Welding device used for welding ring-shaped piece of steering pipe column

A technology of welding equipment and steering column, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easy welding deviation, thin ring piece, poor welding efficiency, etc., and achieve high-efficiency production , fast transposition welding, and the effect of ensuring welding quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

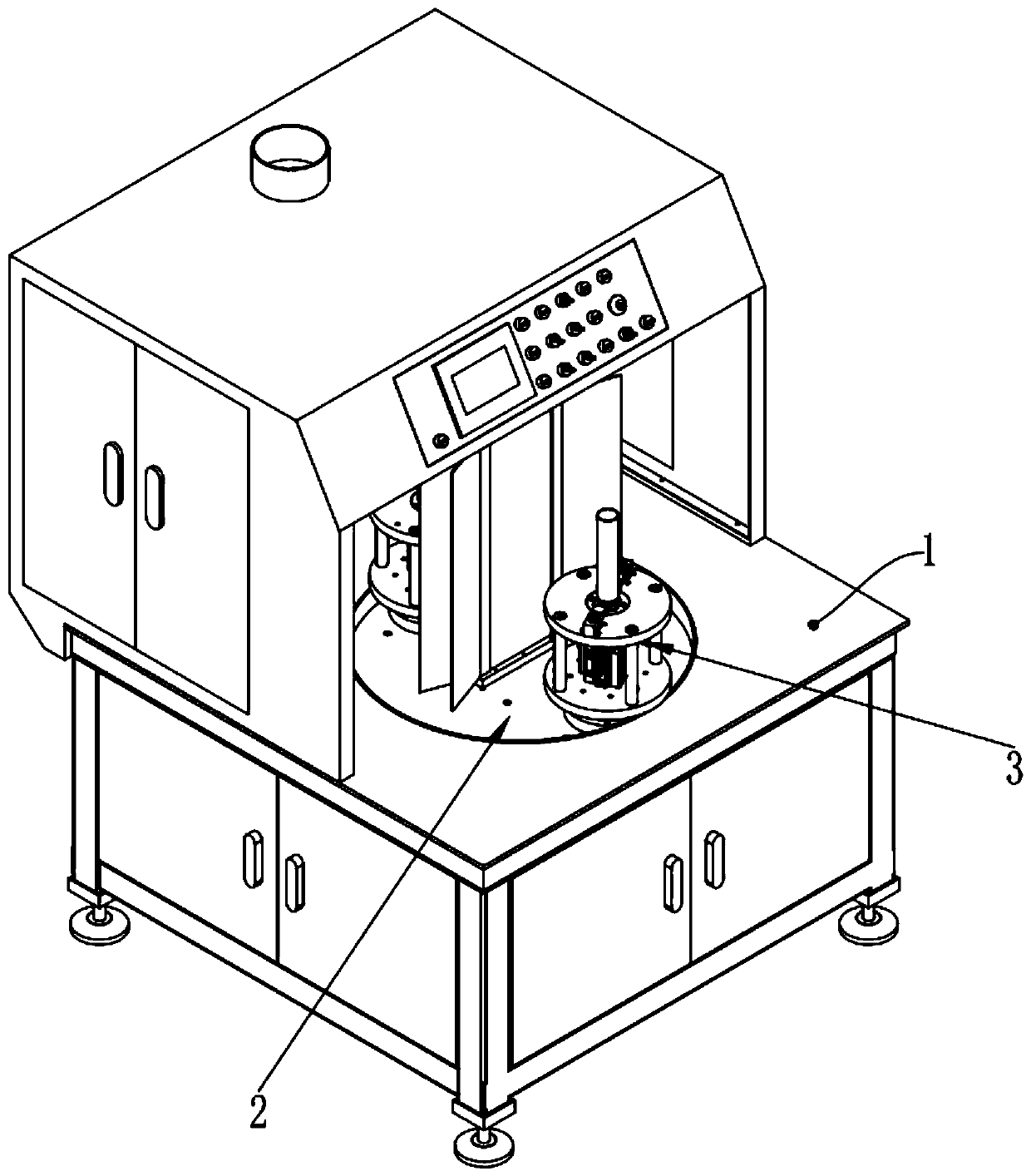

[0037] A welding device for welding an annular piece of a steering column, comprising a frame 1, an indexing mechanism 2, a clamping and rotating mechanism 3 and a welding torch 4;

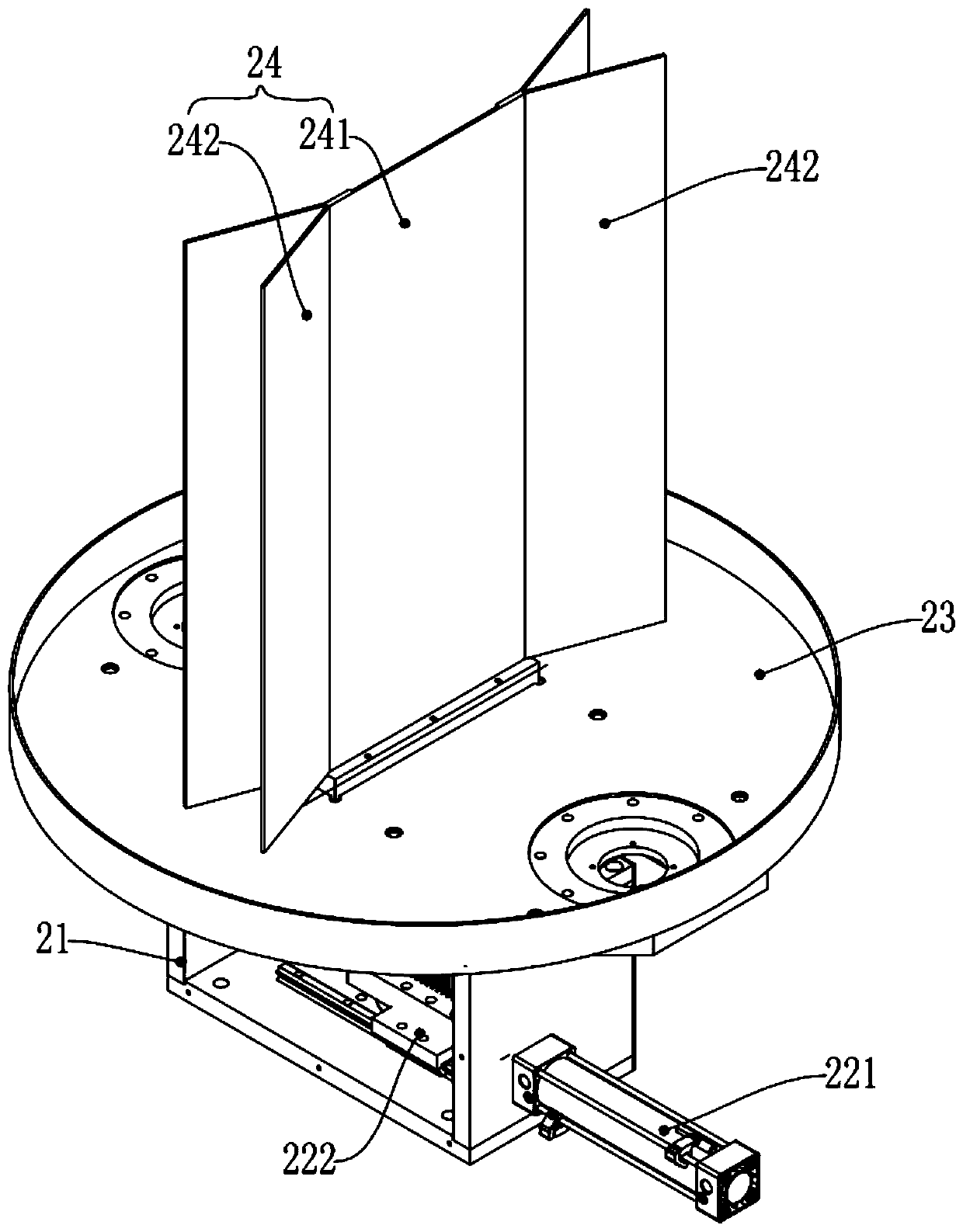

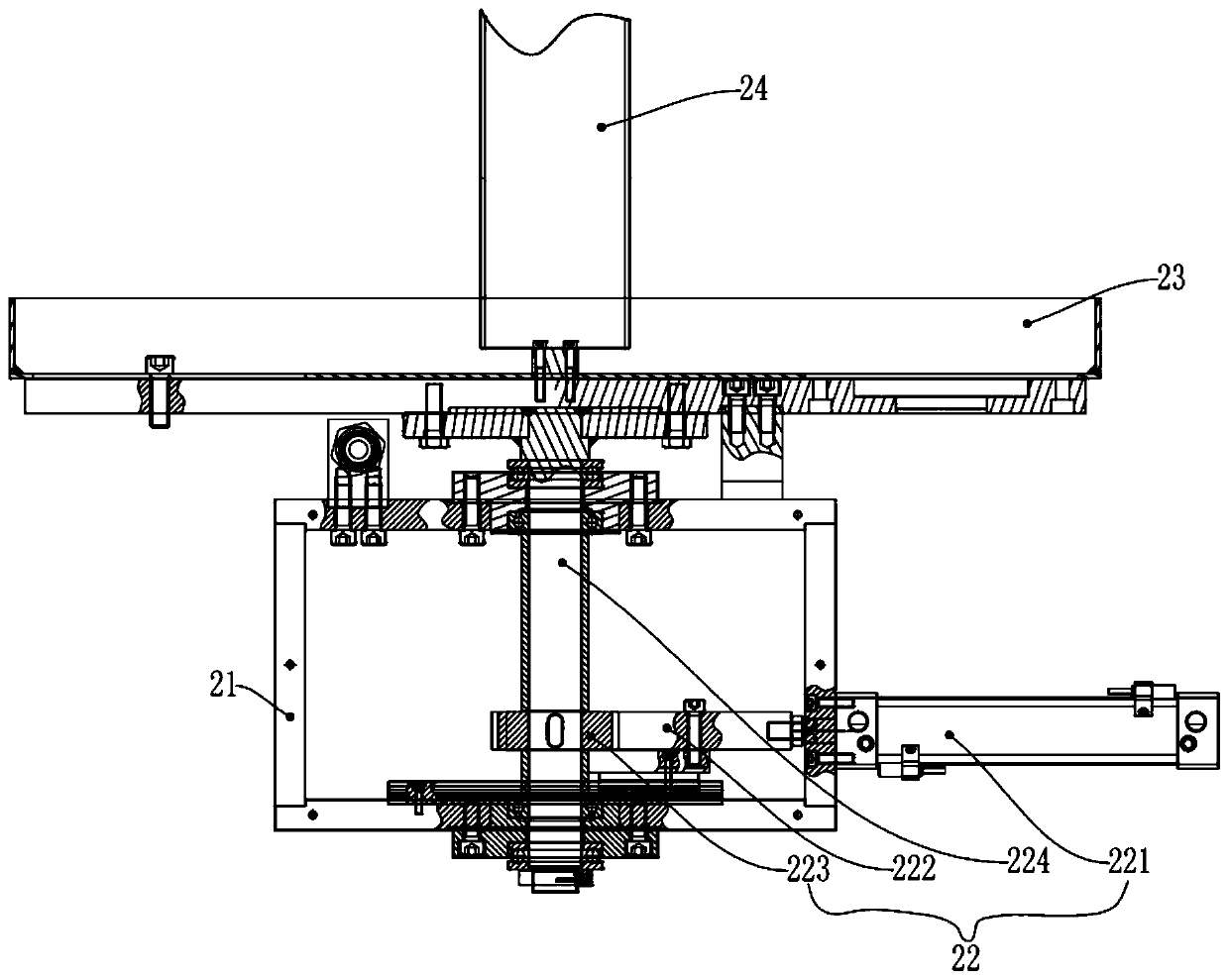

[0038] The indexing mechanism 2 is installed on the frame 1; the clamping and rotating mechanism 3 is installed on the indexing mechanism 2;

[0039] The clamping and rotating mechanism 3 is provided with at least two groups;

[0040] The indexing mechanism 2 is used to rotate the above two groups of the clamping and rotating mechanisms 3 by 180 degrees;

[0041] The clamping and rotating mechanism 3 includes a swinging device 31, a cylinder positioning device 32 and a clamping device 33;

[0042] The swing device 31 is installed on the indexing mechanism 2, the column positioning device 32 and the clamping device 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com