Long welding seam robot welding process

A robot welding and welding robot technology, applied in welding equipment, manipulators, manufacturing tools, etc., can solve the problems of non-standard structural welds and other problems, and achieve the effects of long gas escape time, improved quality, and continuous welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

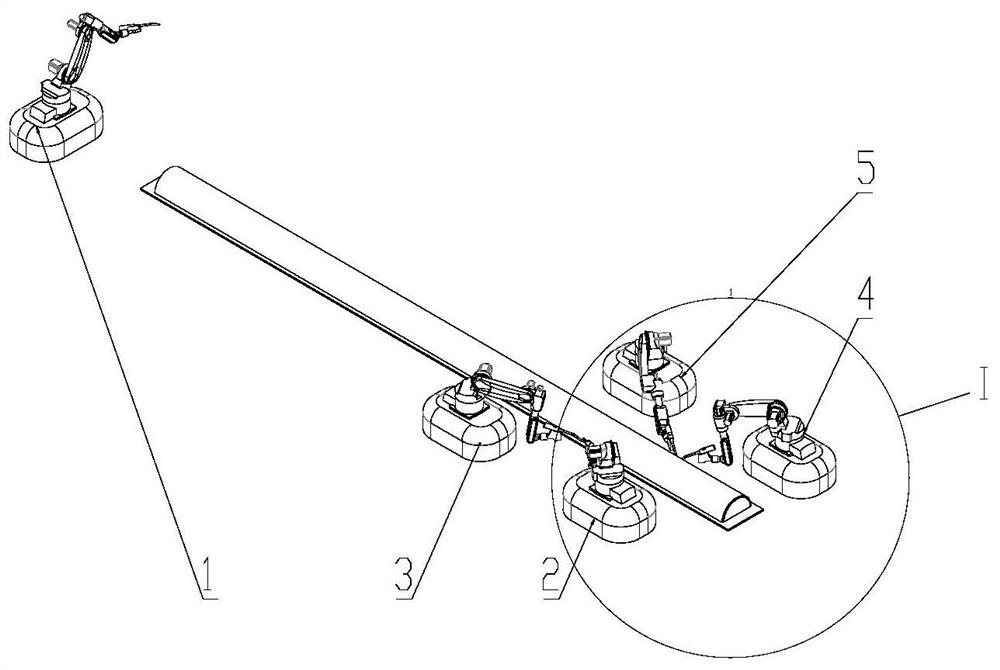

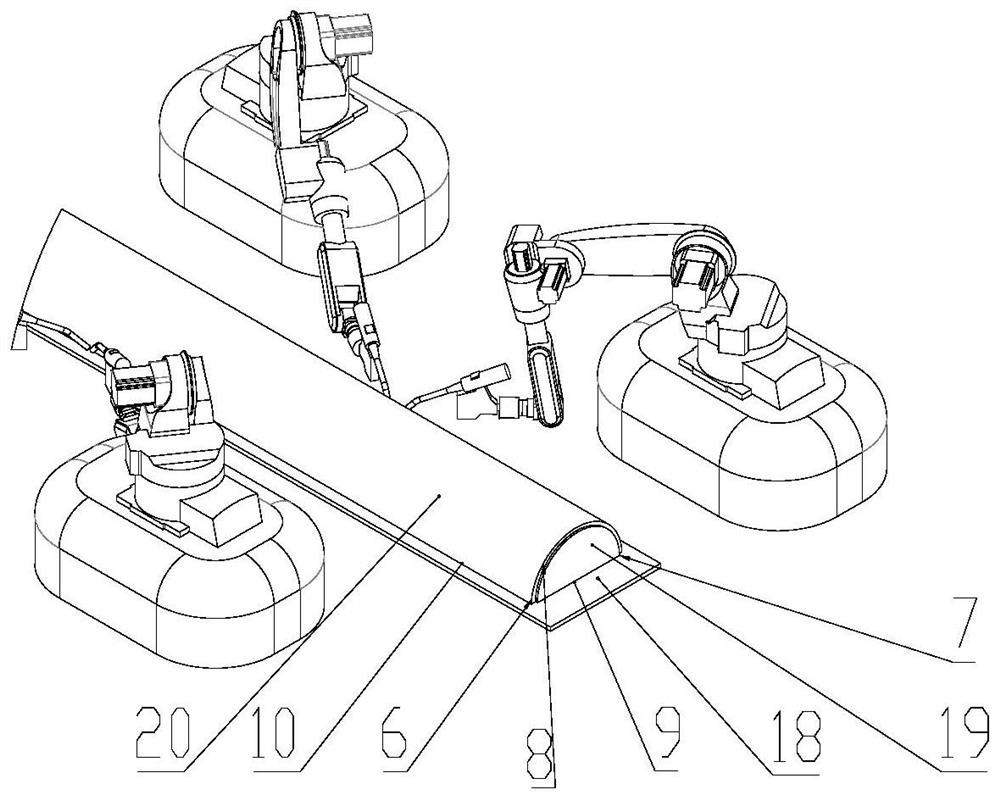

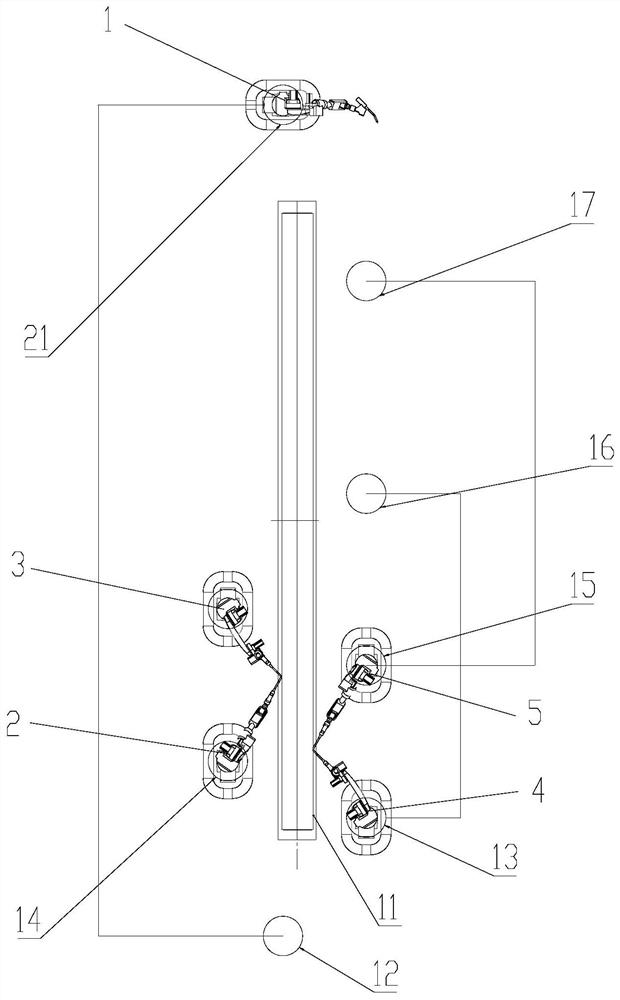

[0052] A robot welding process for long seams provided by the present invention includes an auxiliary welding robot 1, a sequence a welding robot 2 on the left side, a b sequence welding robot 3 on the left side, a sequence a welding robot 4 on the right side and a b sequence welding robot 5 on the right side ,Such as Figure 1-2 As shown, the specific welding process is:

[0053] 1) The auxiliary welding robot 1, the left a-sequence welding robot 2 and the right a-sequence welding robot 4 are simultaneously welding on one end of the cover plate 20, the auxiliary welding robot 1 is in the parking space 12 at the first end, and the left a-sequence welding robot 2 is in the first parking space 14 on the left, and the sequence welding robot 4 is in the first parking space 13 on the right, such as image 3 As shown; the arc starting point is at the intersection of the vertical plate 19, the cover plate 20 and the bottom plate 18 (the intersection of the arched upper arc weld 8, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com