Reinforcement Cage Skeleton Forming Device for Pile Hole Foundation

A forming device and reinforcement cage technology, applied in the field of building construction, can solve the problems that the strength of pile holes cannot meet the requirements of building construction, the effect of transverse rib welding is not ideal, and the distribution of transverse ribs is uneven, so as to avoid swing and radial swing Eliminate and improve the effect of distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

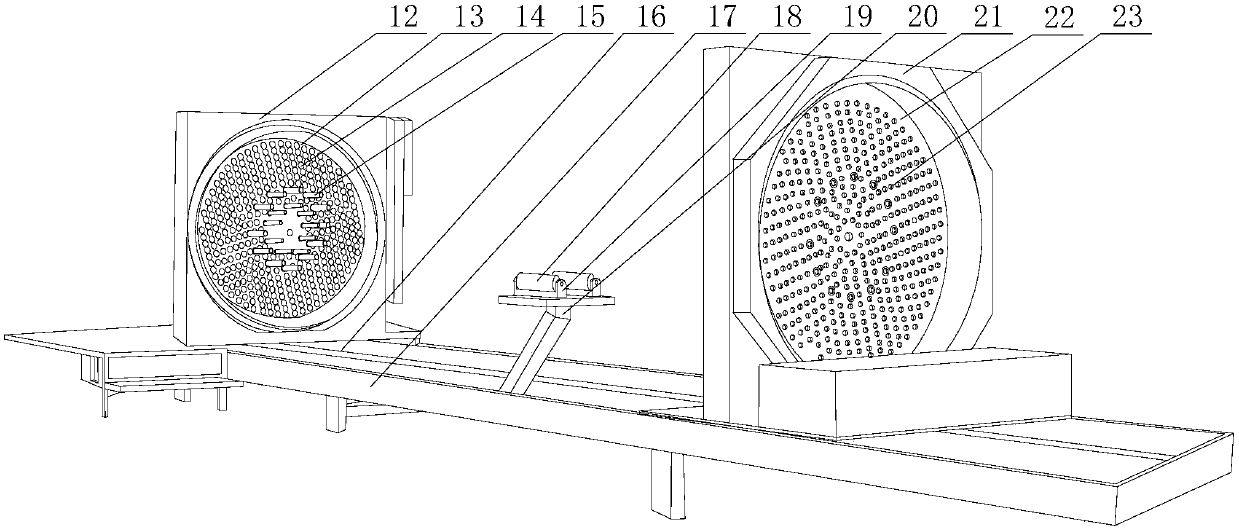

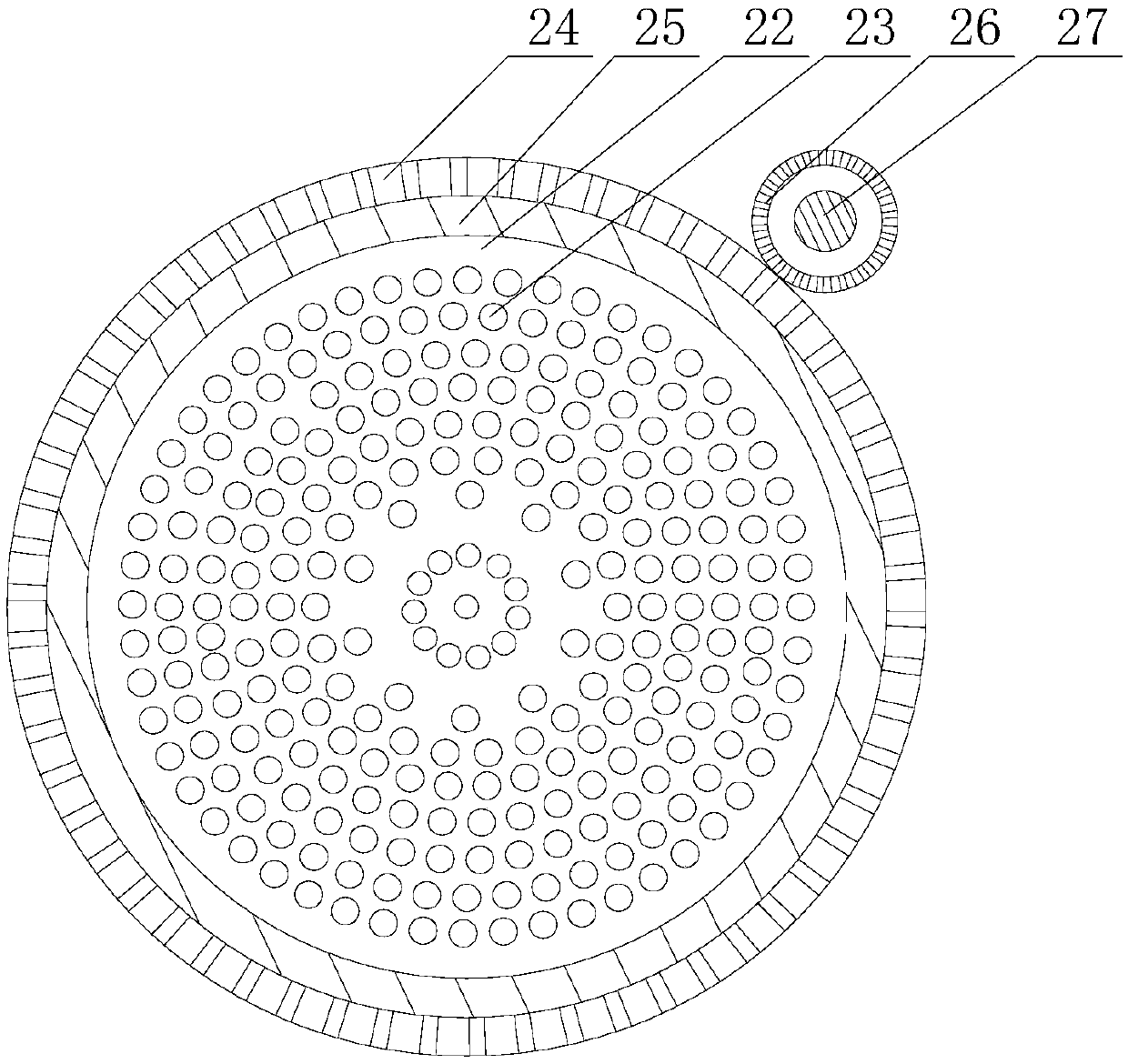

[0029] Such as Figure 1~5 As shown, the present embodiment includes a base 17, a guide rail 16 is provided in the middle of the base 17, the first support plate 12 is fixed on one end of the guide rail 16, and the second support plate 21 is slidably arranged on the other end of the guide rail 16. A first turntable 13 is rotated on the first support plate 12, and a plurality of butt holes 14 are opened on the first turntable 13. The plurality of butt holes 14 are radially distributed outward along the radial direction of the first turntable 13. Two coaxial bearings 25 are rotatably arranged on the second support plate 21, and there is a gap between the two bearings 25, and the second turntable 22 opposite to the first turntable 13 is rotatably arranged in the two bearings 25. , and an annular toothed belt 24 is provided in the middle of the outer peripheral wall of the second turntable 22, and the toothed belt 24 extends outwards after passing through the gap, and a motor is f...

Embodiment 2

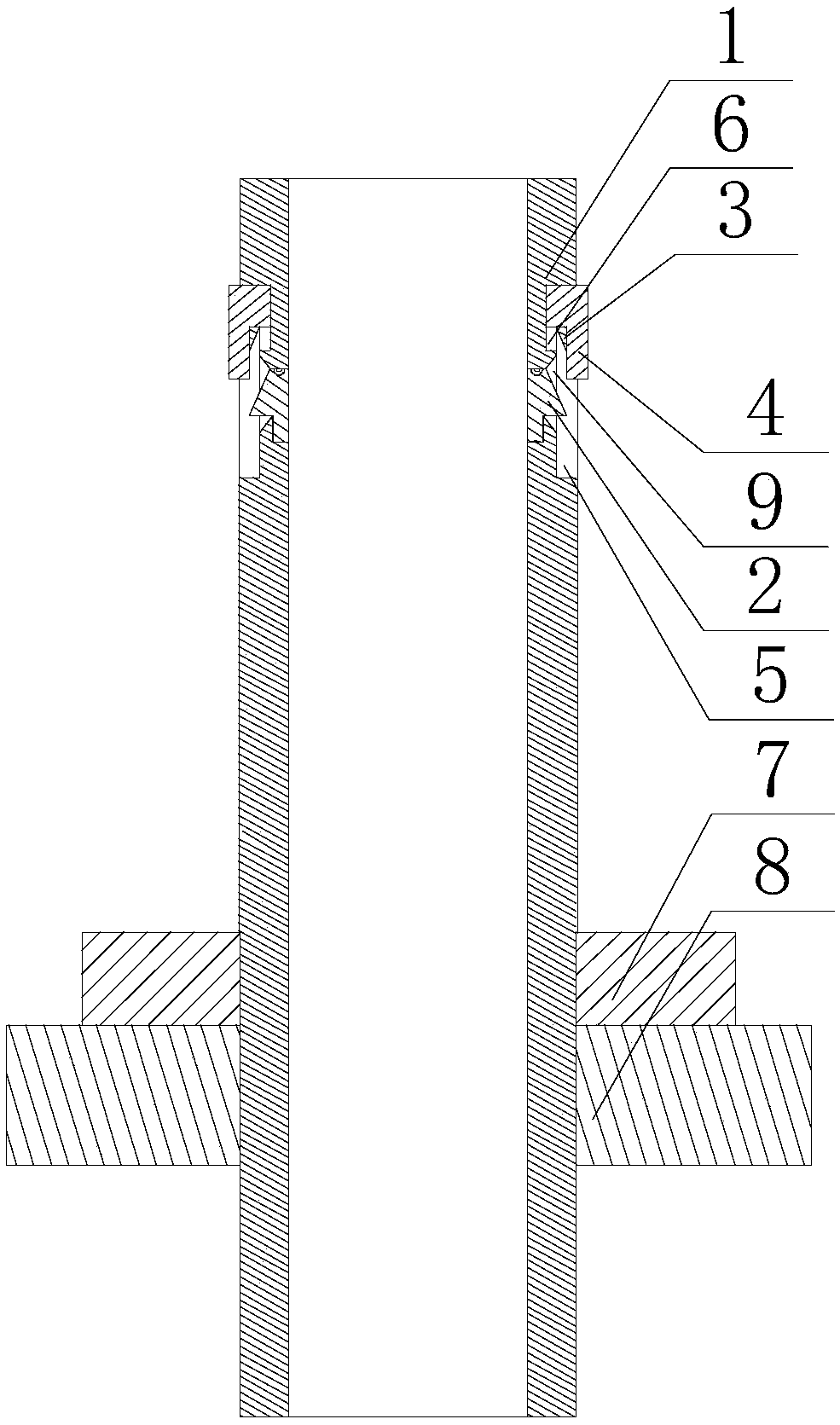

[0034] Such as Figure 1~5 As shown, in this embodiment, transition arcs 11 are respectively provided on both sides of the contact block 10. When the pressure block 2 rotates along the circumferential direction of the annular groove 9 to contact with the contact block 10, the inner side wall of the pressure block 2 and the A smooth transition is realized between the outer side walls of the contact block 10 . When the pressure ring 4 is adjusted to be in contact with the outer side wall of the contact block 10, since the inner peripheral wall of the protrusion 3 is smooth, the two ends of the contact block 10 on the circumferential track of the limit groove 5 are likely to collide with the inner peripheral wall of the protrusion 3. Scratching causes the protrusion 3 to be damaged, so that the adjustment accuracy of the protrusion 3 in the later period is reduced. For this, the applicant sets excessive arcs at the two ends of the protrusion 3, so that the inner wall of the protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com