Automobile part welding auxiliary device capable of performing rotational adjustment

A technology for auxiliary devices and auto parts, applied in auxiliary devices, welding/cutting auxiliary equipment, auxiliary welding equipment, etc., can solve problems such as easy shaking, impact on personnel breathing system, poor fixing effect of auto parts, etc., to improve practical performance , Avoid random rotation and ensure the effect of welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

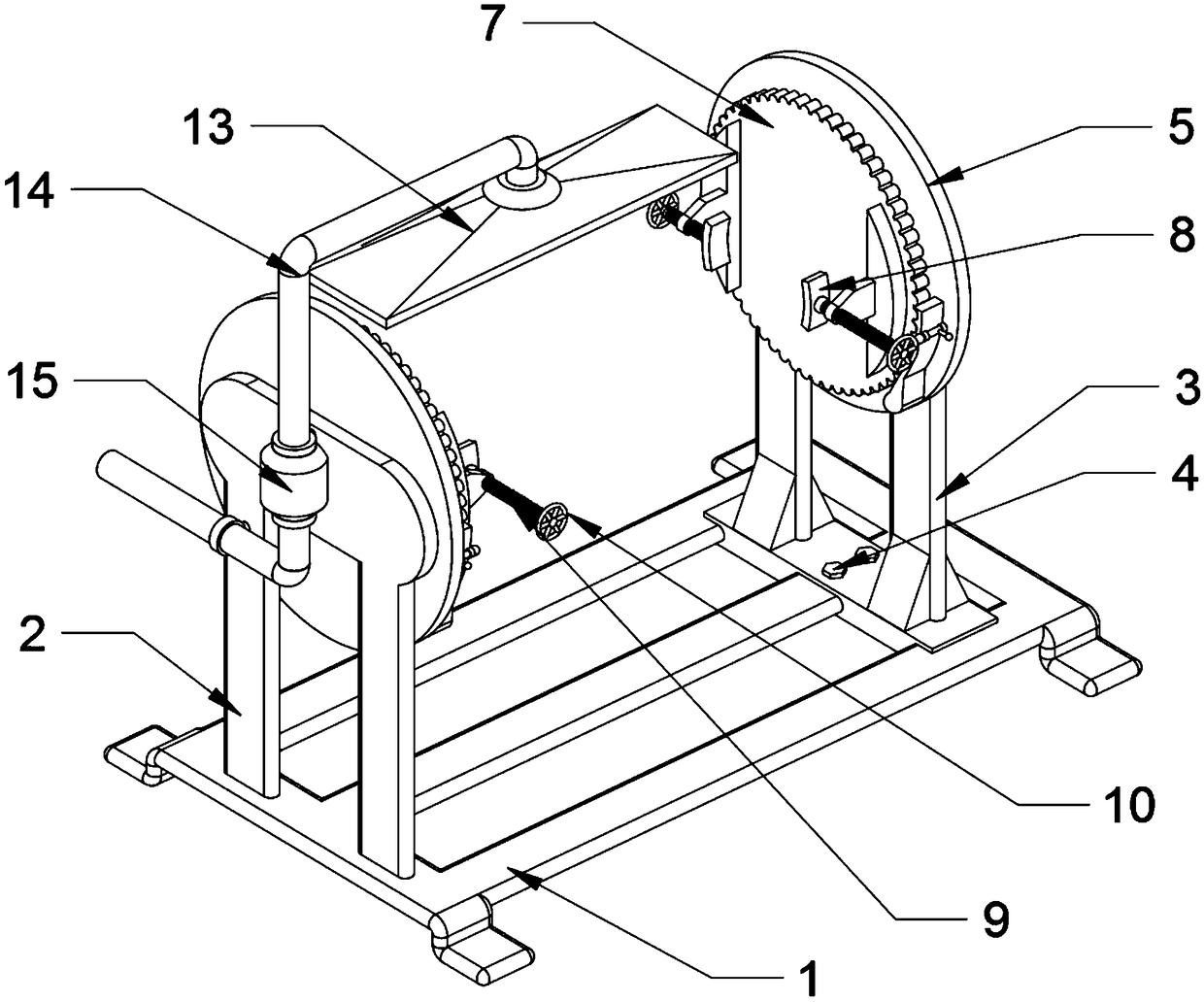

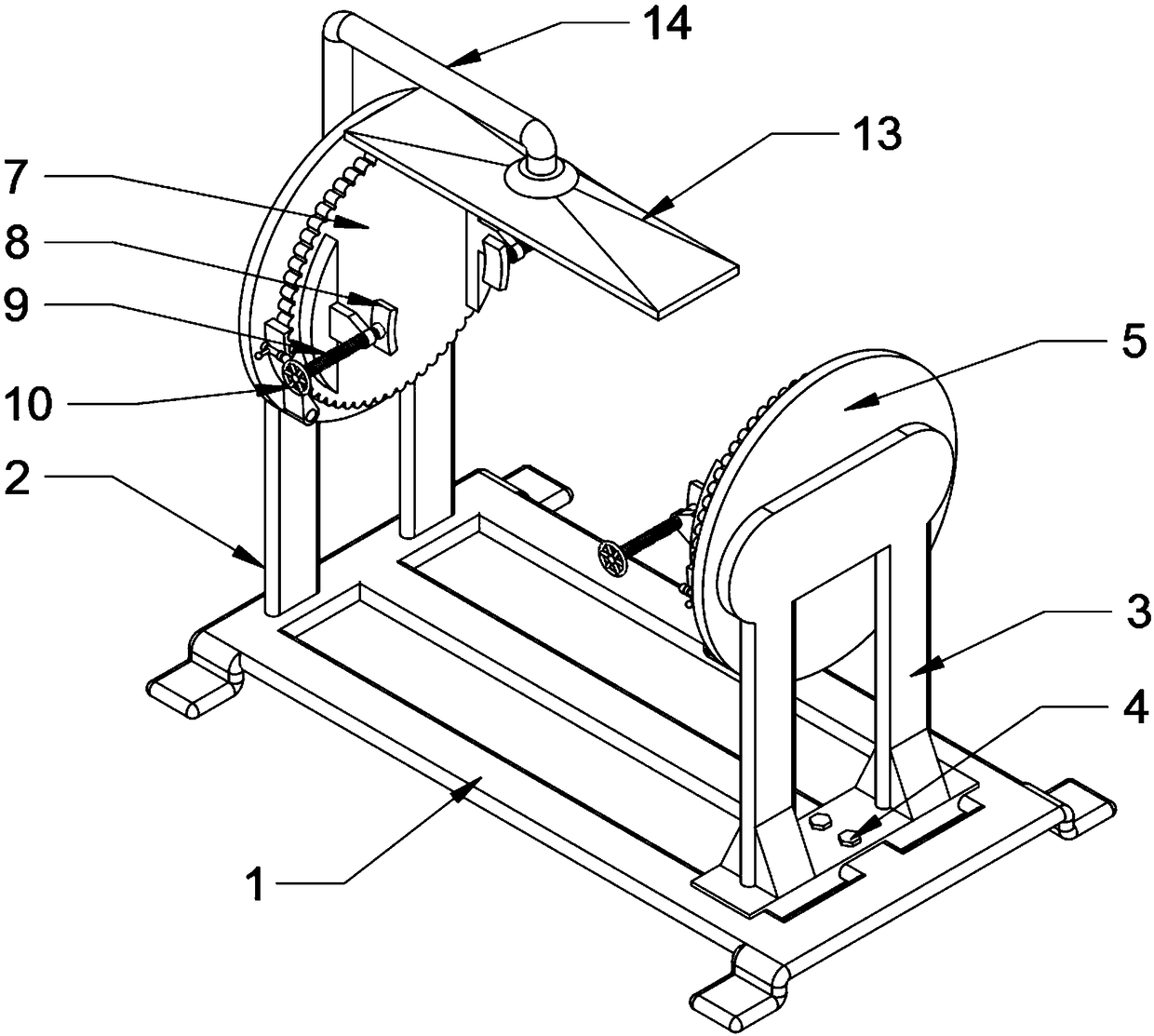

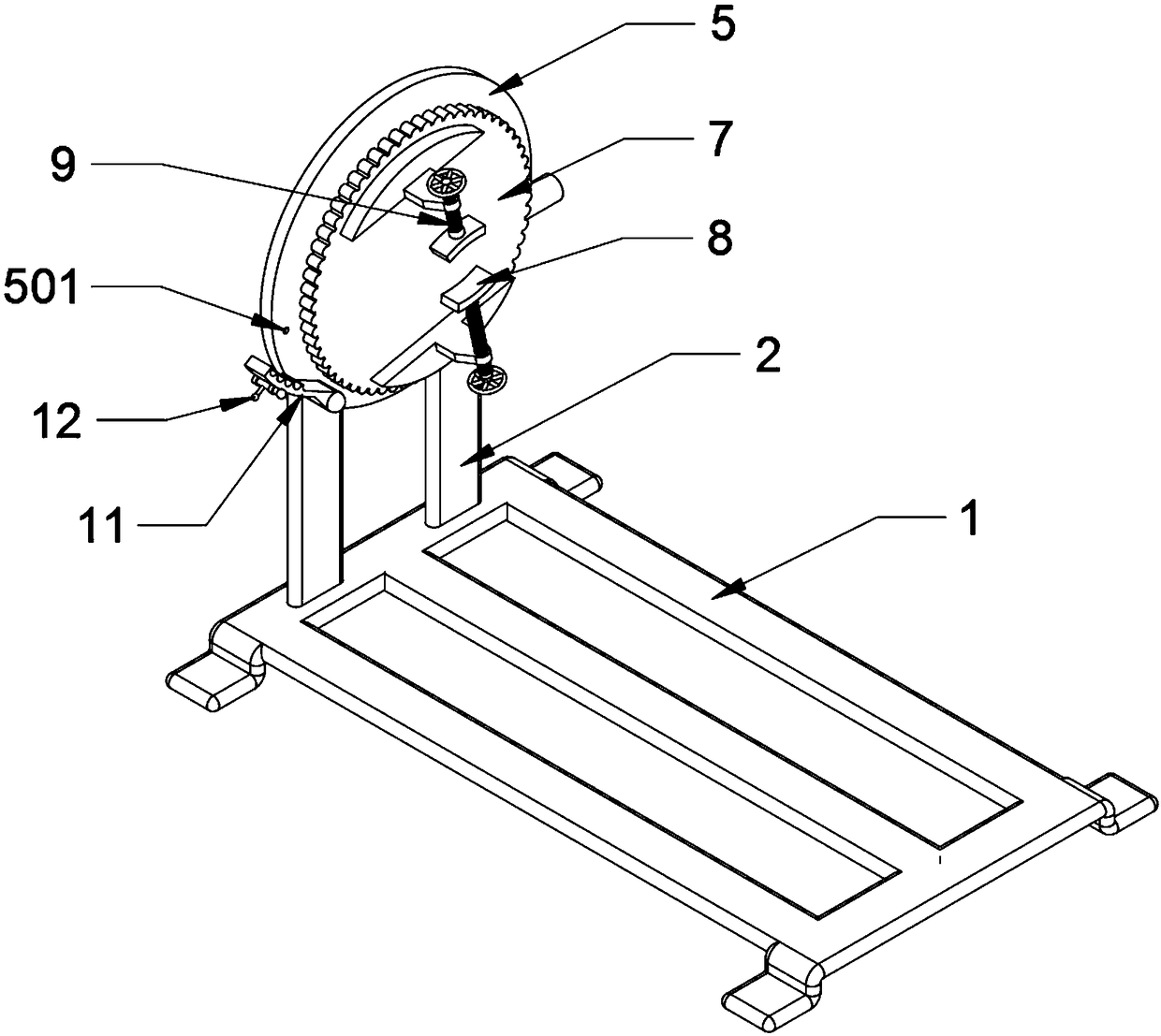

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The invention provides an auxiliary device for welding assembly of automobile parts that can be rotated and adjusted. Plate 7, clamp block 8, threaded shaft 9, turning handle 10, fixed bar 11, latch 12, smoke hood 13, ventilation duct 14 and smoke exhaust fan 15; the bottom of the support frame 2 is installed on the left end of the top end surface of the base 1, and The movable support frame 3 is installed on the right end of the top end face of the base 1; there are two positioning bolts 4, and the two positioning bolts 4 are installed on the movable support frame 3; there are two receiving plates 5, and the two receiving plates 5 are circular plate-shaped structures, and two receiving plates 5 are installed on the top of the inner end surface of the support frame 2 and the movable support frame 3 respectively; a positioning groove 501 is opened at the bottom of the inner end surface of the receiving plate 5; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com