Manufacturing method for ribbed FRP members

A manufacturing method and component technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of high production cost and high production cost of FRP components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

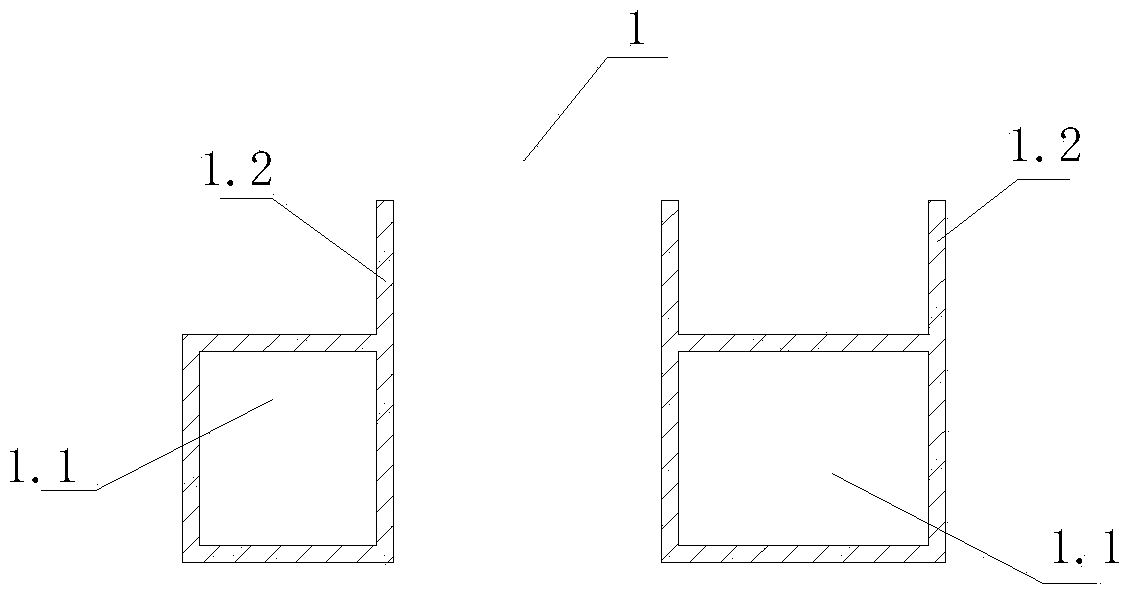

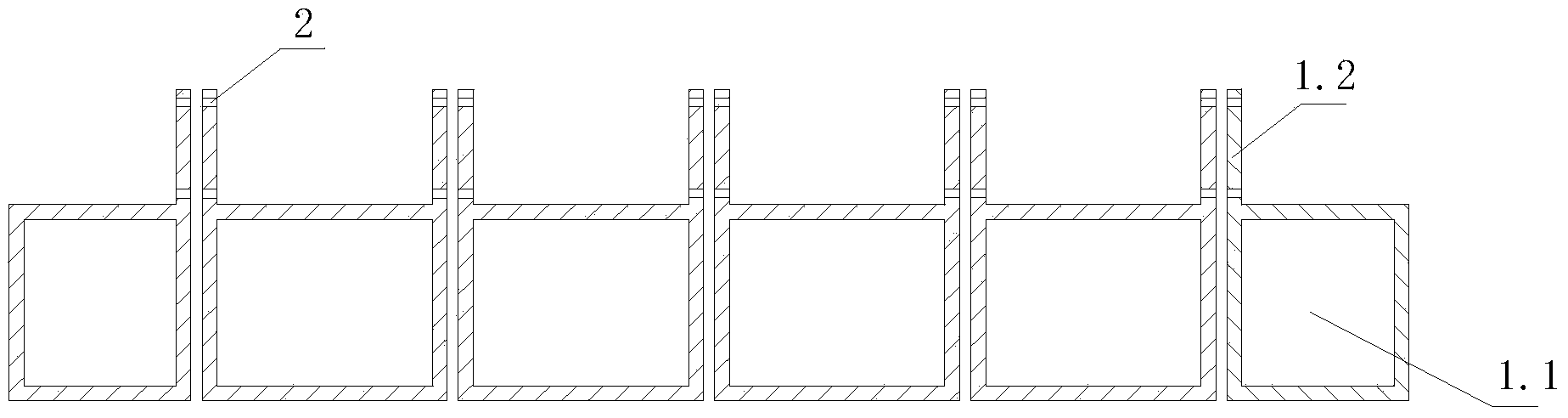

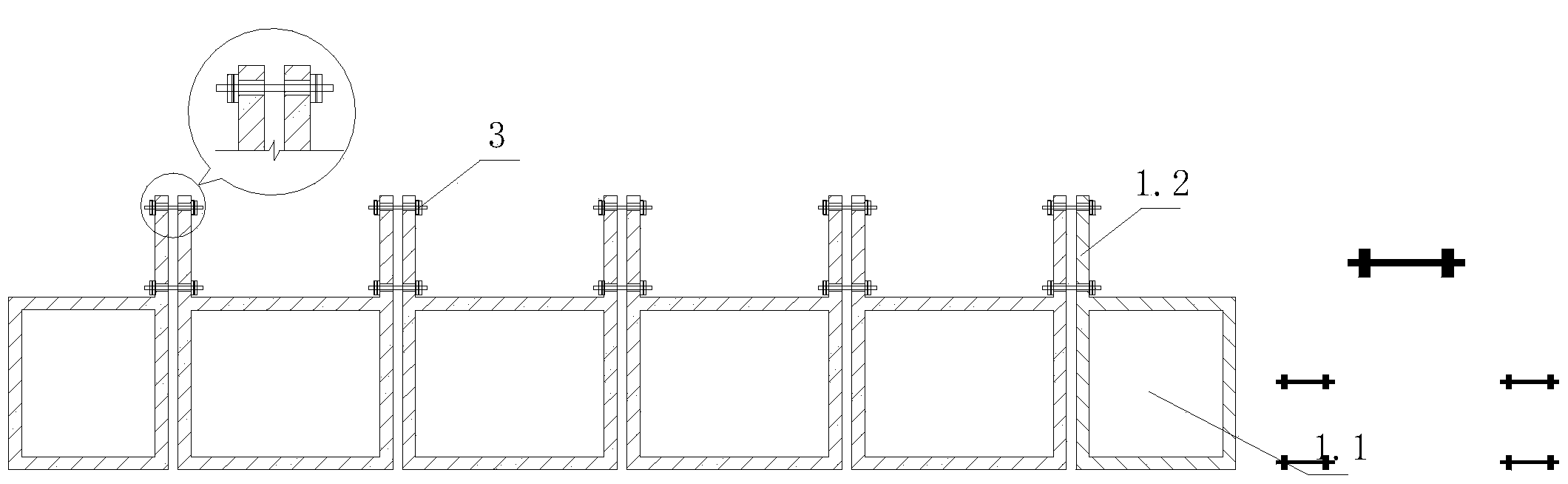

[0028] The invention is attached Figure 1-41 shown.

[0029] The manufacturing method of this ribbed FRP component comprises the following steps: the first step is to make the FRP basic block, and its structural form is as follows: figure 1 , Figure 6-29 , Figures 31 to 32 , Figures 34 to 38 shown. The FRP basic block 1 is divided into two parts: the lower FRP basic bottom plate 1.1 and the upper FRP basic longitudinal rib 1.2, at least one of the FRP basic bottom plate 1.1 and the FRP basic longitudinal rib 1.2 adopts a hollow section form. Figure 1-28 It is a structural schematic diagram of the FRP basic block 1 composed of the FRP basic bottom plate 1.1 in the form of a hollow section and the basic longitudinal plate rib 1.2 of the FRP in the form of a solid section; Figures 29 to 31 It is a structural schematic diagram of an FRP basic block 1 composed of an FRP basic base plate 1.1 in the form of a solid section and a basic FRP longitudinal plate rib 1.2 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com