Discrete igbt modules and substrates

A substrate and module technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of low assembly efficiency, difficulty in ensuring the insulation and heat dissipation effect of IGBT and metal plate at the same time, and achieve high assembly efficiency and good heat dissipation effect , the effect of quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

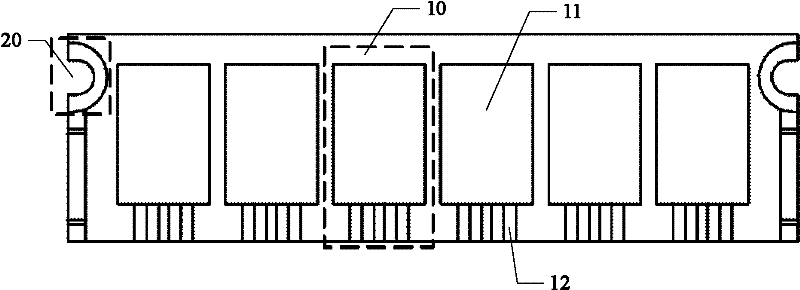

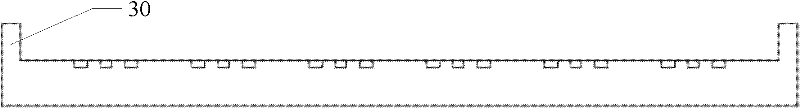

[0024] Such as figure 1 As shown, the top view of the substrate of a sub-main IGBT module mentioned in an embodiment of the present invention includes:

[0025] A groove 10 matching the IGBT, where the IGBT is placed;

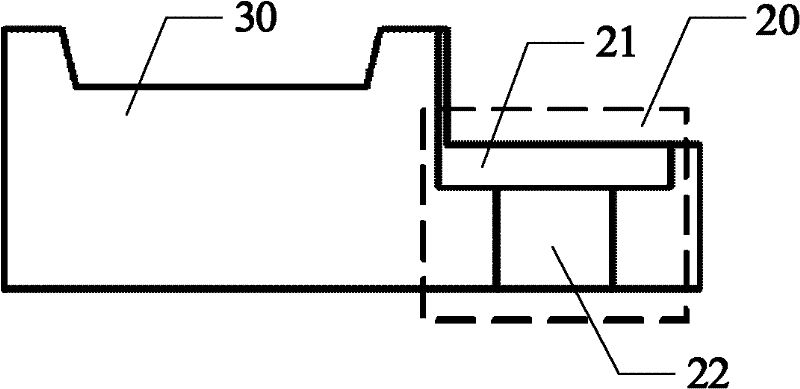

[0026] The through holes 20 matched with the screws are used to install the screws to fix the base plate on the heat sink metal plate.

[0027] The material of the substrate in the above embodiments is ceramic, which has good insulation and heat dissipation. The shape of the above-mentioned groove 10 is consistent with that of the IGBT, which can play the role of positioning the IGBT. During assembly, the IGBT is placed in the groove 10, and an easily curable insulating material, such as epoxy resin, is poured on the top of the IGBT to complete the package. A module is formed, that is, a discrete IG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com