Stainless steel sheet welding method capable of preventing weld cracks

A welding method and technology of weld cracks, which are applied in the field of welding stainless steel sheets, and can solve problems such as welding cracks and scrapping of weldments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

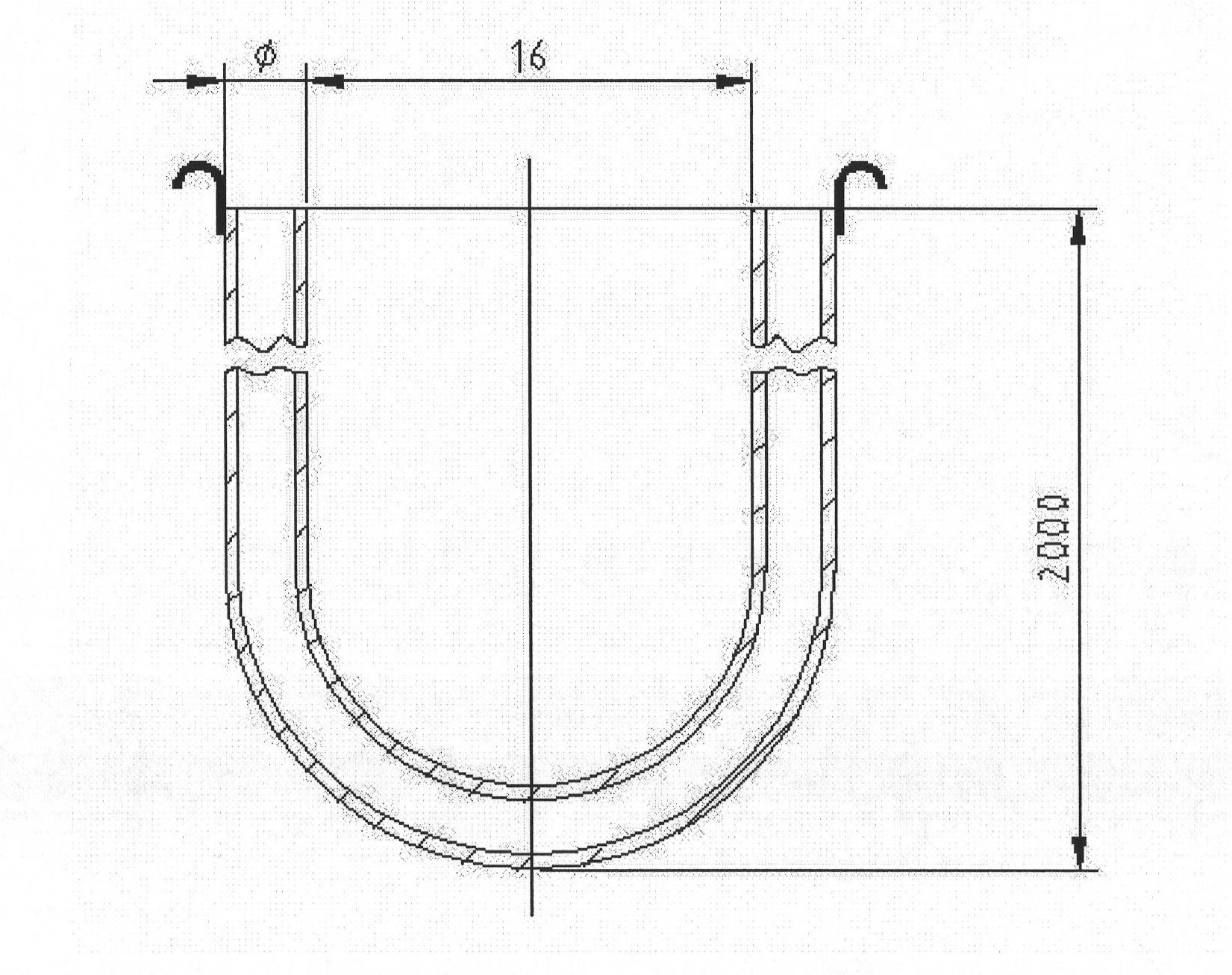

[0023] The tank body of a product is welded by stainless steel plate (material 304L) with a thickness of 6mm and a length of 1.5-1.8m, and the length of the fillet weld is 2.2m. Multiple ribs are set in the tank, and flanges or socket frames are set at both ends, and the structure is relatively complicated. The maximum length of the steel plate required for the stainless steel box can reach 6m, and the height is 2.2m. A large number of straight welds and fillet welds are required, because the tank in the working state is filled with high-temperature alkaline media, which has a high airtightness for welding. requirements.

[0024] The following steps and process parameters are used to make:

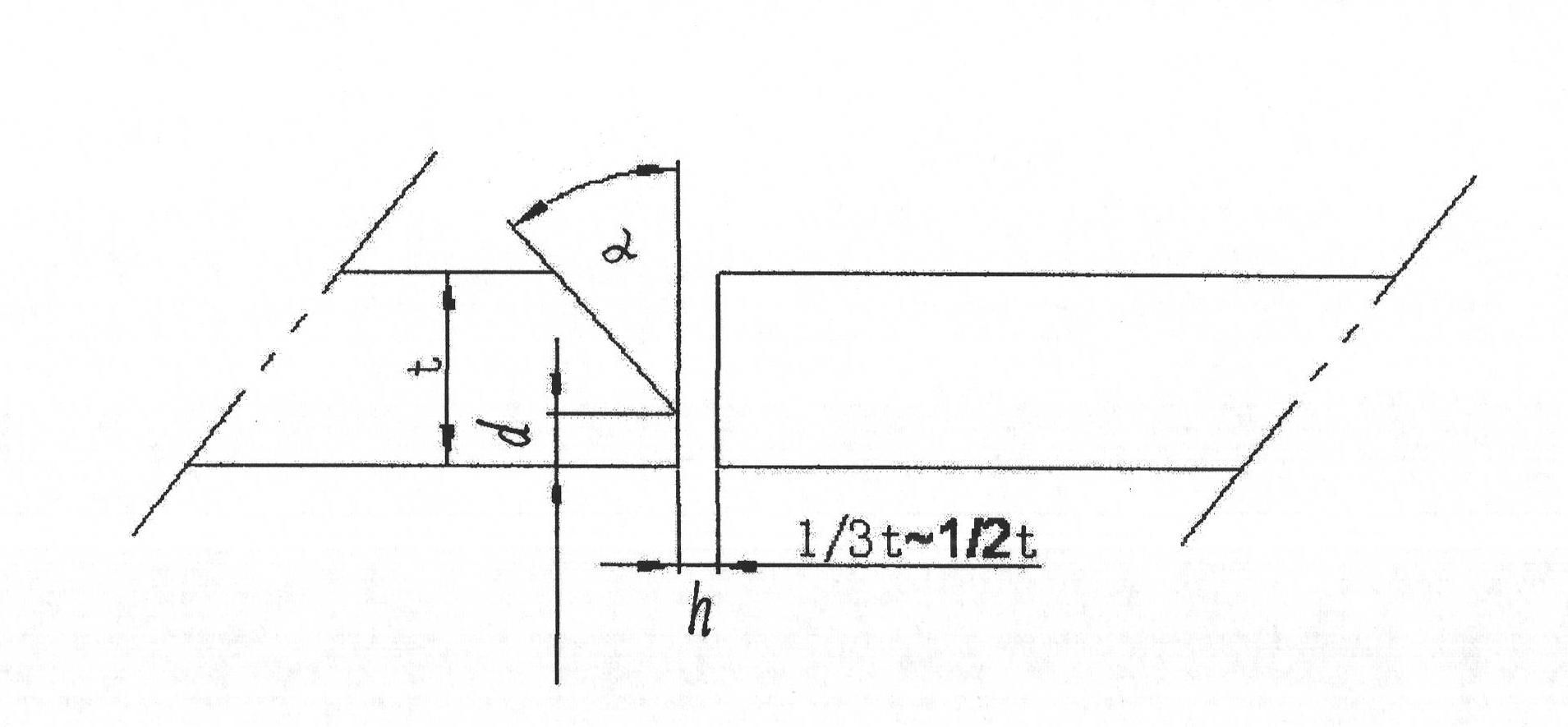

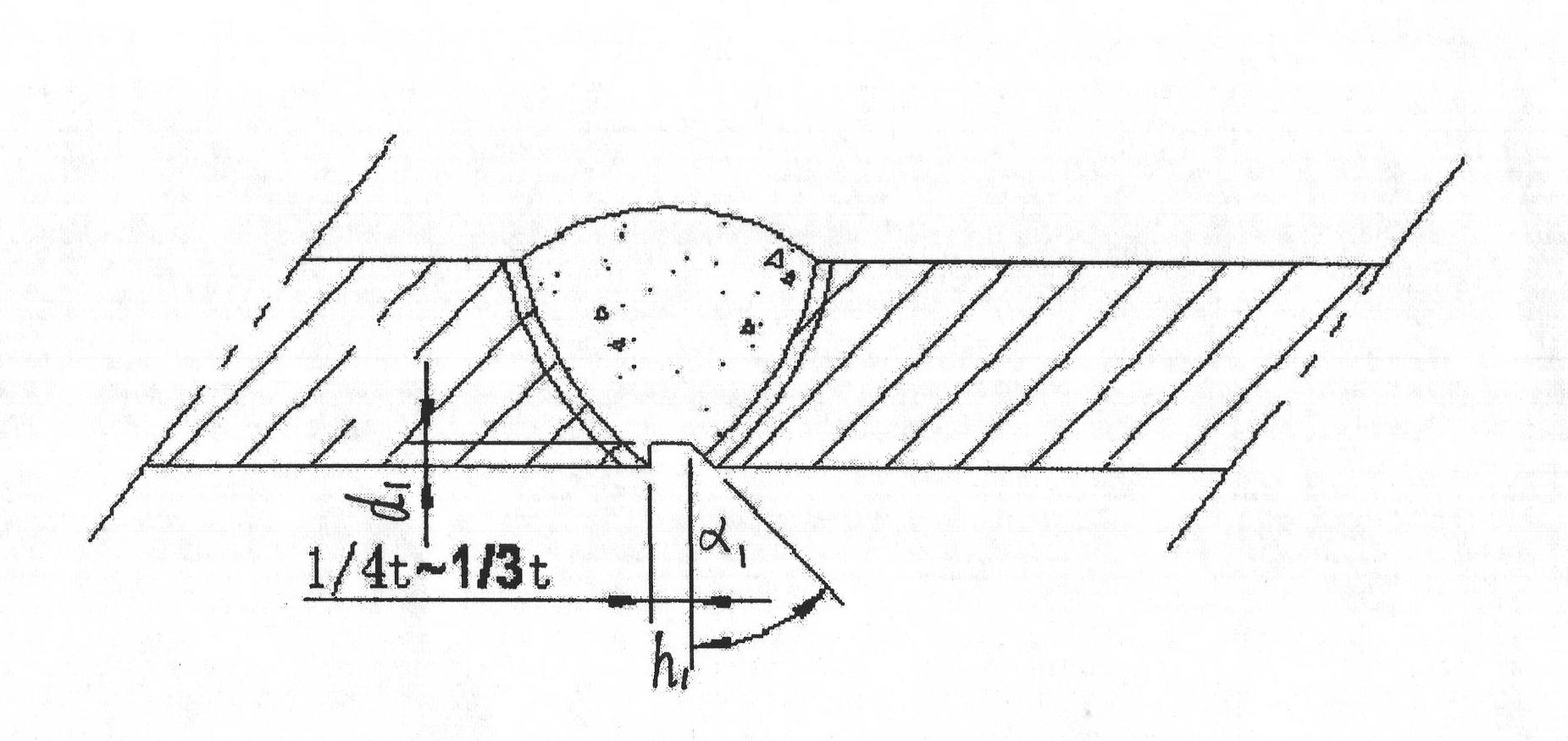

[0025] 1) Process a groove on a stainless steel sheet to be welded, the groove cutting angle α is 15°, the uncut thickness d is 1 / 3t, and the gap h between the other stainless steel sheet to be welded is 1 / 3t, Where t is the thickness of the welded stainless steel sheet;

[0026] 2) Wip...

Embodiment 2

[0035] The product type is the same as in Example 1, the material of the stainless steel sheet is 304L, the thickness is 8mm, the welding length is 6m, and the height is 2.2m.

[0036] The following steps and process parameters are used to make:

[0037] 1) A groove is processed on a stainless steel sheet to be welded, the groove cutting angle α is 30°, the uncut thickness d is 1 / 2t, and the gap h between the other stainless steel sheet to be welded is 1 / 2t, Where t is the thickness of the welded stainless steel sheet;

[0038] 2) Wipe the processed surface of the stainless steel sheet to be welded with welding ketone to remove the oil stain on the surface; preheat the welding place to 80-120°C;

[0039] 3) After splicing the two stainless steel sheets to be welded, perform spot welding at intervals of 100mm, keep the positions of the two welded sheets fixed, and keep the gap between them even;

[0040] 4) Use the mixed gas of carbon dioxide and argon as the active shielding...

Embodiment 3

[0047] The product type is the same as in Example 1, the material of the stainless steel sheet is 304L, the thickness is 6mm, the welding length is 6m, and the height is 2.2m.

[0048] The following steps and process parameters are used to make:

[0049] 1) Process a groove on a stainless steel sheet to be welded, the groove cutting angle α is 20°, the uncut thickness d is 1 / 3t, and the gap h between the other stainless steel sheet to be welded is 1 / 3t, Where t is the thickness of the welded stainless steel sheet;

[0050] 2) Wipe the processed surface of the stainless steel sheet to be welded with welding ketone to remove the oil stain on the surface; preheat the welding place to 80-120°C;

[0051] 3) After splicing the two stainless steel sheets to be welded, perform spot welding at intervals of 100mm, keep the positions of the two welded sheets fixed, and keep the gap between them even;

[0052] 4) Use the mixed gas of oxygen or carbon dioxide and argon as the active shie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com