Wall material and production method thereof

A manufacturing method and wall material technology, applied in the field of architectural or decorative wall materials, can solve the problems of poor flexibility, weak flame retardancy, and unsightly appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

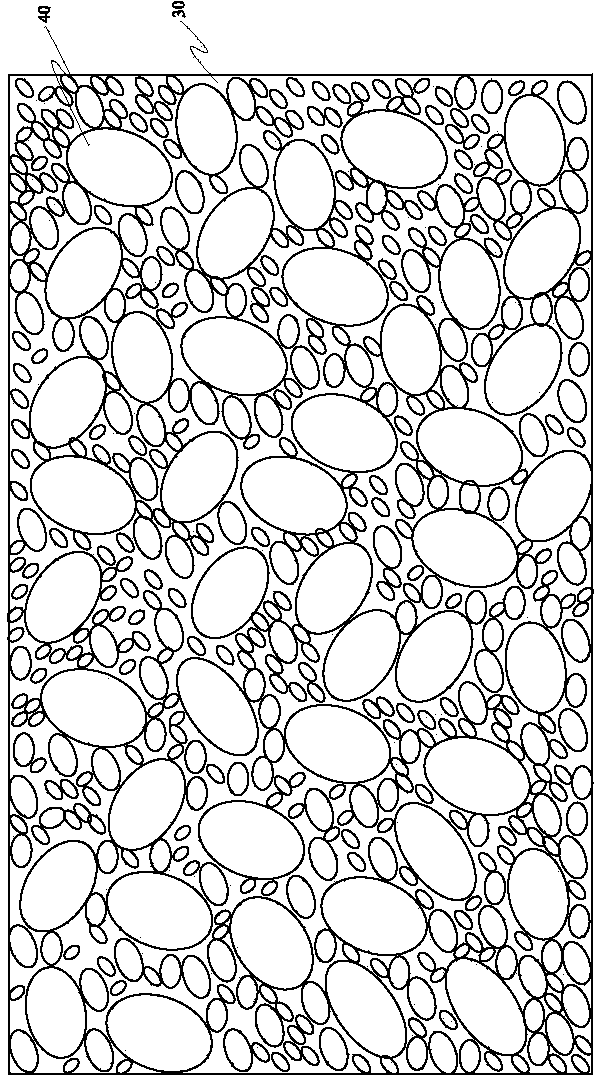

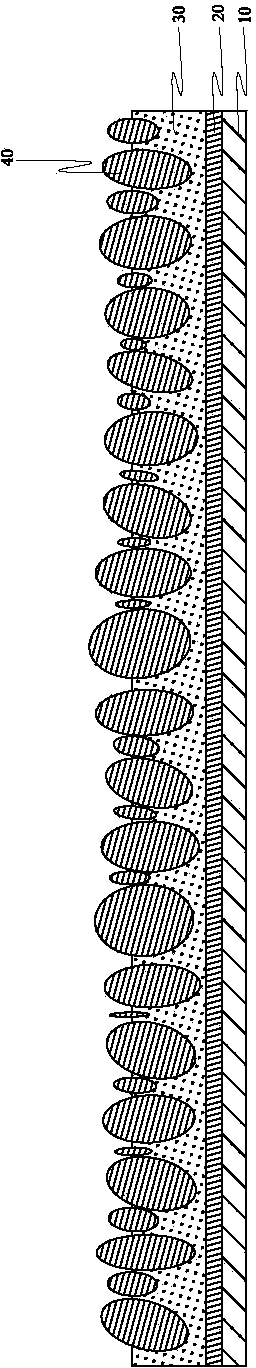

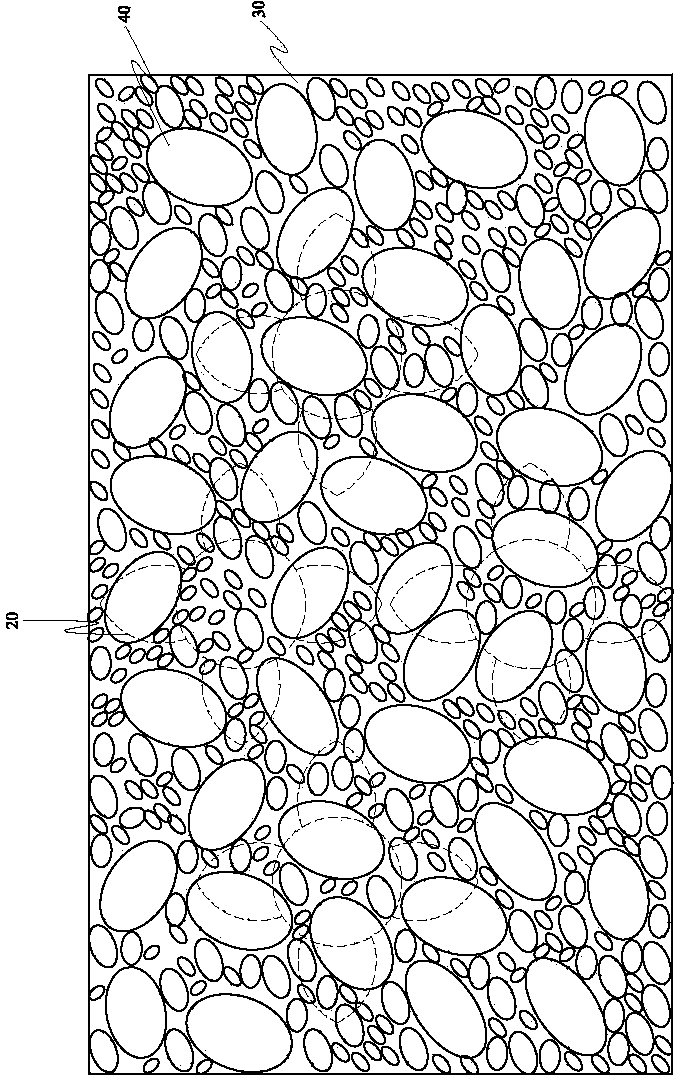

[0044] Please refer to figure 1 and figure 2 As shown, it has shown the specific structure of the first preferred embodiment of the present invention, the overall structure of the wall material is flexible, and it includes a base layer 10, a pattern layer 20, a transparent layer stacked sequentially from bottom to top. Resin bonding layer 30 and stone particle layer 40 .

[0045]The base layer 10 is a flexible thin sheet material, which contains 20% to 30% by weight of a non-halogen flame retardant, so that the base layer 10 can be folded 180 degrees under the premise of strong flame retardancy, and the flexibility and even if the base layer 10 reaches a preset temperature and burns, it will not produce dense smoke, will not release toxic gases, and is beneficial to environmental protection. In this embodiment, the base layer 10 is artificial fiber non-woven fabric, polyester mesh or glass fiber. The non-halogen flame retardant is set on the base layer 10 by impregnation. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com