A fixture for laser welding of fuel cell bipolar plates

A laser welding and fuel cell technology, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of complicated welding process, achieve the effect of simplifying welding process and improving production tempo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

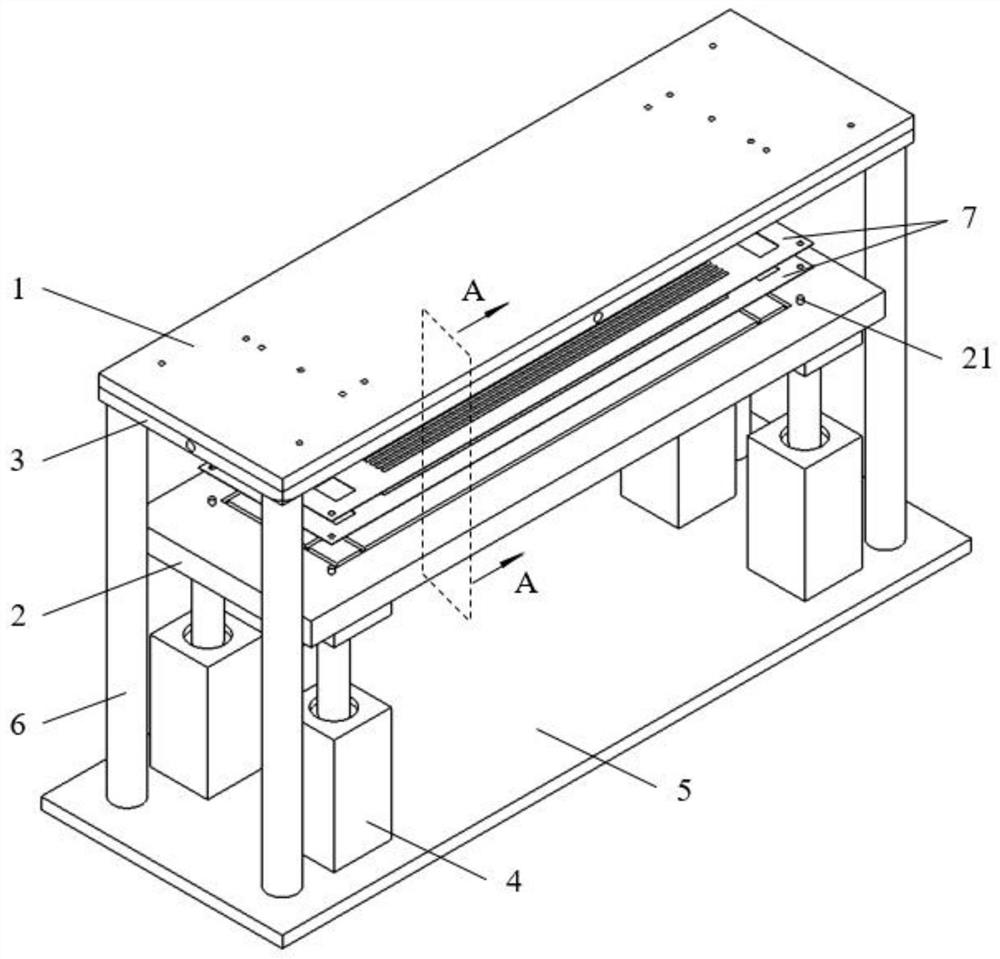

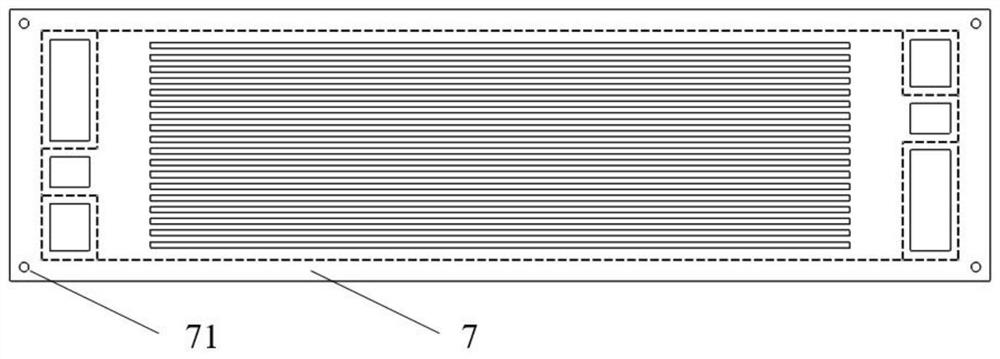

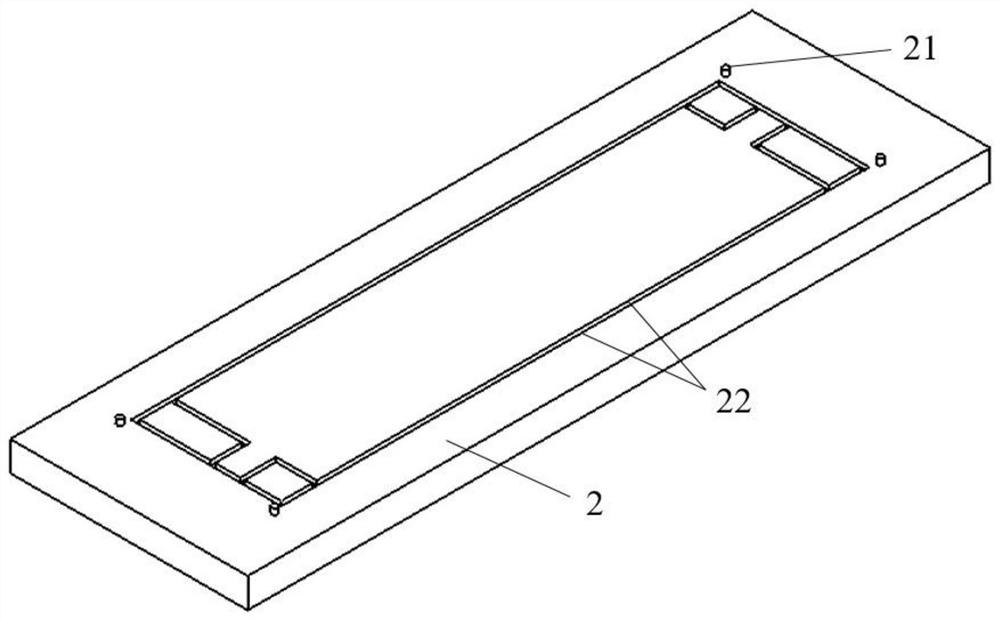

[0036] Such as figure 1 As shown, a fixture for laser welding of a fuel cell bipolar plate 7 includes a first press plate 1, a second press plate 2, a profiling plate 3, a driving device 4, a bottom plate 5 and a support member 6, wherein,

[0037] Both the first pressing plate 1 and the second pressing plate 2 are straight plates. The first platen 1 is made of materials capable of penetrating laser light 8 , such as transparent quartz glass, transparent sapphire glass and the like. The second pressing plate 2 , the profiling plate 3 , the bottom plate 5 and the supporting member 6 are made of metal parts such as steel or aluminum alloy. The first pressing plate 1 is horizontally fixed on the bottom plate 5 through the support member 6, the second pressing plate 2 is fixed horizontally on the bottom plate 5 through the driving device 4, and the first pressing plate 1 is located directly above the second pressing plate 2 and the first pressing plate 1 It is spaced apart from ...

Embodiment 2

[0055] This embodiment is another embodiment of Embodiment 1. In this embodiment, the material of the profiling plate 3 is made of a material through which the laser light 8 can pass, such as transparent quartz glass or transparent sapphire glass. The rest of the structure of this embodiment is the same as that of Embodiment 1.

[0056] Such as Figure 9 As shown, when long-distance galvanometer laser welding is used, the angle between the path of the laser 8 and the bipolar plate 7 is small, and the laser 8 must pass through the profiling plate 3 to be irradiated on the surface of the bipolar plate 7 Therefore, after the material of the profiling plate 3 is set to a material through which the laser 8 can pass, long-distance galvanometer laser welding can be realized to ensure the welding quality in the long-distance area. When the format of the bipolar plate 7 is large, there is no need to move the emitting end of the laser 8 to a large extent, only need to adjust the emitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com