Fixing device for welding of alternating current capacitor terminal

A technology for fixing devices and capacitors, which is applied in the field of capacitors. It can solve problems affecting the welding efficiency of capacitor terminals and the main board, capacitor position offset, and heavy manual operation burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

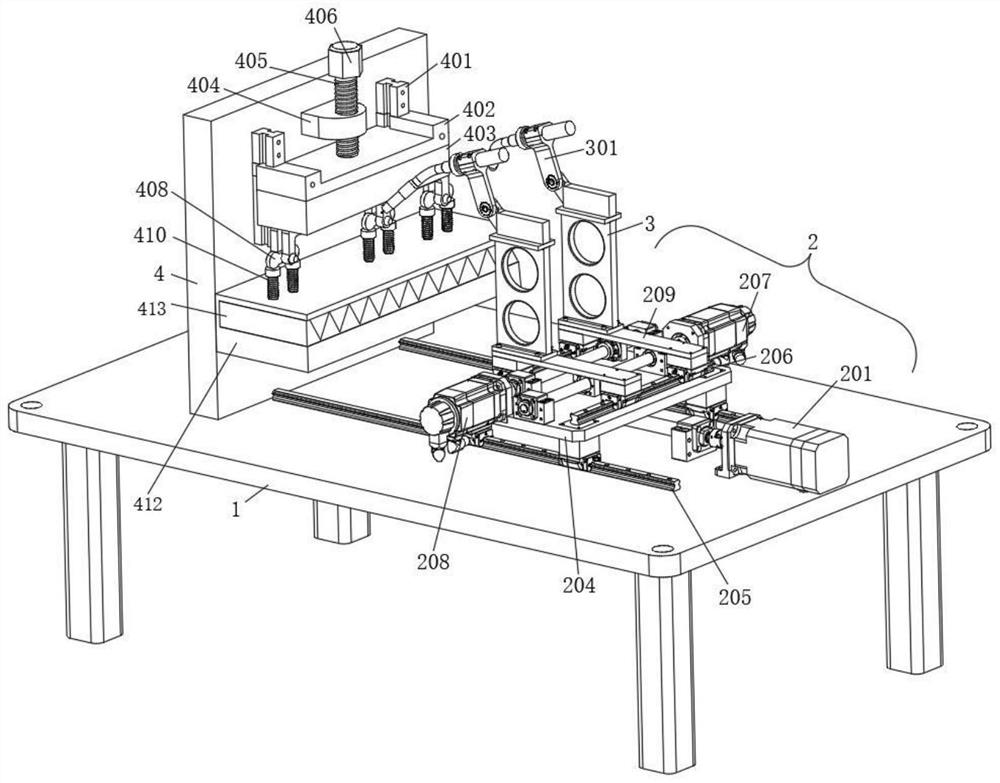

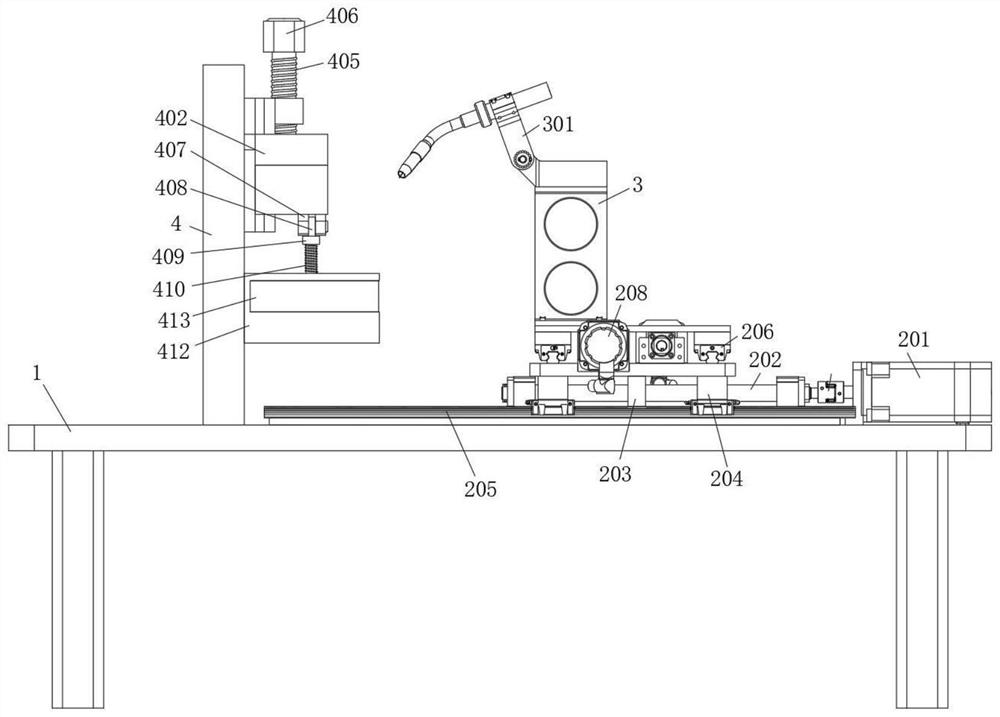

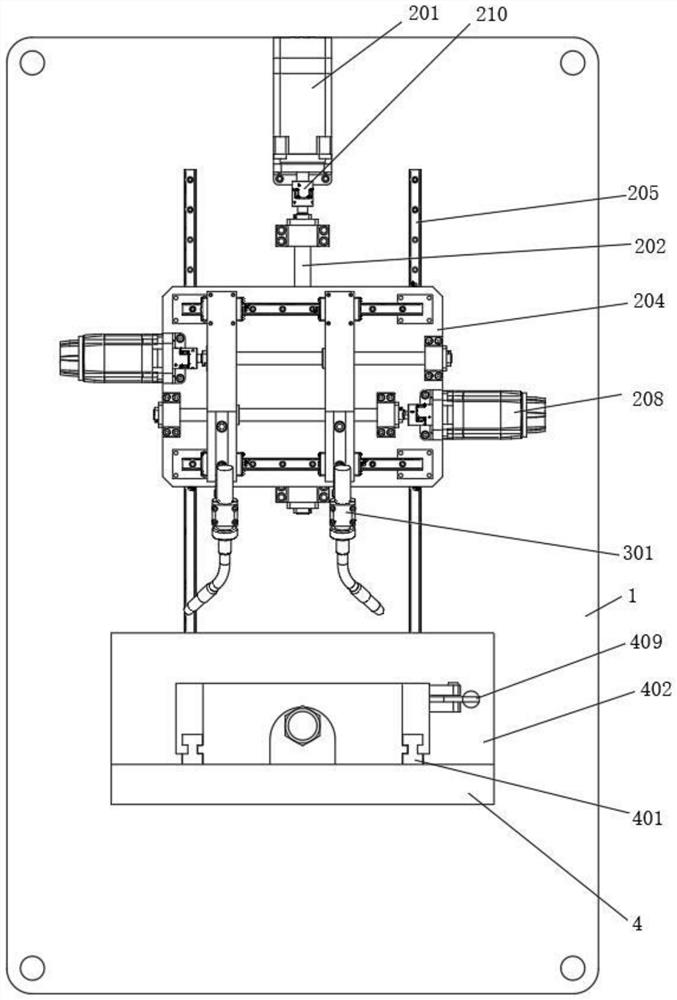

[0029] refer to Figure 1-5 , a fixing device for welding AC capacitor terminals, in order to enhance the applicability and flexibility of use of the fixing device, and improve the stability of the overall welding, a support platform 1 is provided here, and the top of the support platform 1 is provided with a bump The top of the support table 1 is provided with a mobile welding structure 2 and a vertical plate 4. In order to improve the efficiency of welding, a capacitor fixing structure for simultaneously fixing multiple capacitors is provided on the vertical side of the vertical plate 4 here. In order to facilitate welding tools Flexible use, the terminals can be welded at multiple angles, so as to ensure the firmness of the capacitor terminal welding. Here, a support plate 3 is fixedly connected to the top side of the mobile welding structure 2, and the top of the support plate 3 is rotatably connected to a movable fixed head 301 ;

[0030] The capacitor fixing structure i...

Embodiment 2

[0034] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, in order to play a certain protective role and not hinder the function implementation of the capacitor fixing structure, a hollow protective shroud is fixedly connected to the bottom side of the pressure plate 402 here. 403 , the lowest point of the protective shroud 403 is higher than the balance guide block 408 .

[0035] In this embodiment, some components of the capacitor fixing structure are protected by the protective shroud 403 to prevent them from being damaged by external factors, thereby prolonging the service life of the components.

Embodiment 3

[0037] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, in order to facilitate the screwing of the second threaded rod 405 and prevent the second threaded rod 405 from breaking away from the fixing ear 404, an end cover 406 is fixedly connected to the top of the second threaded rod 405 , and the width of the end sleeve 406 is greater than the diameter of the second threaded rod 405 .

[0038] In this embodiment, the threaded rod 2 405 is driven to rotate by rotating the end sleeve 406 , thereby realizing the pressing down of the pressing plate 402 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com