Portal frame device for welding steel pipe piles

A steel pipe pile and gantry technology, which is applied in the field of steel pipe pile welding, can solve the problems of poor fixing effect, affecting the welding accuracy of steel pipe piles, affecting the welding quality of steel pipe piles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

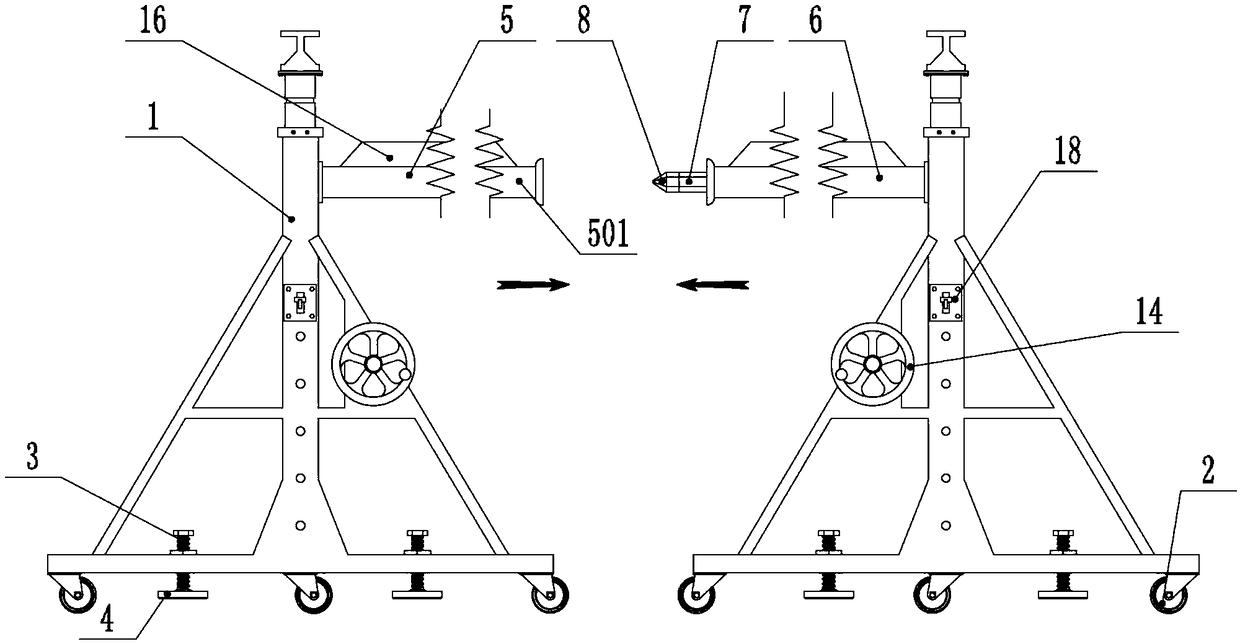

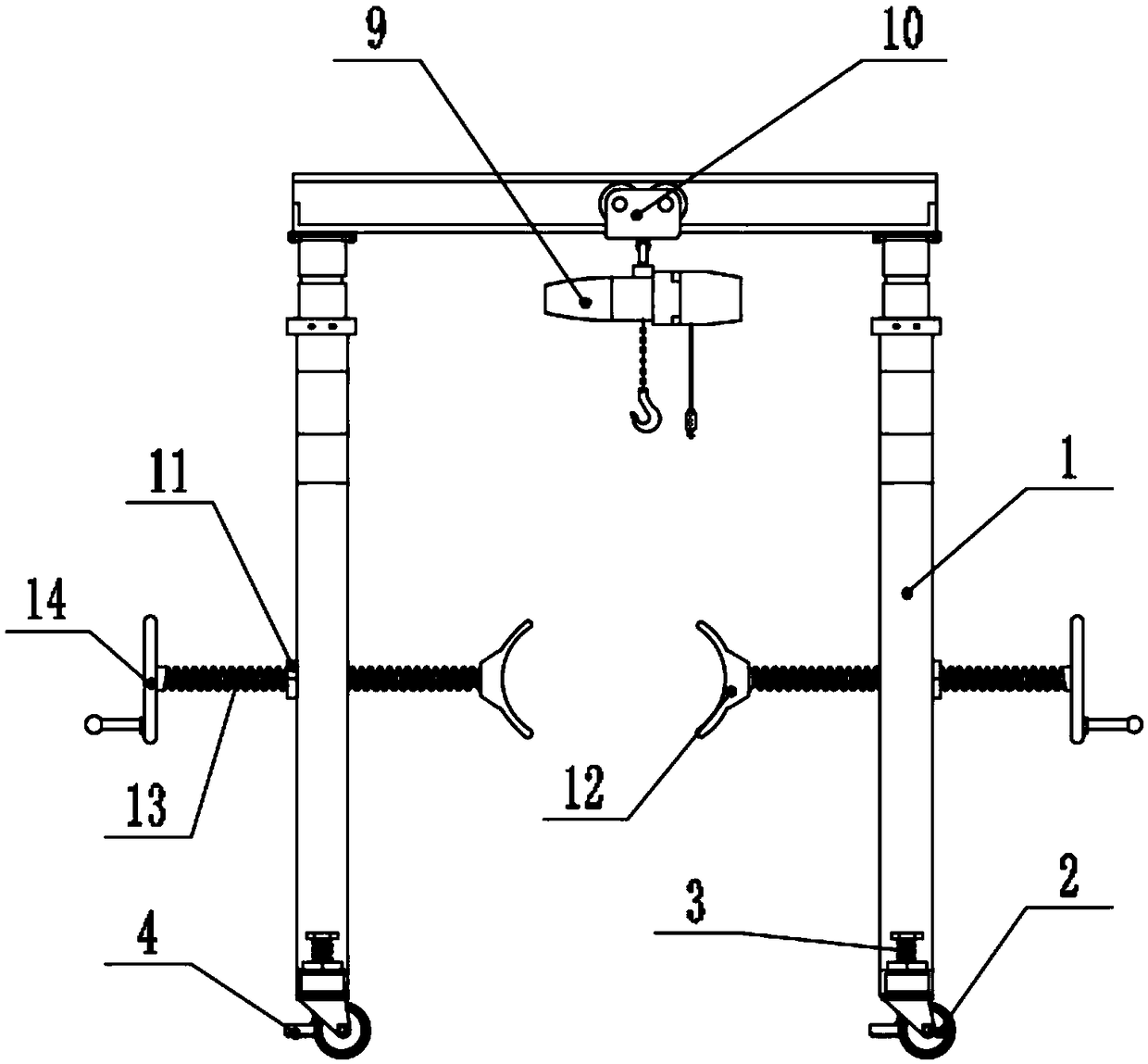

[0037] as attached figure 1 To attach Figure 10 Shown:

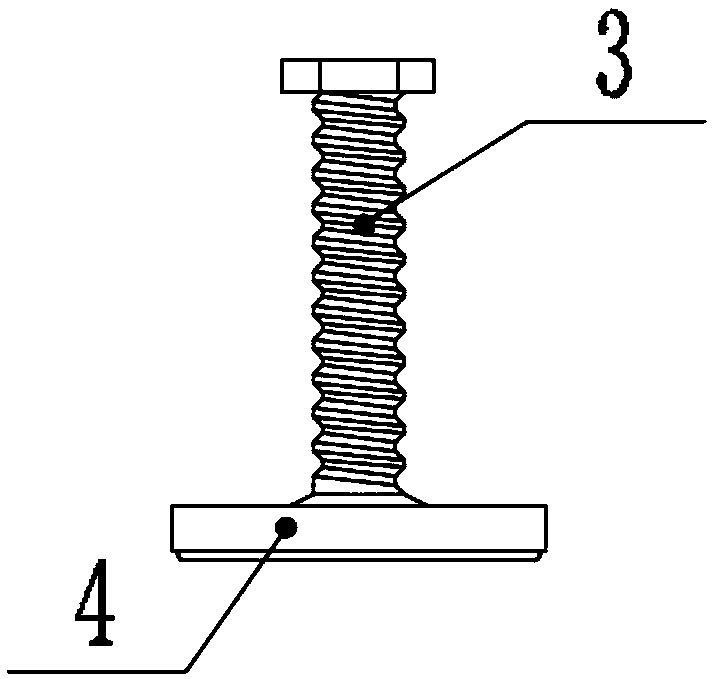

[0038]The invention provides a gantry equipment for steel pipe pile welding, which includes a gantry main body 1, a universal wheel 2, a fixed threaded shaft 3, a fixed support plate 4, a left connecting rod 5, a hexagonal connecting groove 501, and a right connecting Rod 6, hexagonal column 7, hexagonal magnetic cone 8, electric hoist 9, roller assembly 10, nut block 11, clamp block 12, threaded shaft 13, hand wheel 14, fan 15, smoke collecting cover 16, flexible Smoke exhaust pipe 17 and smoke exhaust switch 18; the top of the gantry main body 1 is a "worker" shaped slide rail structure, and six universal wheels 2 are installed on the front and rear ends of the bottom end of the gantry main body 1; the fixed threaded shaft 3 There are eight places in total, and the eight fixed threaded shafts 3 are respectively installed at the bottom of the two gantry main bodies 1, and the top of the fixed threaded shafts 3 is a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com