Patents

Literature

35results about How to "Easy to make and construct" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

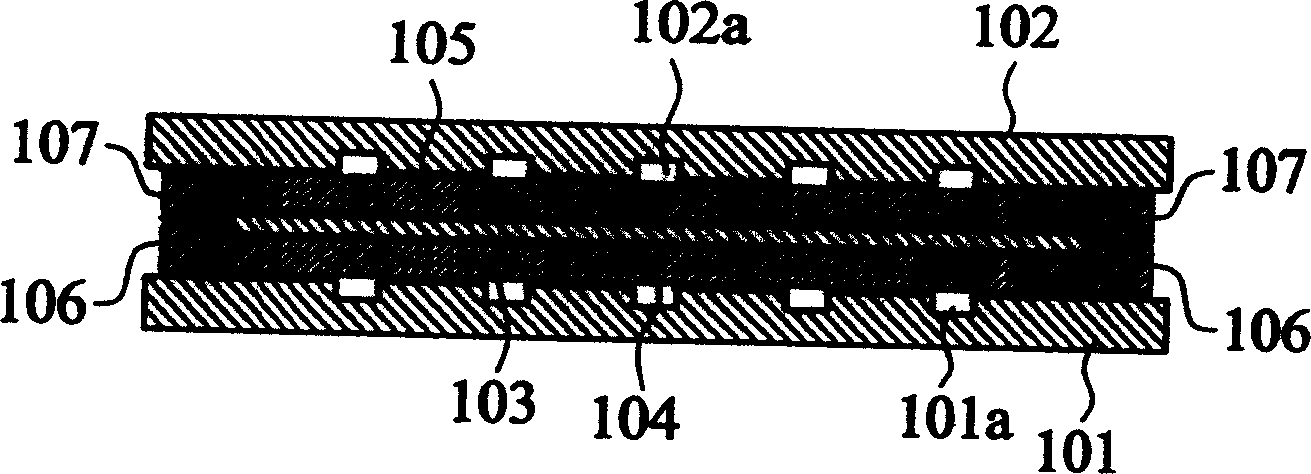

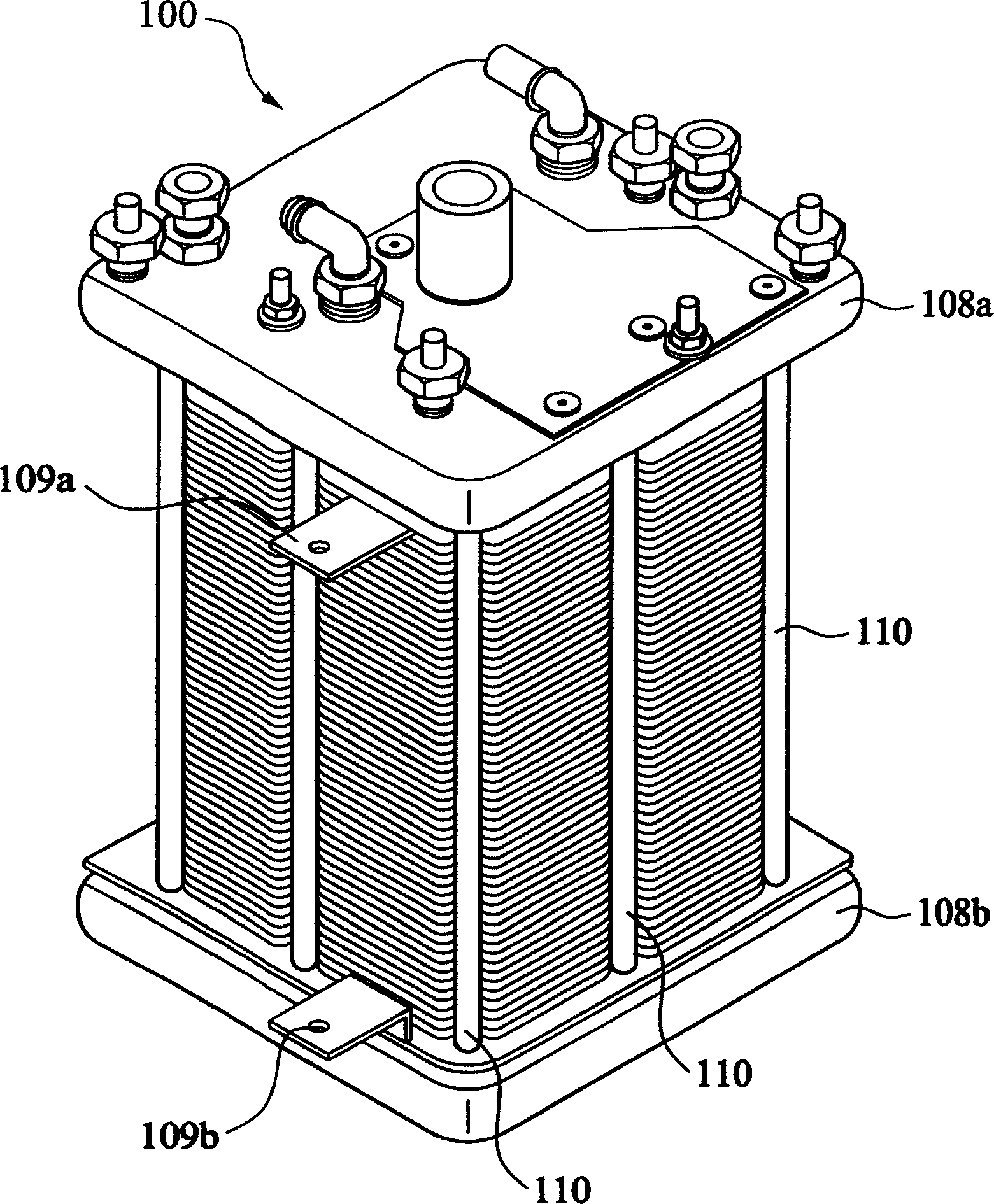

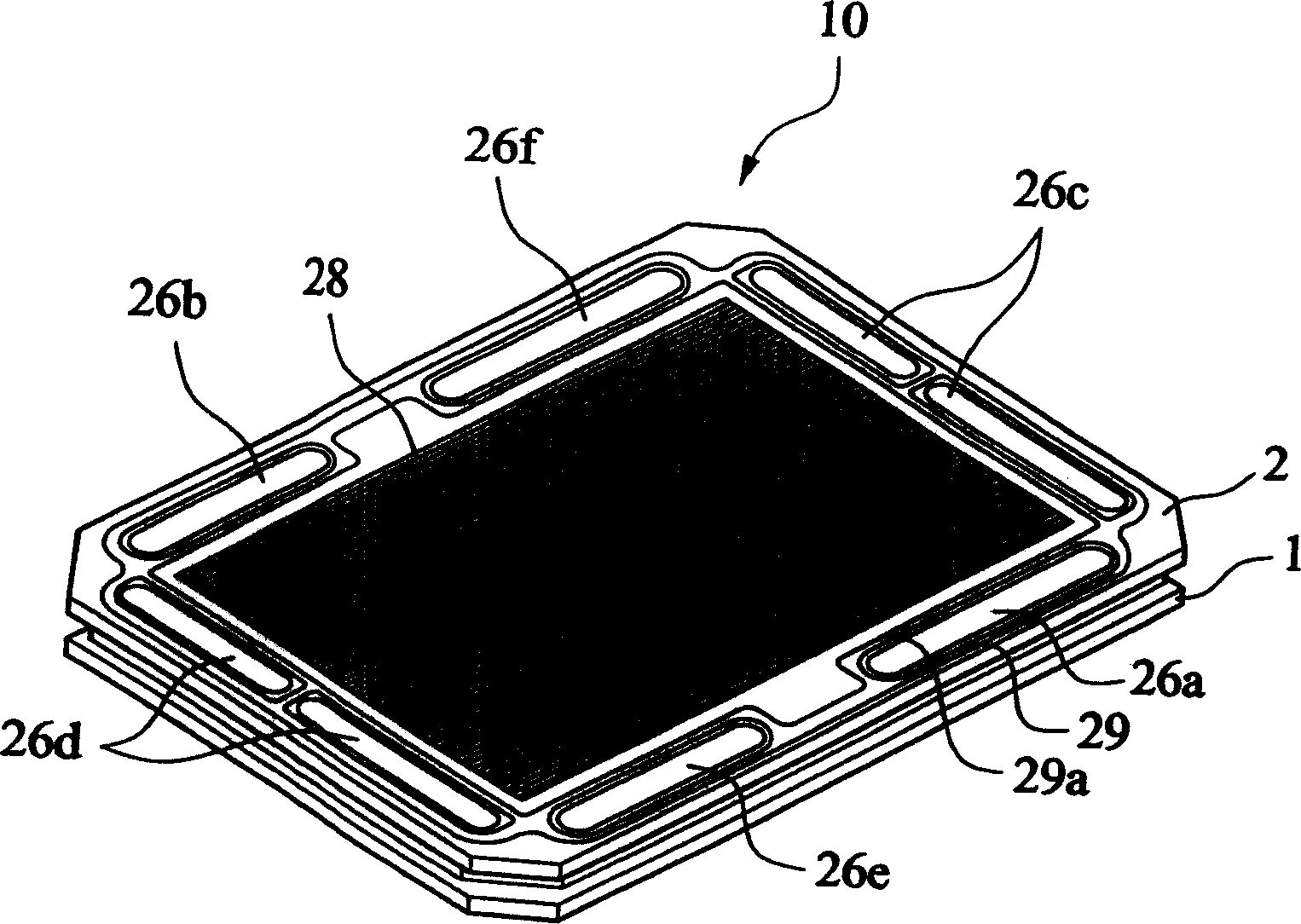

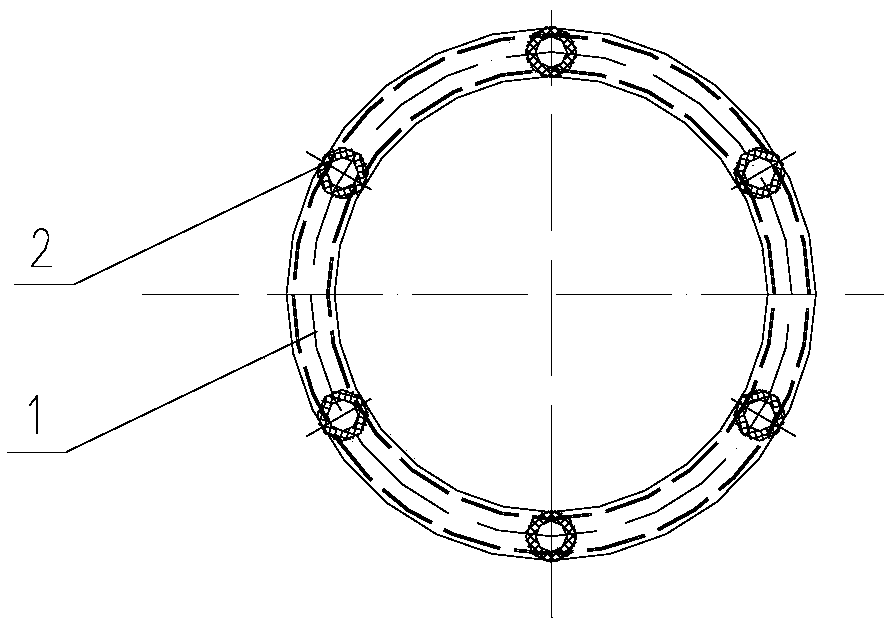

Seal structure for modularized proton exchange film fuel cell

ActiveCN1635643AEasy to make and constructImprove qualityFuel cells groupingCell component detailsEngineeringElectrical and Electronics engineering

A sealed structure of modularized proton exchange membrane fuel battery, which contains a round concave part and an extended round part in positive plate of said fuel battery, a round concave part and interconnected extended concave part in negative plate, silica gel pre-coated in circumference area corresponded round concave part and extended round concave part in positive and negative plate, before the gel solidified the positive plate, membrane assembly and negative plate are align laminated and pressed to form enclosed round surface and the proton exchange membrane is tightly pressed and located at the intermediate position to make the through holes between positive plate and negative plate respectively form enclosed round surface.

Owner:ASIA PACIFIC FUEL CELL TECH

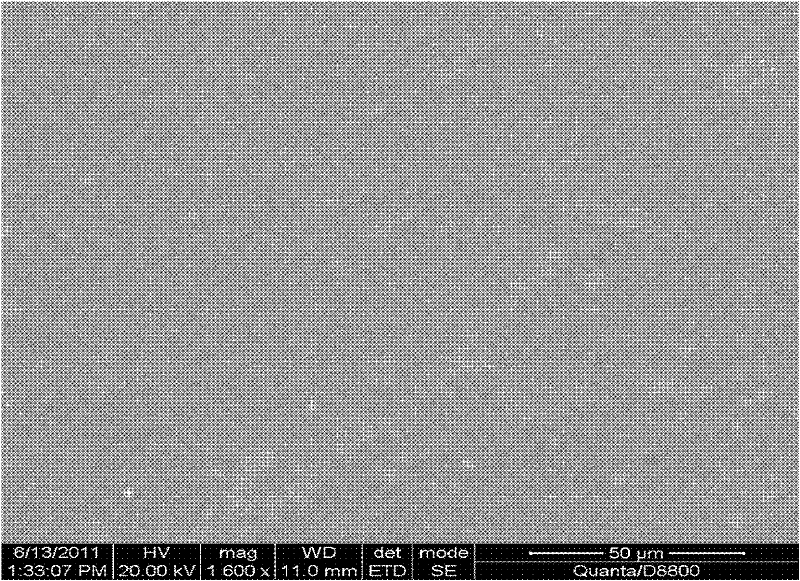

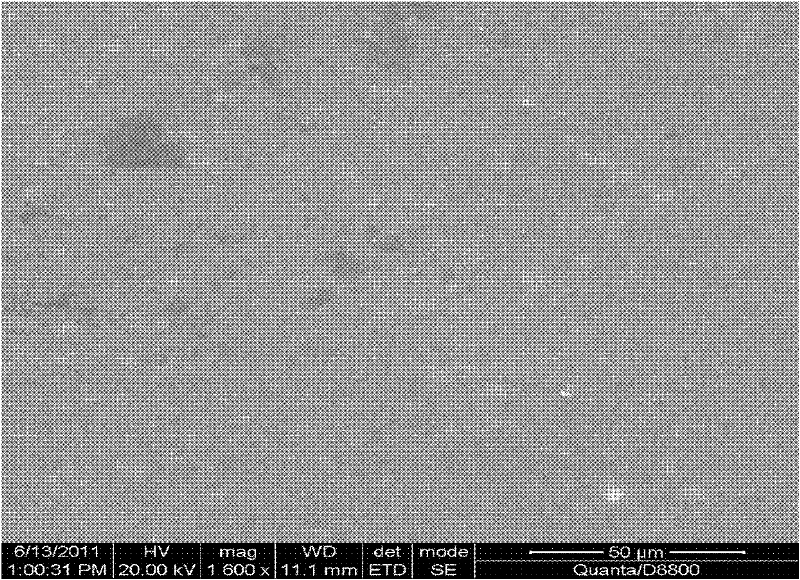

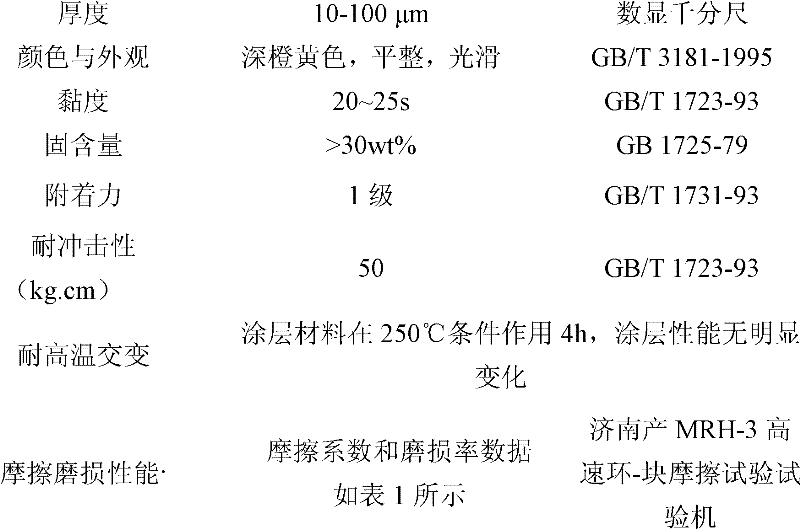

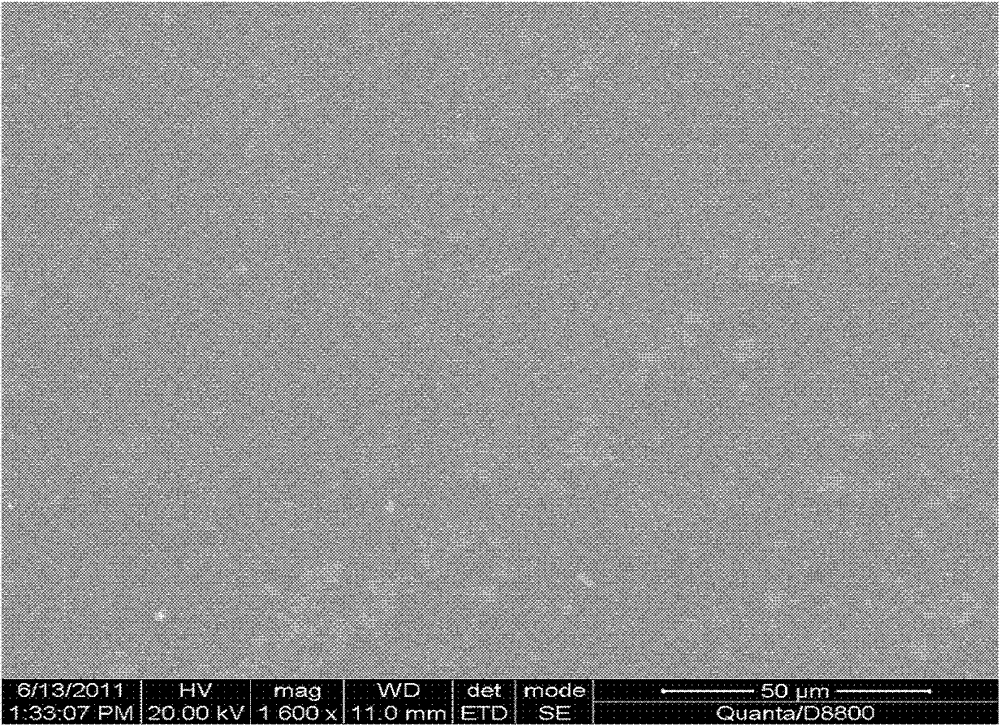

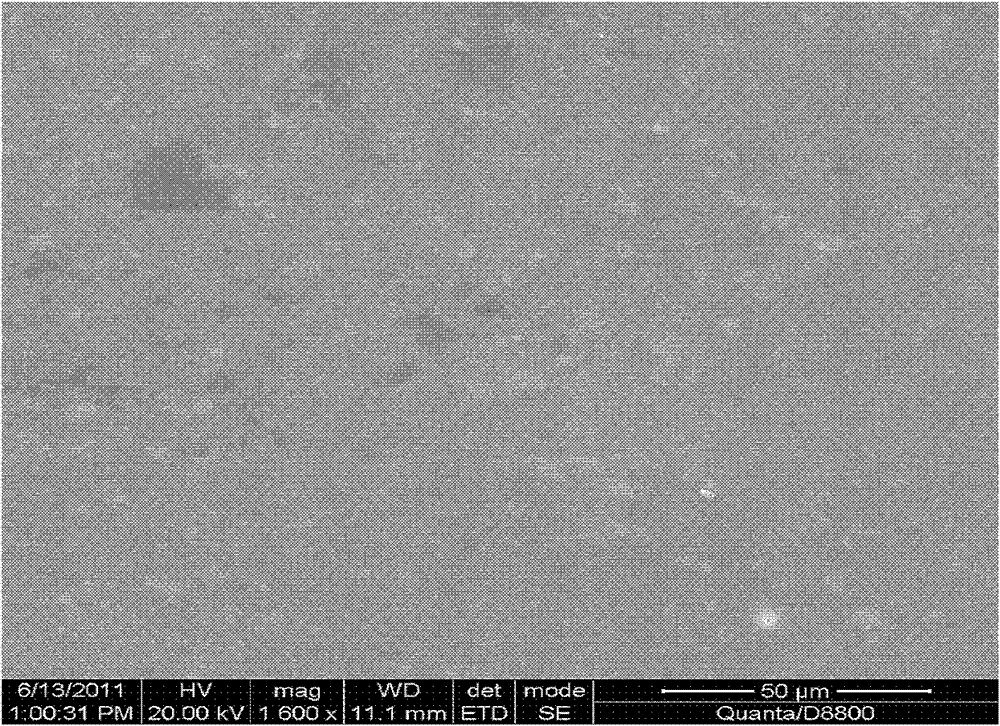

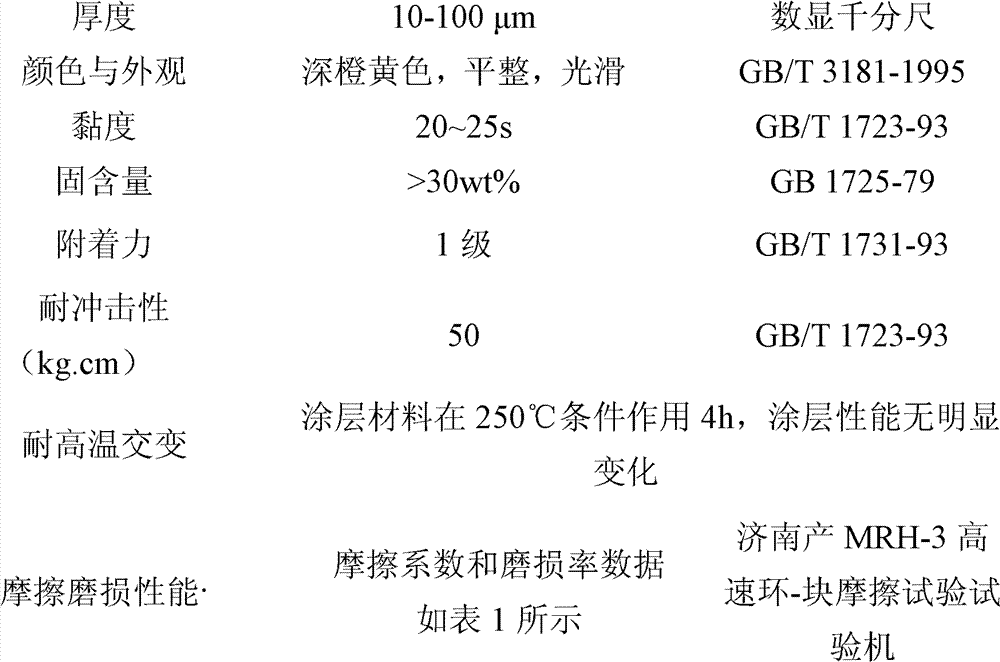

A polyimide-based self-lubricating wear-resistant coating material and its preparation method

InactiveCN102286248AGood anti-friction and anti-wear propertiesImprove carrying capacityPretreated surfacesCoatingsMuffle furnacePolytetrafluoroethylene

The invention discloses a polyimide-based self-lubricating abrasion-resistant coating material and a preparation method thereof. The coating material consists of the following raw materials in part by weight: 100 parts of polyimide bonded resin, 10 to 50 parts of irradiation polytetrafluoroethylene micro-powder solid lubricating agent and 200 to 400 parts of organic solvent. The preparation method comprises the following steps of: weighing and mixing the raw materials, and performing ultrasonic dispersion and magnetic stirring to form uniform resin solution; pouring the resin solution into a spray gun, and spraying the resin solution to the surface of a workpiece subjected to surface polishing and cleaning treatment under the pressure of 0.10 to 0.40Pa and under the action of oil-free compressed air, wherein the distance between the nozzle of the spray gun and the workpiece is not less than 20 centimeters, and the spray gun and the workpiece form an angle of 60 to 90 degrees; and putting the coated workpiece into a muffle furnace, performing section curing, cooling the workpiece to room temperature together with the furnace after curing, and thus obtaining the abrasion-resistant coating material on the surface of the workpiece. The coating material has the properties of low friction, high load resistance, abrasion resistance and high temperature resistance; and the preparationmethod is simple, easy in operation and low in cost.

Owner:SOUTH CHINA UNIV OF TECH

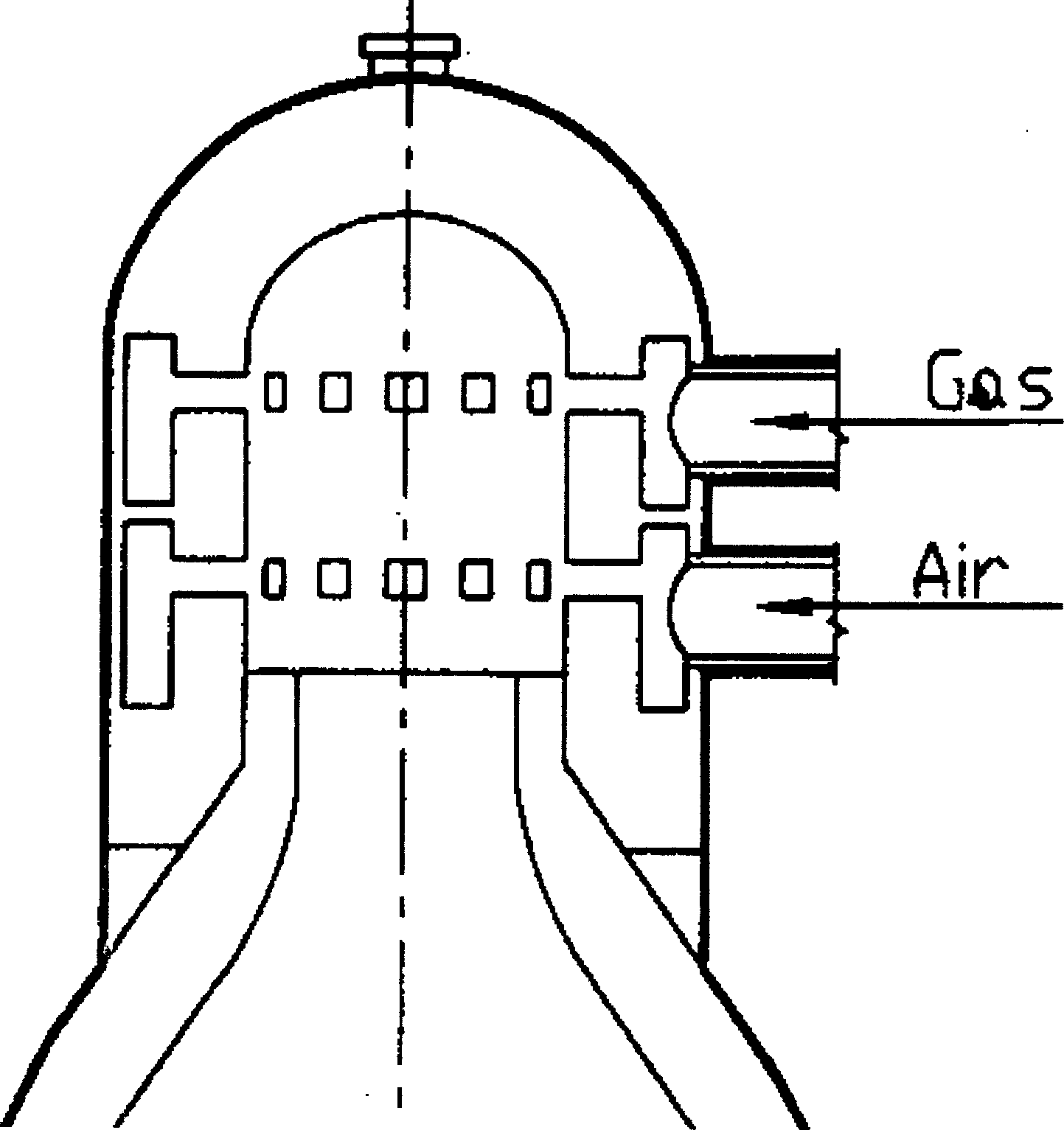

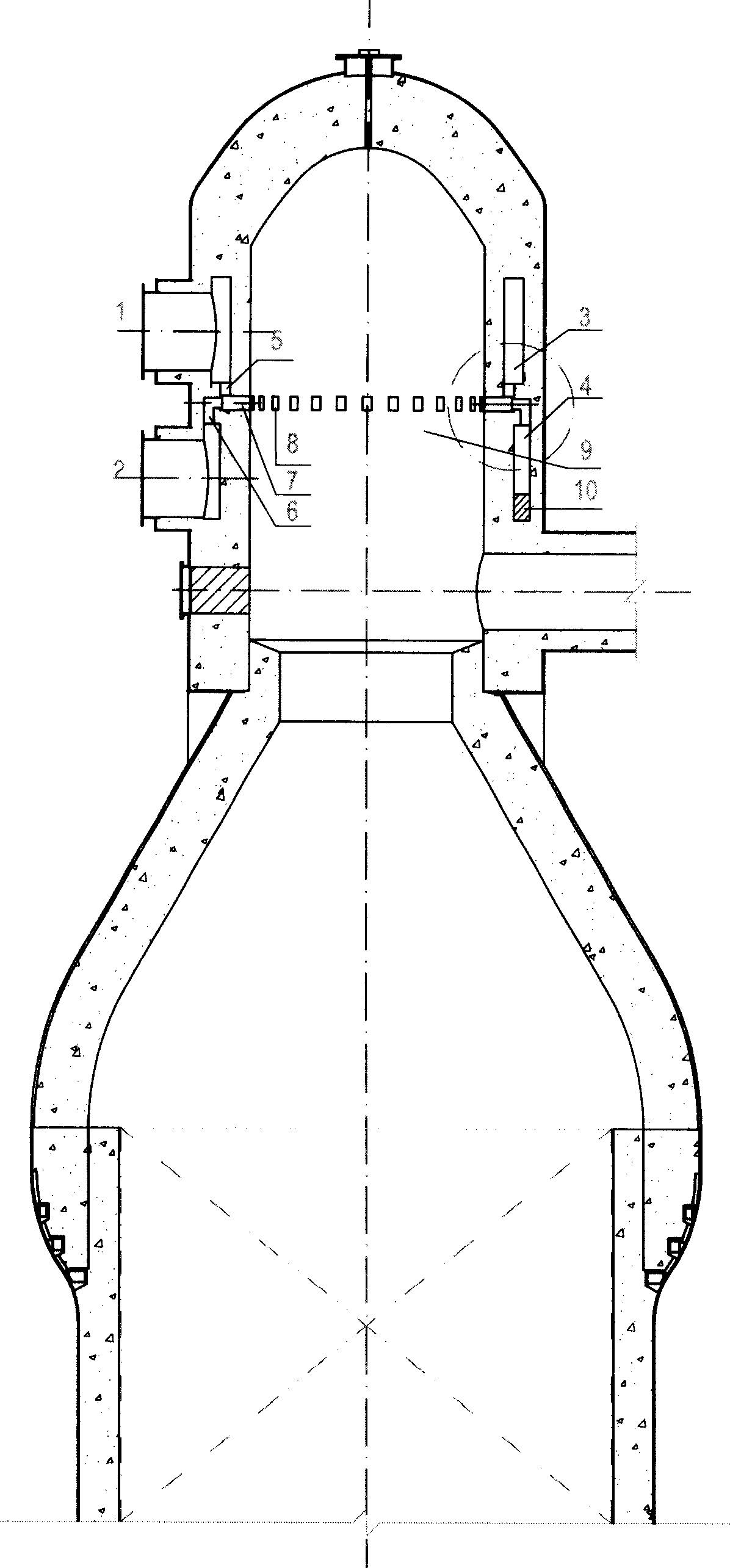

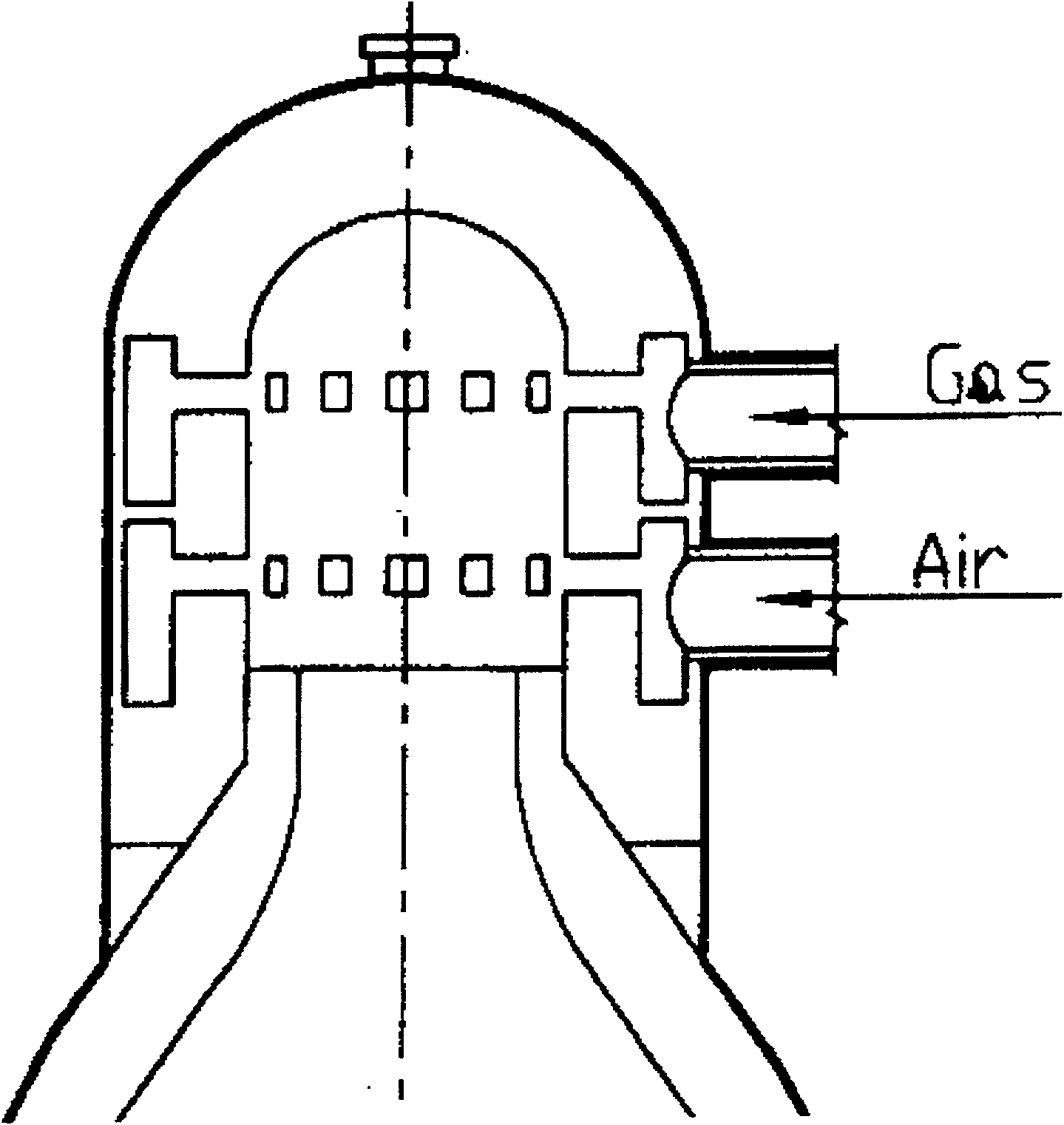

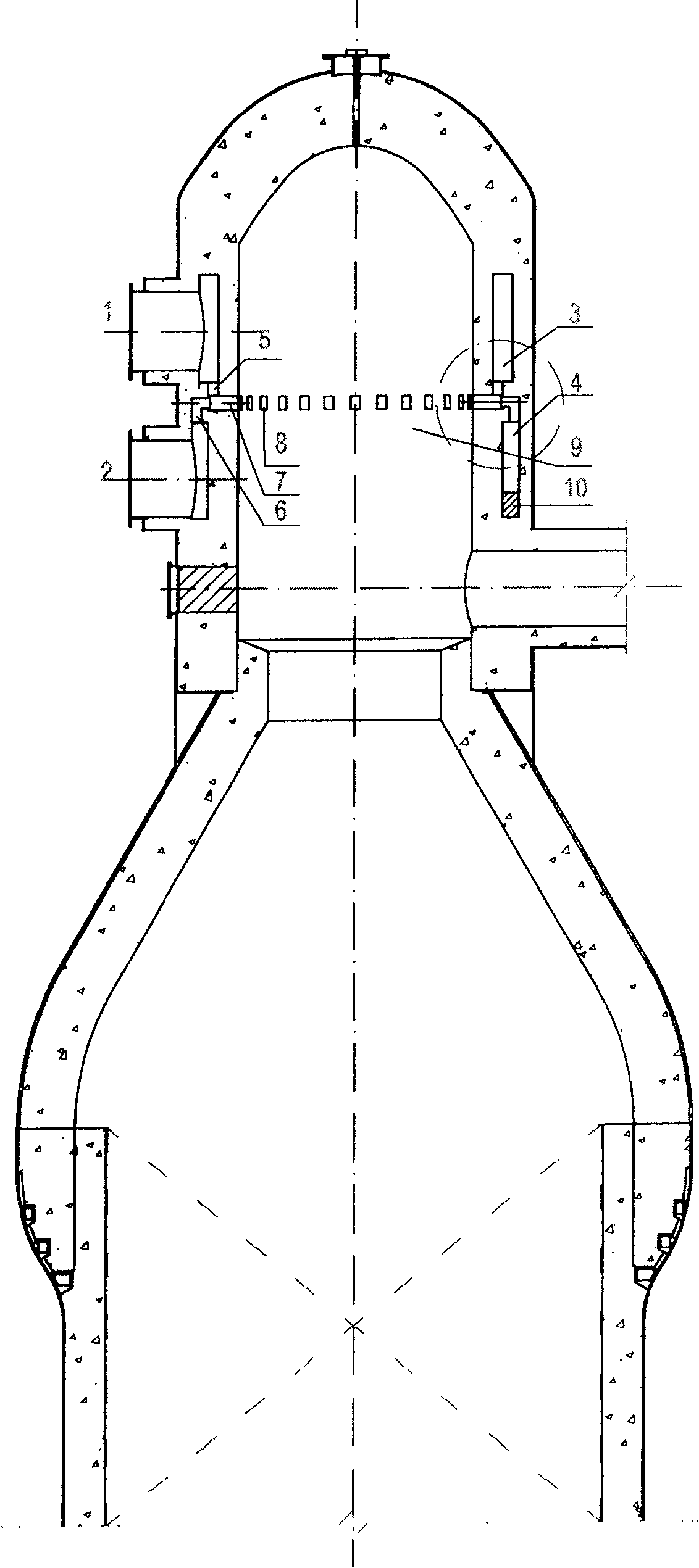

Multiple fire hole flame-free ceramic burner

InactiveCN1858492ANovel structureExtended service lifeBrick-hot blast stovesIndirect carbon-dioxide mitigationCombustorBrick

The multiple fire hole flame-free ceramic burners is used in flameless combustion industrial furnace and kiln, especially hot blast stove for iron making blast furnace. The multiple fire hole flame-free ceramic burner has two outer ring gas channels. After air through the air inlet and gas through the gas inlet enter the air preheating ring channel and the gas ring channel, gas and air are preheated in between two ring channels before jetting to the mixer for mixing and jetting through the combustion nozzle to combust. The gas ring channel has guide bricks for homogeneous distribution of gas. The present invention has unique structure, small size and great power, and is suitable for various kinds of hot blast stove with heat accumulator.

Owner:武汉冶金建筑研究院 +1

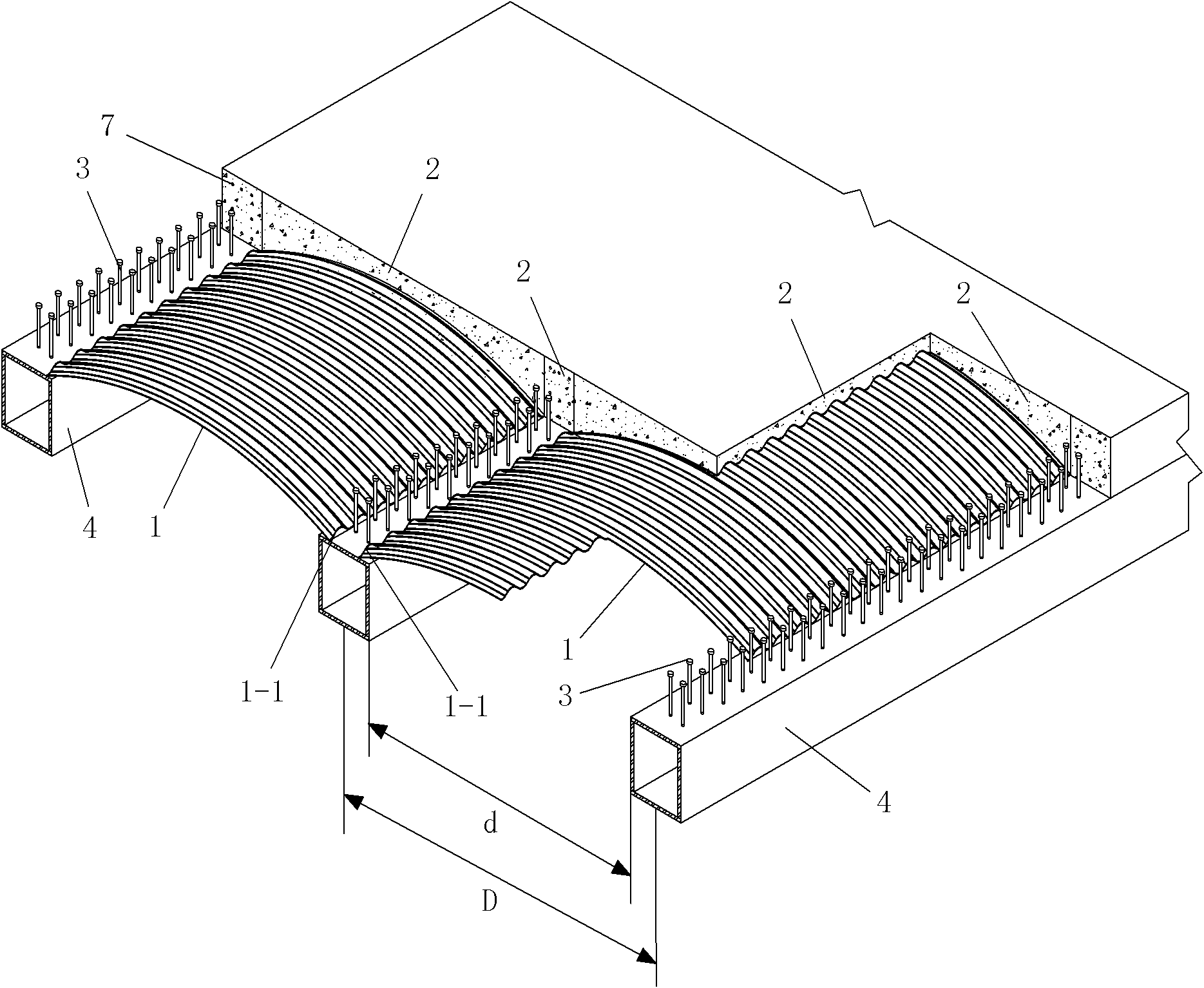

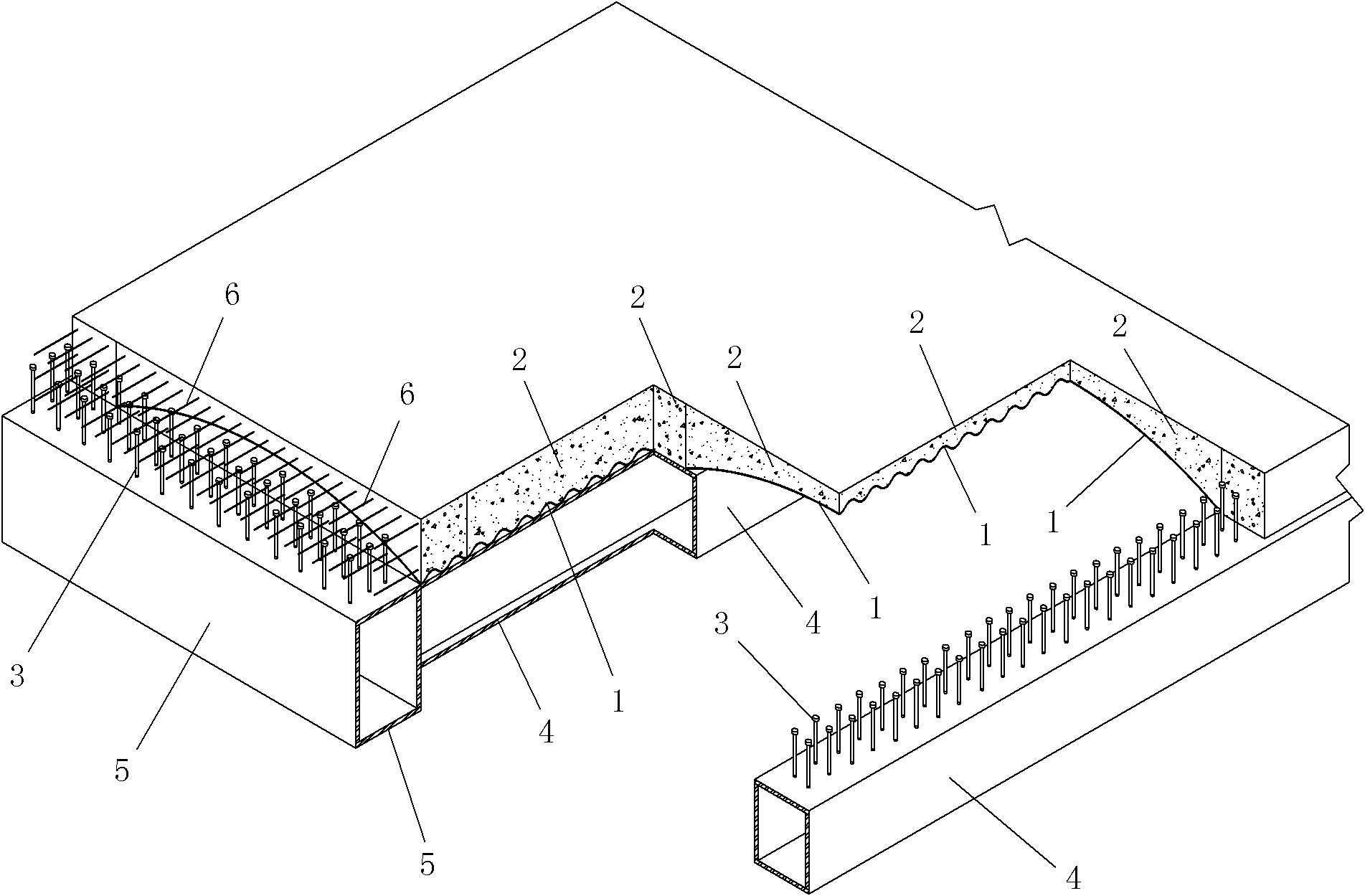

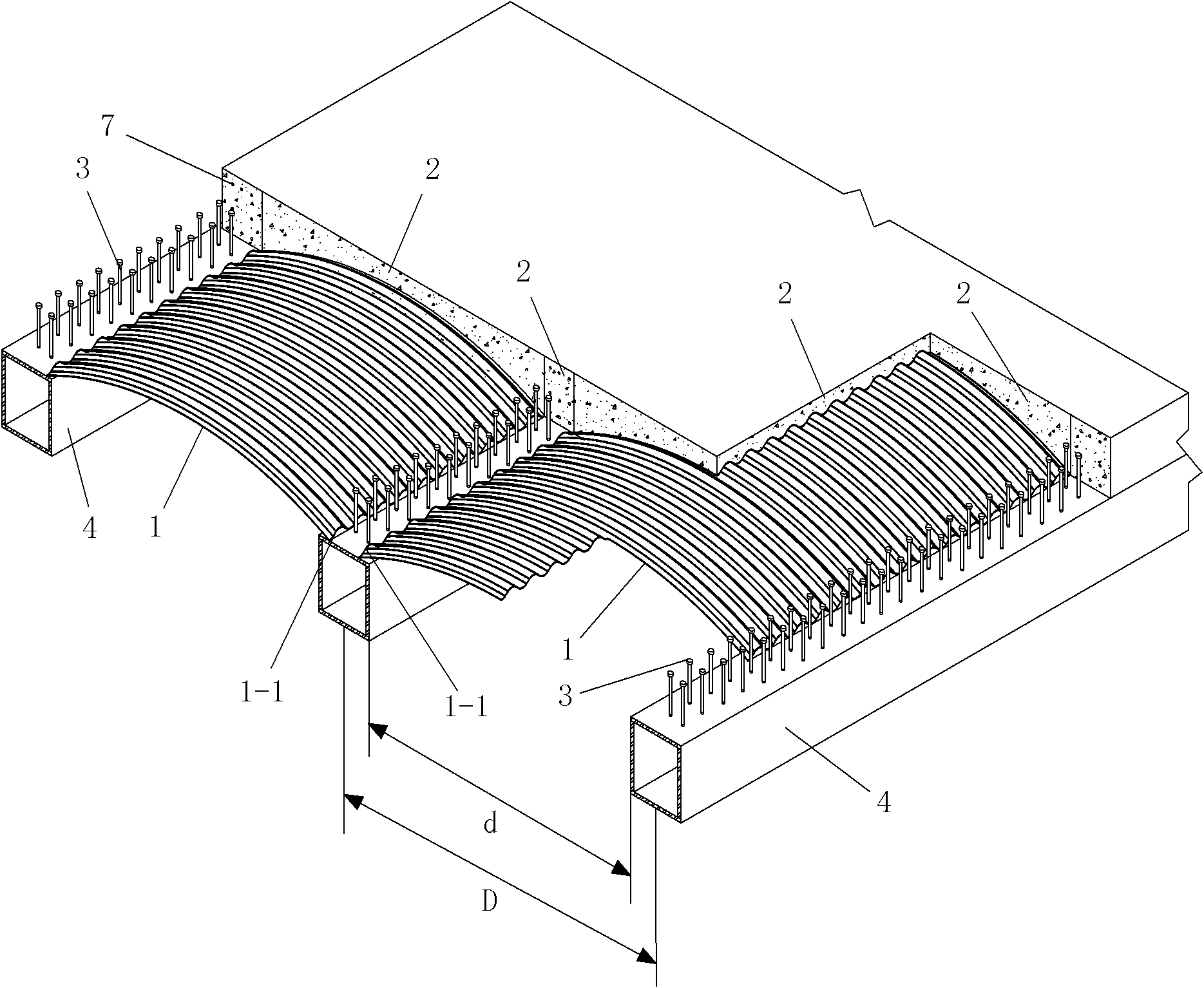

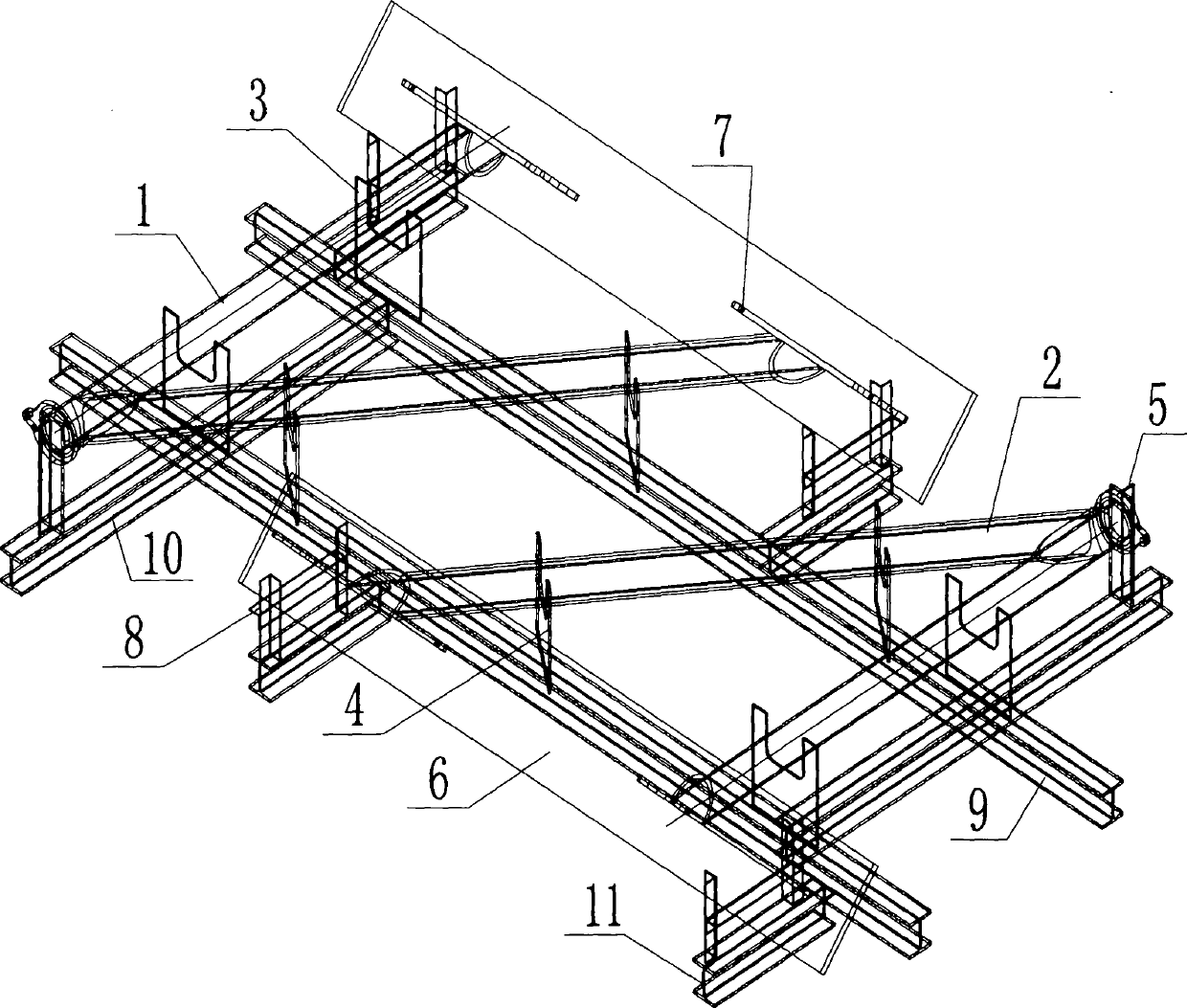

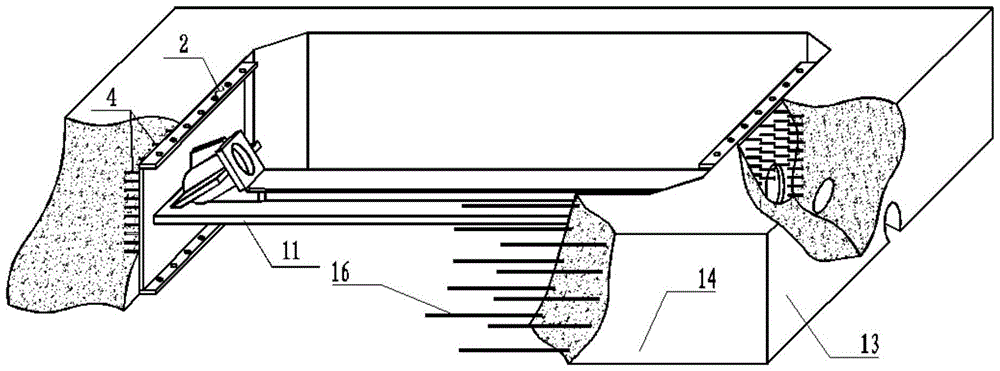

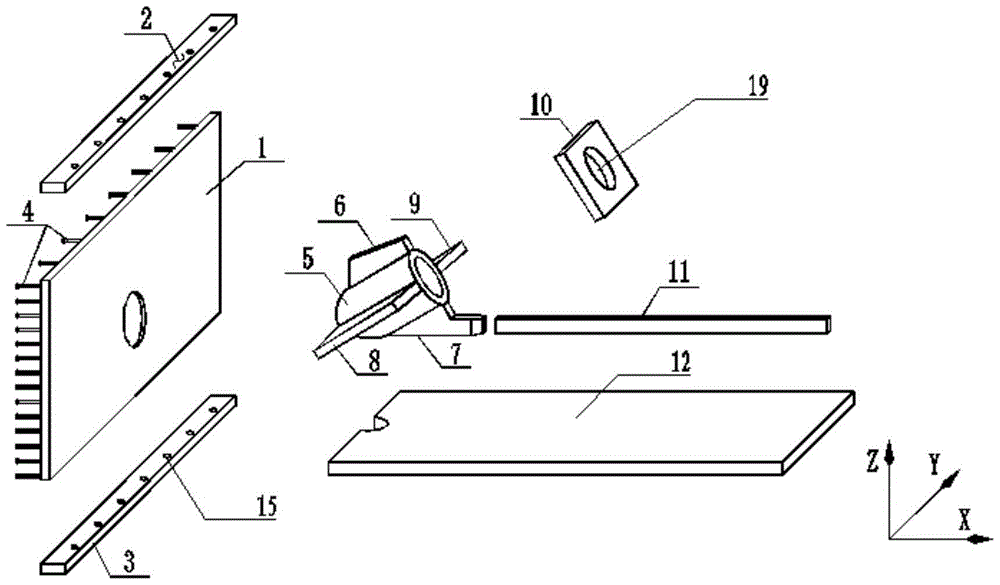

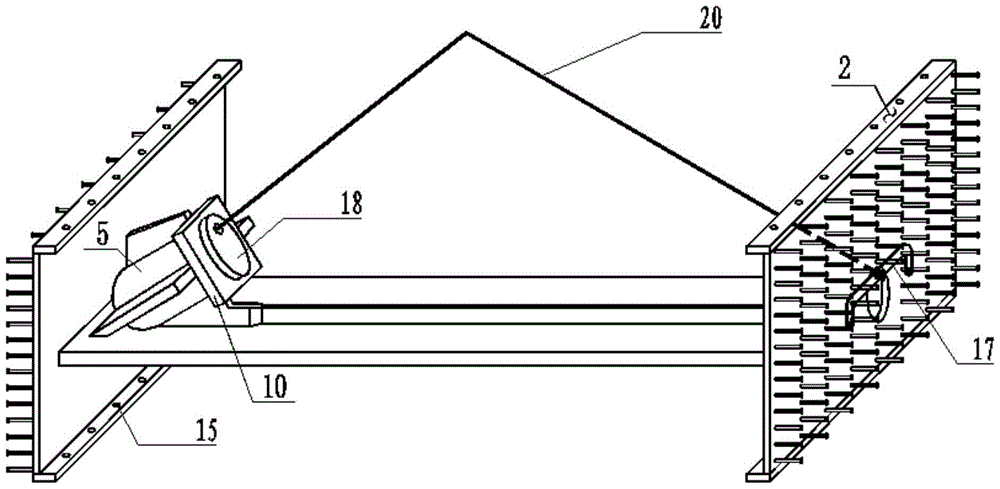

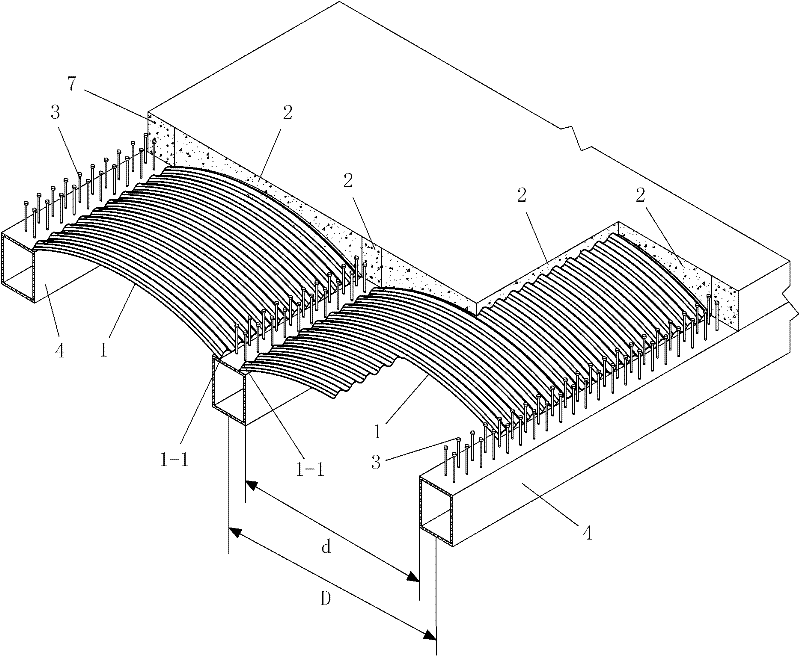

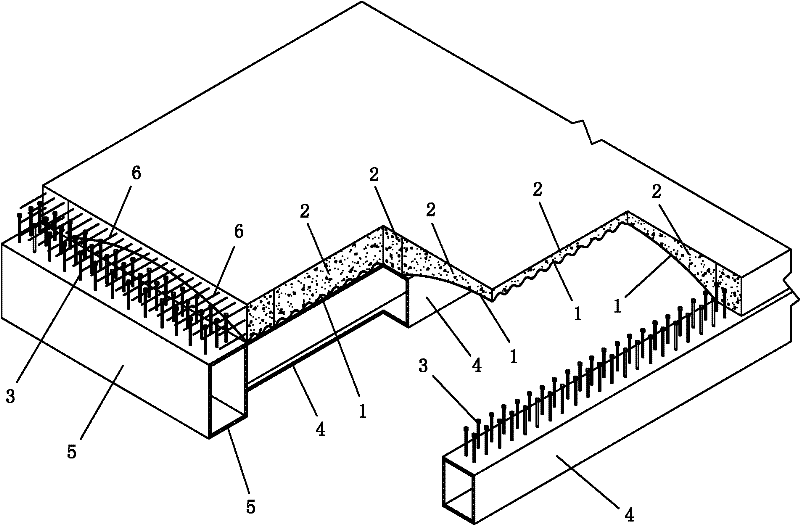

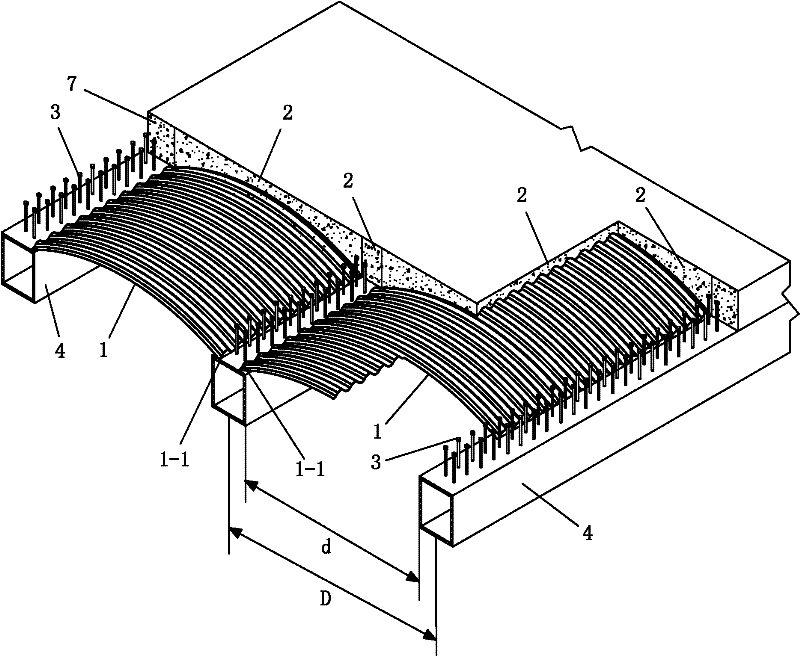

Combined bridge deck of arched corrugated steel plates and concrete

InactiveCN102121227AIncreased bending stiffnessImprove adhesionBridge structural detailsBridge materialsBridge deckStructural engineering

The invention discloses a combined bridge deck of arched corrugated steel plates and concrete, and the combined bridge deck comprises a bridge deck substrate consisting of a plurality of rows of arched corrugated steel plates arranged in parallel, a bridge deck bottom supporting structure for supporting and fixing the bridge deck substrate, and a concrete top layer formed on the bridge deck substrate in a pouring manner; the bridge deck bottom supporting structure is formed by assembling a plurality of beams which comprise a plurality of rows of lower vertical beams arranged in parallel and a plurality of lines of lower beams arranged in parallel; each row of arched corrugated steel plates are all fastened between two rows of lower vertical beams; arch springings on the left and right of the corrugated steel plates are fixedly arranged on the two adjacent rows of lower vertical beams respectively; the corrugation of each corrugated steel plate is in the transverse direction; and the rows of lower vertical beams and the rows of corrugated steel plates form a formed bottom template for pouring the formed concrete top layer. The combined bridge deck of arched corrugated steel plates and concrete is simple in structure, convenient to manufacture and construct and good in structural mechanical property, and can be used for effectively solving the problems existing in the existing bridge deck structure.

Owner:CHANGAN UNIV +1

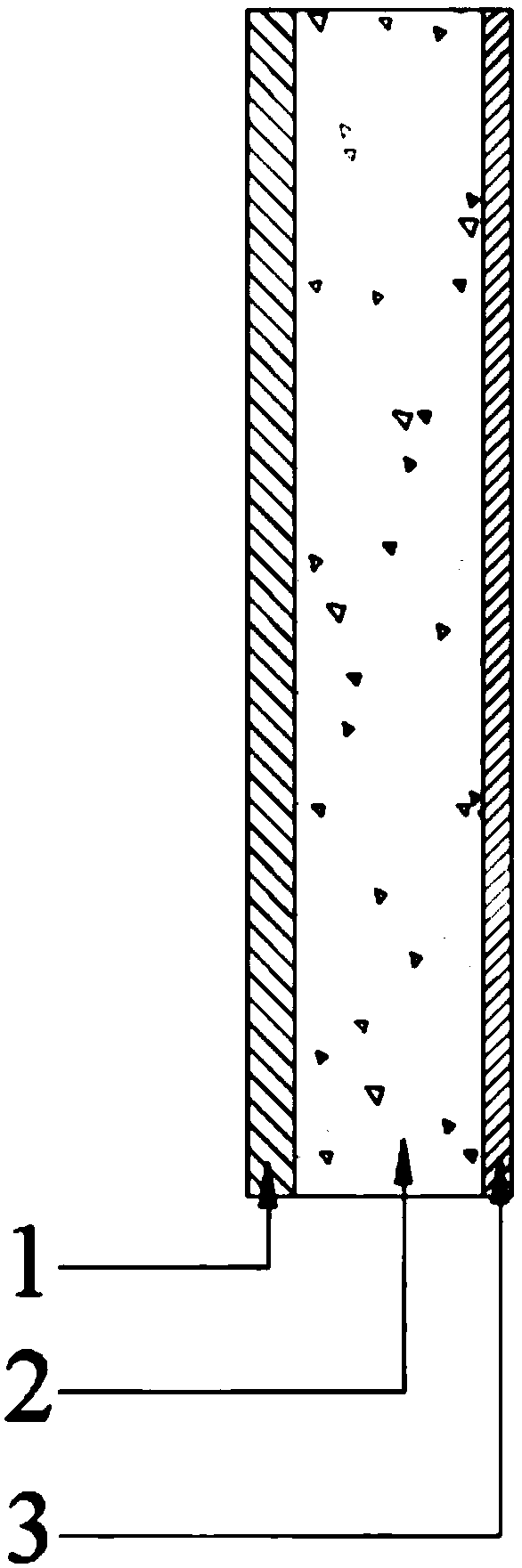

Composite wall

The invention relates to the technical field of housing construction and particularly discloses a composite wall, the composite wall comprises an external wall panel, an internal wall panel and a packing layer arranged between the external wall panel and the internal wall panel, wherein the composition of materials of the external wall panel comprises cements, mine wastes, lignocelluloses, straw powders, water reducing agents, alkali-resistant glass fibers and concrete waterproofer. The external wall panel of the composite wall disclosed by the invention is similar to a steel plate in nature, has a certain tenacity, and is sturdy and durable, water-proof and fire-proof, heat-proof and sound-proof, light in material, environmental-friendly, and convenient in manufacture and construction, therefore, the performances in various aspects of the whole composite wall are effectively improved, and the composite wall is easy to popularize and use.

Owner:中科巨匠建筑科技有限公司

Wall material and production method thereof

InactiveCN104088419AWon't fall offImprove flexibilityCovering/liningsSynthetic resin layered productsHalogenResin adhesive

The invention discloses a wall material and a production method thereof. The wall material comprises a substrate, a pattern layer, a transparent resin adhesive layer and a stone particle layer which are sequentially laminated from bottom to top, wherein the substrate contains 20 to 30 weight percent of non-halogen flame retardant; the transparent resin adhesive layer contains 70 to 80 weight percent of acrylic acid copolymer resin, 0.5 to 1 weight percent of thickening agent and 20 to 30 weight percent of non-halogen flame retardant; the stone particle layer comprises a plurality of stone particles; a part of each stone particle is embedded and adhered into the transparent resin adhesive layer. According to the wall material and the production method thereof, a product has high flexibility, and can be freely bent without dropping the stone particles; the whole product has high flame retardance, and is attractive in appearance and practical; in addition, the product also has the advantages of light weight, convenience in production and construction, high waterproof capability and sound insulation capability, environment friendliness and the like.

Owner:彭艺郎

Composite wall body

InactiveCN108395184ALight materialEasy to manufacture and constructBuilding componentsCeramicwareThermal insulationSteel plates

The invention relates to the technical field of building constructions and particularly discloses a composite wall body. The composite wall body comprises an external wall board, an inner wall board and a filling layer filled between the external wall board and the inner wall board, wherein the external wall board is prepared from the following material components: cement, mine wastes, lignocellulose, straw powder, a water reducing agent, alkali-resistant glass fibers and a concrete water-proofing agent. The external wall board of the composite wall body disclosed by the invention is similar to a steel plate in property and has the advantages of certain toughness, sturdiness, durability, waterproof and fireproof properties, thermal insulation, sound insulation, lightweight materials, low carbon, environment friendliness and convenience in manufacturing construction; the overall performance of the composite wall body is effectively improved, and further the composite wall body is easy to promote and use.

Owner:陈锦华

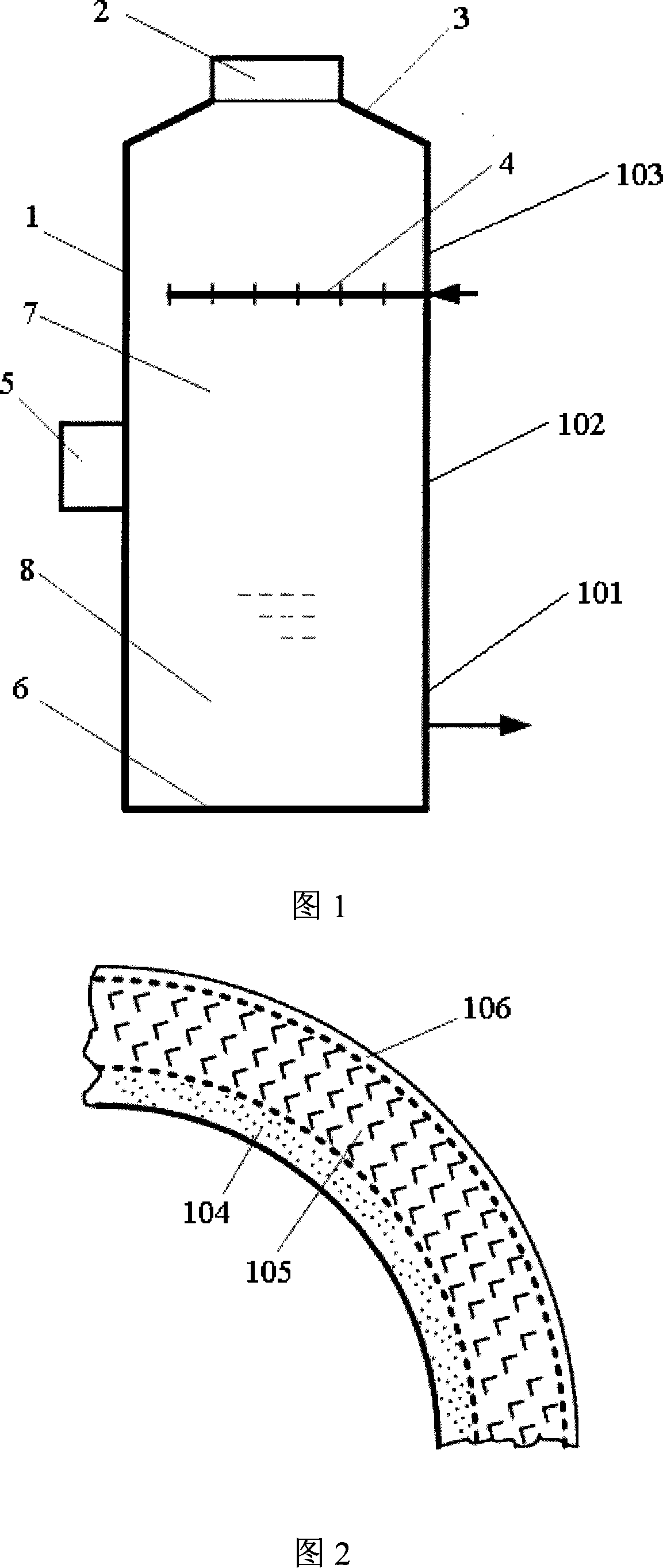

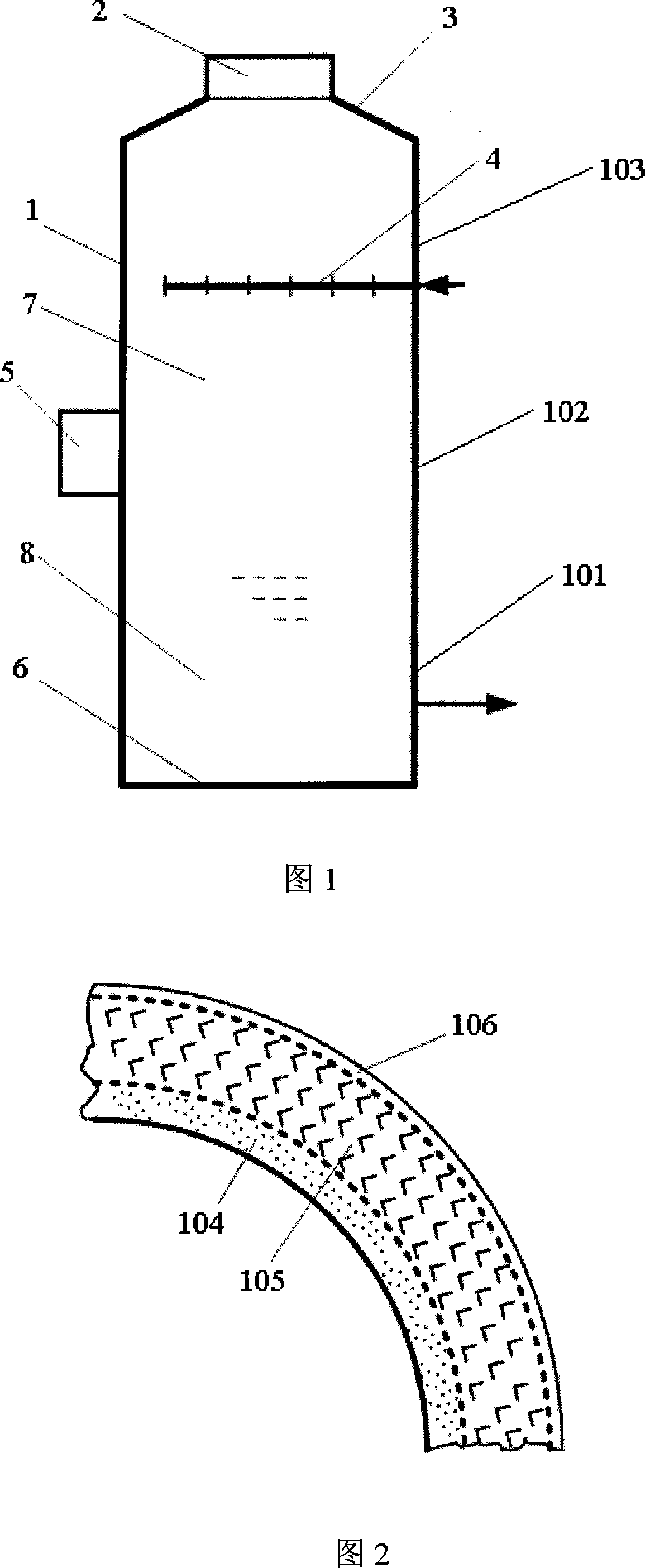

Special composite material and uses thereof

The present invention relates to a special composite material and the application. This composite material comprises inorganic fiber, organic resin, and resin curing accelerator, among which inorganic fiber is 5 to 80 parts by weight (pbw), organic resin 20 to 95 pbw. The ratio of resin curing accelerator to organic resin is 0.01 to 0.1. The composite material can be used to prepare tower of flue gas desulfurizer, which comprises a tower body, a top flue gas pipeline installed on the tower body, a top cover connecting the bottom of the top flue gas pipeline with the tower, a liquid absorption distributor under the top cover, a central section of flu gas pipeline under the liquid absorption distributor, and a bottom plate. The tower body, the top cover and the bottom plate are made of the composite material. By adopting the polymer composite material with comparatively low price to make the flue gas desulfurizer tower, the invention has the advantages of quick and convenient manufacturing, reliable product quality, high performance price ratio and suitability for large-scale popularization.

Owner:娄爱娟

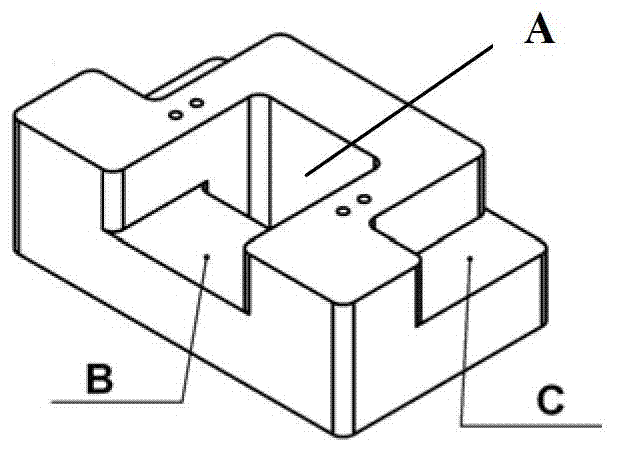

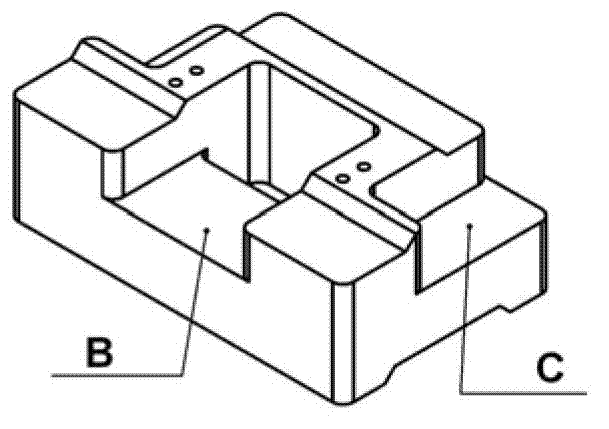

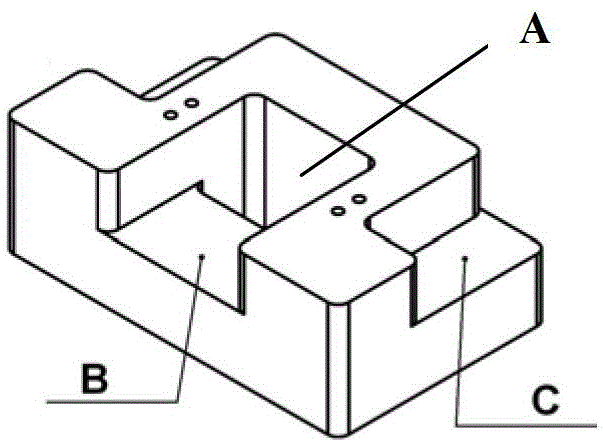

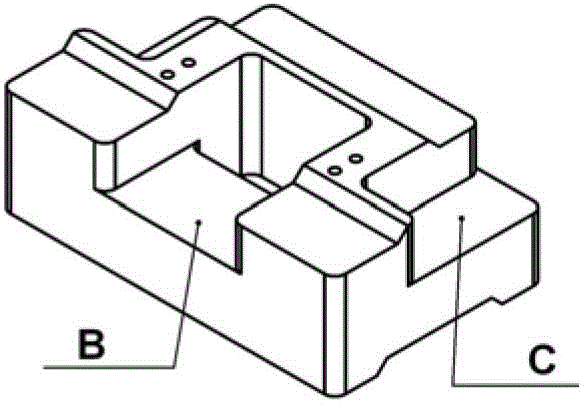

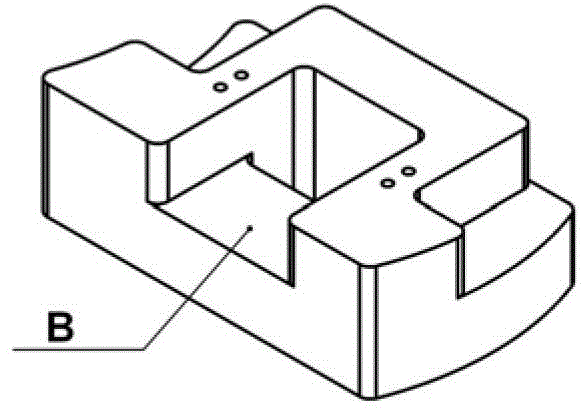

Building block and wall structure formed by same

InactiveCN102966073ASimple structureEasy to make and constructArtificial islandsCoastlines protectionArchitectural engineeringWater seepage

The invention discloses a building block. The building block is a hexahedron comprising a front face, a back face, a top face, a bottom face, a left face and a right face. A through-hole is formed at the middle of the building block and penetrates from the top face to the bottom face. A back notch extends from a side edge of the top face towards the back face, a front notch extends forward from the middle part of the top face, the front notch communicates with the through-hole, and the back notch is isolated from the through-hole. In a wall, a plurality of building blocks are stacked continuously in a staggered manner. When one building block is stacked with another beneath building block to form the wall, the through-hole of the building block is communicated with the back notch of the beneath building block, and the front notch and the through-hole of the building block are communicated with the back notch of the beneath building block to form a water seepage passage. The invention also discloses a wall structure formed by the building block. The building block and the wall structure have the advantages of simplified structure, convenience in manufacture and construction, and improved ecological property.

Owner:谢理波

Manufacturing method for ribbed FRP members

InactiveCN103643633AEasy to make and constructFast constructionBridge structural detailsEngineeringUltimate tensile strength

The invention discloses a manufacturing method for ribbed FRP members. The method comprises the following steps: manufacturing basic FRP splicing blocks; forming bolt holes in the basic FRP splicing blocks; placing the basic FRP splicing blocks according to a certain sequence, and mounting bolts or end bolts in the bolt holes of the adjacent basic FRP splicing blocks; regularly arranging glue injection nozzles in gaps between the adjacent basic FRP splicing blocks, and performing edge sealing processing for the peripheries of the gaps at splicing positions of the adjacent basic FRP splicing blocks; injecting glue into the gaps in the splicing positions of the adjacent basic FRP splicing blocks through the glue injection nozzles; after the glue is solidified, dismantling or retaining the bolts and end bolts; after the glue is fully solidified and reach a certain strength, forming horizontal through holes in FRP longitudinal plate ribs formed by the adjacent basic FRP splicing blocks. The ribbed FRP members in size is not limited by sizes of the basic FRP splicing blocks, and can be freely spliced according to the actual size required by the construction site, so that the advantages that manufacturing and construction are simple and convenient, the construction speed is fast, the structural mechanics performance is excellent and the economic performance is considerable are achieved.

Owner:黄海林

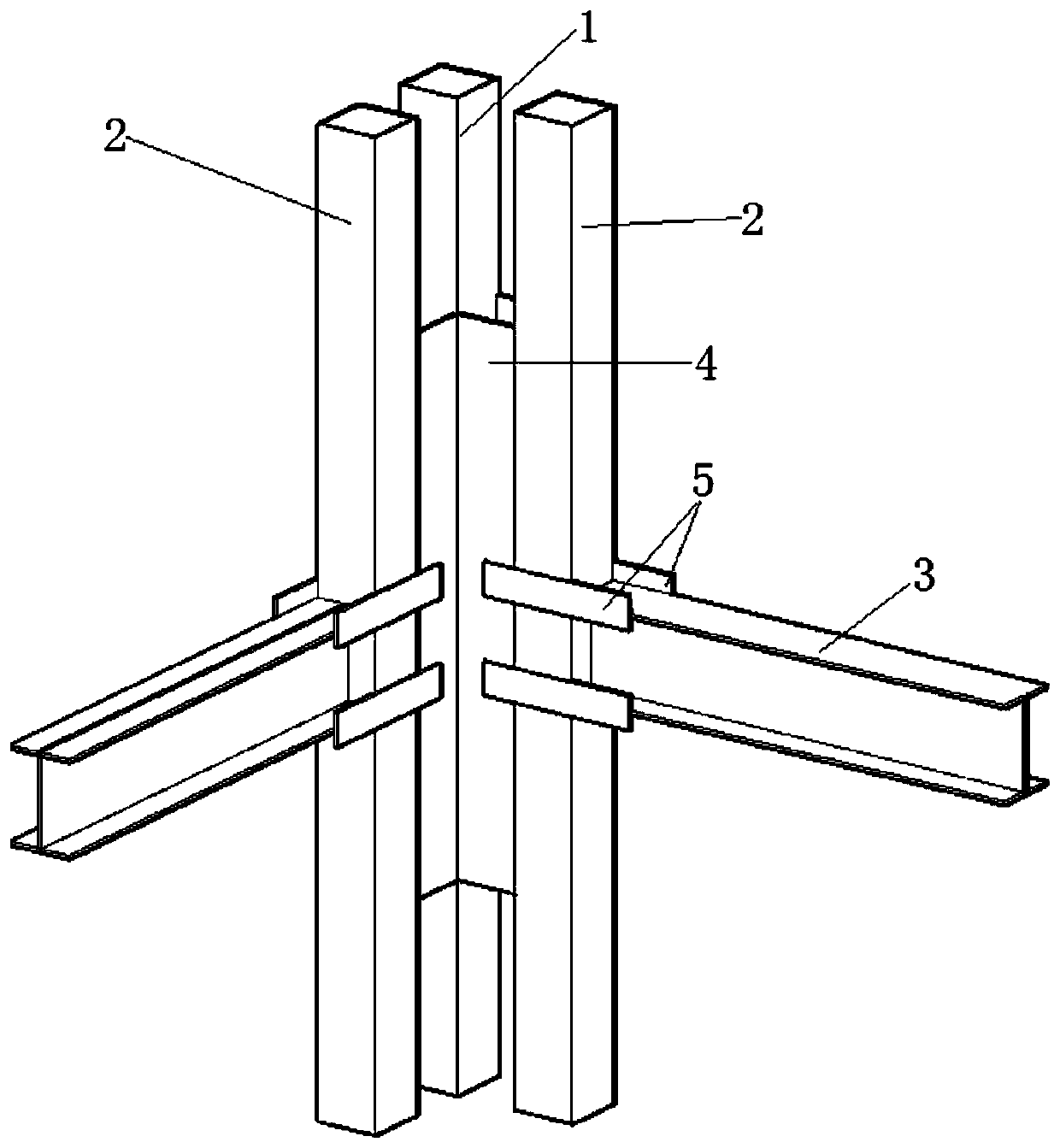

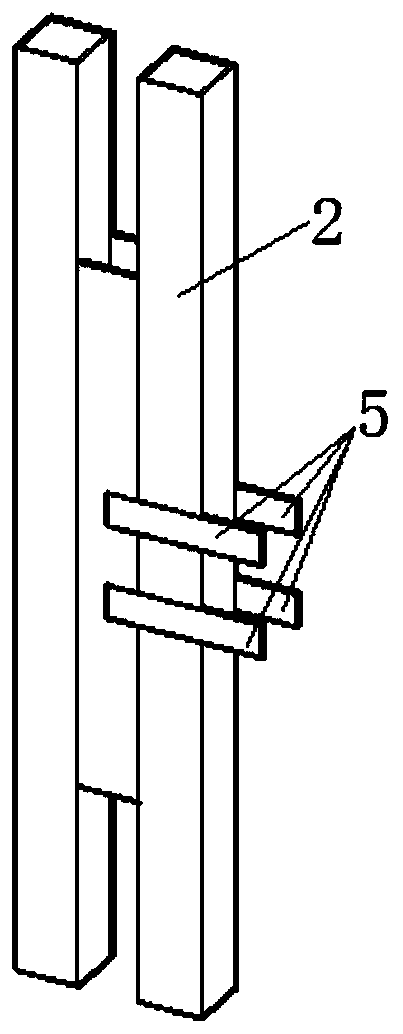

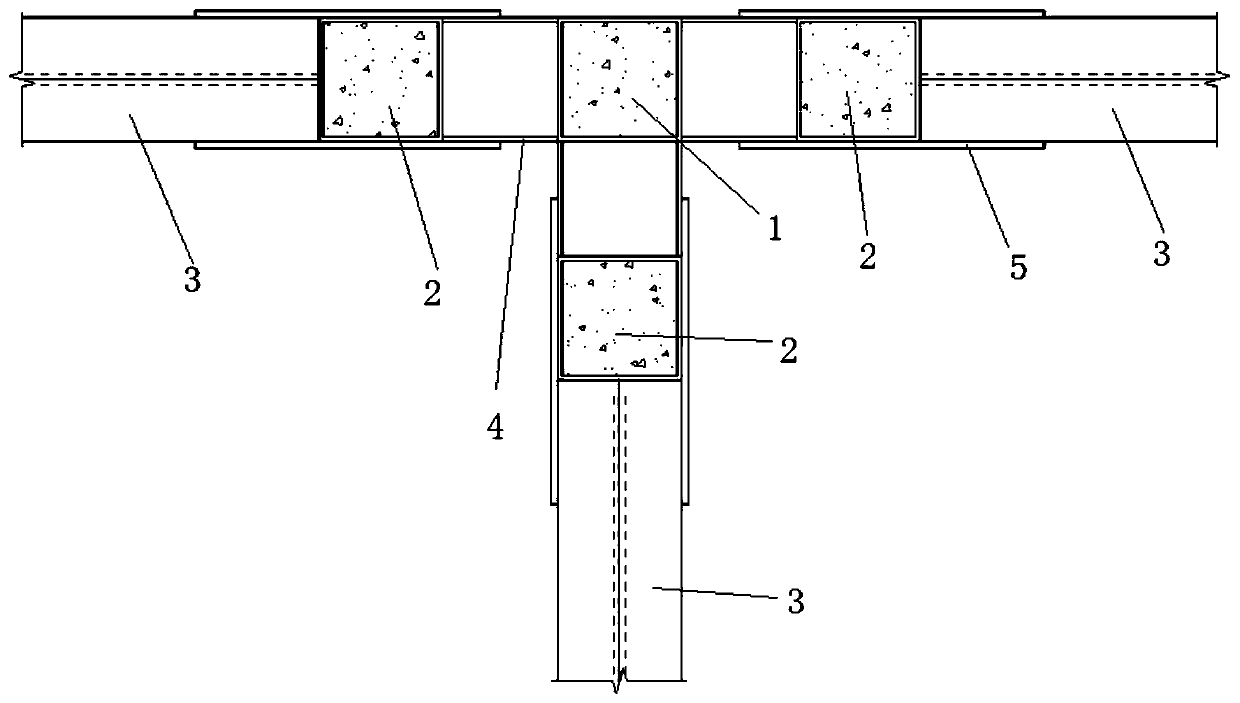

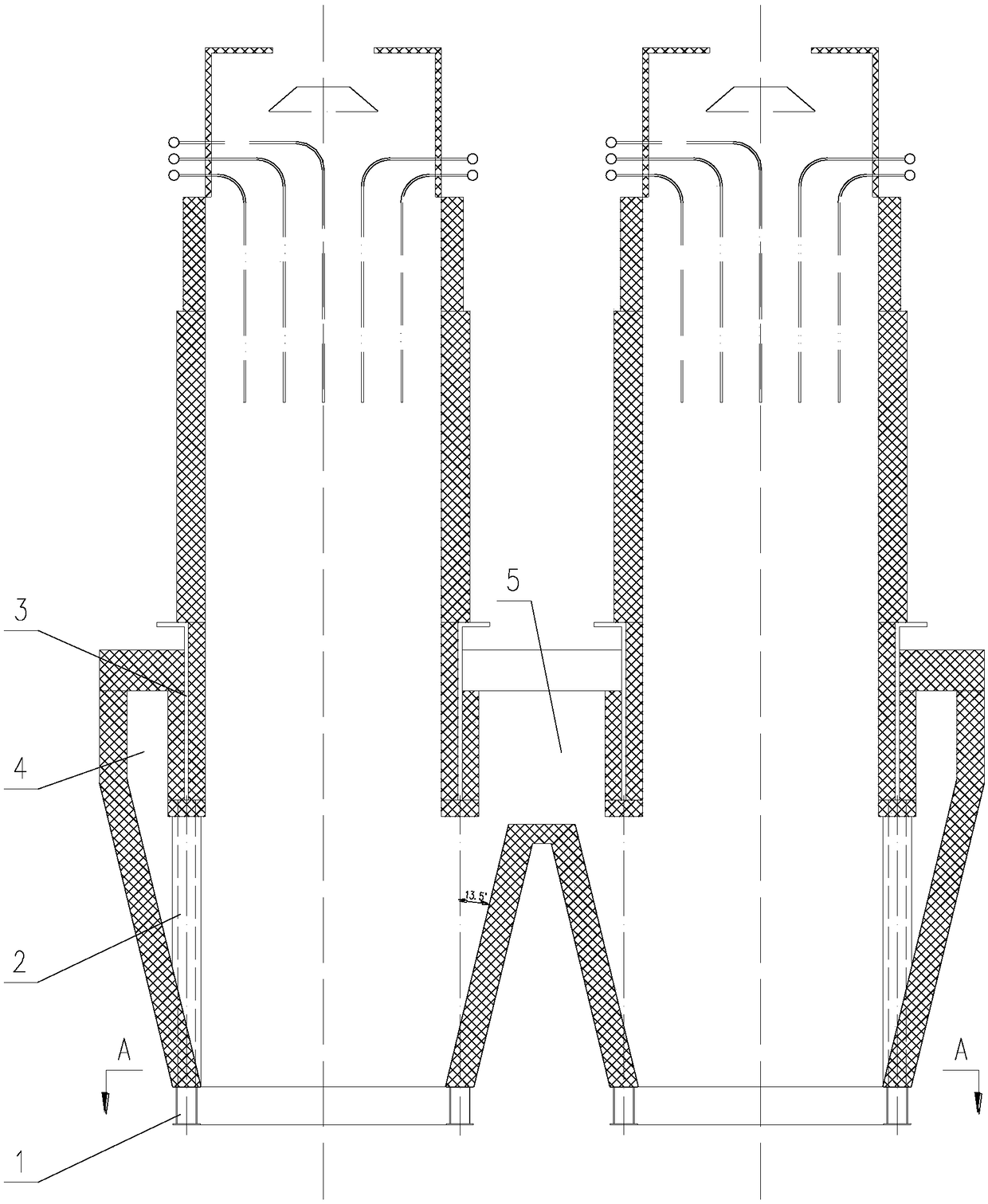

Assembling type concrete-filled steel pipe combined column node area connection structure

InactiveCN110284605AMeet the seismic requirementsMake sure to work togetherBuilding constructionsMachining processFlange

The invention relates to the field of architectural structure members and discloses an assembling type concrete-filled steel pipe combined column node area connection structure. The assembling type concrete-filled steel pipe combined column node area connection structure comprises a central square steel pipe, end square steel pipes, H-type steel beams, connecting plates and stiffening plates. The central square steel pipe and the end square steel pipes are connected through two parallel connecting plates. The H-type steel beams are perpendicularly fixed to the end square steel pipes. Two side edges of flange plates of the H-type steel beams and the inner and outer side faces of the end square steel pipes are in the same horizontal plane. The stiffening plates are fixedly arranged on the inner sides and the outer sides of the end square steel pipes. The two ends of the stiffening plates are fixedly connected with the connecting plates and the flange plates of the H-type steel beams respectively. According to the assembling type concrete-filled steel pipe combined column node area connection structure, anti-seismic requirements for strong columns and weak beams and strong nodes and weak members can be satisfied; structural integrity is good; structural rigidity is high; node stress is more reasonable; it is guaranteed each branch column can work cooperatively and bear the stress together; and the whole machining process is all completed in a factory, only installation is needed to be conducted on site, the construction period is shortened greatly, and the project cost is saved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

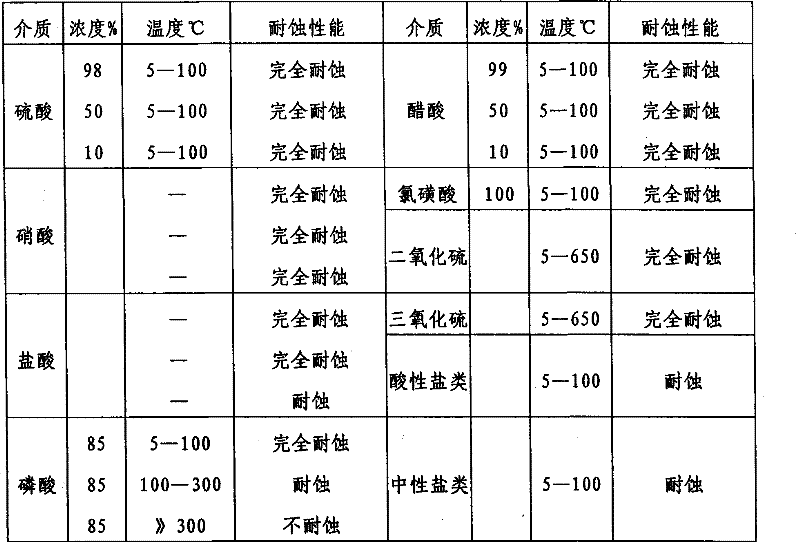

A kind of preparation method of composite material

The invention provides a method for preparing a composite material, which is characterized in that the composite material uses specific fibers as reinforcing materials and a rubber compound composed of specific adhesives, acid-resistant powders, modifiers and curing agents as cementing materials. It is formed through processes such as glue preparation, primer application, reinforcing layer laying, top glue application, curing and curing, and acidification treatment. The invention has the advantages of convenient production and construction, low cost, good repairability, and resistance to concentrated acid and acid at normal or high temperatures. The advantage of flue gas corrosion is that its temperature resistance to concentrated acid can reach 350℃, and its temperature resistance to acidic flue gas can reach 600℃~800℃.

Owner:JIANGXI COPPER CORP

Method and tool for manufacturing Y-shaped tubes of pile legs

InactiveCN103962982ASpeed up mass productionEasy to make and constructWork holdersBatch productionManufacturing engineering

The invention discloses a method and a tool design for manufacturing Y-shaped tubes of pile legs of a drilling platform. The method and the tool design are characterized in that the Y-shaped tubes of the quadrilateral pile leg of a self-lifting drilling platform are high in manufacturing precision requirement, large in number and high in construction workload for welding, cutting, grinding, coating, assembling and the like, a tool enabling precision controlling and manufacturing in batch need to be arranged, two support plates are arranged under each of a straight tube and an inclined tube to support weight of each Y-shaped tube, H-shaped steels for ejection are arranged at the ends for connecting every two Y-shaped tubes, angular templates for ejection are arranged at separate ends of the Y-shaped tubes according to actual shapes, precision in shapes of two ends of each Y-shaped tube is guaranteed, the purpose of repeatedly and quickly utilizing the tool for Y-shaped tube manufacturing is realized, and transverse H-shaped steel structures are arranged under support structures to serve as fixed bases. The method and the design have the advantages that speed of batch production of the Y-shaped tubes is increased, requirement on the precision can be met without measuring data by one by one, simplicity in manufacturing and utilizing is achieved, and construction period and cost are reduced.

Owner:江齐锋

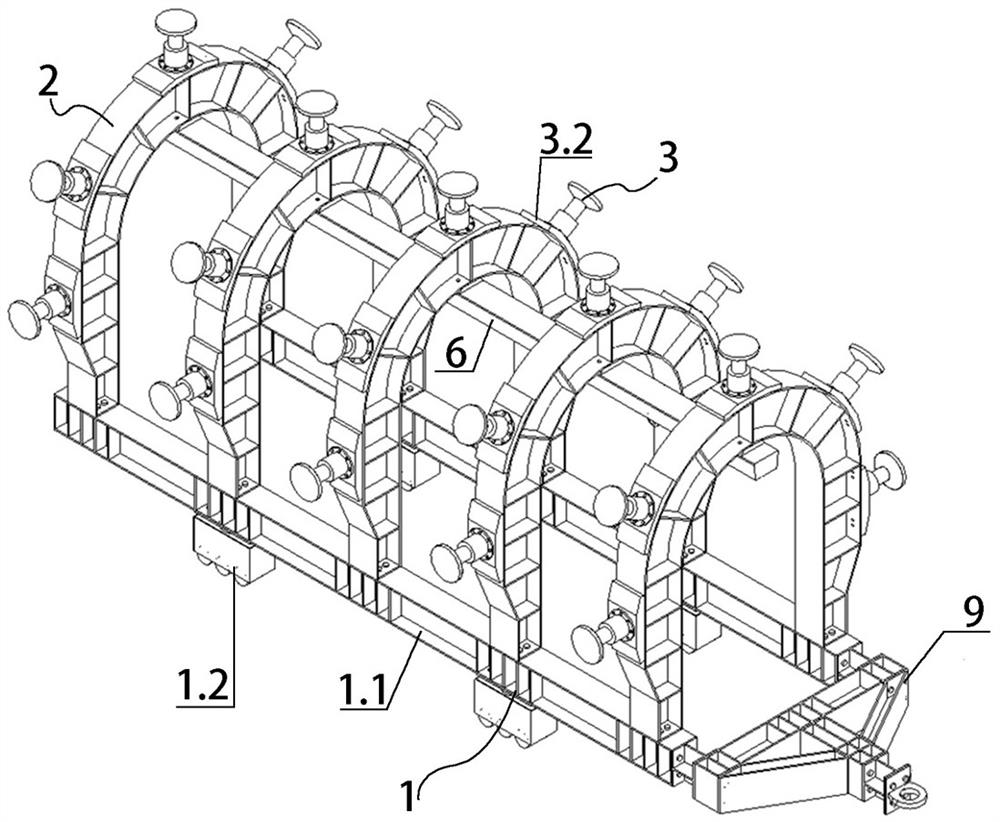

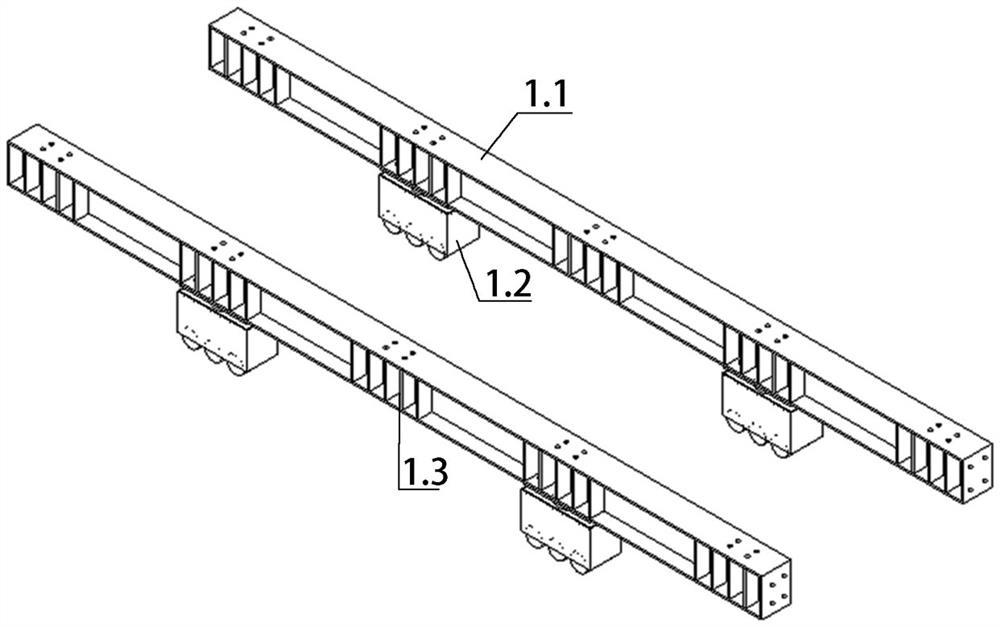

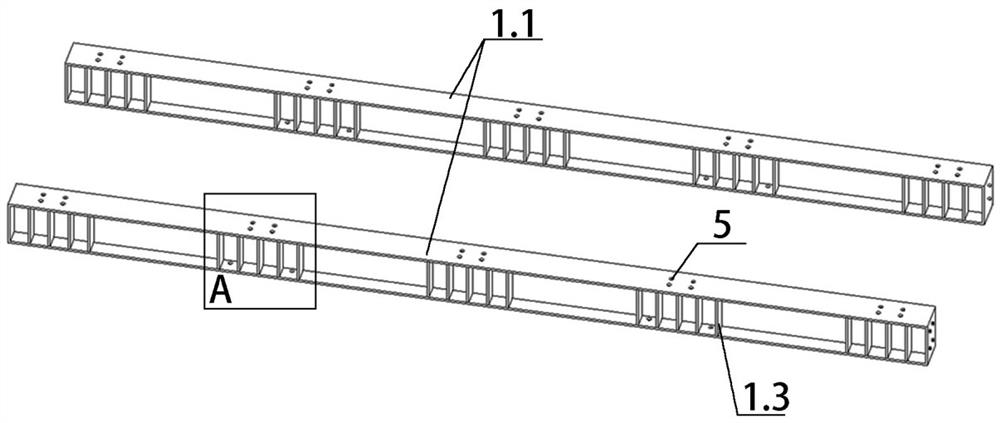

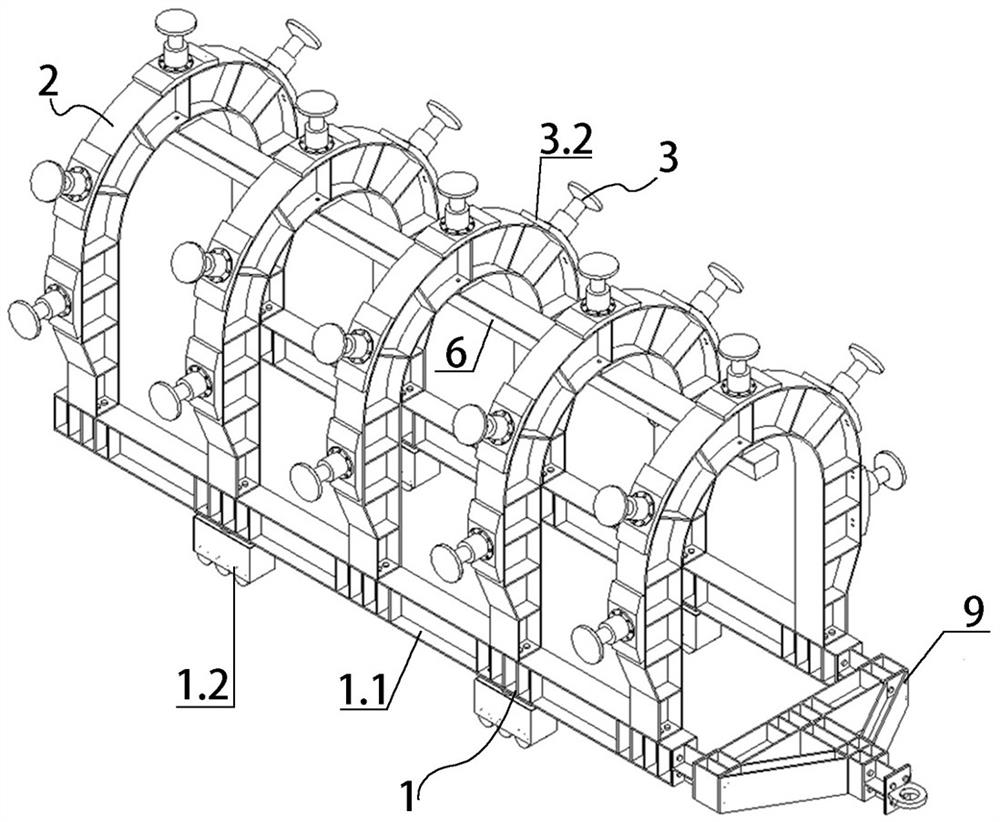

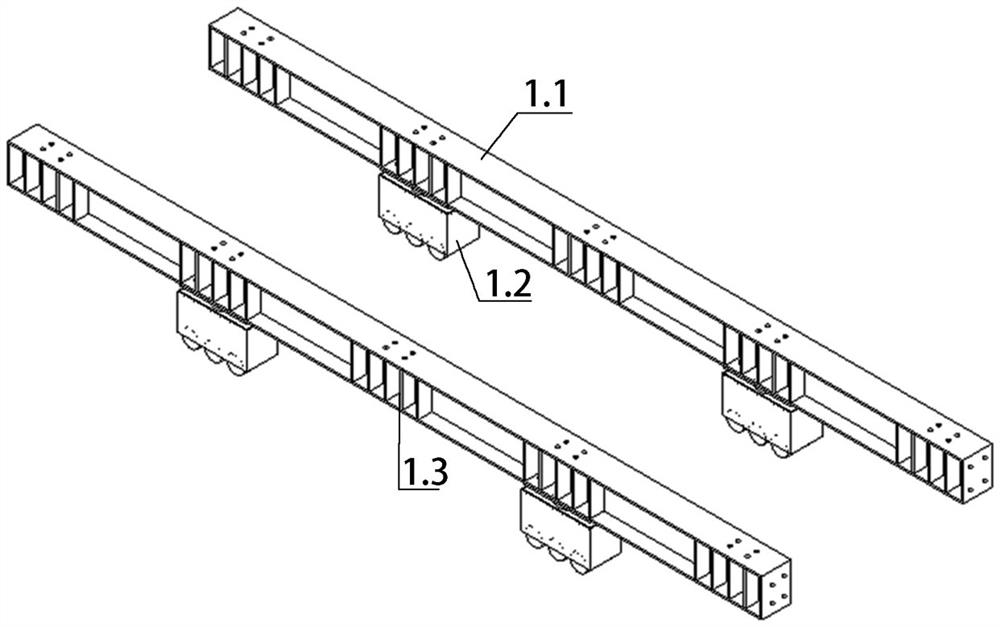

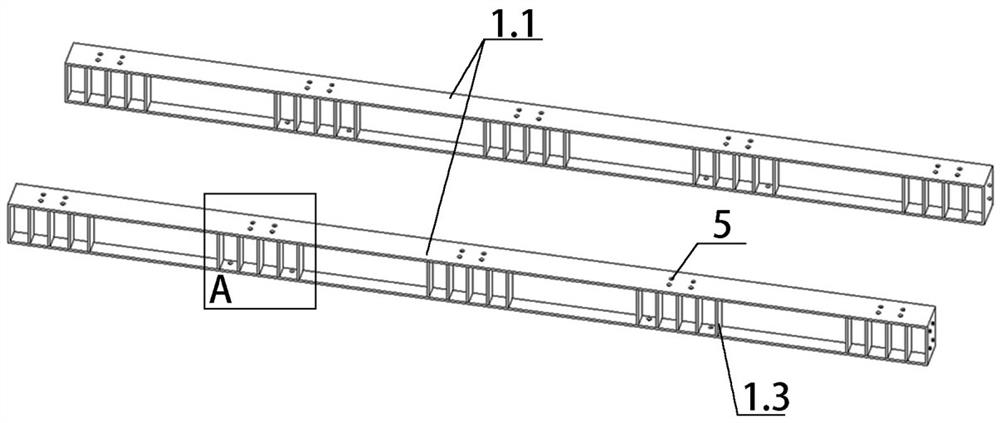

Assembly type trolley used for tunnel shield segment support and using method thereof

ActiveCN111794779ASimple structureEasy to make and constructUnderground chambersHydro energy generationSupporting systemJackscrew

The invention discloses an assembly type trolley used for tunnel shield segment support and a using method thereof. The assembly type trolley comprises a movable chassis, a supporting arch frame, a hydraulic support system, a slide rail and a pull frame, wherein an arched frame of the support arch frame is spanned on left and right main beams; a hydraulic lifting jack of the hydraulic supporting system is perpendicular to the outer surface of the arched frame; the bottom of the hydraulic support system is fixedly connected to the arched frame through a mounting base; the top of the hydraulic support system is provided with a rubber gasket which is in contact with a shield segment; the slide rail horizontally penetrates through the bottom of the arch top in a longitudinal direction; a transporting hanger is arranged in a rail with a downward opening of the slide rail; the pull frame is a horizontal framework beam which is fixed to the end part of one side of the movable chassis; and thehorizontal framework beam is connected to pull equipment to drive the trolley to move. The assembly type trolley can freely replace the lifting jack according to different pressure, and enables supporting strength to meet design requirements; and a pull device is connected to the chassis through a cross part, so that a main stress component is prevented from local deformation, and the component can be freely replaced, and therefore, the assembly type trolley is strong in adaptability.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

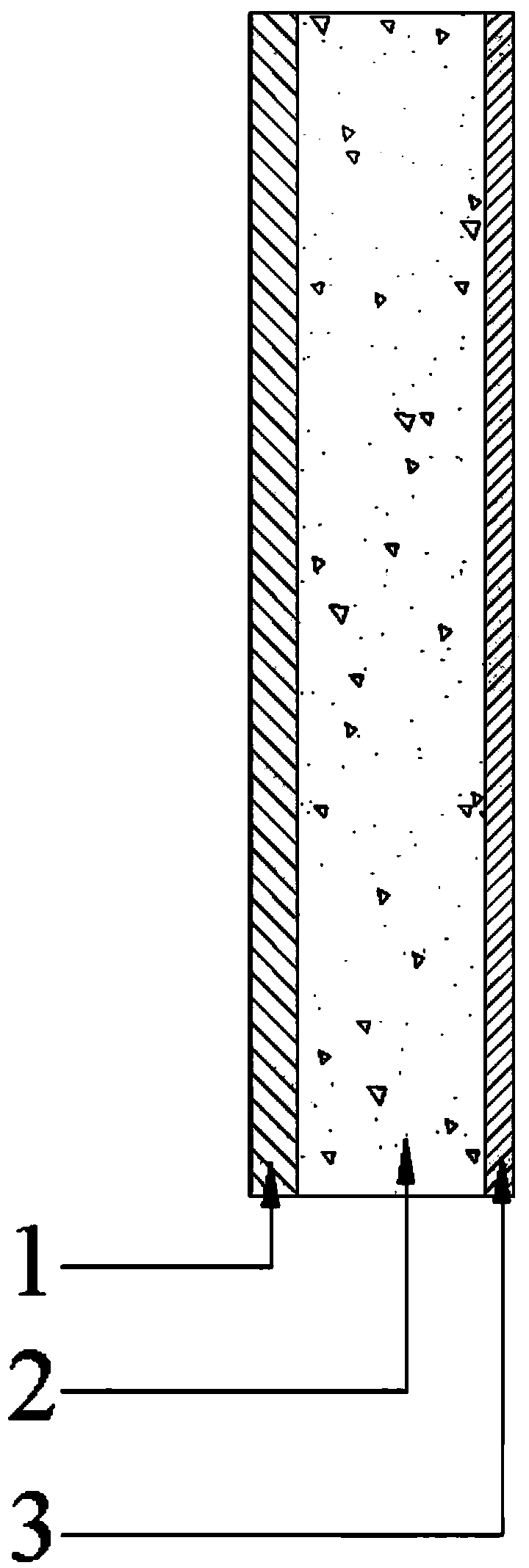

Double-steel-plate reinforced concrete composite beam

The invention discloses a double-steel-plate reinforced concrete composite beam with high strength, low material consumption and convenient machining. The double-steel-plate reinforced concrete composite beam is provided with an upper steel plate and a lower steel plate. Hoop-shaped shear-resistance bars are welded between the upper steel plate and the lower steel plate. The vertical part of the hoop-shaped shear-resistance bars is perpendicular to the upper steel plate and the lower steel plate. The outer edges of the vertical part of the hoop-shaped shear-resistance bars move inwards with adistance being H relative to the connecting lines between the side edges of the upper steel plate and the lower steel plate. The hoop-shaped shear-resistance bars are evenly arranged at intervals in the length direction of the upper steel plate and the lower steel plate. Concrete is arranged between the upper steel plate and the lower steel plate, so that the hoop-shaped shear-resistance bars areburied in the concrete. The double-steel-plate reinforced concrete composite beam can be widely applied to various building structures.

Owner:HANGXIAO STEEL STRUCTURE

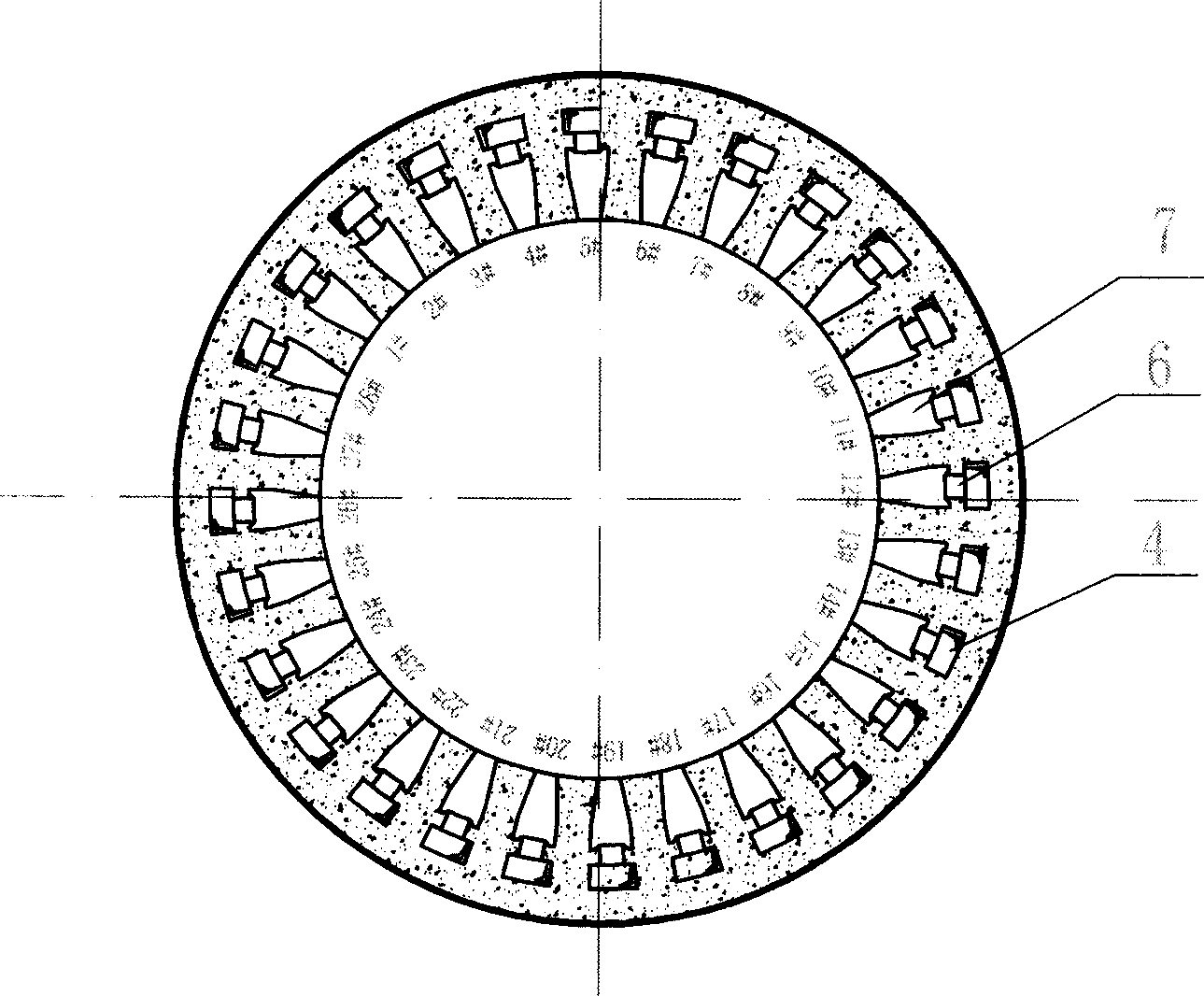

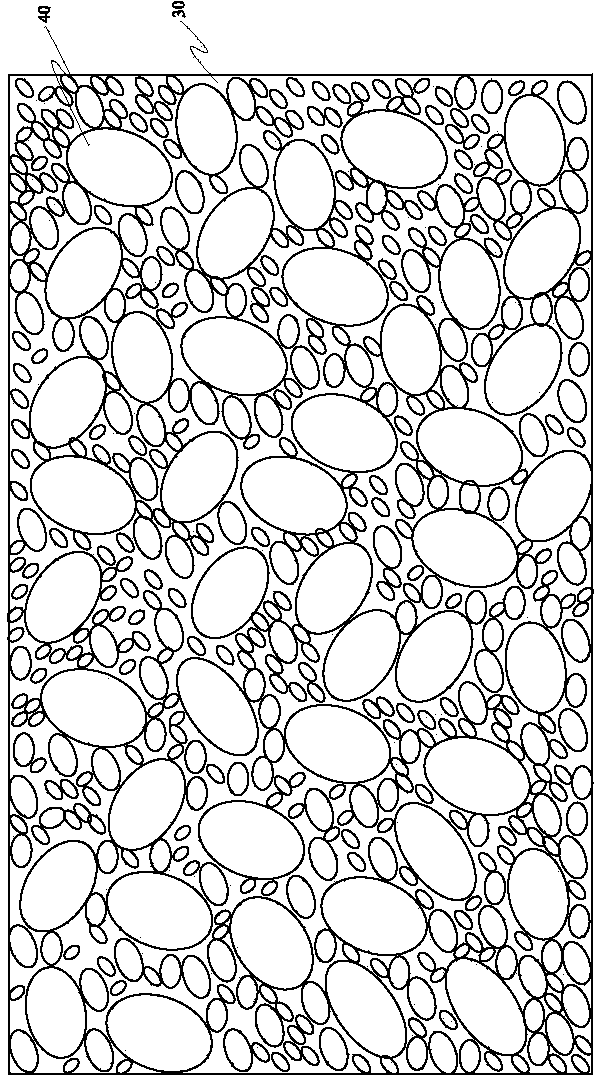

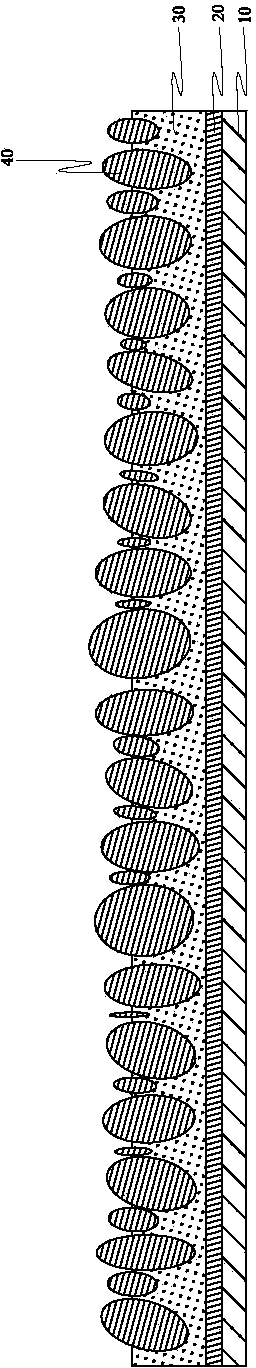

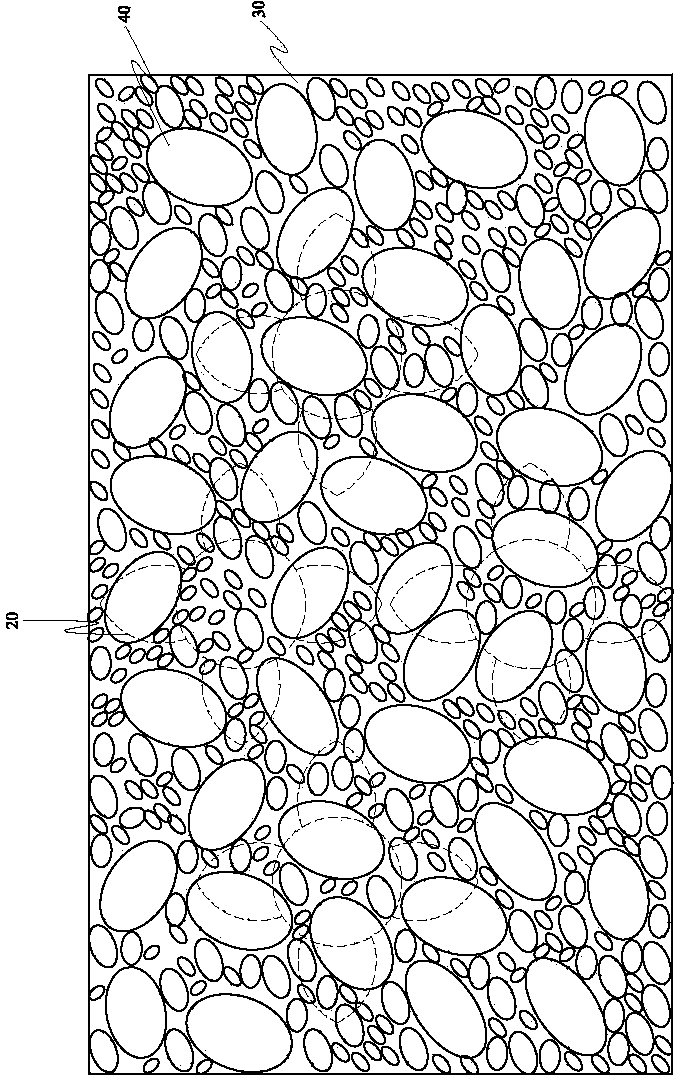

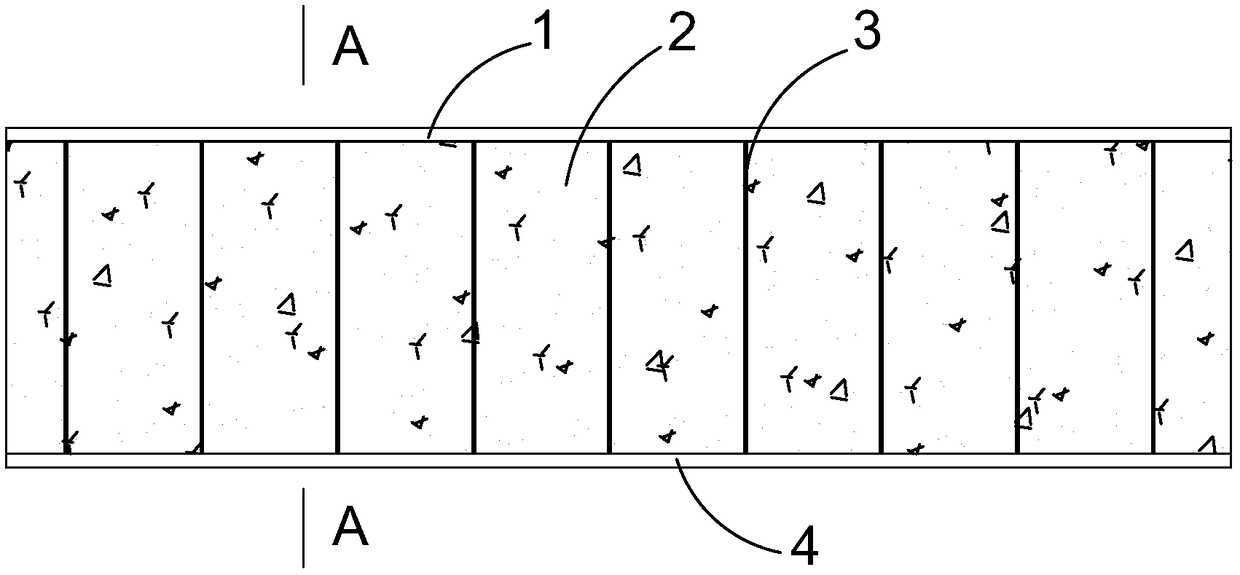

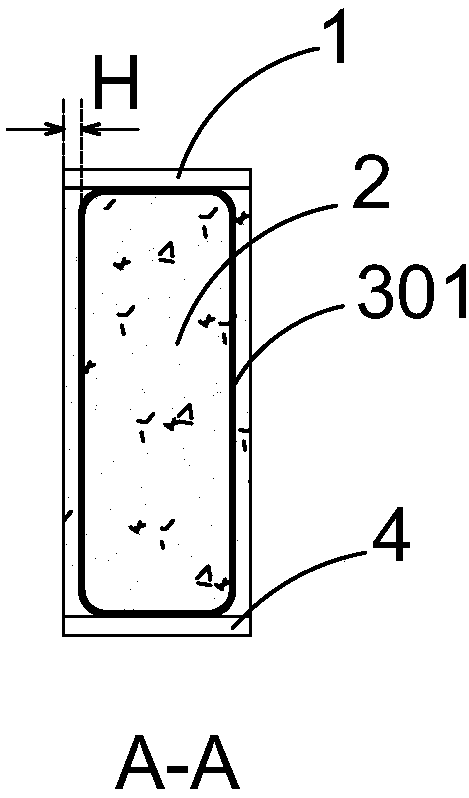

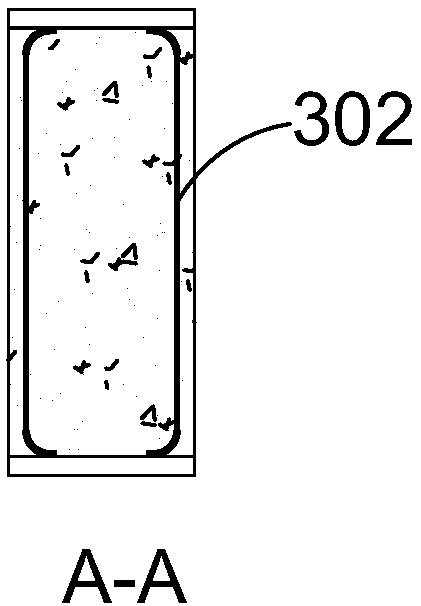

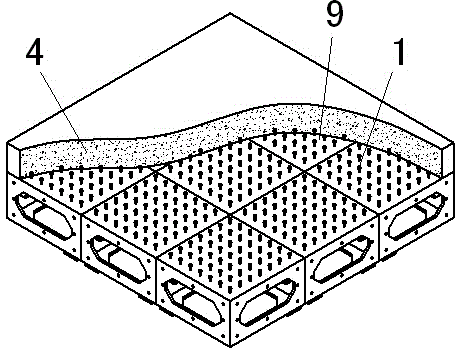

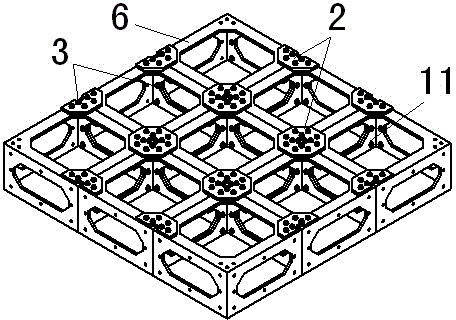

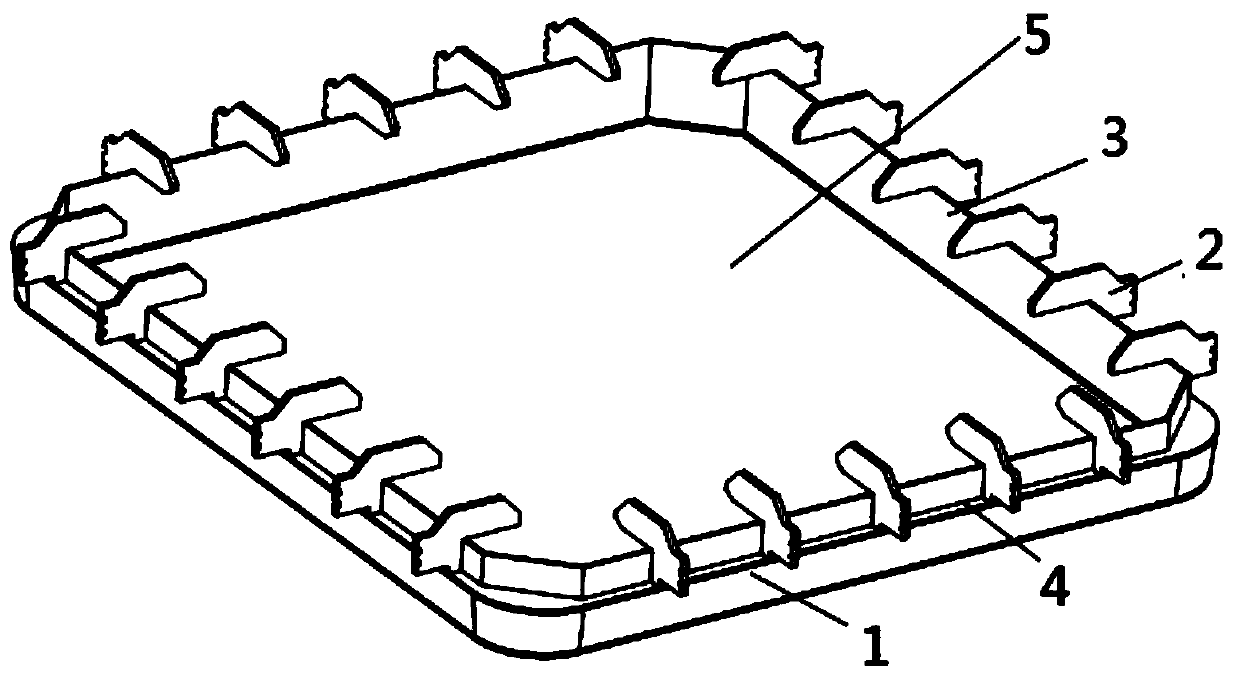

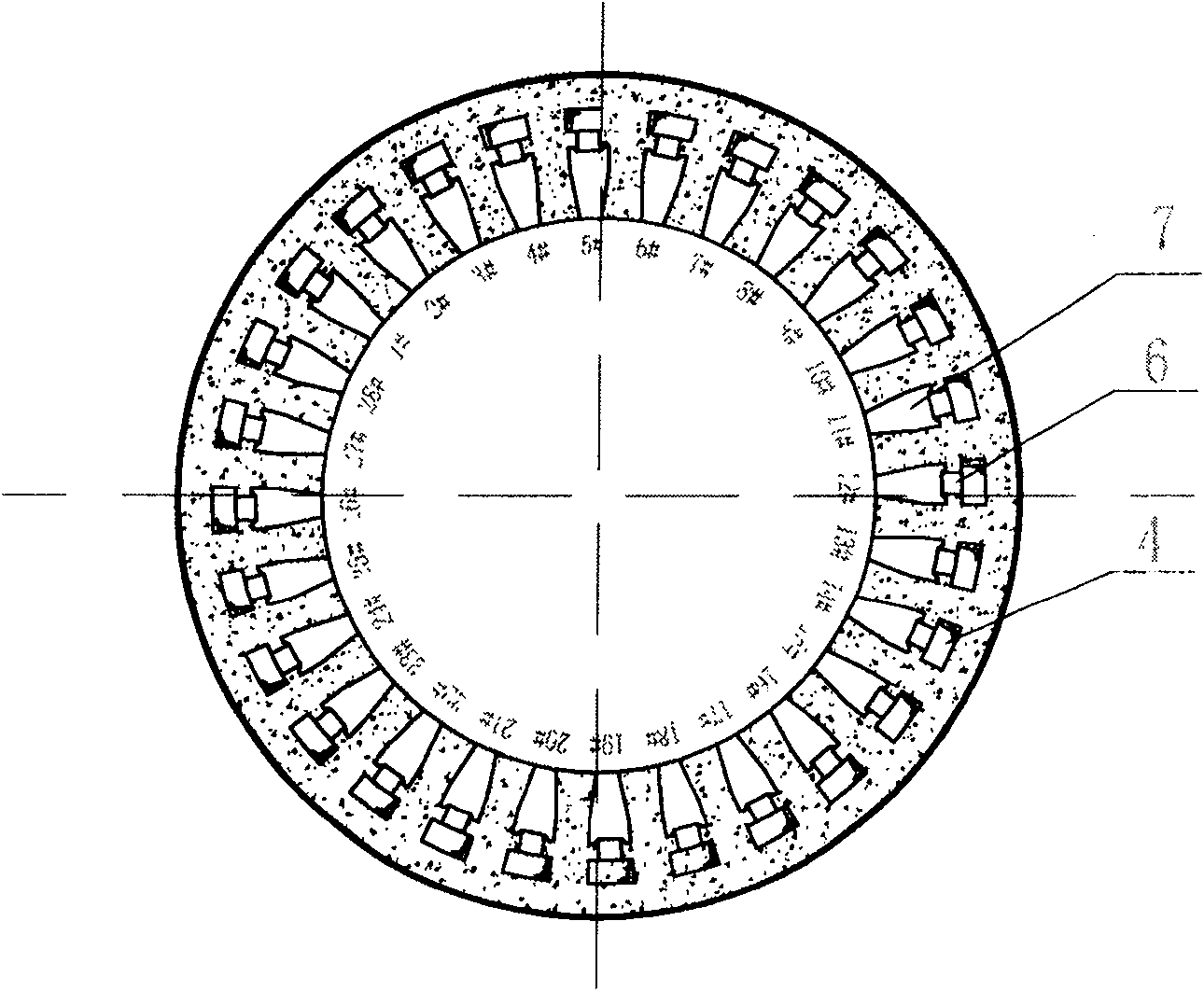

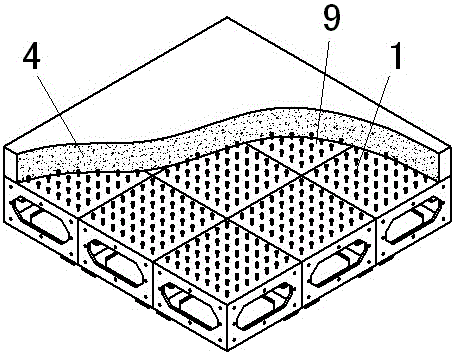

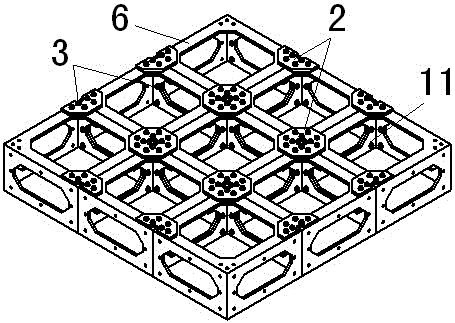

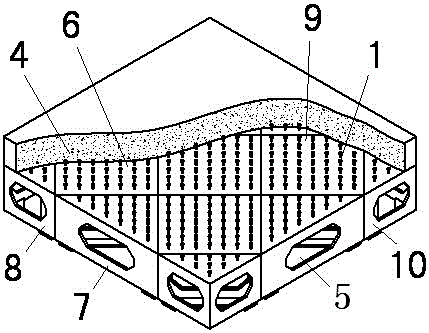

Combined long-span ribbed slab structure

InactiveCN104563354AImprove performanceTake advantage of the tensile strengthFloorsFloor slabEconomic benefits

The invention discloses a combined long-span ribbed slab structure. The ribbed slab is formed by splitting steel form shells of different shapes; the frontages of the steel form shells of the different shapes are uniformly distributed with rivets (1), the sides of the steel form shells of the different shapes are connected through bolts, and the backs of the steel form shells of the different shapes are connected to form a slab plane through connecting plates (2) and bolts (3); a reinforced bar casting concrete layer (4) is paved on the plane of the slab and is closely connected with the plane of the slab to form the combined long-span ribbed slab through the uniformly distributed rivets (1). Compared with the prior art, the combined long-span ribbed slab structure provided by the invention has a few of combined components; furthermore, the combined long-span ribbed slab is processed in batches by a professional factory, good interchangeability and convenience in field splitting can be realized, the field labor capacity can be reduced, the construction period can be reduced significantly and the economic benefit can be improved; an existing wooden form can be substituted by the plane of the slab formed by splitting the steel form shells, therefore, the compressive property can be improved and the cost saving can be realized; in addition, lightening holes are formed in side plates, therefore materials can be saved and dead weight can be reduced.

Owner:GUIZHOU UNIV

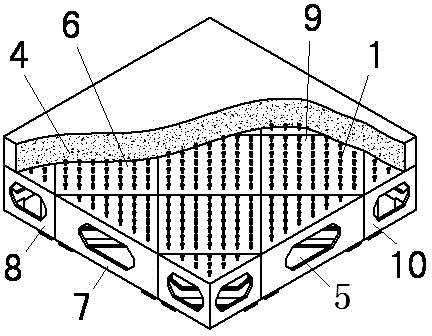

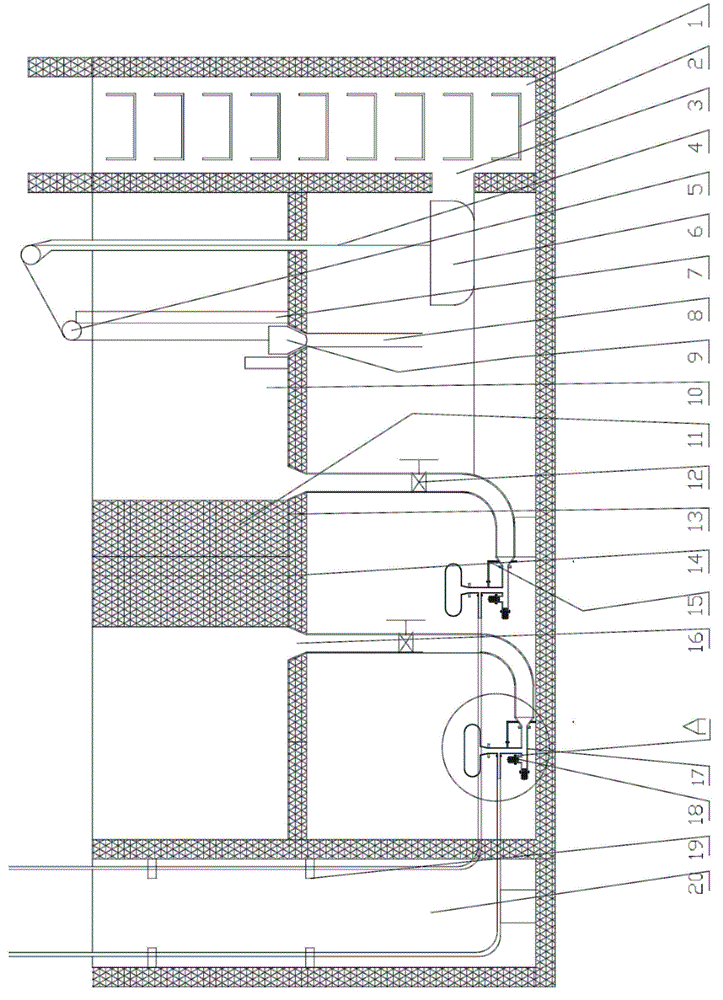

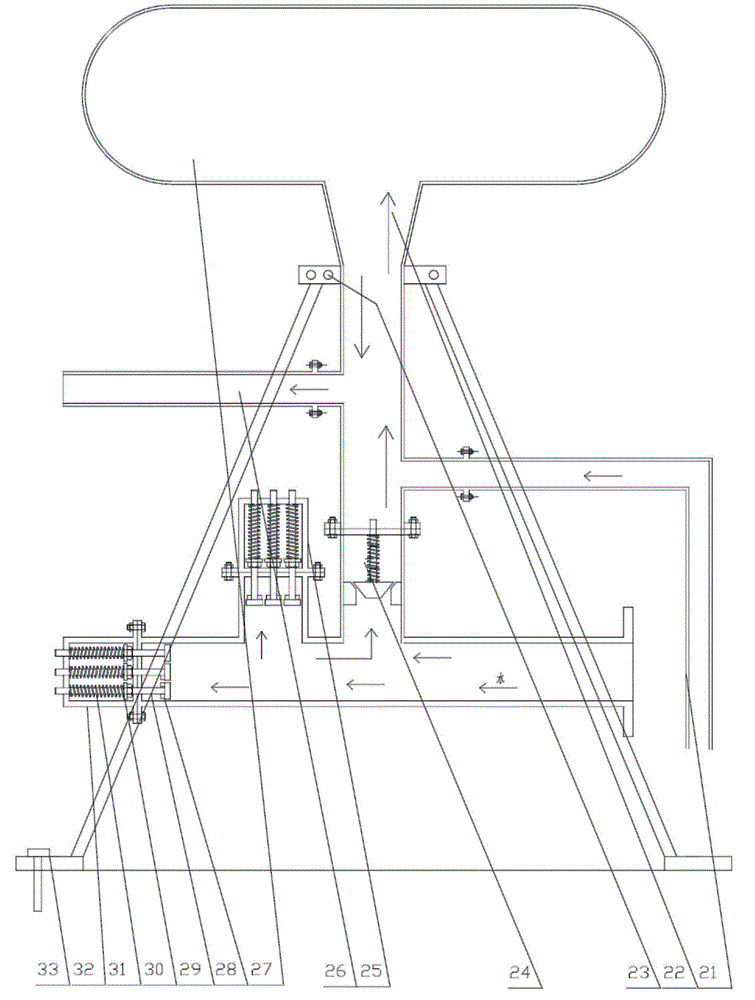

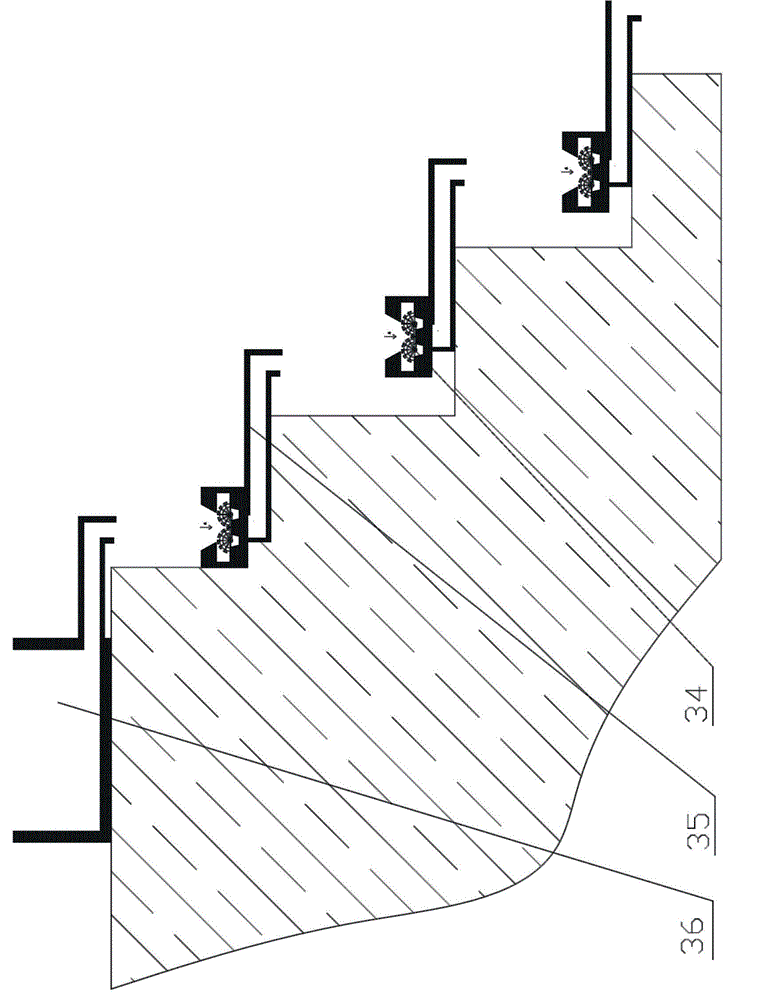

Double-hearth vertical kiln with cooling supporting stand columns

ActiveCN108996927AThe overall structure is simple and reliableSimple and smooth structureStructural engineeringKiln

The invention relates to a double-hearth vertical kiln with cooling supporting stand columns. The double-hearth vertical kiln comprises two kiln hearths which are connected through a connecting channel, wherein an annular channel is arranged in each kiln hearth; an annular channel inner drum is arranged in each annular channel; the bottom part of each kiln hearth is provided with a supporting ringbeam; each supporting ring beam has a hollow structure; the upper part of each supporting ring beam is provided with a cooling supporting stand column; the interior of each cooling supporting stand column is hollow; each cooling supporting stand column is connected with a supporting ring beam and an annular channel inner drum; and the interiors of a supporting ring beam located at the bottom partof each kiln hearth, a cooling supporting stand column and an annular channel inner drum are in mutual communication. The double-hearth vertical kiln with the cooling supporting stand columns provided by the invention has the following advantages: the annular channels of the double-hearth vertical kiln with a circular cross section are simple and reliable in structure; meanwhile, the problems ofcooling of an internal structure and supporting of the weight of inner drums are solved; the annular channels are simple and clear in structure and accumulate little dust; and production inspection, repairing and maintenance are less, so more benefits are created for enterprises.

Owner:WISCODRI WUGANG ENG

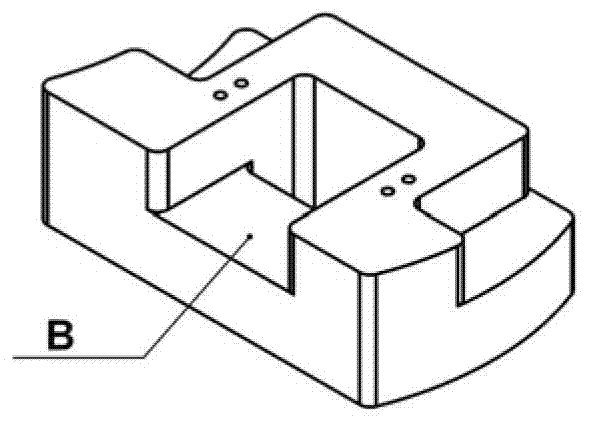

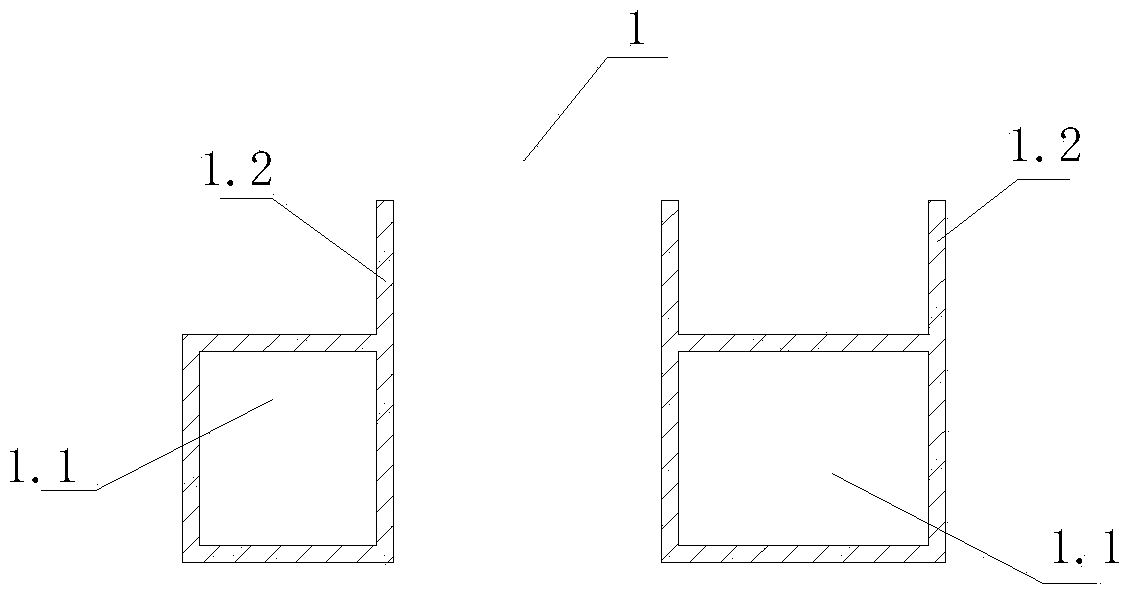

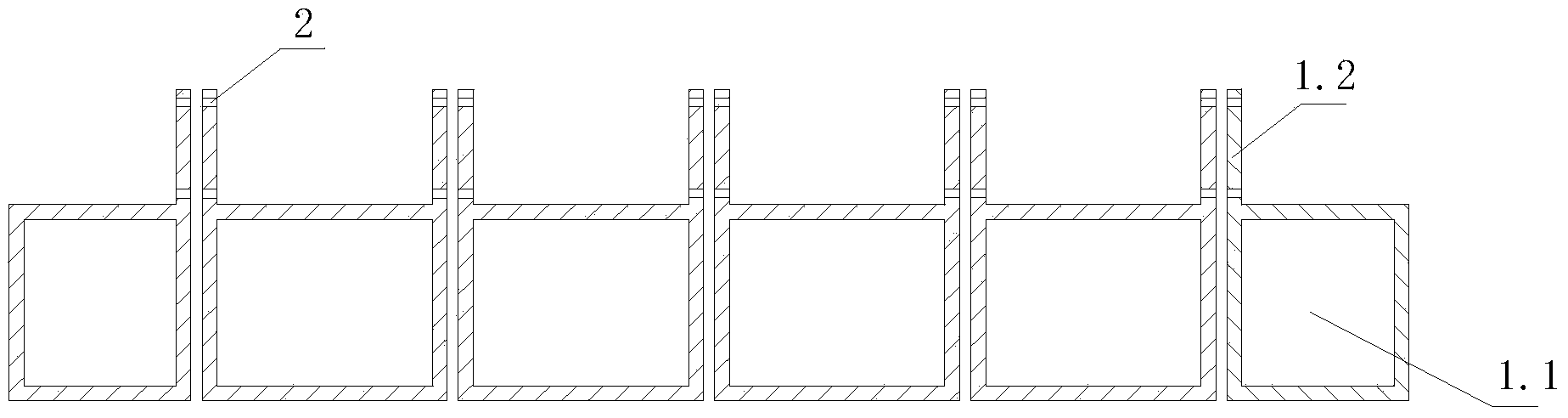

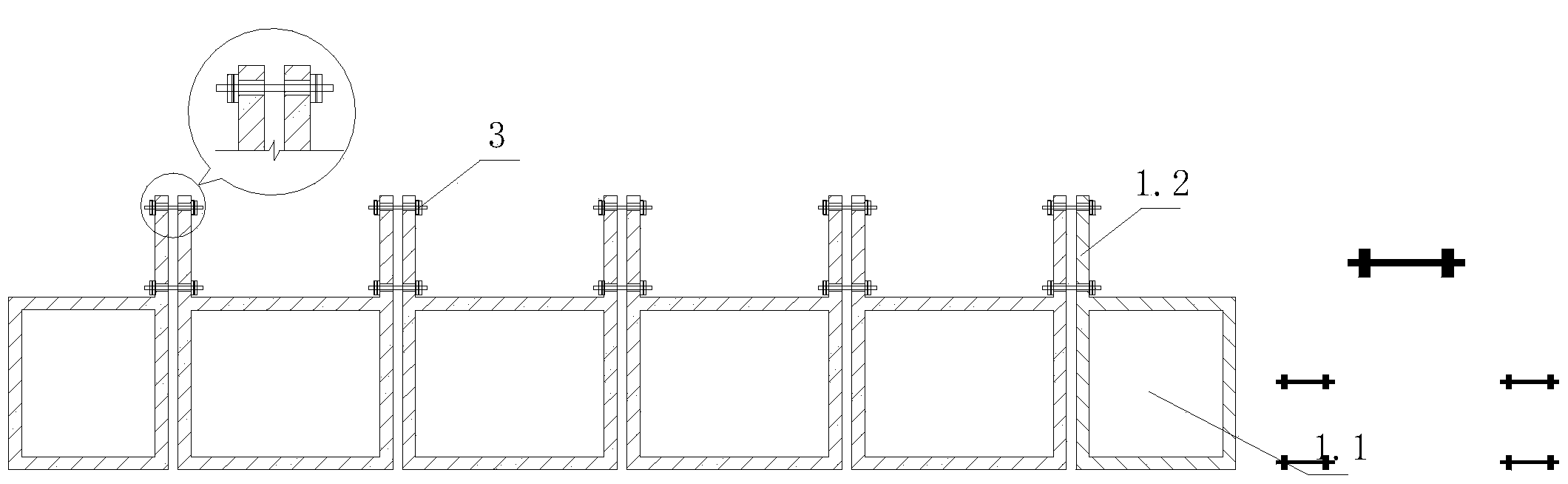

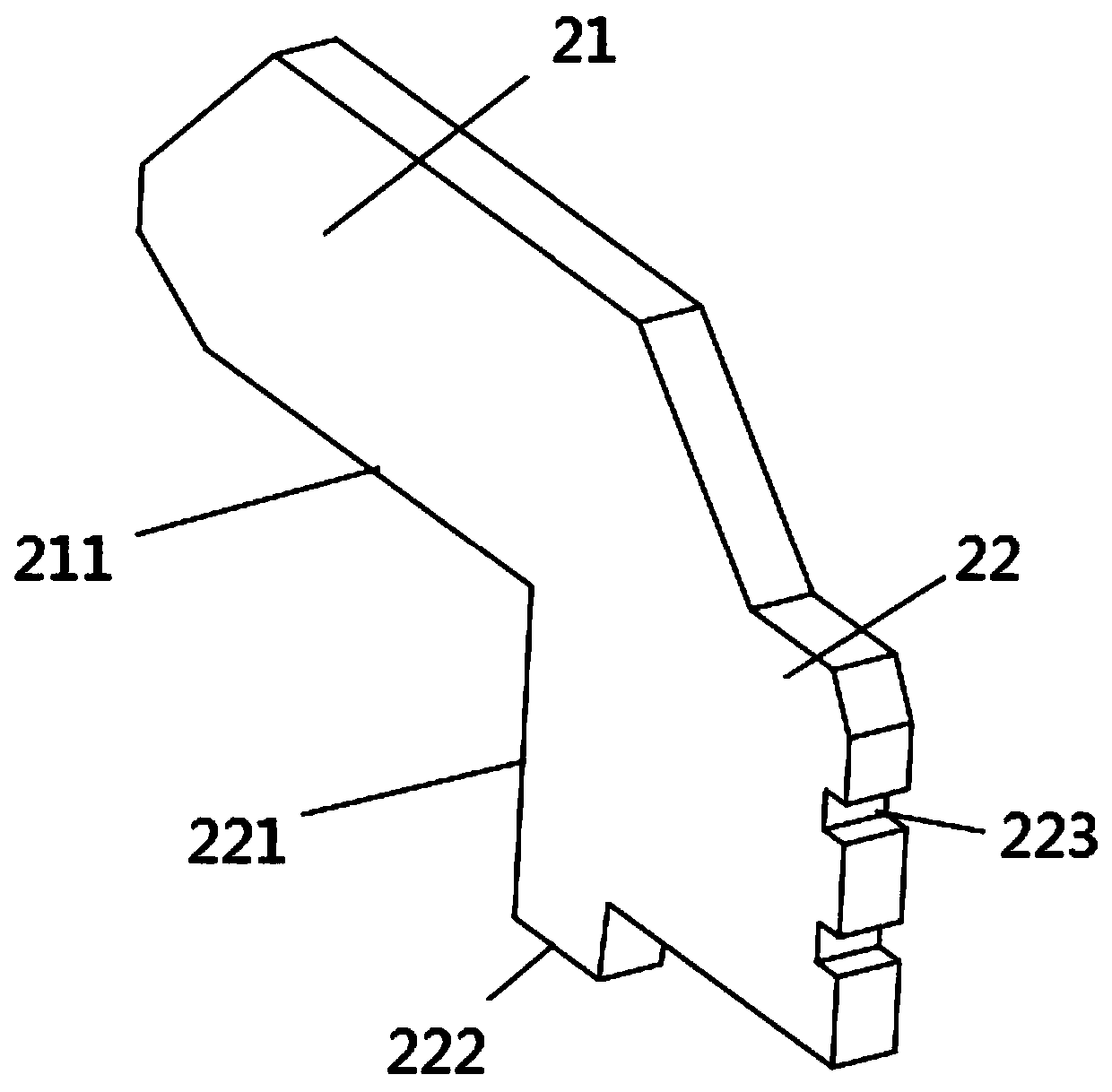

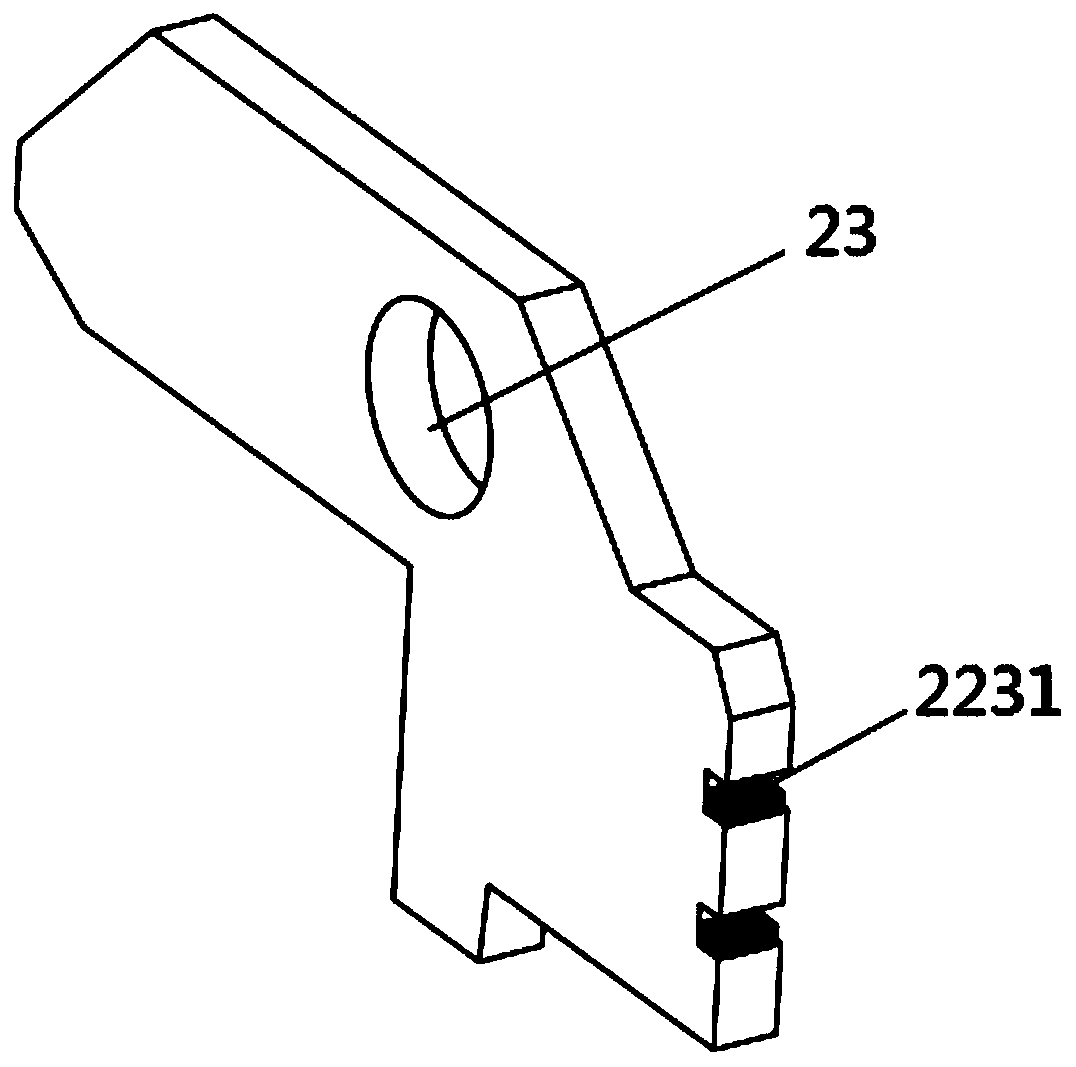

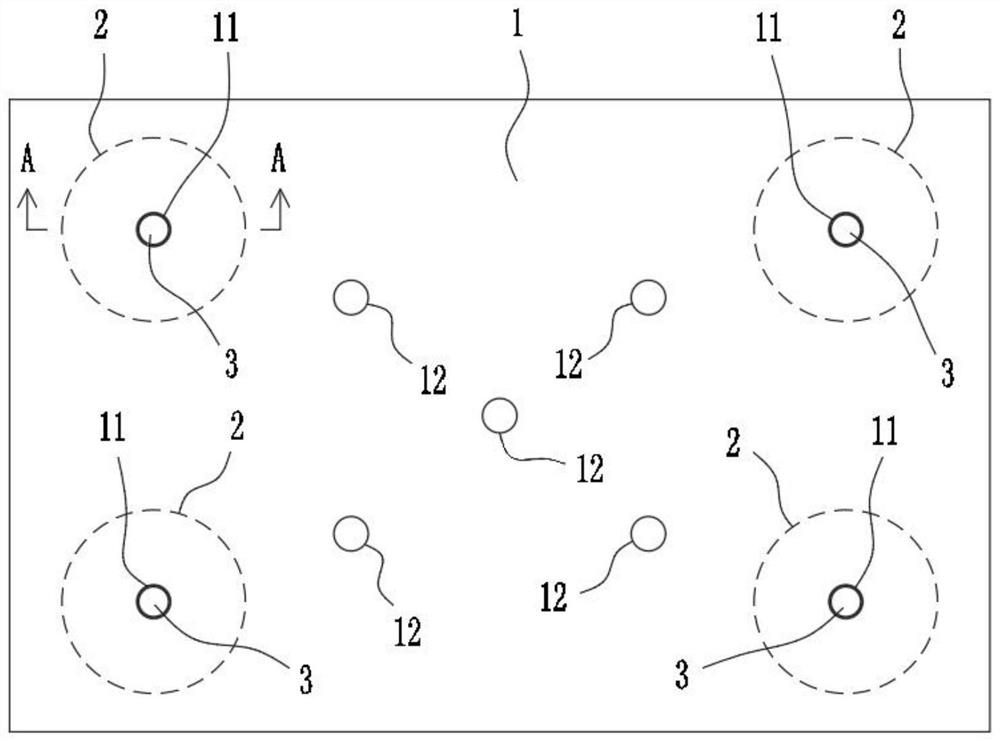

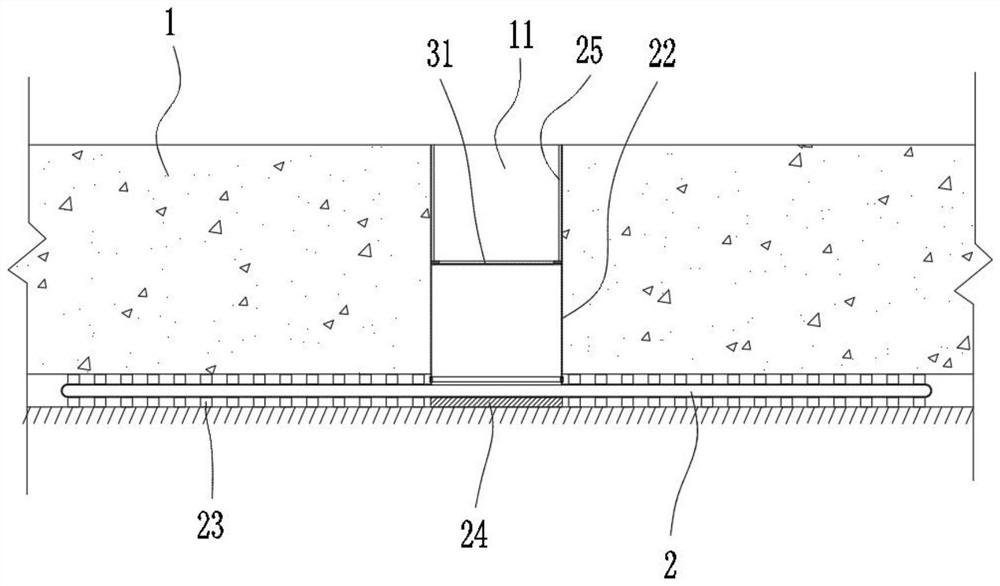

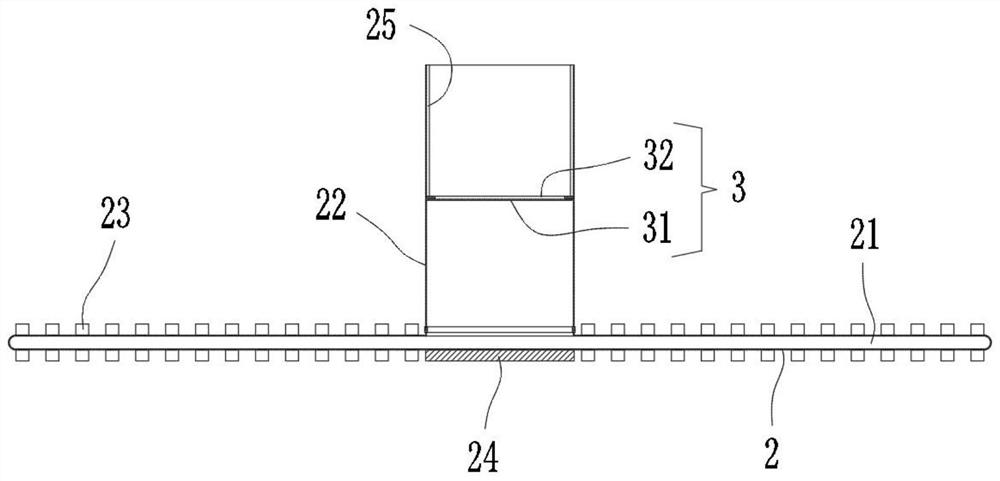

Waterstop section forming member on pipe joint of electric power pipe gallery and method of preparing standard pipe joint

PendingCN110468877AEasy to make and constructConstruction does not affectArtificial islandsProtective foundationEngineeringMechanical engineering

The invention discloses a waterstop section forming member on a pipe joint of an electric power pipe gallery and a method of preparing a standard pipe joint and relates to municipal engineering. The waterstop section forming member on the pipe joint of the electric power pipe gallery comprises a body matched with the forming shape of the waterstop section on the pipe joint and a plurality of waterstop clamping units. The body matched with the forming shape of the waterstop section on the pipe joint defines a cavity, and the waterstop clamping units are arranged on the body matched with the forming shape of the waterstop section on the pipe joint. The waterstop section forming member solves a problem that the waterstops are not tightly connected to the pipe joint, and is regular in shape, good in post-mounting sealing effect and good in waterproofness.

Owner:成都交投建筑工业化有限公司

Polyimide-based self-lubricating abrasion-resistant coating material and preparation method thereof

InactiveCN102286248BImprove carrying capacityImprove high temperature resistancePretreated surfacesCoatingsHigh loadTemperature resistance

The invention discloses a polyimide-based self-lubricating abrasion-resistant coating material and a preparation method thereof. The coating material consists of the following raw materials in part by weight: 100 parts of polyimide bonded resin, 10 to 50 parts of irradiation polytetrafluoroethylene micro-powder solid lubricating agent and 200 to 400 parts of organic solvent. The preparation method comprises the following steps of: weighing and mixing the raw materials, and performing ultrasonic dispersion and magnetic stirring to form uniform resin solution; pouring the resin solution into a spray gun, and spraying the resin solution to the surface of a workpiece subjected to surface polishing and cleaning treatment under the pressure of 0.10 to 0.40Pa and under the action of oil-free compressed air, wherein the distance between the nozzle of the spray gun and the workpiece is not less than 20 centimeters, and the spray gun and the workpiece form an angle of 60 to 90 degrees; and putting the coated workpiece into a muffle furnace, performing section curing, cooling the workpiece to room temperature together with the furnace after curing, and thus obtaining the abrasion-resistant coating material on the surface of the workpiece. The coating material has the properties of low friction, high load resistance, abrasion resistance and high temperature resistance; and the preparationmethod is simple, easy in operation and low in cost.

Owner:SOUTH CHINA UNIV OF TECH

A compact cable-stayed steel anchor beam and its construction method

ActiveCN105297613BReasonable forceExtended service lifeBridge structural detailsBridge erection/assemblySteel barTower

The invention discloses a compact stay cable steel anchor beam and a construction method thereof. The steel anchor beam comprises a steel straining beam mechanism, beam end steel anchoring mechanisms and a stay cable anchor head bearing mechanism, wherein the steel straining beam mechanism, the beam end steel anchoring mechanisms and the stay cable anchor head bearing mechanism are matched to form the novel stay cable steel anchor beam. The construction method comprises the steps of (1), assembling the steel anchor beam; (2), hoisting the steel anchor beam; (3), after the steel anchor beam is hoisted to the position, relieving and removing hoisting equipment and installing the steel anchor beam; (4), binding steel bars of a tower column, installing templates and pouring the tower column. The steel anchor beam is simple and compact in structure, convenient to construct, low in construction cost, high in safety and long in service life. The construction method has the advantages that construction is convenient, the construction cost is low and the construction efficiency is high.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

A kind of assembled trolley for tunnel shield segment support and using method thereof

ActiveCN111794779BSimple structureEasy to make and constructUnderground chambersHydro energy generationSupporting systemTraction frame

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Multiple fire hole flame-free ceramic burner

InactiveCN100578085CNovel structureExtended service lifeBrick-hot blast stovesIndirect carbon-dioxide mitigationBrickCombustor

The multiple fire hole flame-free ceramic burners is used in flameless combustion industrial furnace and kiln, especially hot blast stove for iron making blast furnace. The multiple fire hole flame-free ceramic burner has two outer ring gas channels. After air through the air inlet and gas through the gas inlet enter the air preheating ring channel and the gas ring channel, gas and air are preheated in between two ring channels before jetting to the mixer for mixing and jetting through the combustion nozzle to combust. The gas ring channel has guide bricks for homogeneous distribution of gas. The present invention has unique structure, small size and great power, and is suitable for various kinds of hot blast stove with heat accumulator.

Owner:武汉冶金建筑研究院 +1

Combined bridge deck of arched corrugated steel plates and concrete

InactiveCN102121227BIncreased bending stiffnessImprove adhesionBridge structural detailsBridge materialsSheet steelBridge deck

The invention discloses a combined bridge deck of arched corrugated steel plates and concrete, and the combined bridge deck comprises a bridge deck substrate consisting of a plurality of rows of arched corrugated steel plates arranged in parallel, a bridge deck bottom supporting structure for supporting and fixing the bridge deck substrate, and a concrete top layer formed on the bridge deck substrate in a pouring manner; the bridge deck bottom supporting structure is formed by assembling a plurality of beams which comprise a plurality of rows of lower vertical beams arranged in parallel and aplurality of lines of lower beams arranged in parallel; each row of arched corrugated steel plates are all fastened between two rows of lower vertical beams; arch springings on the left and right of the corrugated steel plates are fixedly arranged on the two adjacent rows of lower vertical beams respectively; the corrugation of each corrugated steel plate is in the transverse direction; and the rows of lower vertical beams and the rows of corrugated steel plates form a formed bottom template for pouring the formed concrete top layer. The combined bridge deck of arched corrugated steel plates and concrete is simple in structure, convenient to manufacture and construct and good in structural mechanical property, and can be used for effectively solving the problems existing in the existing bridge deck structure.

Owner:CHANGAN UNIV +1

A combined long-span dense-ribbed floor structure

InactiveCN104563354BImprove performanceTake advantage of the tensile strengthFloorsFloor slabEconomic benefits

The invention discloses a combined long-span ribbed slab structure. The ribbed slab is formed by splitting steel form shells of different shapes; the frontages of the steel form shells of the different shapes are uniformly distributed with rivets (1), the sides of the steel form shells of the different shapes are connected through bolts, and the backs of the steel form shells of the different shapes are connected to form a slab plane through connecting plates (2) and bolts (3); a reinforced bar casting concrete layer (4) is paved on the plane of the slab and is closely connected with the plane of the slab to form the combined long-span ribbed slab through the uniformly distributed rivets (1). Compared with the prior art, the combined long-span ribbed slab structure provided by the invention has a few of combined components; furthermore, the combined long-span ribbed slab is processed in batches by a professional factory, good interchangeability and convenience in field splitting can be realized, the field labor capacity can be reduced, the construction period can be reduced significantly and the economic benefit can be improved; an existing wooden form can be substituted by the plane of the slab formed by splitting the steel form shells, therefore, the compressive property can be improved and the cost saving can be realized; in addition, lightening holes are formed in side plates, therefore materials can be saved and dead weight can be reduced.

Owner:GUIZHOU UNIV

Building block and wall structure formed by same

InactiveCN102966073BSimple structureEasy to make and constructArtificial islandsCoastlines protectionArchitectural engineeringStructural engineering

The invention discloses a building block. The building block is a hexahedron comprising a front face, a back face, a top face, a bottom face, a left face and a right face. A through-hole is formed at the middle of the building block and penetrates from the top face to the bottom face. A back notch extends from a side edge of the top face towards the back face, a front notch extends forward from the middle part of the top face, the front notch communicates with the through-hole, and the back notch is isolated from the through-hole. In a wall, a plurality of building blocks are stacked continuously in a staggered manner. When one building block is stacked with another beneath building block to form the wall, the through-hole of the building block is communicated with the back notch of the beneath building block, and the front notch and the through-hole of the building block are communicated with the back notch of the beneath building block to form a water seepage passage. The invention also discloses a wall structure formed by the building block. The building block and the wall structure have the advantages of simplified structure, convenience in manufacture and construction, and improved ecological property.

Owner:谢理波

Leveling device for prefabricated concrete pavement slab and leveling method thereof

PendingCN113550212APrevent leakageEasy to operateSingle unit pavingsRoads maintainenceArchitectural engineeringGrout

The invention discloses a leveling device for a prefabricated concrete pavement slab and a leveling method of the leveling device. The leveling device comprises the prefabricated concrete pavement slab and a plurality of rubber bags with grouting cavities, wherein the rubber bags are pre-buried at the bottom of the prefabricated concrete pavement slab; a grouting pipe communicated with the grouting cavity is arranged at the top of each rubber bag, a grout leakage prevention structure is arranged in each grouting pipe and comprises a sealing elastic piece and an annular check ring located above the sealing elastic piece, an edge of one side of each sealing elastic piece is fixedly connected with an inner wall of the corresponding grouting pipe, and an edge of the other side of each sealing elastic piece abuts against a lower surface of the corresponding annular check ring; leveling grouting holes fixedly connected with the grouting pipes and at least one filling grouting hole are formed in the prefabricated concrete pavement slab in a penetrating mode. The whole leveling process is convenient to operate, the structure is simple, and preparation and construction are easy.

Owner:SOUTH CHINA AGRI UNIV +1

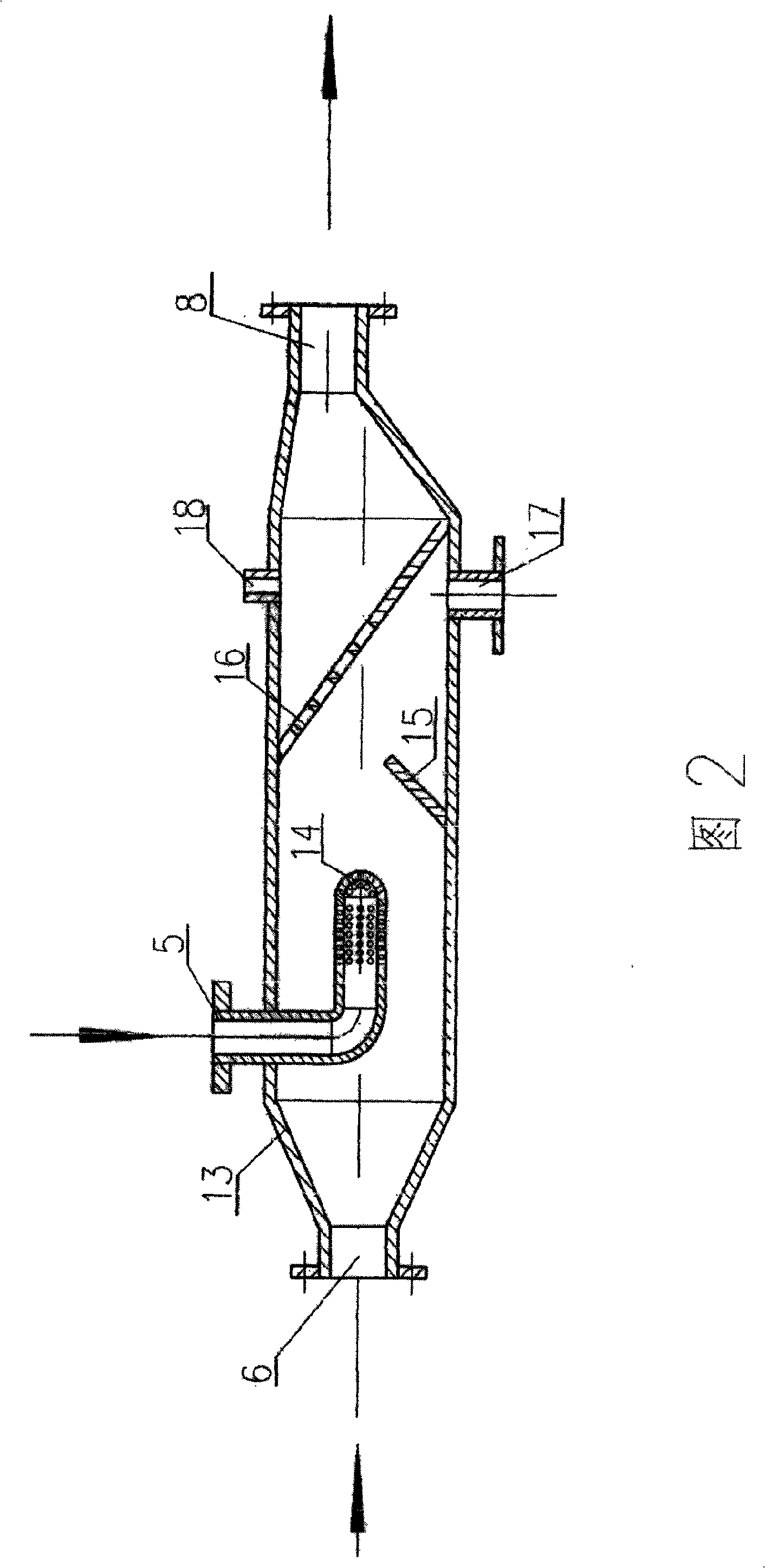

Compound material smoke exhaust and desulfurizing tower and fabricating method thereof

InactiveCN101224386AEasy to make and constructImprove product qualityDispersed particle separationFiberFlue gas

The invention provides a compound material smoke-venting desulfurizing tower and a manufacturing method thereof. The compound material smoke-venting desulfurizing tower comprises a tower body, a top flue-gas connecting pipe arranged at the center or the eccentric part of the upper part of the tower body or on the edge part of the tower body neighboring the top part, a top cover which is arranged at the lower part of the top flue-gas connecting pipe and is connected with the tower body, a absorbing-liquid distributor arranged under the top cover in the tower body, a middle flue-gas connecting pipe arranged on the lower part of the absorbing-liquid distributor and a soleplate. The tower body, the top cover and the soleplate are all made of compound materials, including inorganic fiber, organic resin and resin solidifying assistant agent, and the weight shares of the compound materials are as the following: 10 to 80 parts of inorganic fiber, 20 to 90 parts of organic resin, and the proportion between the organic resin and the resin solidifying assistant agent is 0.01 to 0.1. The compound material smoke-venting desulfurizing tower of the invention adopts the macromolecule compound material with comparative low price, and the manufacturing and construction are convenient, the quality is reliable, and the service life is long. The invention is easy for industrial implementation.

Owner:娄爱娟

Design and manufacturing method of a rail vehicle electrical wiring harness

ActiveCN104951586BReduced wiring workReduce occupancySpecial data processing applicationsModularityElectric vehicle

Owner:CRRC QINGDAO SIFANG CO LTD

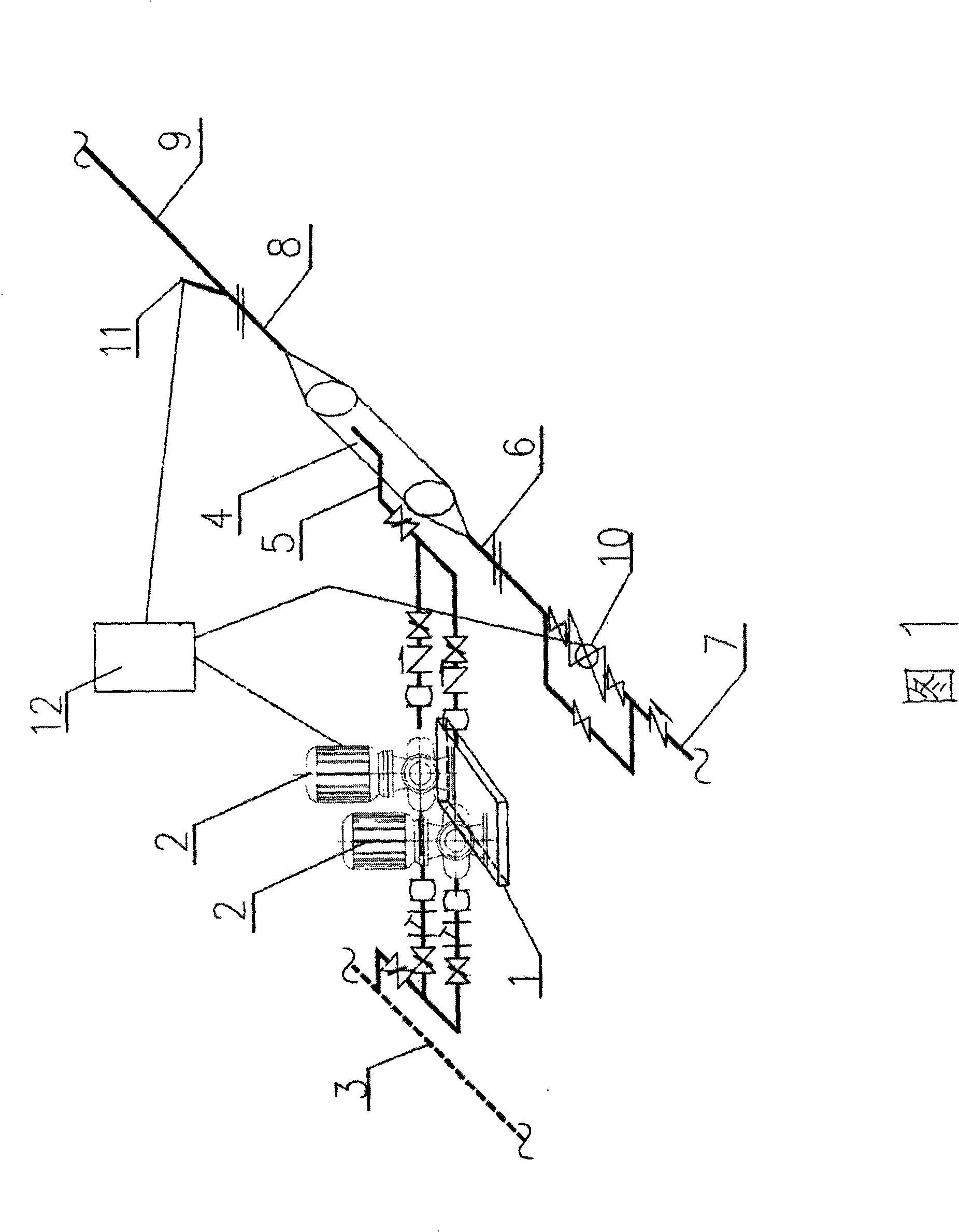

Trapezoidal power station for automatically rising still water and recycling water

InactiveCN104060588ASolve the installationPrevent inaccessibleWater-power plantsConventional hydroenergy generationWater storage tankHorizontal axis

The invention discloses a trapezoidal power station for automatically rising still water and recycling water, relates to the field of power generation, and solves the problem of high cost. Water in a water reservoir or a river automatically flows into an upper water storage tank; the bottom of the upper water storage tank is connected with a direct-through pipe; the top end of the direct-through pipe is connected with a water plug and a nylon rope in a sleeving way; the other end of the nylon rope is fixedly connected with a buoy; the bottom of the upper water storage tank is connected with a water inlet pipeline; the other end of the water inlet pipeline is connected with a pressure pump; the maximum pressure is quickly generated for collision by utilizing the inertia of drop water flow in the upper water storage tank so as to achieve multiple water hammer effects to automatically extrude and rise the water with extremely high pressure to the lift height; two large row wheels and a center shaft are connected with a plurality of blades; the two ends of the center shaft are connected with bevel gears and then are meshed with horizontal axis bevel gears; the large row wheels rotate synchronously. Water flows down to the middle part of each layer of each trapezoidal large row wheel in sequence through a bell-mouthed funnel; the center shaft rotates to drive a multi-layer power generator group to generate power; the problem of energy crisis is solved effectively. The trapezoidal power station for automatically rising the still water and recycling the water is simple and practical in structure, and long in service life.

Owner:贺绍瑜

Geothermal energy direct connecting unit heater

InactiveCN101315203AReach heat medium parametersLess investmentLighting and heating apparatusSpace heating and ventilation detailsGeothermal heatingEngineering

The invention relates to a geothermal direct-connect heat supply unit. A water pump is arranged on a pedestal. A water inlet pipe is arranged in front of the water pump and connected with a low-temperature heating backwater main pipe of a pipe network. A water outlet pipe is arranged in the back of the water pump and connected with a lateral water-mixing elbow pipe of a water mixer. A main water inlet pipe of the water mixer is connected with a high-temperature heating water supply main pipe of the pipe network. A water outlet pipe of the water mixer is connected with a geothermal heating water supply main pipe. A temperature controller is arranged on the main water inlet pipe of the water mixer. A temperature sensor is arranged on the water outlet pipe of the water mixer. The signal input end of a frequency-variable control cabinet is connected with the temperature sensor. The output end of the frequency-variable control cabinet is connected with the control ends of the water pump and the temperature controller respectively. The geothermal direct-connection heat supply unit has the advantages of low cost, easy construction, small size, low running costs, environmental friendliness, easy management, high safety and reliability, convenient maintenance and easy promotion, and can prepare the hot water required for geothermal heating.

Owner:徐立华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com