Waterstop section forming member on pipe joint of electric power pipe gallery and method of preparing standard pipe joint

A technology for power pipe gallery and forming components, which is used in underwater structures, cable installation, water conservancy projects, etc. problems, to achieve the effect of saving manpower, good waterproof performance, and convenient production and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

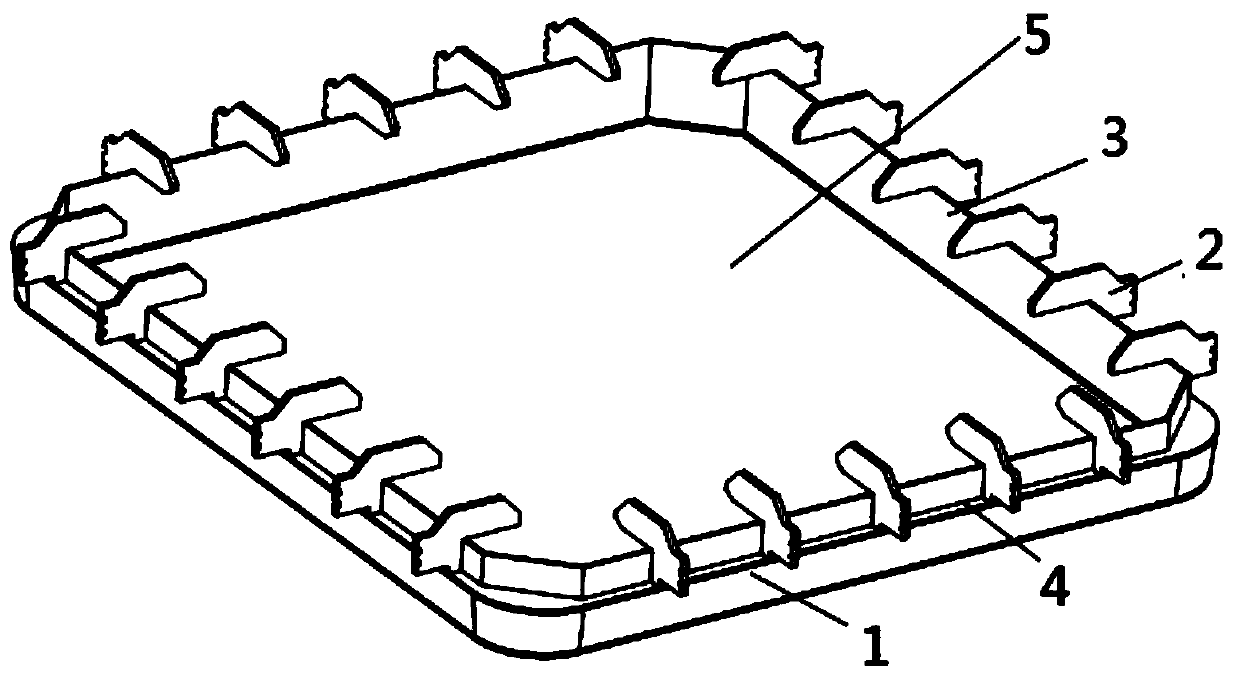

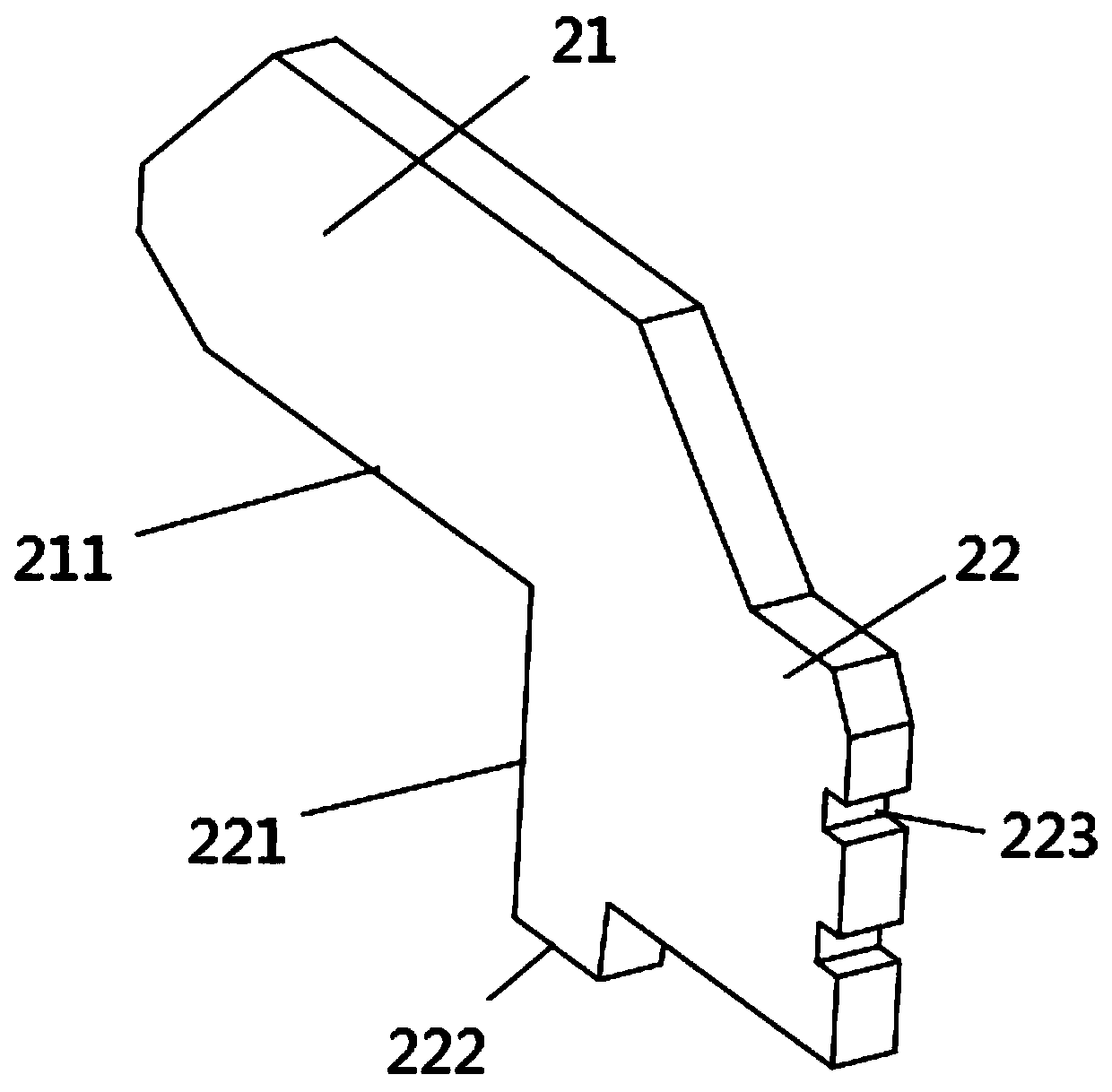

[0034] like figure 1 , a forming member of the upper water stop section of the pipe section of the power pipe gallery, including a body 1 and a plurality of water stop clamping units 2 that match the shape of the water stop section of the pipe section upper water stop section, and the upper water stop section of the pipe section The body 1 matching the shape of the waterstop forms a cavity 5, and several clamping units 2 of the waterstop are arranged on the body 1 matching the shape of the waterstop on the pipe joint.

[0035] The main body 1 that matches the shape of the waterstop of the waterstop section on the pipe joint can be round, square, or irregular in shape according to municipal requirements.

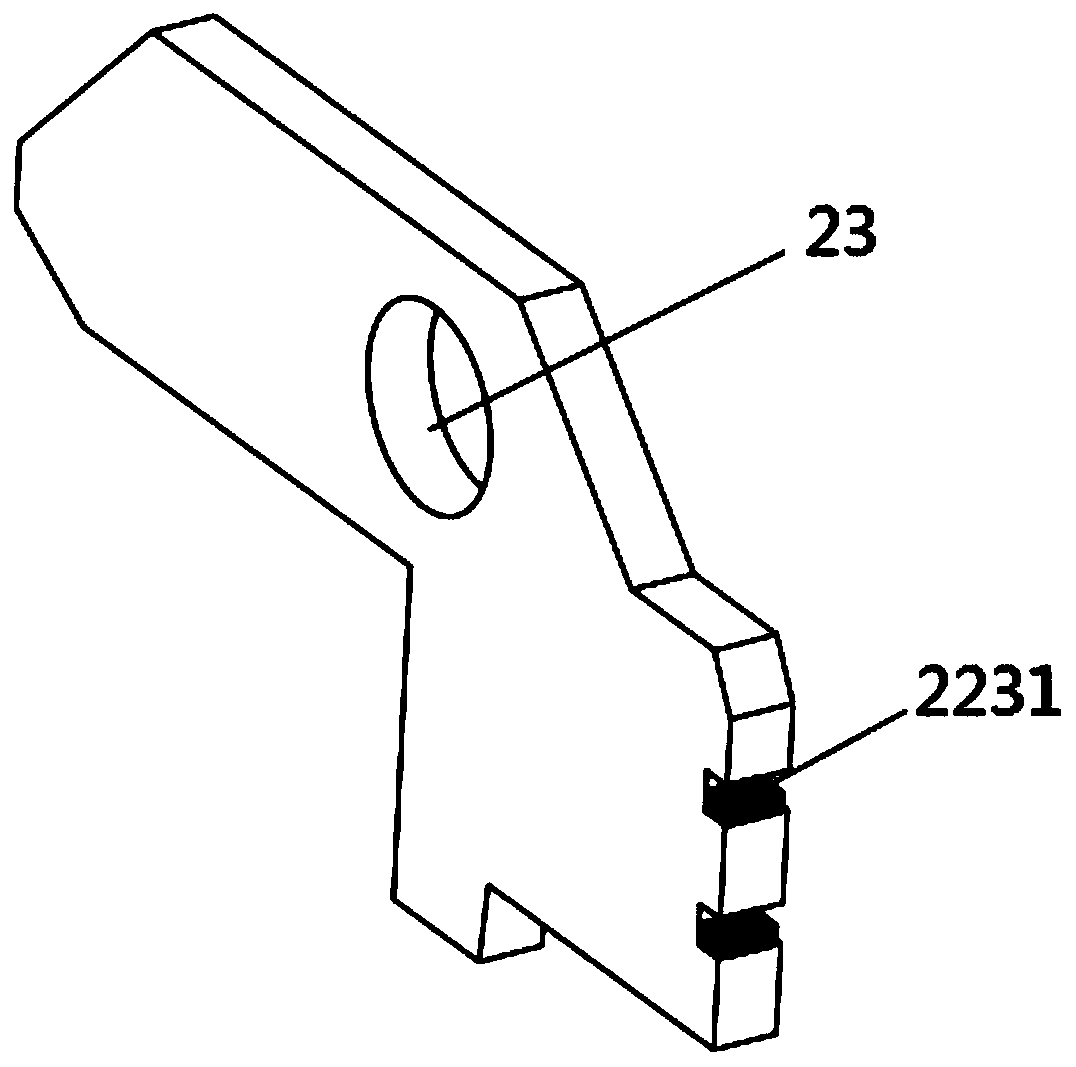

[0036] Several waterstop clamping units 2 can be fixedly connected to the body 1 that matches the shape of the waterstop on the pipe joint, or can be detachably connected to the waterstop on the pipe joint for replacement and prolonging the service life. On the main body 1 w...

Embodiment 2

[0046] like Figure 4 , a forming member of the upper water stop section of the pipe section of the power pipe gallery, including a body 1 and a plurality of water stop clamping units 2 that match the shape of the water stop section of the pipe section upper water stop section, and the upper water stop section of the pipe section The body 1 matching the shape of the waterstop forms a cavity 5, and several clamping units 2 of the waterstop are arranged on the body 1 matching the shape of the waterstop on the pipe joint.

[0047] The main body 1 that matches the shape of the waterstop of the waterstop section on the pipe joint can be round, square, or irregular in shape according to municipal requirements.

[0048] Several waterstop clamping units 2 can be fixedly connected to the body 1 that matches the shape of the waterstop on the pipe joint, or can be detachably connected to the waterstop on the pipe joint for replacement and prolonging the service life. On the main body 1 ...

Embodiment 3

[0054] like figure 2 and 5 , a forming member of the upper water stop section of the pipe section of the power pipe gallery, including a body 1 and a plurality of water stop clamping units 2 that match the shape of the water stop section of the pipe section upper water stop section, and the upper water stop section of the pipe section The body 1 matching the shape of the waterstop forms a cavity 5, and several clamping units 2 of the waterstop are arranged on the body 1 matching the shape of the waterstop on the pipe joint.

[0055] The main body 1 that matches the shape of the waterstop of the waterstop section on the pipe joint can be round, square, or irregular in shape according to municipal requirements.

[0056] Several waterstop clamping units 2 can be fixedly connected to the body 1 that matches the shape of the waterstop on the pipe joint, or can be detachably connected to the waterstop on the pipe joint for replacement and prolonging the service life. On the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com