Method and tool for manufacturing Y-shaped tubes of pile legs

A production method and human-shaped technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of difficult production, slow construction speed, and inability to batch production, so as to speed up batch production and reduce construction period. and cost, make and use simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings.

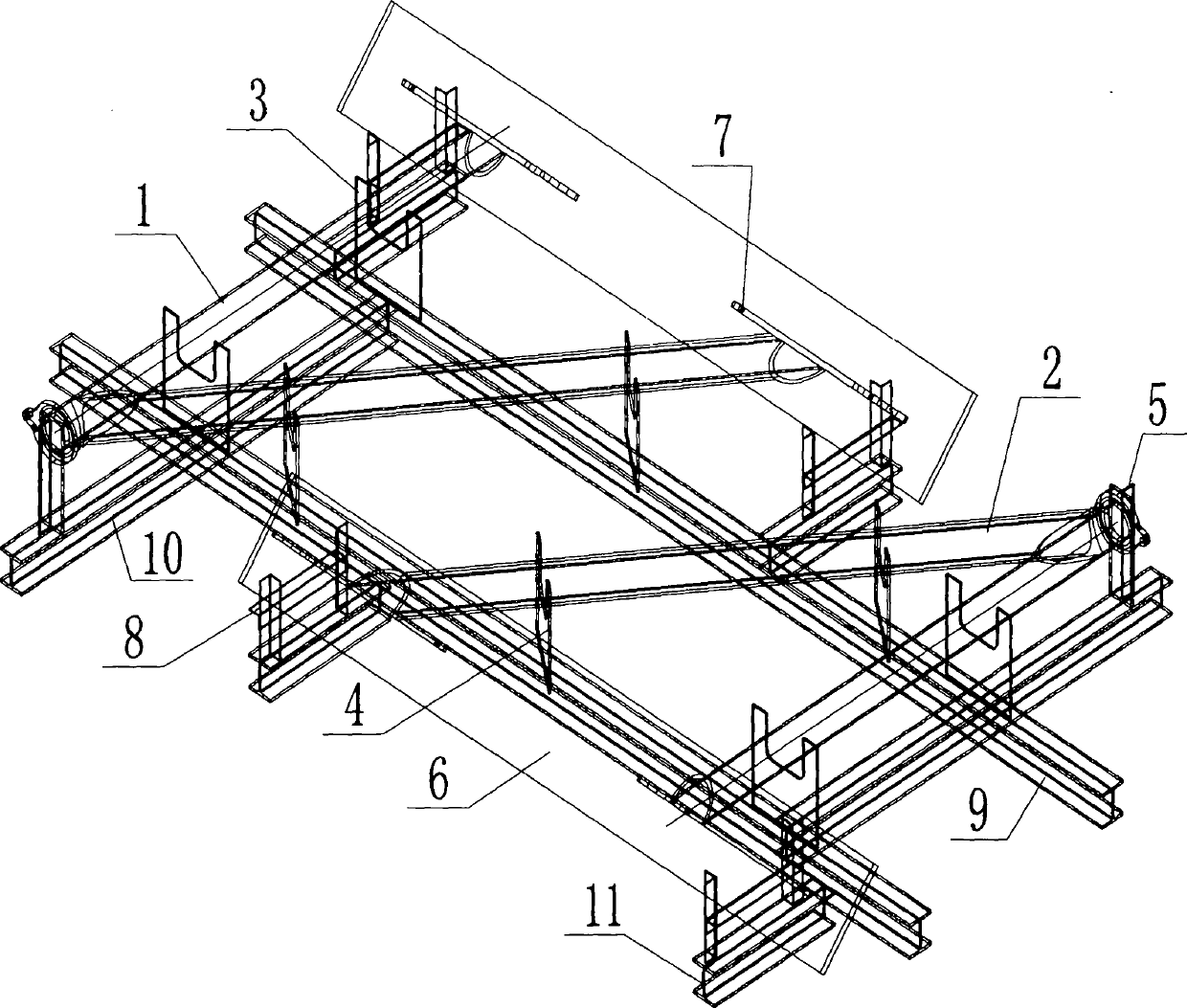

[0008] 1. If figure 1 As shown, the manufacturing method and tooling of human-shaped pipes for pile legs are the method and design of the human-shaped pipe structure for drilling platform legs, and the characteristics are: the human-shaped pipes of quadrilateral pile legs on jack-up drilling platforms are in the process of making Among them, the precision requirements are extremely high, and the quantity is large, and the construction work such as welding, cutting, grinding, painting, and assembly is extremely large, so a tooling that controls its accuracy should be installed, and human-shaped tube structures can be produced in batches. Two support plates are respectively arranged under the straight pipe (1) and the inclined pipe (2) of the pipe. The support plates should be able to support the weight of the man-shaped pipe, and a vertical support I-beam (5 ) to withs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com