Automatic welding equipment for double annular welding beads

An automatic welding and welding bead technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high maintenance costs, poor working conditions, and high requirements for the accuracy of fixtures with the skill level of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

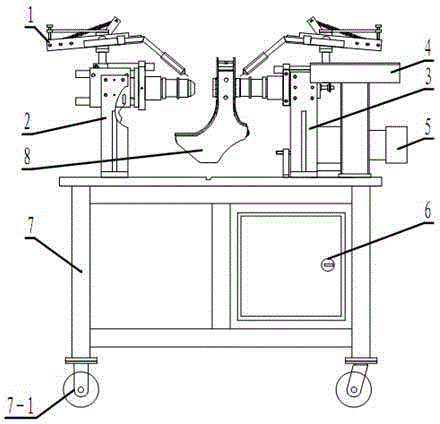

[0030] Referring to Fig. 1, the present invention includes a welding torch position switching and welding torch clamping adjustment mechanism 1, a left positioning mechanism 2, a right positioning mechanism 3, an operation station 4, a power output mechanism 5, a control mechanism 6 and a base platform 7. The welding torch position switching and welding torch clamping adjustment mechanism 1 includes two symmetrical parts, which are respectively assembled with the left positioning mechanism 2 and the right positioning mechanism 3. The left positioning mechanism 2, the right positioning mechanism 3 and the operating station 4 are all fixed on the base platform 7, the power output mechanism 5 is assembled with the right positioning mechanism 3, and the bottom of the base platform 7 is provided with casters 7-1, and the overall equipment can move with the transformation of the working place.

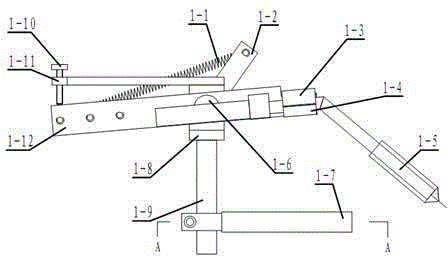

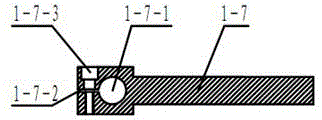

[0031] See Figure 2, image 3 , Figure 4 , the welding torch angle switching and welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com