Full-automatic double-head ultrasonic plastic bottle cap welding device

An ultrasonic, fully automatic technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of slow ultrasonic welding cover, potential safety hazards, high labor intensity, etc., to improve product quality and operational safety. , Intuitive operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

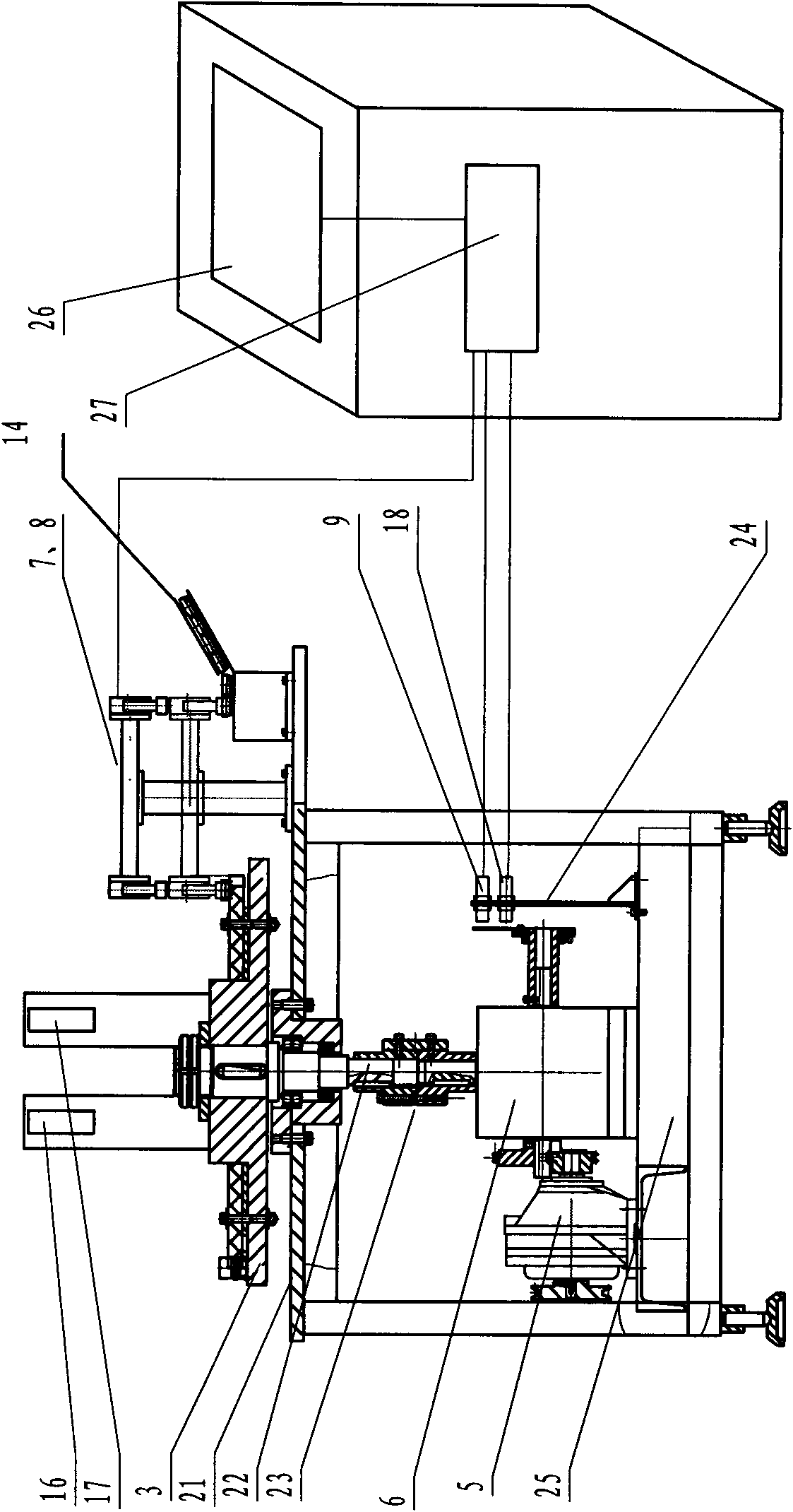

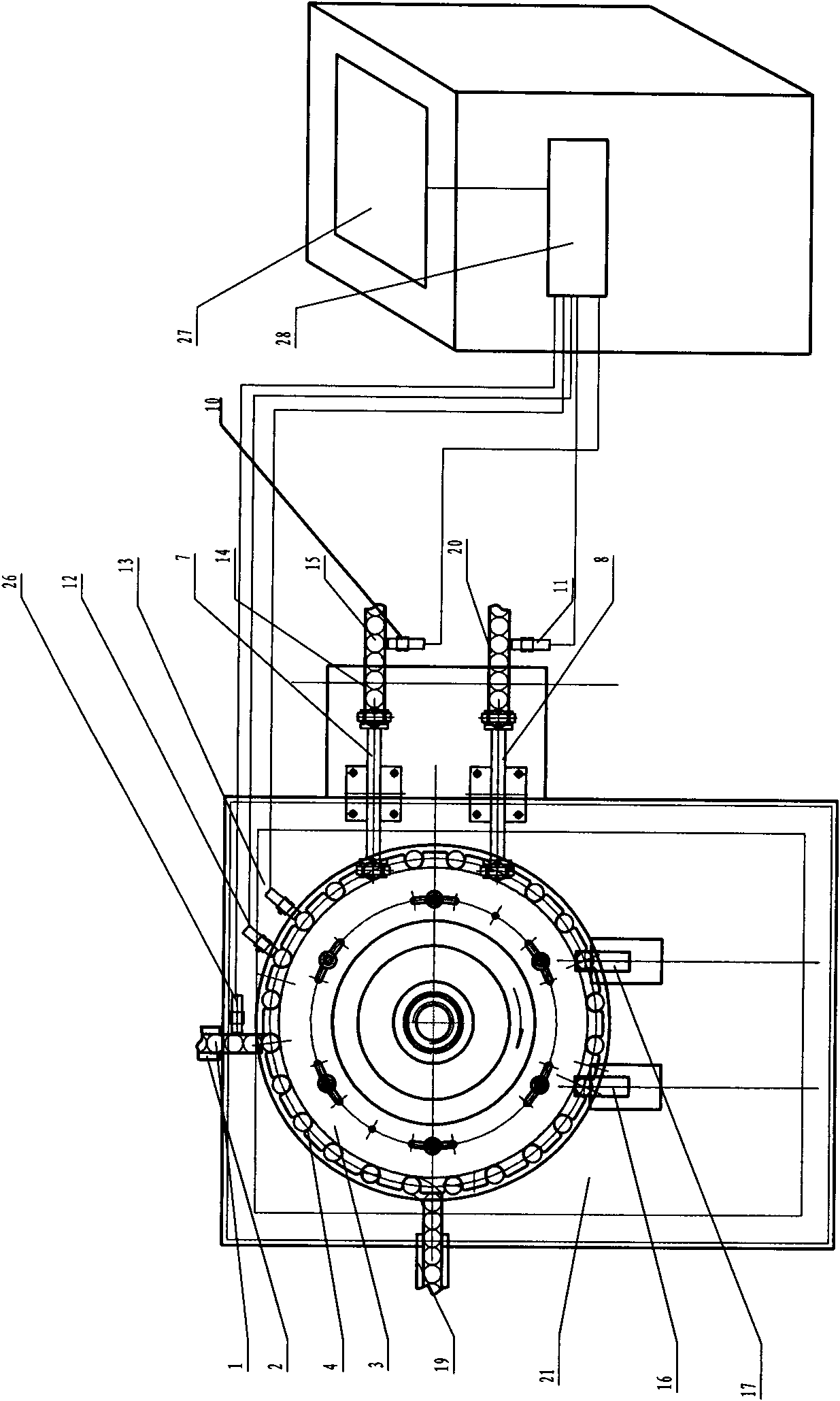

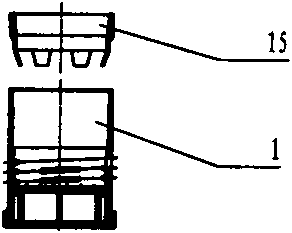

[0013] Example 1, see figure 1 , 2 , processed into a bracket, the base 25 is fixed at the bottom of the bracket, and the worktable 21 is fixed at the top; the main shaft motor 5, the indexing box 6 and the synchronous sensor bracket 24 are fixed on the base 25, and the main shaft motor 5 is driven by a chain. The indexing box 6, the indexing box 6 is connected with the main shaft 22 through the coupling 23, the main shaft 22 drives the tray 3 to do intermittent motion, the tray 3 has a tooth mouth 4, the first bottle cap cylinder detection sensor 12 and the second bottle cap cylinder detection Sensor 13, the first synchronous photoelectric sensor 9 and the second synchronous photoelectric sensor 18 are installed on the synchronous sensor bracket 24; 8 is fixed on the working surface 21, the first pneumatic manipulator 7 and the second pneumatic manipulator 8 are respectively connected with the first gear sleeve slideway 14 and the second gear sleeve slideway 20, and the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com