Horizontal fillet welding seam angle-wrapping process suitable for automatic welding

An automatic welding and automatic welding technology, which is applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of many angle changes and difficult programming of robots, etc. It takes a long time to achieve, simplifies the workload of trial teaching, and expands the coverage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

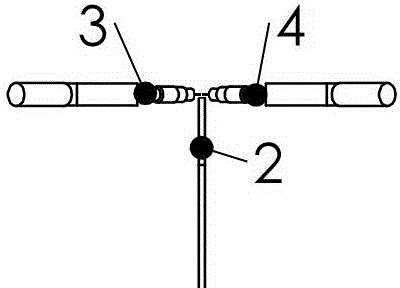

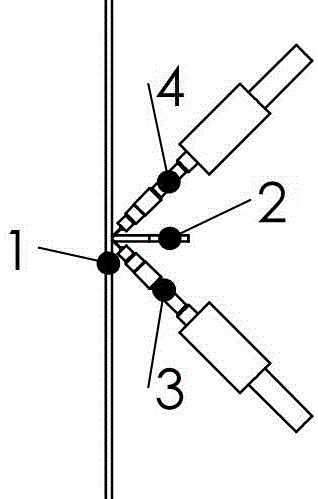

[0029] The two welding torches are welding torch one 3 and welding torch two 4 respectively.

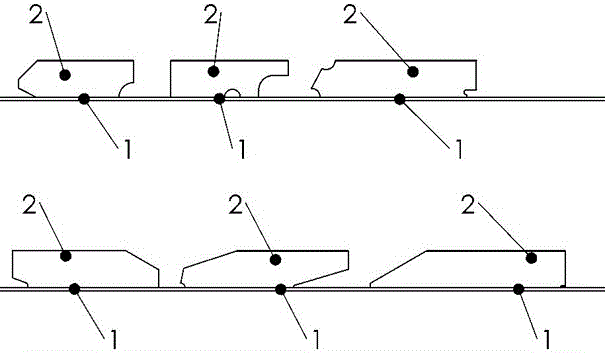

[0030] Refer to attached figure 1 , when the group is welded vertically, the end of the rib 2 also needs to be welded to the bottom plate 1, the weld between the end of the rib 2 and the bottom plate 1, and the weld transition from the end to the normal horizontal fillet weld are defined as horizontal fillet welds Seam wrap fillet welds.

[0031] Refer to attached figure 2 , 3 4. In order to carry out corner welding in automatic welding, use two welding torches one 3 and two welding torches 4 in a posture parallel to the end of the reinforcing rib, such as figure 2 , 3 The posture shown; the two welding torches parallel to the end of the reinforcing rib are arranged symmetrically on both sides of the reinforcing rib;

[0032] Welding torch one 3 and welding torch two 4 respectively arrive at reinforcing rib 2, welding torch one path point A5 and welding torch two path point A9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com