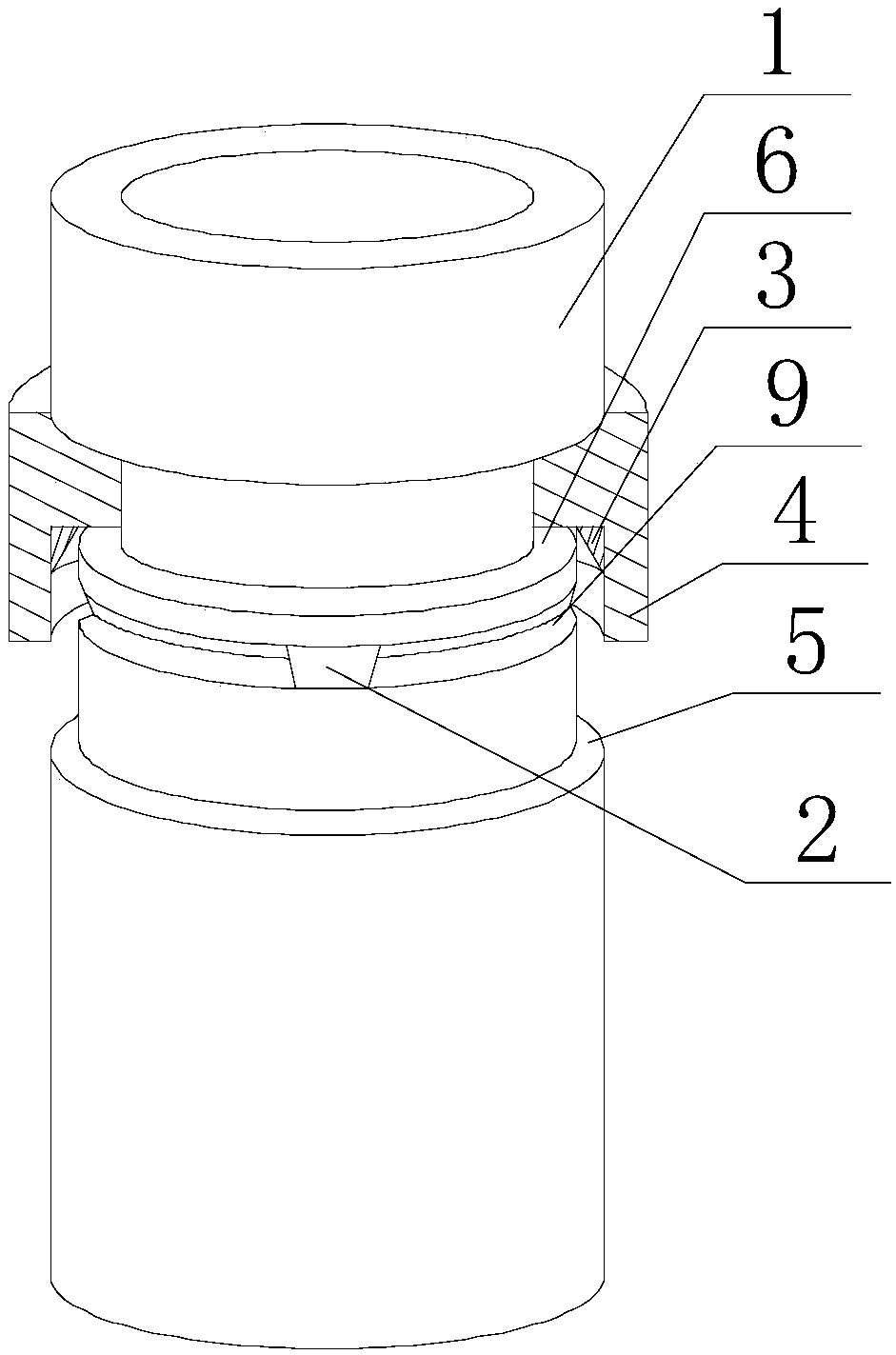

[0024] Such as Figure 1~3As shown, this embodiment includes the following steps: firstly, two opposite cylinders respectively act on the two ends of a longitudinal rib, and one end of the cylinder penetrates the installation hole on the turntable, and ensures that the snap ring and the nut are installed respectively. At both ends of the hole, tighten the nuts so that the cylinder is fastened on the turntable, then align the end of the longitudinal rib with the axis of the cylinder until the end of the longitudinal rib is inserted into the cylinder, and rotate the pressure ring to make it along the cylinder The axis of the body moves towards the direction of the snap ring, so that the oblique contact block on the pressure block contacts the inner side wall of the annular protrusion, and the protrusion presses the contact block, so that the inner side wall of the pressure block approaches the axis of the cylinder , to realize the extrusion of the inner wall of the briquetting b...

Embodiment 2

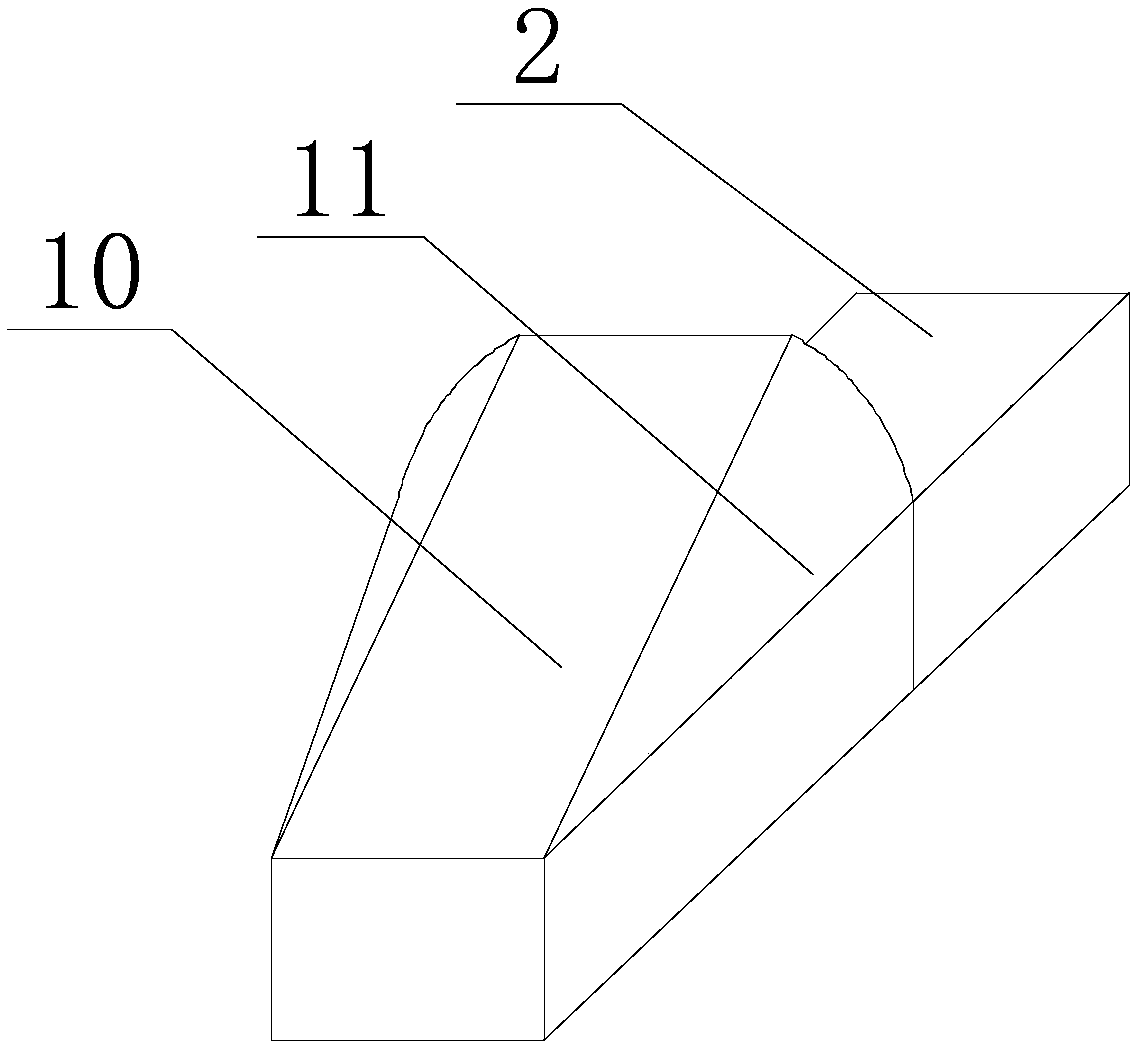

[0029] Such as Figure 1~3 As shown, in this embodiment, transition arcs 11 are respectively provided on both sides of the contact block 10. When the pressure block 2 rotates along the circumferential direction of the annular groove 9 to contact with the contact block 10, the inner side wall of the pressure block 2 and the A smooth transition is realized between the outer side walls of the contact block 10 . When the pressure ring 4 is adjusted to be in contact with the outer side wall of the contact block 10, since the inner peripheral wall of the protrusion 3 is smooth, the two ends of the contact block 10 on the circumferential track of the limit groove 5 are likely to collide with the inner peripheral wall of the protrusion 3. Scratching causes the protrusion 3 to be damaged, so that the adjustment accuracy of the protrusion 3 in the later period is reduced. For this, the applicant sets excessive arcs at the two ends of the protrusion 3, so that the inner wall of the protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com