Welding method of carbon steel thin-plate box

A welding method and thin plate technology, applied in welding equipment, arc welding equipment, workpiece edge parts, etc., can solve the problems of large manual operation error, prolonged working hours, scrap, etc., and achieve convenient production, good process stability, and reasonable selection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The sheet material is Q235A, the thickness is 6mm, and the welding length is 6m.

[0032] The following steps and process parameters are used to make:

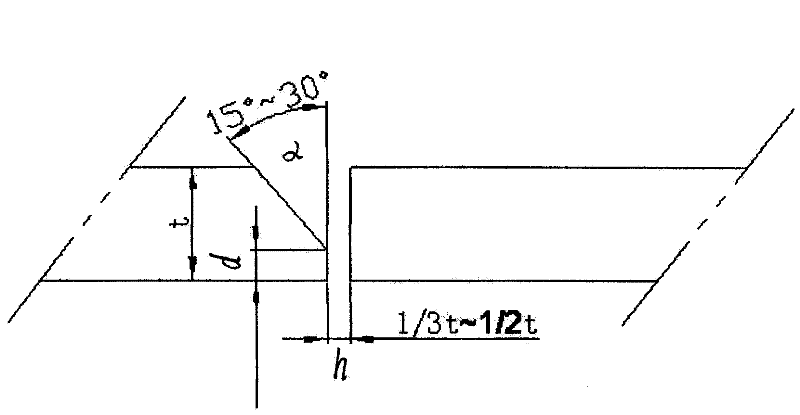

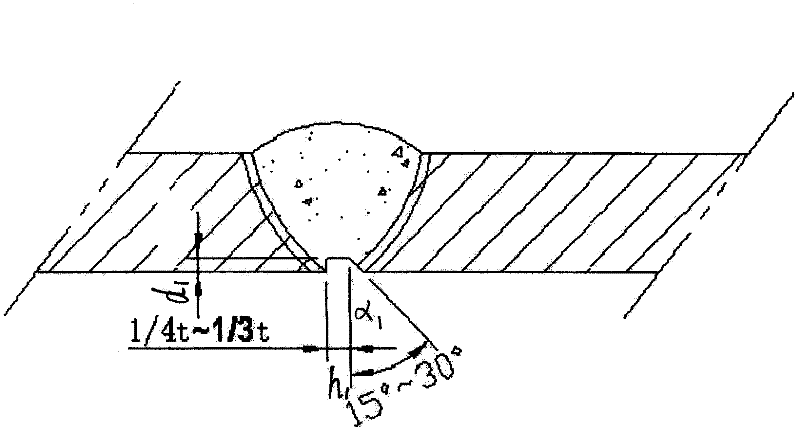

[0033] 1) Process a bevel on a thin plate to be welded, the groove cut angle α is 15°, the uncut thickness d is 1 / 3t, and the gap h between the other thin plate to be welded is 1 / 3t, where t is the thickness of the welded sheet;

[0034] 2) Wipe the processed surface of the thin plate to be welded with welding ketone to remove the oil stain on the surface;

[0035] 3) After splicing the two welded sheets, perform spot welding at intervals of 100 mm, keep the positions of the two welded sheets fixed, and keep the gap between them even;

[0036] 4) Submerged arc automatic welding is used for welding, and the welding parameters are selected as follows: welding current I: 38A, welding speed v: 80mm.min -1 , CO 2 Gas flow Q: 13L.min -1 ;

[0037] 5) After welding one side, turn it over to grind and clean the welding sl...

Embodiment 2

[0047] The sheet material is Q235A, the thickness is 6mm, and the welding length is 8m.

[0048] The following steps and process parameters are used to make:

[0049] 1) Process a bevel on a thin plate to be welded, the groove cut angle α is 30°, the uncut thickness d is 1 / 2t, and the gap h between the other thin plate to be welded is 1 / 2t, where t is the thickness of the welded sheet;

[0050] 2) Wipe the processed surface of the thin plate to be welded with welding ketone to remove the oil stain on the surface;

[0051] 3) After splicing the two welded sheets, perform spot welding at intervals of 100 mm, keep the positions of the two welded sheets fixed, and keep the gap between them even;

[0052] 4) Submerged arc automatic welding is used for welding, and the welding parameters are selected as follows: welding current I: 48A, welding speed v: 100mm.min -1 , CO 2 Gas flow Q: 13L.min -1 ;

[0053]5) After welding one side, turn it over to grind and clean the welding sl...

Embodiment 3

[0063] The sheet material is Q235A, the thickness is 6mm, and the welding length is 6m.

[0064] The following steps and process parameters are used to make:

[0065] 1) Process a bevel on a thin plate to be welded, the groove cut angle α is 25°, the uncut thickness d is 1 / 3t, and the gap h between the other thin plate to be welded is 1 / 3t, where t is the thickness of the welded sheet;

[0066] 2) Wipe the processed surface of the thin plate to be welded with welding ketone to remove the oil stain on the surface;

[0067] 3) After splicing the two welded sheets, perform spot welding at intervals of 100 mm, keep the positions of the two welded sheets fixed, and keep the gap between them even;

[0068] 4) Submerged arc automatic welding is used for welding, and the welding parameters are selected as follows: welding current I: 43A, welding speed v: 90mm.min -1 , CO 2 Gas flow Q: 13L.min -1 ;

[0069] 5) After welding one side, turn it over to grind and clean the welding sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com