Intelligent laser welding device

A laser welding and intelligent technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of deposition and poor welding quality, and achieve the effect of simplified operation, convenient and fast welding, and good welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below by means of specific embodiments:

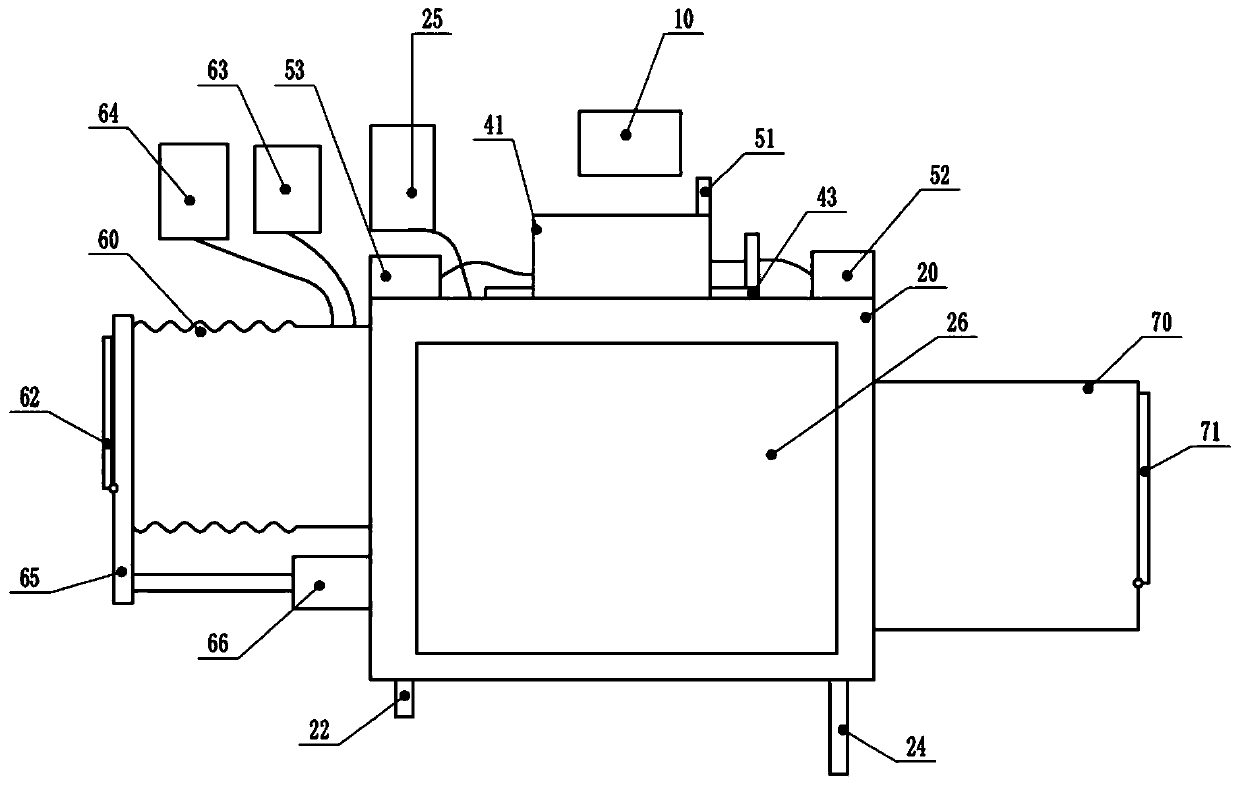

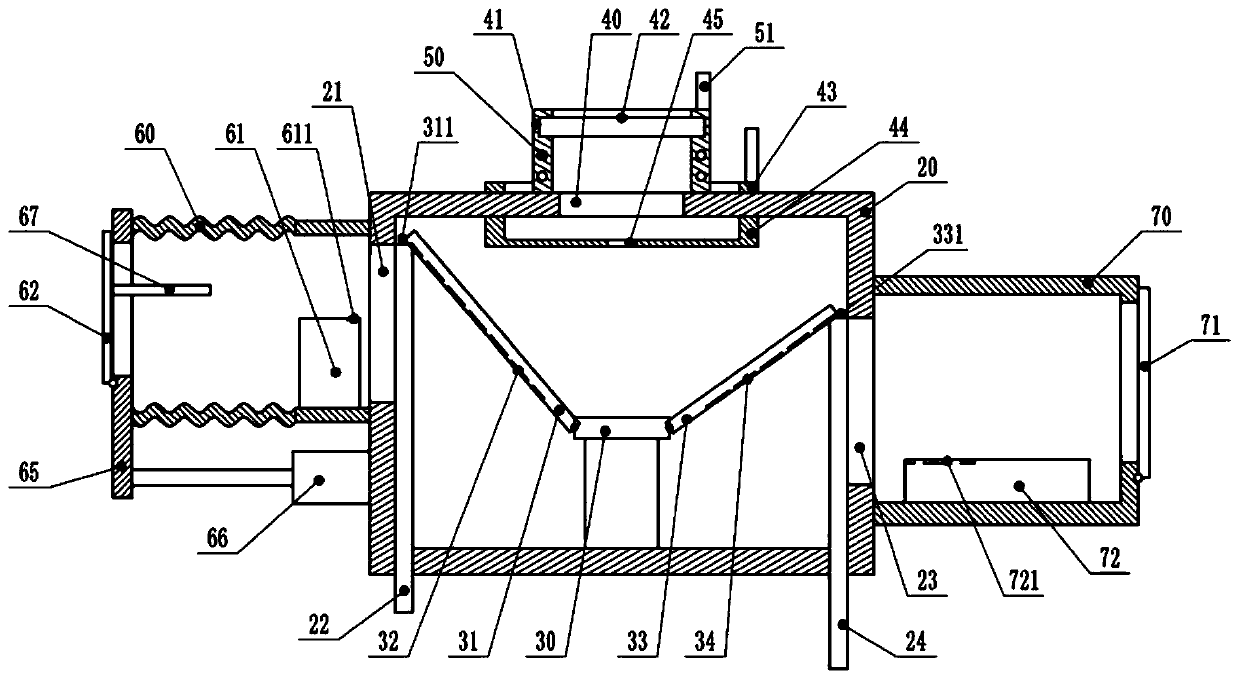

[0036] The reference signs in the accompanying drawings include: laser head 10, vacuum chamber 20, feed port 21, feed door 22, discharge port 23, discharge door 24, second air pump 25, first electromagnet 26, Platen 30, first push plate 31, first buckle 311, first chute 32, second push plate 33, second buckle 331, second chute 34, transmission hole 40, box 41, laser transmission Lens 42, magnetic ring 43, protective tube 44, transparent protective lens 45, cold water pipe 50, fan 51, cold water tank 52, hot water tank 53, feed chamber 60, first workbench 61, first draw-in groove 611, the first A door 62, a first air pump 63, a gas cylinder 64, a baffle 65, a cylinder 66, a push rod 67, a discharge chamber 70, a second door 71, a second workbench 72, and a second slot 721.

[0037] Such as figure 1 , figure 2 As shown, the intelligent laser welding device includes a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com