Continuous type heat collection strip welding method without medium and its compacting device

A welding method and a technology of a pressing device, which are applied in welding equipment, non-electric welding equipment, arc welding equipment, etc., can solve the problems of non-continuity, high scrap rate, and limitation of heat-collecting strip specifications, and achieve simple and convenient operation , reduce scrap rate, smooth movement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

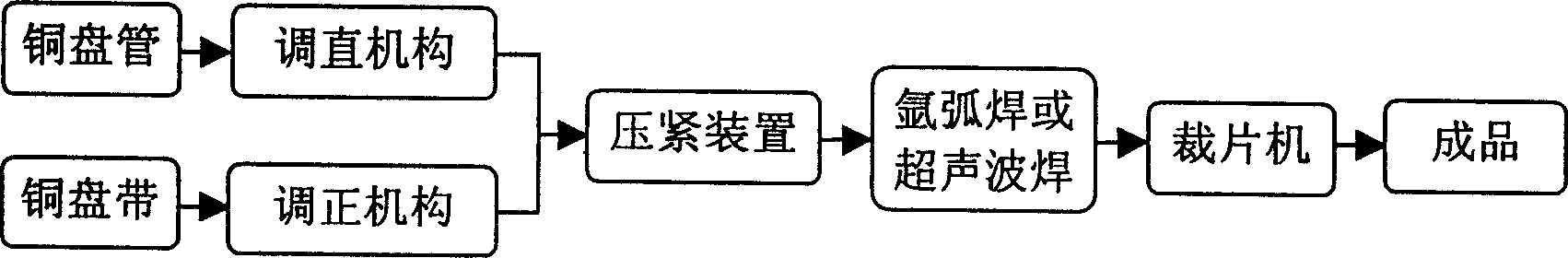

[0037] Refer to attached figure 1 and 2 . The continuous all-copper solar heat collecting strip medium-free welding method includes the following process:

[0038] 1) adjust

[0039] The copper coil tube is straightened by the straightening mechanism and then transported to the workbench, and the copper coil is conveyed to the workbench after being adjusted by the adjustment mechanism;

[0040] 2) Compression

[0041] On the workbench, use the pressing device to press the straightened copper pipe and the adjusted copper strip tightly;

[0042] 3) Welding

[0043] welding the compressed strips together with argon arc or ultrasonic welding;

[0044] 4) Cutting pieces

[0045] The cutting machine is used to blank and shape according to the required different sizes to obtain the finished product with the required specifications.

Embodiment 2

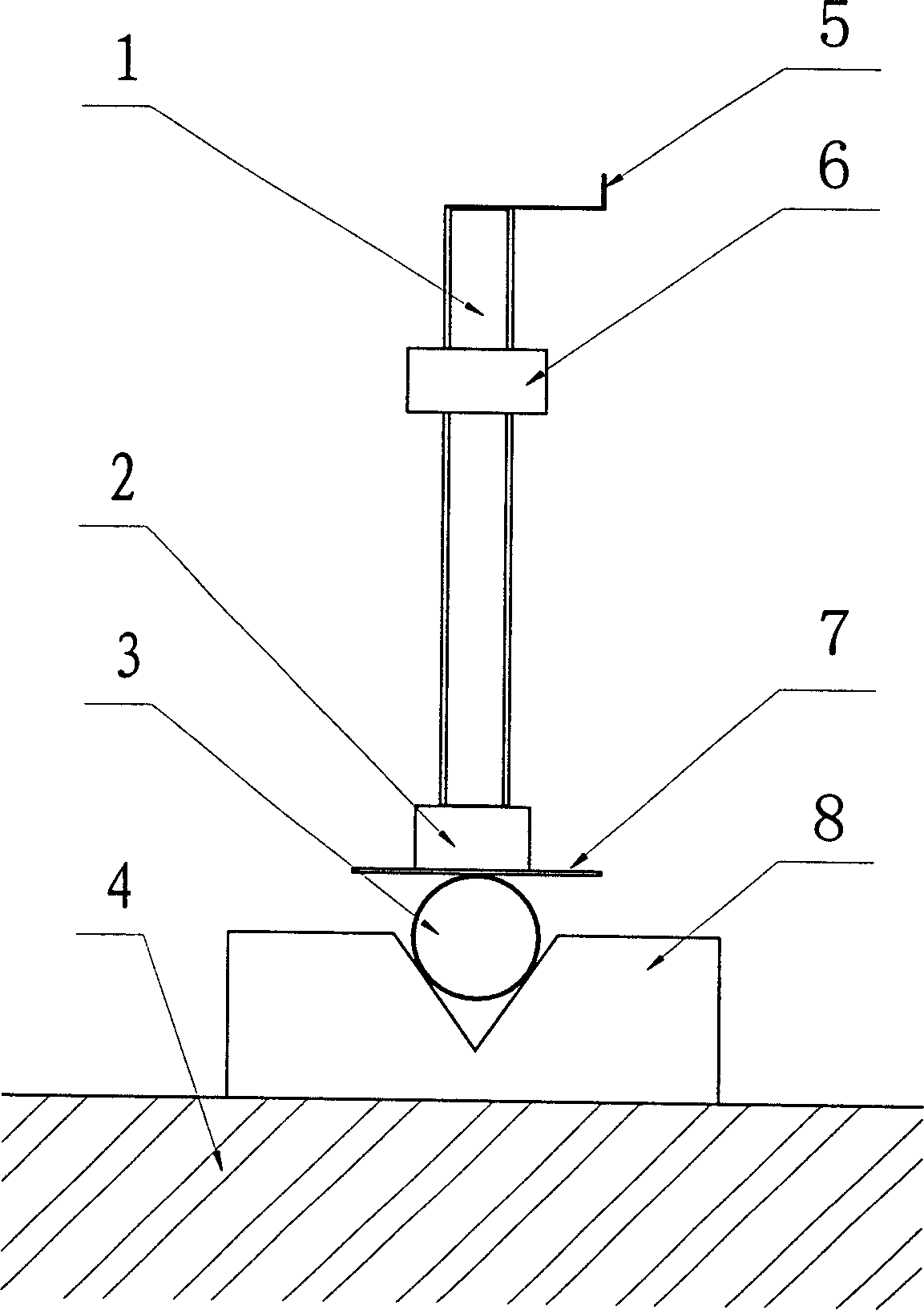

[0047] Refer to attached figure 1 and 2 . The continuous all-copper solar heat collection strip medium-free welding pressing device consists of a fixed frame and a movable mechanism. The lower part of the pressing device is an iron block 8 with a V-shaped groove. The iron block 8 is located on the workbench 4. The pressing device The upper part is a screw mechanism. The lead screw mechanism is assembled by a lead screw 1 with a handle 5 and a pressure head 2 and a fixed nut 6 . The welding pressing device can press the copper pipe 3 and the copper strip 7 tightly, so that argon arc welding or ultrasonic welding can be carried out well, so that the welding process can be continuously carried out, and the production efficiency and yield of products can be greatly improved.

Embodiment 3

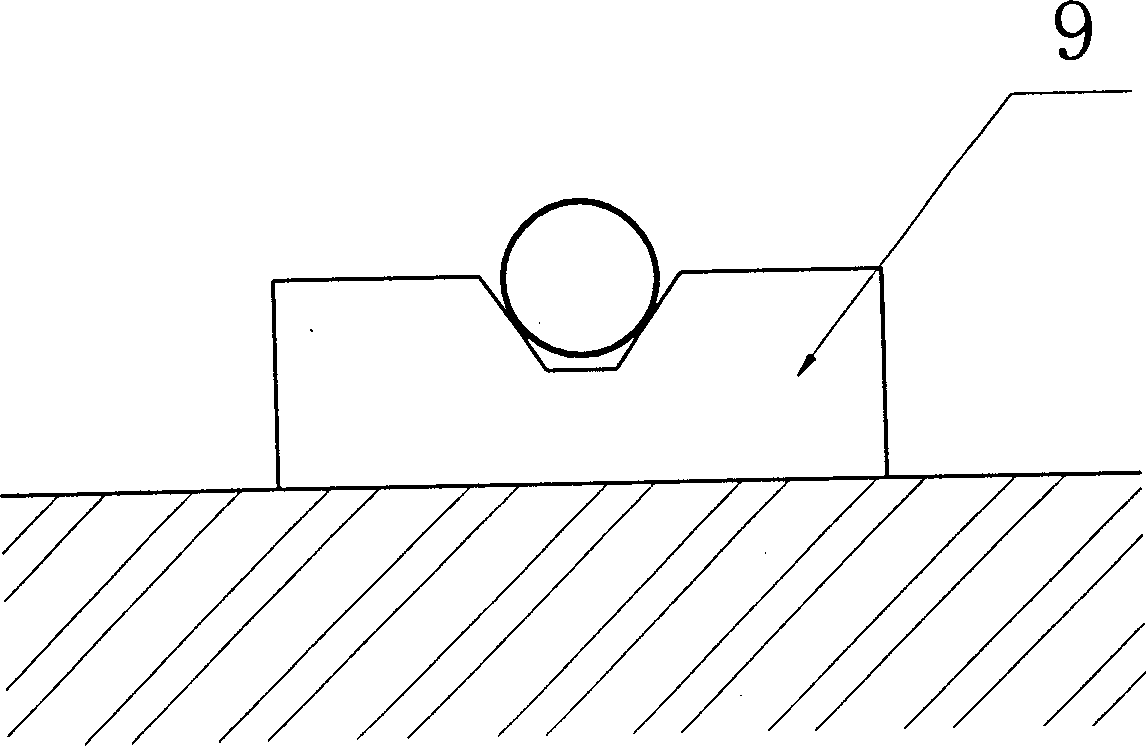

[0049] Refer to attached figure 1 and 3 . The continuous all-copper solar heat collection strip medium-free welding pressing device is composed of a fixed frame and a movable mechanism. The lower part of the pressing device is an iron block 9 with a T-shaped slot, and the upper part is a screw mechanism. Lead screw structure is the same as embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com