Plate spring clamp combined structure for heavy-load dumper

A combined structure, dump truck technology, applied in the direction of springs, leaf springs, vehicle parts, etc., can solve problems such as damage to leaf spring clamps, and achieve the effects of stress relief, production convenience, and fracture resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

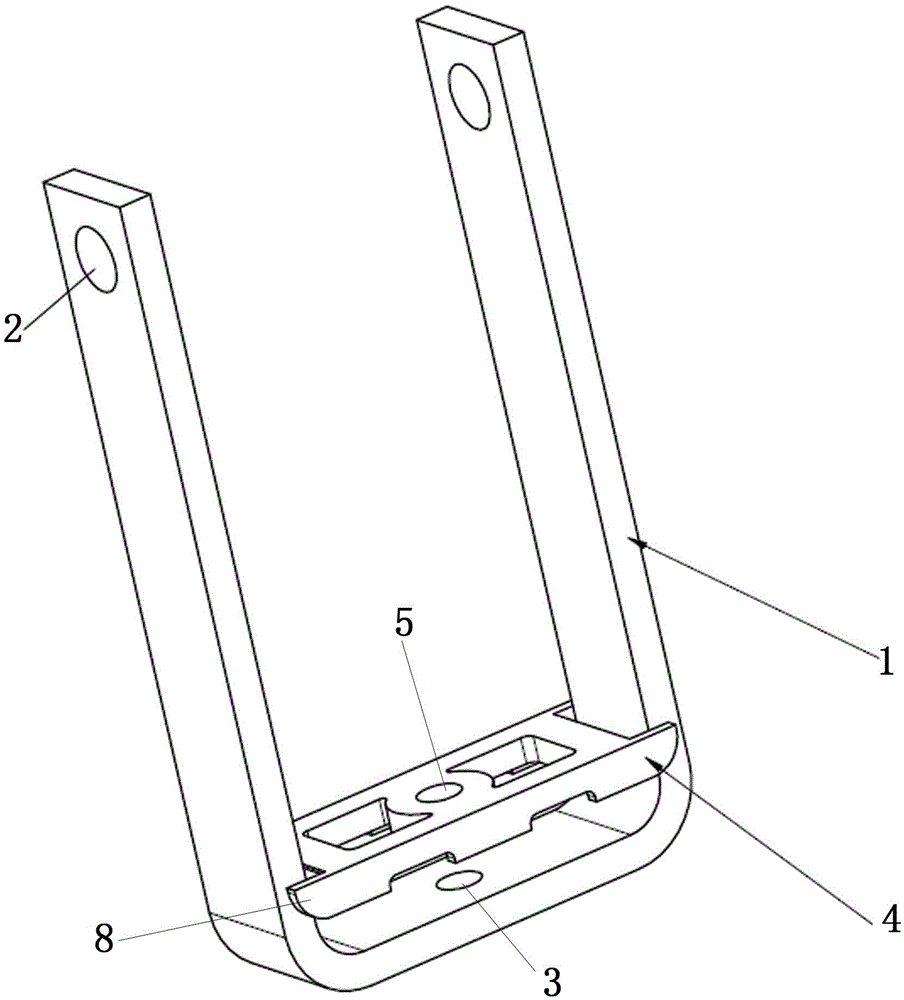

[0015] A combination structure of leaf spring clamps for heavy-duty dump trucks, including a U-shaped leaf spring clamp 1, side holes 2 are opened on both sides of the leaf spring clamp 1 near the U-shaped opening, and bottom holes 3 are opened at the bottom ; It also includes a clamp seat 4 that is movably connected between the U-shaped openings of the leaf spring clamp 1; The structure has a rivet hole 5 riveted with the lowermost piece of the leaf spring and the leaf spring clamp 1; the leaf spring clamp 1 is made of a steel plate with a thickness of 8 mm and a width of 30 mm.

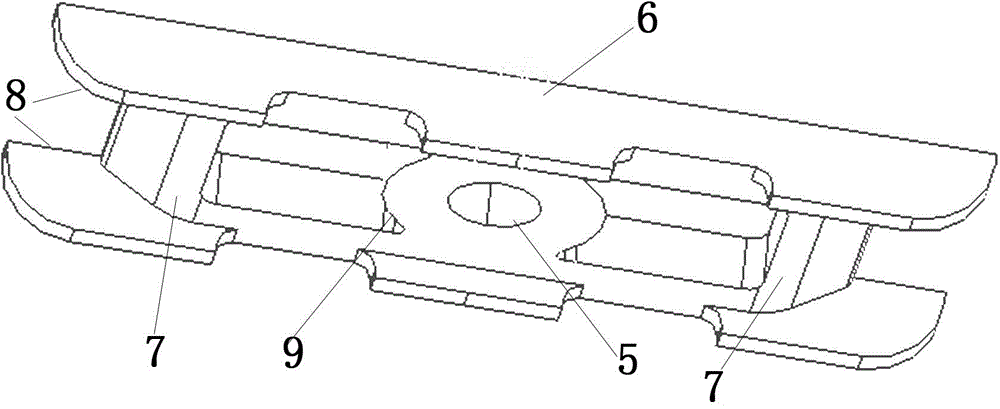

[0016] The clamp seat 4 includes a pair of longitudinal plates 6, a pair of transverse plates 7 are connected between the ends of the two longitudinal plates 6, and both ends of each longitudinal plate 6 extend outward with a limiting plate 8 and the limiting plate 8 The plate 8 and the horizontal plate 7 together form a position-limiting structure; the middle part of the vertical plate 6 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com