A compact cable-stayed steel anchor beam and its construction method

A technology of cable-stayed steel and cable-stayed anchors, which is applied in bridges, bridge parts, bridge construction, etc., and can solve the problems of difficulty in utilizing the advantages of shear connectors, many processes such as hoisting, positioning and locking, and unreasonable vertical force and other issues, to achieve the effect of cost reusability, high construction efficiency and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

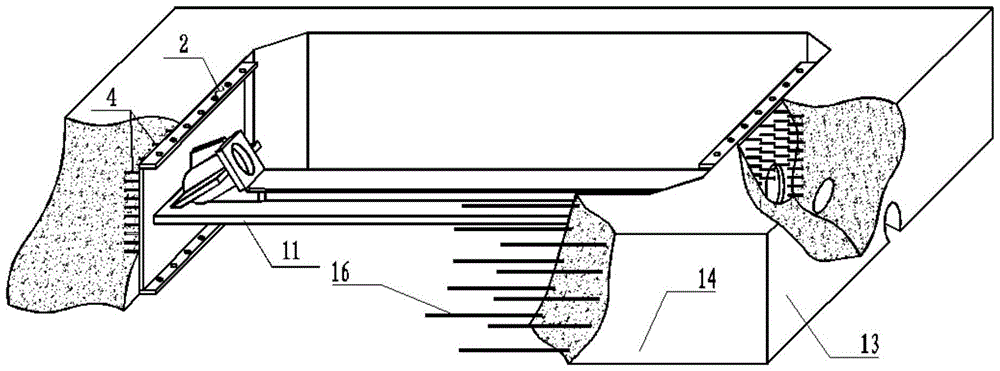

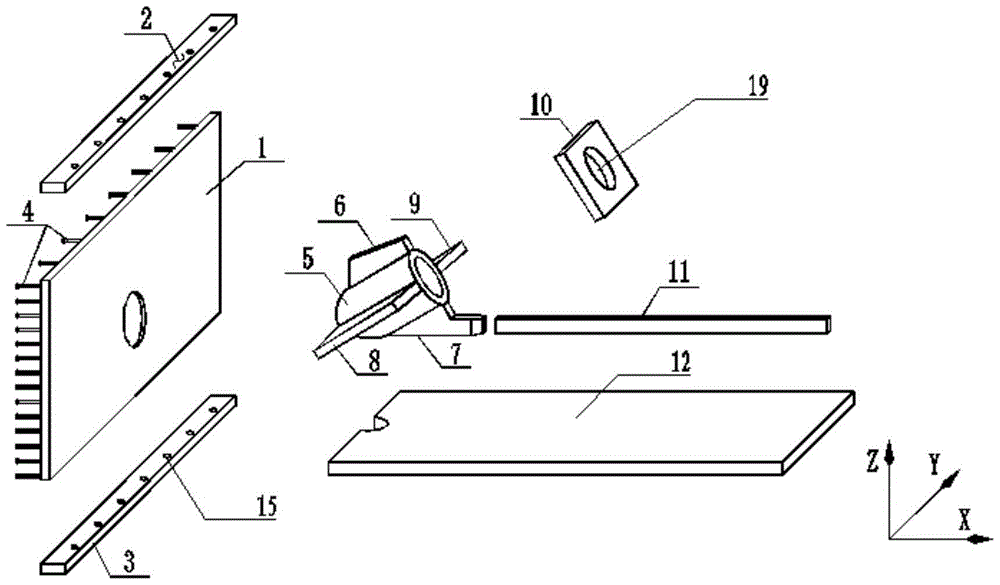

Embodiment 1

[0037] A construction method of a compact cable-stayed steel anchor beam, the steps of which are:

[0038] 1) according to the structure assembly compact stay cable steel anchor beam of above-mentioned compact stay cable steel anchor beam;

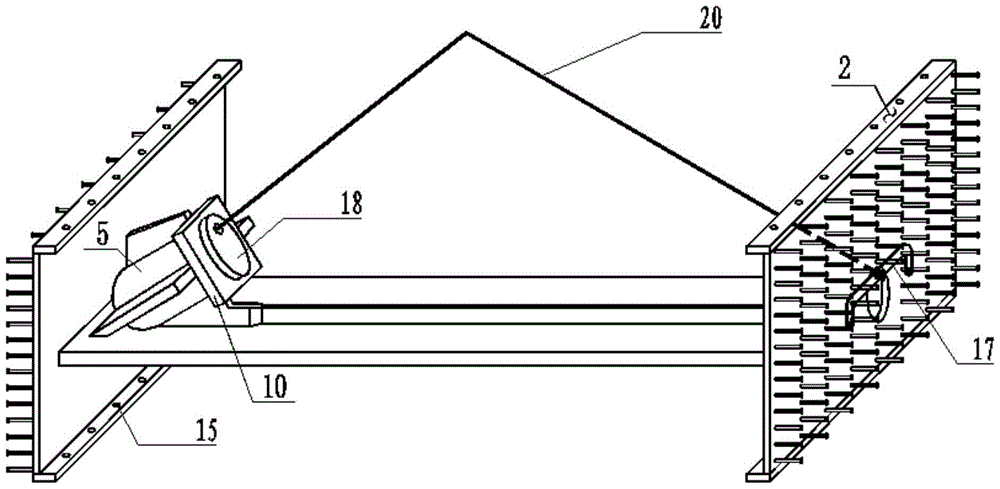

[0039] 2) if image 3 As shown, two U-shaped steel rods 17 are taken, and the two U-shaped steel rods 17 are symmetrically fixed on the outside of the installation holes of the two steel anchor plates, so that the horizontal part of the middle part of the U-shaped steel rods 17 is parallel to the ground, and each U-shaped steel rod 17 passes through the Installed by clamping on two shear connectors;

[0040] 3) Take the soft rope 20 and two wooden plugs 18 with holes, first pass the two wooden plugs through the through holes 19 of the two pressure bearing plates and insert them into the two supporting steel pipes, and then pass the two ends of the soft rope respectively Two wooden stoppers, and then the two ends of the soft rope are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com