Titanium and titanium alloy welding process

A welding process and titanium alloy technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low efficiency, high energy consumption per unit, high welding cost, etc., to achieve simple equipment, reduce energy consumption, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

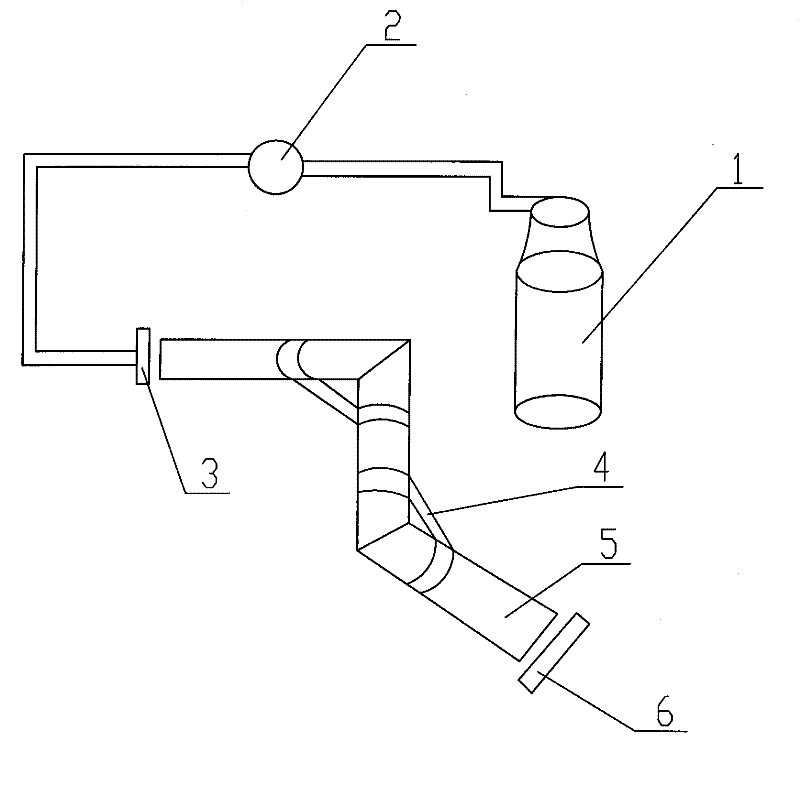

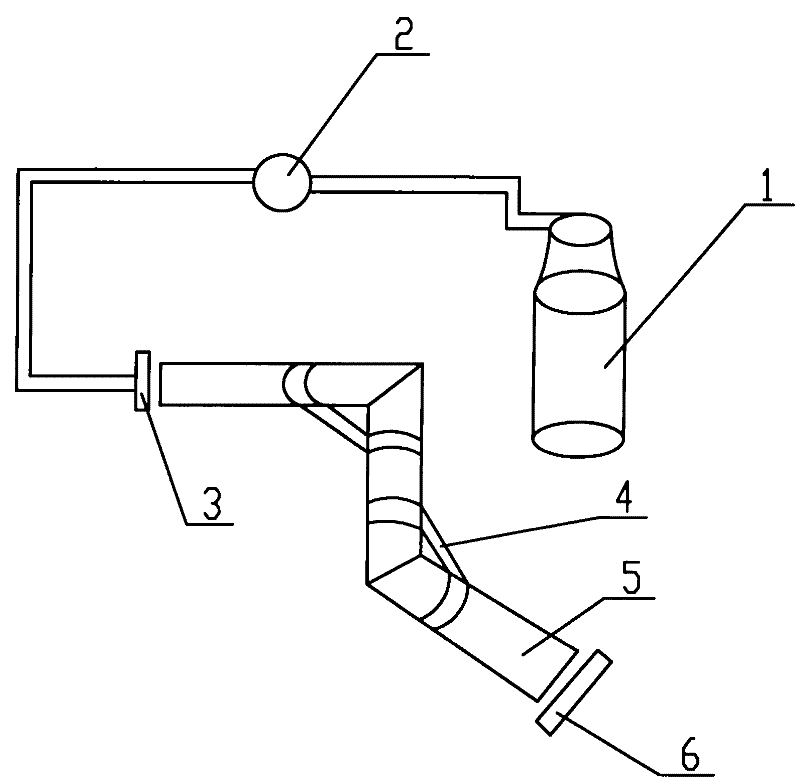

[0008] Such as figure 1 As shown, it is a schematic diagram of the welding process of the present invention, a titanium and titanium alloy welding process, which is characterized in that: firstly, the parts to be welded are fixed with a clamp as required, and the top of the parts to be welded is blocked with a plug , the other end is equipped with an argon filling interface, and it is filled with argon through the argon gas cylinder and the argon filling pipeline. When the joint of the parts to be welded has argon overflow, it is welded. The parts to be welded are The middle is a hollow titanium product. The invention adopts external argon filling to the product, avoids vacuuming for welding, reduces energy consumption, improves production efficiency, and can also produce continuously; the equipment required by the invention is simple, and its cost is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com